Abstract

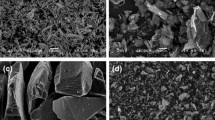

Obtaining bulk copper-based composite materials with improved physical and mechanical properties often requires pre-treatment of the initial raw materials. Especially it concerns metal matrix composites (MMC) containing copper as a matrix and silicon carbide as a reinforcing component. However, the final properties of Cu/SiC MMC depend on successful solving the problem of silicon solubility in liquid-phase copper during the sintering process. In this work, we demonstrate the possibility of high-energy treatment of copper and silicon carbide by the plasma dynamic method to obtain a pre-activated charge for further sintering. Analytical studies by X-ray diffractomtery (XRD), scanning electron microscopy (SEM), and transmission electron microscopy (TEM) methods testify to the possibility of obtaining highly dispersed composite Cu/SiC materials of different phase and grain size composition depending on the synthesis conditions. The application of polymodal Cu/SiC powders pre-activated by the plasma dynamic method as a charge is established to ensure producing bulk samples by the spark plasma sintering (SPS) method and allow increasing the relative density by ~ 5%–10% and the hardness of the final products by more than 30% compared with pure copper samples produced by the same method.

Graphical Abstract

Similar content being viewed by others

Data Availability

The datasets generated during and/or analyzed during the current study are not publicly available due to the Russian Federation legislation in the field of materials published abroad but are available from the corresponding author on reasonable request.

References

I. Pranoto, M.A. Rahman, P.A.P. Mahardhika, Pool boiling heat transfer performance and bubble dynamics from pin fin-modified surfaces with geometrical shape variation. Energies 15, 1847 (2022). https://doi.org/10.3390/en15051847

B.L. Rakshith, L.G. Asirvatham, A.A. Angeline, S. Manova, J.R. Bose, J.P. Selvin Raj, O. Mahian, S. Wongwises, Cooling of high heat flux miniaturized electronic devices using thermal ground plane: an overview. Renew. Sustain. Energy Rev. 170, 112956 (2022). https://doi.org/10.1016/j.rser.2022.112956

Z. He, Y. Yan, Z. Zhang, Thermal management and temperature uniformity enhancement of electronic devices by micro heat sinks: a review. Energy 216, 119223 (2021). https://doi.org/10.1016/j.energy.2020.119223

E.M. Abo-Zahhad, S. Ookawara, A. Radwan, M.F. Elkady, A.H. El-Shazly, Optimization of stepwise varying width microchannel heat sink for high heat flux applications. Case Stud. Therm. Eng. 18, 100587 (2020). https://doi.org/10.1016/j.csite.2020.100587

X. Yuan, Y. Du, J. Su, Approaches and potentials for pool boiling enhancement with superhigh heat flux on responsive smart surfaces: a critical review. Renew. Sustain. Energy. Rev 156, 111974 (2022). https://doi.org/10.1016/J.RSER.2021.111974

M. Egbo, A review of the thermal performance of vapor chambers and heat sinks: Critical heat flux, thermal resistances, and surface temperatures. Int. J. Heat Mass Transf. 183, 122108 (2022). https://doi.org/10.1016/J.IJHEATMASSTRANSFER.2021.122108

H. Asgari, M. Salarian, H. Ma, A. Olubamiji, M. Vlasea, On thermal expansion behavior of invar alloy fabricated by modulated laser powder bed fusion. Mater. Des. 160, 895–905 (2018). https://doi.org/10.1016/J.MATDES.2018.10.025

H. Yang, L. Ma, 1D to 3D multi-stable architected materials with zero Poisson’s ratio and controllable thermal expansion. Mater. Des. 188, 108430 (2020). https://doi.org/10.1016/J.MATDES.2019.108430

J. Sheng, L.D. Wang, D. Li, W.P. Cao, Y. Feng, M. Wang, Z.Y. Yang, Y. Zhao, W.D. Fei, Thermal expansion behavior of copper matrix composite containing negative thermal expansion PbTiO3 particles. Mater. Des. 132, 442–447 (2017). https://doi.org/10.1016/J.MATDES.2017.06.061

G. Sundberg, P. Paul, C. Sung, T. Vasilos, Identification and characterization of diffusion barriers for Cu/SiC systems. J. Mater. Sci. 40, 3383–3393 (2005). https://doi.org/10.1007/S10853-005-2847-1

T. Schubert, B. Trindade, T. Weißgärber, B. Kieback, Interfacial design of Cu-based composites prepared by powder metallurgy for heat sink applications. Mater. Sci. Eng. A 475, 39–44 (2008). https://doi.org/10.1016/J.MSEA.2006.12.146

A. Brendel, V. Paffenholz, T. Köck, H. Bolt, Mechanical properties of SiC long fibre reinforced copper. J. Nucl. Mater. 386–388, 837–840 (2009). https://doi.org/10.1016/J.JNUCMAT.2008.12.251

L. Dyachkova, E.E. Feldshtein, On the properties of composites based on sintered bronze with alumina additives. Compos. B Eng. 45, 239–247 (2013). https://doi.org/10.1016/J.COMPOSITESB.2012.07.024

Y. Geng, Y. Ban, B. Wang, X. Li, K. Song, Y. Zhang, Y. Jia, B. Tian, Y. Liu, A.A. Volinsky, A review of microstructure and texture evolution with nanoscale precipitates for copper alloys. J. Market. Res. 9, 11918–11934 (2020). https://doi.org/10.1016/j.jmrt.2020.08.055

Y. Ban, M. Zhou, Y. Zhang, Y. Jia, Y. Pang, Y. Li, S. Tang, X. Li, A.A. Volinsky, E.S. Marchenko, Abnormally high work hardening ability and excellent comprehensive properties of copper alloys due to multiple twins and precipitates. Mater. Des. 228, 111819 (2023). https://doi.org/10.1016/j.matdes.2023.111819

W. Wu, S. Ye, R. Wang, C. Zhang, Y. Zhang, X. Lu, Microstructure and wear behavior of plasma cladded Ni-based alloy coating on copper under different preheating temperature. J. Market. Res. 23, 1609–1617 (2023). https://doi.org/10.1016/j.jmrt.2023.01.092

Z. Wang, Z. Tang, L. Xu, Z. Han, J. Liu, L. Zhang, Thermal properties and thermal cycling stability of graphite/copper composite fabricated by microwave sintering. J. Market. Res. 20, 1352–1363 (2022). https://doi.org/10.1016/j.jmrt.2022.07.147

Y. Zhou, Y. Liu, K. Song, S. Li, C. Feng, Q. Zhu, X. Peng, S. Yang, X. Li, P. Zhang, Mechanisms for high strength and ultra-high electrical conductivity of Cu-3.5wt%Ag alloy prepared by thermomechanical treatment. Mater. Today Commun. 33, 104819 (2022). https://doi.org/10.1016/j.mtcomm.2022.104819

T. Thankachan, K.S. Prakash, V. Kavimani, Investigating the effects of hybrid reinforcement particles on the microstructural, mechanical and tribological properties of friction stir processed copper surface composites. Compos. B Eng. 174, 107057 (2019). https://doi.org/10.1016/J.COMPOSITESB.2019.107057

F. Nazeer, Z. Ma, L. Gao, F. Wang, M.A. Khan, A. Malik, Thermal and mechanical properties of copper-graphite and copper-reduced graphene oxide composites. Compos. B Eng. 163, 77–85 (2019). https://doi.org/10.1016/J.COMPOSITESB.2018.11.004

M.R. Akbarpour, H. Mousa Mirabad, S. Alipour, Microstructural and mechanical characteristics of hybrid SiC/Cu composites with nano- and micro-sized SiC particles. Ceram. Int. 45, 3276–3283 (2019). https://doi.org/10.1016/J.CERAMINT.2018.10.235

R.A. Raimundo, F.A. Costa, M.A. Morales, A.G.P. Silva, U.U. Gomes, Effect of the high energy milling on the microstructure of Cu-20%WC composite powders prepared with recycled WC. Int. J. Refract. Metals Hard Mater. 90, 105223 (2020). https://doi.org/10.1016/j.ijrmhm.2020.105223

M.I. Abd El Aal, H.S. Kim, Effect of the fabrication method on the wear properties of copper silicon carbide composites. Tribol. Int. 128, 140–154 (2018). https://doi.org/10.1016/j.triboint.2018.07.024

G. Celebi Efe, M. Ipek, S. Zeytin, C. Bindal, An investigation of the effect of SiC particle size on Cu-SiC composites. Compos. B Eng. 43, 1813–1822 (2012). https://doi.org/10.1016/j.compositesb.2012.01.006

G. Celebi Efe, T. Yener, I. Altinsoy, M. Ipek, S. Zeytin, C. Bindal, The effect of sintering temperature on some properties of Cu–SiC composite. J. Alloys. Compd. 509, 6036–6042 (2011). https://doi.org/10.1016/J.JALLCOM.2011.02.170

H. Kumar, R. Prasad, P. Kumar, Effect of multi-groove reinforcement strategy on Cu/SiC surface composite fabricated by friction stir processing. Mater. Chem. Phys. 256, 123720 (2020). https://doi.org/10.1016/j.matchemphys.2020.123720

S. Kumar, A. Yadav, V. Patel, B. Nahak, A. Kumar, Mechanical behaviour of SiC particulate reinforced Cu alloy based metal matrix composite. Mater. Today Proc. 41, 186–190 (2021). https://doi.org/10.1016/j.matpr.2020.08.580

N.T. Câmara, R.A. Raimundo, C.S. Lourenço, L.M.F. Morais, D.D.S. Silva, R.M. Gomes, M.A. Morales, D.A. Macedo, U.U. Gomes, F.A. Costa, Impact of the SiC addition on the morphological, structural and mechanical properties of Cu-SiC composite powders prepared by high energy milling. Adv. Powder Technol. 32, 2950–2961 (2021). https://doi.org/10.1016/j.apt.2021.06.006

A. Devaraju, P. Sivasamy, R. Gopi, A. Muthiah, Studies on wear behaviour of silicon carbide and fly ash reinforced copper based metal matrix composites. Mater. Today Proc. 39, 888–891 (2021). https://doi.org/10.1016/j.matpr.2020.10.1006

Y. Xiong, W. Hu, Y. Shu, X. Luo, Z. Zhang, J. He, C. Yin, K. Zheng, Atomistic simulation on the generation of defects in Cu/SiC composites during cooling. J. Mater. Sci. Technol. 123, 1–12 (2022). https://doi.org/10.1016/j.jmst.2021.10.058

K.E. Pappacena, M.T. Johnson, S. Xie, K.T. Faber, Processing of wood-derived copper-silicon carbide composites via electrodeposition. Compos. Sci. Technol. 70, 485–491 (2010). https://doi.org/10.1016/j.compscitech.2009.12.019

C. Rado, B. Drevet, N. Eustathopoulos, The role of compound formation in reactive wetting: the Cu/SiC system. Acta Mater. 48, 4483–4491 (2000). https://doi.org/10.1016/S1359-6454(00)00235-4

G. Sundberg, P. Paul, C. Sung, T. Vasilos, Fabrication of CuSiC metal matrix composites. J. Mater. Sci. 41, 485–504 (2006). https://doi.org/10.1007/s10853-005-2622-3

K.E. Pappacena, M.T. Johnson, H. Wang, W.D. Porter, K.T. Faber, Thermal properties of wood-derived copper-silicon carbide composites fabricated via electrodeposition. Compos. Sci. Technol. 70, 478–484 (2010). https://doi.org/10.1016/j.compscitech.2009.11.011

S.H. Kee, W.J. Kim, J.P. Jung, Copper-silicon carbide composite plating for inhibiting the extrusion of through silicon via (TSV). Microelectr. Eng. 214, 5–14 (2019). https://doi.org/10.1016/j.mee.2019.04.019

S. Chatterjee, S. Chabri, H. Chakraborty, N. Bhowmik, A. Sinha, Micromechanical and nanoscratch behavior of SiCp dispersed metal matrix composites. J. Mater. Eng. Perf. 24, 3407–3418 (2015). https://doi.org/10.1007/S11665-015-1633-8

S. Nosewicz, B. Romelczyk-Baishya, D. Lumelskyj, M. Chmielewski, P. Bazarnik, D. Jarząbek, K. Pietrzak, K. Kaszyca, Z. Pakieła, Experimental and numerical studies of micro- and macromechanical properties of modified copper–silicon carbide composites. Int. J. Solids. Struct. 160, 187–200 (2019). https://doi.org/10.1016/j.ijsolstr.2018.10.025

M. Chmielewski, K. Pietrzak, M. Teodorczyk, S. Nosewicz, D. Jarząbek, R. Zybała, P. Bazarnik, M. Lewandowska, A. Strojny-Nędza, Effect of metallic coating on the properties of copper-silicon carbide composites. Appl. Surf. Sci. 421, 159–169 (2017). https://doi.org/10.1016/j.apsusc.2016.12.130

W. Węglewski, P. Pitchai, M. Chmielewski, P.J. Guruprasad, M. Basista, Thermal conductivity of Cu-matrix composites reinforced with coated SiC particles: numerical modeling and experimental verification. Int. J. Heat Mass Transf. 188, 122633 (2022). https://doi.org/10.1016/j.ijheatmasstransfer.2022.122633

S.D. Oguntuyi, K. Nyembwe, M.B. Shongwe, O.T. Johnson, J.R. Adewumi, N. Malatji, P.A. Olubambi, Improvement on the fabrication of SiC materials: Processing, reinforcing phase, fabricating route—a review. Int. J. Lightweight Mater. Manuf. 6, 225–237 (2023). https://doi.org/10.1016/j.ijlmm.2022.10.005

A. Sivkov, I. Rakhmatullin, I. Shanenkov, Y. Shanenkova, Boron carbide B4C ceramics with enhanced physico-mechanical properties sintered from multimodal powder of plasma dynamic synthesis. Int. J. Refract. Metals Hard Mater. 78, 85–91 (2019). https://doi.org/10.1016/j.ijrmhm.2018.09.003

I. Shanenkov, D. Nikitin, A. Ivashutenko, Y. Shanenkova, Y. Vympina, D. Butenko, W. Han, A. Sivkov, Studies on the thermal stability of nanosized powder of WC1-x-based product prepared by plasma dynamic method, compaction feasibility of the powder and preparation of composite with aluminium. Ceram Int. 47, 6884–6895 (2021). https://doi.org/10.1016/j.ceramint.2020.11.035

I.P. Dojčinović, M.M. Kuraica, B.M. Obradovć, N. Cvetanović, J. Purić, Optimization of plasma flow parameters of the magnetoplasma compressor. Plasma Sour. Sci Technol. 16, 72–79 (2006). https://doi.org/10.1088/0963-0252/16/1/010

A.A. Drozdov, V.E. Kuznetsov, B.V. Ljublin, I.B. Ovchinnikov, V.A. Titov, Simulation of the iter plasma disruption with the plasma accelerator “vika.” Plasma Dev. Oper. 5, 77–98 (1997). https://doi.org/10.1080/10519999708228022

I. Shanenkov, D. Nikitin, A. Ivashutenko, I. Rahmatullin, Y. Shanenkova, A. Nassyrbayev, W. Han, A. Sivkov, Hardening the surface of metals with WC1-x coatings deposited by high-speed plasma spraying. Surf. Coat. Tech. 389, 125639 (2020). https://doi.org/10.1016/j.surfcoat.2020.125639

A. Sivkov, D. Nikitin, I. Shanenkov, A. Ivashutenko, I. Rahmatullin, A. Nassyrbayev, Optimization of plasma dynamic synthesis of ultradispersed silicon carbide and obtaining SPS ceramics on its basis, Int. J. Refract Metals Hard Mater. 79, 123–130 (2019). https://doi.org/10.1016/j.ijrmhm.2018.11.016.

M. Chmielewski, K. Pietrzak, A. Strojny-Nędza, K. Kaszyca, R. Zybała, P. Bazarnik, M. Lewandowska, S. Nosewicz, Microstructure and thermal properties of Cu-SiC composite materials depending on the sintering technique. Sci. Sinter. 49, 11–22 (2017). https://doi.org/10.2298/SOS1701011C

D.-G. Dimitriu, M. Agop, Analysis of low-frequency instabilities in low-temperature magnetized plasma, in Fractional Dynamics, Anomalous Transport and Plasma Science, ed. by C.H. Skiadas (Springer, Cham, 2018). https://doi.org/10.1007/978-3-030-04483-1_5

F.P. Bundy, W.A. Bassett, M.S. Weathers, R.J. Hemley, H.U. Mao, A.F. Goncharov, The pressure-temperature phase and transformation diagram for carbon; updated through 1994. Carbon 34, 141–153 (1996). https://doi.org/10.1016/0008-6223(96)00170-4

J. Puric, I.P. Dojcinovic, V.M. Astashynski, M.M. Kuraica, B.M. Obradovic, Electric and thermodynamic properties of plasma flows created by a magnetoplasma compressor. Plasma Sour. Sci. Technol. 13, 74–84 (2003). https://doi.org/10.1088/0963-0252/13/1/010

R.W. Olesinski, G.J. Abbaschian, The Cu−Si (Copper-Silicon) system. Bull. Alloy Phase Diagr. 7, 170–178 (1986). https://doi.org/10.1007/BF02881559

H. Shi, W. Zhang, J. Wang, D. Wang, C. Wang, Z. Xiong, J. Wu, Z. Bai, X. Yan, Scalable synthesis of a porous structure silicon/carbon composite decorated with copper as an anode for lithium ion batteries. Appl Surf Sci. 620, 156843 (2023). https://doi.org/10.1016/j.apsusc.2023.156843

B.D. Polat, O. Keles, Designing self-standing silicon-copper composite helices as anodes for lithium ion batteries. J. Alloys Compd. 677, 228–236 (2016). https://doi.org/10.1016/j.jallcom.2016.03.125

Z. Zhou, Y. Zhang, Y. Hua, P. Dong, Y. Lin, M. Xu, D. Wang, X. Li, L. Han, J. Duan, Molten salt electrolytic synthesis of silicon-copper composite nanowires with enhanced performances as lithium ion battery anode. J Alloys Compd. 751, 307–315 (2018). https://doi.org/10.1016/j.jallcom.2018.04.128

X. Yang, G. Xu, C. Jin, B. Liu, P. Ouyang, K. Kong, Y. Lan, Z. Yue, X. Li, F. Sun, L. Zhou, Si/Cu3Si/Cu composite material synthesized by low cost and high efficiency method as anode materials for lithium-ion batteries. Solid State Ion. 342, 115057 (2019). https://doi.org/10.1016/j.ssi.2019.115057

G.L. Lu, F.H. Liu, X. Chen, J.F. Yang, Cu nanowire wrapped and Cu3Si anchored Si@Cu quasi core-shell composite microsized particles as anode materials for Li-ion batteries. J. Alloys Compd. 809, 151750 (2019). https://doi.org/10.1016/j.jallcom.2019.151750

A. Sivkov, Y. Shanenkova, Y. Vympina, D. Nikitin, I. Shanenkov, Deposition of copper coatings on internal aluminum contact surfaces by high-energy plasma spraying. Surf. Coat. Tech. 440, 128484 (2022). https://doi.org/10.1016/j.surfcoat.2022.128484

I. Shanenkov, A. Ivashutenko, Y. Shanenkova, D. Nikitin, Y. Zhu, J. Li, W. Han, A. Sivkov, Composite material WC1-x@C as a noble-metal-economic material for hydrogen evolution reaction. J. Alloys Compd. 834, 155116 (2020). https://doi.org/10.1016/J.JALLCOM.2020.155116

O.L. Khasanov, E.S. Dvilis, A.O. Khasanov, Z.G. Bikbaeva, V.V. Polisadova, T.V. Milovanova, Influence of ultradispersed fraction of boron carbide powder on strength properties of the ceramics manufactured by SPS method. Adv. Mat. Res. 872, 45–51 (2013). https://doi.org/10.4028/www.scientific.net/AMR.872.45

M.R. Akbarpour, Effects of mechanical milling time on densification, microstructural characteristics and hardness of Cu–SiC nanocomposites prepared by conventional sintering process. Mater. Chem. Phys. 261, 124205 (2021). https://doi.org/10.1016/j.matchemphys.2020.124205

P. Bazarnik, S. Nosewicz, B. Romelczyk-Baishya, M. Chmielewski, A. Strojny Nędza, J. Maj, Y. Huang, M. Lewandowska, T.G. Langdon, Effect of spark plasma sintering and high-pressure torsion on the microstructural and mechanical properties of a Cu–SiC composite. Mater. Sci. Eng. A 766, 138350 (2019). https://doi.org/10.1016/j.msea.2019.138350

M.R. Akbarpour, S. Alipour, Wear and friction properties of spark plasma sintered SiC/Cu nanocomposites. Ceram Int. 43, 13364–13370 (2017). https://doi.org/10.1016/j.ceramint.2017.07.037

Acknowledgements

This work was supported by the Russian Science Foundation, grant number 21-73-10245, https://rscf.ru/project/21-73-10245/.

Funding

This work was supported by the Russian Science Foundation, Grant number 21–73-10245, https://rscf.ru/project/21-73-10245/.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. All experiments were performed by AN and AT. Ponomarev, under the supervision of AS. YV was responsible for analyzing synthesized powder by means of SEM and TEM methods. XRD studies and their interpretation were performed by IS. DN was responsible for spark plasma sintering procedure. Material preparation, data collection and analysis were performed by IS and DN. The original draft was written by IS and DN and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shanenkov, I., Nikitin, D., Nassyrbayev, A. et al. Plasma Dynamic Synthesis of Dispersed Cu/SiC Composites with a Controlled Phase Composition. Met. Mater. Int. 30, 814–831 (2024). https://doi.org/10.1007/s12540-023-01533-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-023-01533-4