Abstract

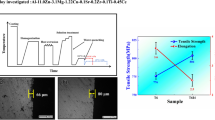

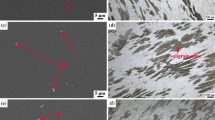

The microstructure and mechanical properties of a highly alloyed aluminum alloy Al-11.3Zn-3.1 Mg-1.6Cu-0.2Zr under four kinds of aging were investigated. The matrix precipitates were featured by η + η' for T6 and RRA, GP zone for T6I4, and GP zone + η' for T6R6I4 (T6 + Retrogression + T6I4), respectively. The grain boundary precipitates were featured by continuous GBPs for T6, and discontinuous GBPs for RRA, T6I4, and T6R6I4. The precipitate-free zone width exhibited a decreasing trend from RRA to T6, to T6R6I4, and finally to T6I4. The alloys subjected to T6I4 and T6R6I4 exhibited higher tensile strength and ductility. The precipitate strengthening of the four aged alloys was quantitatively analyzed and discussed in detail. T6I4 and T6R6I4 alloys exhibited a yield strength of 787 MPa and 751 MPa, ultimate tensile strengths of 792 MPa and 778 MPa, and elongation values of 7.8% and 8.3%, respectively.

Graphical Abstract

Similar content being viewed by others

References

Y. Liao, H. Yan, W. Xia, J. Chen, B. Su, X. Li, L. Zhao, Met. Mater. Int. 28, 1014 (2022). https://doi.org/10.1007/s12540-020-00961-w

J.H. Hong, H. Kim, W. Kim, Y.N. Kwon, D. Kim, Met. Mater. Int. 28, 871 (2022). https://doi.org/10.1007/s12540-020-00949-6

L. Luo, Z. Liu, S. Bai, J. Cao, F. Liu, L. Ou, J. Zhao, Met. Mater. Int. 28, 2277 (2022). https://doi.org/10.1007/s12540-021-01120-5

Y. Fan, X. Tang, S. Wang, B. Chen, Met. Mater. Int. 27, 4204 (2021). https://doi.org/10.1007/s12540-020-00875-7

J. Liu, Y. Zhang, X. Li, Z. Li, B. Xiong, J. Zhang, Trans. Nonferrous Met. Soc. China 24, 1481 (2014). https://doi.org/10.1016/S1003-6326(14)63216-7

Z. Chen, Y. Mo, Z. Nie, Metall. Mater. Trans. A 44, 3910 (2013). https://doi.org/10.1007/s11661-013-1731-x

H. Yin, K. Wen, Z. Li, X. Li, Y. Li, J. Mater. Res. Technol. 26, 3646 (2023). https://doi.org/10.1016/j.jmrt.2023.08.138

K. Wen, B. Xiong, Y. Zhang, Z. Li, X. Li, S. Huang, L. Yan, H. Yan, H. Liu, Mater. Sci. Eng. A 716, 42 (2018). https://doi.org/10.1016/j.msea.2018.01.040

W. Yang, S. Ji, M. Wang, Z. Li, J. Alloys Compd. 610, 623 (2014). https://doi.org/10.1016/j.jallcom.2014.05.061

G. Sha, A. Cerezo, Acta Mater. 52, 4503 (2004). https://doi.org/10.1016/j.actamat.2004.06.025

J.Z. Liu, J.H. Chen, X.B. Yang, S. Ren, C.L. Wu, H.Y. Xu, J. Zou, Scr. Mater. 63, 1061 (2010). https://doi.org/10.1016/j.scriptamat.2010.08.001

M. Abe, K. Asano, A. Fujiwara, Metall. Trans. 4, 1499 (1973). https://doi.org/10.1007/BF02668000

T. Pardoen, D. Dumont, A. Deschamps, Y. Brechet, J. Mech. Phys. Solids 51, 637 (2003). https://doi.org/10.1016/S0022-5096(02)00102-3

J.F. Li, Z.W. Peng, C.X. Li, Z.Q. Jia, W.J. Chen, Z.Q. Zheng, Trans. Nonferrous Met. Soc. China 18, 755 (2008). https://doi.org/10.1016/S1003-6326(08)60130-2

S.C. Jacumasso, P.H.F. Oliveira, J.P. Martins, A.L.M. Carvalho, Mater. Charact. 152, 180 (2019). https://doi.org/10.1016/j.matchar.2019.04.013

H. Zhong, S. Li, J. Wu, H. Deng, J. Chen, N. Yan, Z. Chen, L. Duan, Mater. Charact. 183, 111617 (2022). https://doi.org/10.1016/j.matchar.2021.111617

L.L. Liu, Q.L. Pan, X.D. Wang, S.W. Xiong, J. Alloys Compd. 735, 261 (2018). https://doi.org/10.1016/j.jallcom.2017.11.070

J. Zhao, Z. Liu, S. Bai, D. Zeng, L. Luo, J. Wang, J. Alloys Compd. 829, 154469 (2020). https://doi.org/10.1016/j.jallcom.2020.154469

J. Zhao, Z. Liu, S. Bai, T. Huang, J. Wang, H. Xie, D. Zeng, L. Luo, Mater. Sci. Eng. A 803, 140490 (2021). https://doi.org/10.1016/j.msea.2020.140490

J. Liu, R. Hu, J. Zheng, Y. Zhang, Z. Ding, W. Liu, Y. Zhu, G. Sha, J. Alloys Compd. 821, 153572 (2020). https://doi.org/10.1016/j.jallcom.2019.153572

S.H. Lee, J.G. Jung, S. IlBaik, D.N. Seidman, M.S. Kim, Y.K. Lee, K. Euh, Mater. Sci. Eng. A 803, 140719 (2021). https://doi.org/10.1016/j.msea.2020.140719

K. Li, H. Idrissi, G. Sha, M. Song, J. Lu, H. Shi, W. Wang, S.P. Ringer, Y. Du, D. Schryvers, Mater. Charact. 118, 352 (2016). https://doi.org/10.1016/j.matchar.2016.06.007

B. Yuan, G. Li, M. Guo, L. Zhuang, J. Mater. Res. Technol. 14, 1518 (2021). https://doi.org/10.1016/j.jmrt.2021.07.067

P. Zhang, K. Shi, J. Bian, J. Zhang, Y. Peng, G. Liu, Acta Mater. 207, 116682 (2021). https://doi.org/10.1016/j.actamat.2021.116682

T. Dorin, F. De Geuser, W. Lefebvre, C. Sigli, A. Deschamps, Mater. Sci. Eng. A 605, 119 (2014). https://doi.org/10.1016/j.msea.2014.03.024

G. Fribourg, Y. Bréchet, A. Deschamps, A. Simar, Acta Mater. 59, 3621 (2011). https://doi.org/10.1016/j.actamat.2011.02.035

I. Westermann, O.S. Hopperstad, K. Marthinsen, B. Holmedal, Mater. Sci. Eng. A 524, 151 (2009). https://doi.org/10.1016/j.msea.2009.06.0.36

T.M. Smith, P. Bonacuse, J. Sosa, M. Kulis, L. Evans, Mater. Charact. 140, 86 (2018). https://doi.org/10.1016/j.matchar.2018.03.051

S.A. Mantri, D. Choudhuri, T. Alam, G.B. Viswanathan, J.M. Sosa, H.L. Fraser, R. Banerjee, Scr. Mater. 154, 139 (2018). https://doi.org/10.1016/j.scriptamat.2018.05.040

Y. Zhao, J. Liu, T.D. Topping, E.J. Lavernia, J. Alloys Compd. 851, 156931 (2021). https://doi.org/10.1016/j.jallcom.2020.156931

T.F. Chung, Y.L. Yang, M. Shiojiri, C.N. Hsiao, W.C. Li, C.S. Tsao, Z. Shi, J. Lin, J.R. Yang, Acta Mater. 174, 351 (2019). https://doi.org/10.1016/j.actamat.2019.05.041

L.K. Berg, J. Gjoønnes, V. Hansen, X.Z. Li, M. Knutson-Wedel, G. Waterloo, D. Schryvers, L.R. Wallenberg, Acta Mater. 49, 3443 (2001). https://doi.org/10.1016/S1359-6454(01)00251-8

G. Waterloo, V. Hansen, J. Gjønnes, S.R. Skjervold, Mater. Sci. Eng. A 303, 226 (2001). https://doi.org/10.1016/S0921-5093(00)01883-9

K. Ma, H. Wen, T. Hu, T.D. Topping, D. Isheim, D.N. Seidman, E.J. Lavernia, J.M. Schoenung, Acta Mater. 62, 141 (2014). https://doi.org/10.1016/j.actamat.2013.09.042

A. Deschamps, Y. Brechet, Acta Mater. 47, 293 (1999). https://doi.org/10.1016/S1359-6454(98)00296-1

R. Ghiaasiaan, B.S. Amirkhiz, S. Shankar, Mater. Sci. Eng. A 698, 206 (2017). https://doi.org/10.1016/j.msea.2017.05.047

H. Wen, T.D. Topping, D. Isheim, D.N. Seidman, E.J. Lavernia, Acta Mater. 61, 2769 (2013). https://doi.org/10.1016/j.actamat.2012.09.036

D.N. Seidman, E.A. Marquis, D.C. Dunand, Acta Mater. 50, 4021 (2002). https://doi.org/10.1016/S1359-6454(02)00201-X

L.M. Cheng, W.J. Poole, J.D. Embury, D.J. Lloyd, Metall. Mater. Trans. A 34, 2473 (2003). https://doi.org/10.1007/s11661-003-0007-2

C. Li, Q.S. Zhou, M.N. Han, S.H. Sha, Y.T. Luo, X.J. Xu, J. Alloys Compd. 956, 170248 (2023). https://doi.org/10.1016/j.jallcom.2023.170248

Acknowledgements

Thanks to the financial support from the Key Projects of Equipment Pre-research Foundation of the Ministry of Equipment Development of the Central Military Commission of China (No:6140922010201) and the Key Projects of Research and Development of Zhenjiang (GY2018021).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, C., Wei, HB., Xu, XJ. et al. Microstructure and Mechanical Properties of a Highly Alloyed Al–Zn–Mg–Cu–Zr Alloy Under T6I4 and T6R6I4 Agings. Met. Mater. Int. 30, 857–871 (2024). https://doi.org/10.1007/s12540-023-01556-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-023-01556-x