Abstract

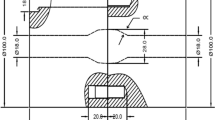

The influence of the semi-die angle (α = 45°, 30° and 22.5°employed in the present experiments) of the cyclic expansion extrusion (CEE) process on grain refinement in Al-alloy AA 6063 processed at 100°C at a pressing velocity of 0.5 mm.s− 1 and subjected to different number of passes is examined. The strain imparted on the specimen strongly depends on the die geometry. Grain refinement as well as increase in the ultimate tensile strength and micro-hardness after 10 CEE passes is the highest when the semi-die angle (α) is 22.5°. TEM images reveal the formation of fine grains after 10 CEE passes. Dislocation generation and cell formation directly depend on the strain imparted and the interactions between the dislocations and the Mg2Si precipitates. The tensile strength and hardness of the CEE processed specimens were compared as a function of the semi-die angle (α) and the results were compared with those of the unprocessed alloy also.

Graphical Abstract

Similar content being viewed by others

Data Availability

The authors conform that the data supporting the findings of this study are within this article.

References

I.V. Alexandrov, K. Zhang, A.R. Kilmametov, K. Lu, R.Z. Valiev, Mater. Sci. Eng. A 234, 331–334 (1997)

J.C. Kim, Y. Nishida, H. Arima, T. Ando, Mater. Lett. 57, 1689–1695 (2003)

Y.S. Park, K.H. Chung, N.J. Kim, E.J. Lavernia, Mater. Sci. Eng. A 374, 211–216 (2004)

C. Xu, Z. Horita, T.G. Langdon, Acta Mater. 56, 5168–5176 (2008)

M. Richert, Q. Liu, N. Hansen, Mater. Sci. Eng. A 260, 275–283 (1999)

Y. Beygelzimer, V. Varyukhin, S. Synkov, D. Orlov. Mater. Sci. Eng. A 503, 14–17 (2009)

N. Pardis, R. Ebrahimi, Mater. Sci. Eng. A 527, 355–360 (2009)

Y. Xu, L.H. JianboJia, Bo Xu,Mater. Charact. 118, 309–323 (2016)

N. Pardis. B. Talebanpour, R. Ebrahimi, S. Zomorodian,Mater. Sci. Eng. A 528, 7537–7540 (2011)

V. Babu, B.P. Shanmugavel, K.A. Padmanabhan, Archiv. Civ. Mech. Eng. 21, 38 (2021)

M. Cai, D.P. Field, G.W. Lorimer, Mater. Sci. Eng. A 373, 65–71 (2004)

W.S. Miller, L. Zhuang, J. Bottema, A. Wittebrood, P. De Smet, A. Haszler, A. Vieregge, Mater. Sci. Eng. A 280, 37–49 (2000)

A. Heinz, A. Haszler, C. Keidel, S. Moldenhauer, R. Benedictus, W. S. Miller. Mater. Sci. Eng. A 280, 102–107 (2000)

H.J. Roven, M. Liu, J.C. Werenskiold, Mater. Sci. Eng. A 483, 54–58 (2008)

B. Adamczyk-Cieślak, J. Mizera, K.J. Kurzydłowski, Mater. Charact. 62, 327–332 (2011)

Y. Iwahashi, J. Wang, Z. Horita, M. Nemoto, T.G. Langdon, Scripta Mater. 35, 143–146 (1996)

S. Suwas, G. Gottstein, R. Kumar, Mater. Sci. Eng. A 471, 1–14 (2007)

M. Furukawa, Z. Horita, T.G. Langdon, Mater. Sci. Eng. A 332, 97–109 (2002)

R.B. Figueiredo, I.J. Beyerlein, A.P. Zhilyaev, T.G. Langdon, Mater. Sci. Eng. A 527, 1709–1718 (2010)

Z.-S. Wang, Y.-J. Guan, G.-C. Wang, C.-K. Zhong, J. Mater. Process. Technol. 215, 205–218 (2015)

N. Thangapandian, S. Balasivanandha Prabu, K.A. Padmanabhan, Mater. Sci. Eng. A 649, 229–238 (2016)

V. Babu, S. Balasivanandha Prabu, K.A. Padmanabhan, Defect Diffus. Forum 385, 223–227 (2018)

V. Babu, B.P. Shanmugavel, K.A. Padmanabhan, Met. Mater. Int. 27, 2919–2932 (2021)

V. Babu, B.P. Shanmugavel, K.A. Padmanabhan, J. Mater. Eng. Perform. 29, 6870–6880 (2020)

B. Avitzur, ASME J. Eng. Ind. 85, 89–95 (1963)

B. Avitzur, ASME J. Eng. Ind. 86, 305–314 (1964)

H.R. Torabi, M.M. Samandari, G. Faraji, A. Masoumi, J. Adv. Mater. Process. 3, 35–48 (2015)

M. Cabibbo, E. Evangelista, M. Vedani, Metall. Mater. Trans. A 36, 1353–1364 (2005)

Y.H. Zhao, X.Z. Liao, Z. Jin, R.Z. Valiev, Y.T. Zhu, Acta Mater. 52, 4589–4599 (2004)

M. Das, G. Das, M. Ghosh, M. Wegner, V. Rajnikant, S. GhoshChowdhury, T.K. Pal, Mater. Sci. Eng. A 558, 525–532 (2012)

R.A. Siddiqui, H.A. Abdullah, K.R. Al-Belushi, J. Mater. Process. Technol. 102, 234–240 (2000)

S.K. Panigrahi, R. Jayaganthan, Mater. Sci. Eng. A 492, 300–305 (2008)

G. Das, M. Das, S. Ghosh, P. Dubey, A.K. Ray, Mater. Sci. Eng. A 527, 1590–1594 (2010)

J. Gubicza, I. Schiller, N.Q. Chinh, J. Illy, Z. Horita, T.G. Langdon, Mater. Sci. Eng. A 460, 77–85 (2007)

A. Kelly 1966 Strong Solids, 84. Oxford, UK: Clarendon Press

A. Chidambaram, S. Balasivanandha Prabu, K.A. Padmanabhan, Mater. Sci. Eng. A 759, 762–769 (2019)

V. Babu, B.P. Shanmugavel, K.A. Padmanabhan, J. Mater. Eng. Perform. 29, 8049–8059 (2020)

M. Furukawa, Z. Horita, M. Nemoto, R.Z. Valiev, T.G. Langdon, Acta Mater. 44, 4619–4629 (1996)

J.B. Lin, Q.D. Wang, M.P. Liu, Y.J. Chen, H.J. Roven, Trans. Nonferrous Met. Soc. China 22, 1902–1906 (2012)

Y. Estrin, A. Vinogradov, Acta Mater. 61, 782–817 (2013)

M.H. Shaeri, M. Shaeri, M. Ebrahimi, M.T. Salehi, S. H. Seyyedein, Prog. Nat. Sci. 26, 182–191 (2016)

B. Chen, D.L. Lin, L. Jin, X.Q. Zeng, C. Lu, Mater. Sci. Eng. A 483, 113–116 (2008)

R. Kapoor, A. Sarkar, R. Yogi, S.K. Shekhawat, I. Samajdar, J.K. Chakravartty, Mater. Sci. Eng. A 560, 404–412 (2013)

O. Sitdikov, T. Sakai, A. Goloborodko, H. Miura, R. Kaibyshev, Mater. Trans. 45, 2232–2238 (2004)

J. Gubicza, N.Q. Chinh, Z. Horita, T.G. Langdon, Mater. Sci. Eng. A 387, 55–59 (2004)

M. Kazeminezhad, E. Hosseini, Mater. Design 31, 94–103 (2010)

M. Ensafi, G. Faraji, H. Abdolvand, Mater. Lett. 197, 12–16 (2017)

I. Mazurina, T. Sakai, H. Miura, O. Sitdikov, R. Kaibyshev, Mater. Sci. Eng. A 483, 662–671 (2008)

G. Faraji, M.M. Mashhadi, H.S. Kim, Mater. Sci. Eng. A 528, 4312–4317 (2011)

F. Liu, H. Yuan, J. Yin, J.T. Wang, Mater. Sci. Eng. A 662, 578–587 (2016)

A. Goloborodko, O. Sitdikov, R. Kaibyshev, H. Miura, T. Sakai, Mater. Sci. Eng. A 381, 121–128 (2004)

M.H. Shaeri, M.T. Salehi, S.H. Seyyedein, M.R. Abutalebi, J.K. Park, Mater. Design 57, 250–257 (2014)

Acknowledgements

The authors thank Prof. Indradev Samajdar, IIT Bombay, for permitting the use of the EBSD facility. The authors also are grateful to PSG College of Technology, Coimbatore, India for making available their TEM facility for this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have influenced the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Babu, V., Shanmugavel, B.P. & Padmanabhan, K.A. On the Role of Semi-Die Angle in Multi-Pass Cyclic Expansion Extrusion: Effects on Microstructure and Mechanical Properties of AA 6063. Met. Mater. Int. 29, 3066–3077 (2023). https://doi.org/10.1007/s12540-023-01423-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-023-01423-9