Abstract

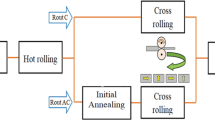

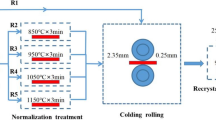

In the present work, the interaction of Sb and initial annealing before single-roll drive rolling on the microstructure, crystallographic texture, and magnetic behavior of 1.2 wt% Si steel was studied. Steel ingots with different antimony percentages were produced under the Ar atmosphere. After homogenization, they were subjected to symmetric hot-rolling. The produced sheets were then divided into two groups. The first group was cold-rolled to 1 mm thickness using a single-roll drive rolling machine, while the second group was subjected to initial annealing before asymmetric cold-rolling. Finally, all samples were annealed at 1000 °C for 3 min. Microstructural studies showed that with the addition of antimony, the mean grain size of samples was decreased. This effect was less significant in samples subjected to initial annealing. Moreover, the addition of antimony positively affected the desired texture. In specific, it yielded a gradual increase of θ-fiber in samples. The intensity of θ-fiber was higher in samples subjected to initial annealing compared with those without initial annealing. The comparison of the effect of average grain size and texture on magnetic behavior showed that grain size acted as the dominant parameter as the coercivity and remanence increased with decreasing grain size. However, in constant grain size, the texture played the main role in enhancing the magnetic behavior by increasing the θ-fiber intensity. The results showed that the combination of antimony and initial annealing before single-roll drive rolling resulted in the best magnetic performance in a low silicon steel sheet.

Graphical Abstract

Similar content being viewed by others

Data availability statement

All data included in this study are available upon request by contact with the corresponding author.

References

T.W. Na, H.K. Park, C.S. Park, H.D. Joo, J.T. Park, H.N. Han, N.M. Hwang, Met. Mater. Int. 24, 1369–1375 (2018). https://doi.org/10.1007/s12540-018-0145-0

Y. Wang, G. Zu, D. Zhang, Y. Han, W. Zhu, H. Sun, B. Wang, X. Ran, Met. Mater. Int. 28, 2849–2862 (2022). https://doi.org/10.1007/s12540-022-01175-y

Y. Du, R.J. O’Malley, M.F. Buchely, Met. Mater. Int. (2022). https://doi.org/10.1007/s12540-022-01184-x

J. Kraner, T. Smolar, D. Volsak, P. Cvahte, M. Godec, I. Paulin, Mater. Technol. 54, 731–743 (2020). https://doi.org/10.17222/mit.2020.158

S.K. Nam, G.H. Kim, D.N. Lee, I. Kim, Metall. Mater. Trans. A 49, 1841–1850 (2018). https://doi.org/10.1007/s11661-018-4538-y

H.Y. Song, H.-H. Lu, H.-T. Liu, H.-Z. Li, D.-Q. Geng, R.D.K. Misra, Z.-Y. Liu, G.-D. Wang, Steel Res. Int. 85, 1477–1482 (2014). https://doi.org/10.1002/srin.201300385

I. Kim, S.K. Nam, G. Kim, D.N. Lee, Mater. Sci. Forum 917, 236–240 (2018). https://doi.org/10.4028/www.scientific.net/MSF.917.236

J.-T. Park, J.A. Szpunar, J. Magn. Magn. Mater. 321, 1928–1932 (2009). https://doi.org/10.1016/j.jmmm.2008.12.015

J.S.M. Pedrosa, S. Da Costa Paolinelli, A.B. Cota, J. Magn. Magn. Mater. 393, 146–150 (2015). https://doi.org/10.1016/j.jmmm.2015.05.058

J. Qin, Y. Yue, Y. Zhang, Y. Cao, P. Yang, J. Magn. Magn. Mater. 439, 38–43 (2017). https://doi.org/10.1016/j.jmmm.2017.05.006

S. Takajo, C.C. Merriman, S.C. Vogel, D.P. Field, Acta Mater. 166, 100–112 (2019). https://doi.org/10.1016/j.actamat.2018.11.054

N. Zhang, P. Yang, W. Mao, Mater. Charact. 108, 85–93 (2015). https://doi.org/10.1016/j.matchar.2015.08.017

G. Sahoo, C.D. Singh, M. Deepa, S.K. Dhua, A. Saxena, Mater. Sci. Eng. A 734, 229–243 (2018). https://doi.org/10.1016/j.msea.2018.07.072

A.A. Uvarkin, A.A. Zaveryukha, M.Y. Polyakov, S.V. Bakhtin, Steel Transl. 40, 290–293 (2010). https://doi.org/10.3103/S0967091210030228

M.F. Rodrigues, M.A. da Cunha, S. da Costa Paolinelli, A.B. Cota, J. Magn. Magn. Mater. 331, 24–27 (2013). https://doi.org/10.1016/j.jmmm.2012.11.009

M. Takashima, T. Obara, T. Kan, J. Mater. Eng. Perform. 2, 249–254 (1993). https://doi.org/10.1007/BF02660293

A. Babapour, S.J. Hosseinipour, R. Jamaati, M. Abbasi, J. Magn. Magn. Mater. 554, 169258 (2022). https://doi.org/10.1016/j.jmmm.2022.169258

M. Mehdi, Y. He, E.J. Hilinski, A. Edrisy, Metall. Mater. Trans. A 50, 3343–3357 (2019). https://doi.org/10.1007/s11661-019-05239-4

M.Z. Salih, B. Weidenfeller, N. Al-Hamdany, H.G. Brokmeier, W.M. Gan, J. Magn. Magn. Mater. 362, 141–149 (2014). https://doi.org/10.1016/j.jmmm.2014.03.009

P. Lejček, P. Šandera, J. Horníková, J. Pokluda, M. Godec, Appl. Surf. Sci. 363, 140–144 (2016). https://doi.org/10.1016/j.apsusc.2015.12.020

P. Lejček, J. Alloys Compd. 378, 85 (2004). https://doi.org/10.1016/j.jallcom.2003.10.076

L. Dechao, D. Junhui, C. Haipeng, W. Haiyan, Mater. Res. Express 7, 56502 (2020). https://doi.org/10.1088/2053-1591/ab8c0b

X.H. Guo, Y.D. Zhang, S.B. Jin, R. Hu, Z.W. Liu, R.Q. Zhang, G. Sha, Mater. Chem. Phys. 236, 121783 (2019). https://doi.org/10.1016/j.matchemphys.2019.121783

N. Li, L. Xiang, P. Zhao, Adv. Mater. Res. 602–604, 435–440 (2012). https://doi.org/10.4028/www.scientific.net/AMR.602-604.435

E.J. Gutiérrez-Castañeda, A. Salinas-Rodríguez, J. Magn. Magn. Mater. 323, 2524–2530 (2011). https://doi.org/10.1016/j.jmmm.2011.05.039

Y. Wan, W. Chen, S. Wu, J. Rare Earths 31, 727–733 (2013). https://doi.org/10.1016/S1002-0721(12)60349-4

X. Bian, Y. Zeng, D. Nan, M. Wu, J. Alloys Compd. 588, 108–113 (2014). https://doi.org/10.1016/j.jallcom.2013.11.010

S.K. Chang, W.Y. Huang, ISIJ Int. 45, 918–922 (2005). https://doi.org/10.2355/isijinternational.45.918

A. Salyom, A. Zentko, V. Fria, P. Marko, G. Konczos, IEEE Trans. Magn. 30, 931–933 (1994). https://doi.org/10.1109/20.312449

F. Vodopivec, M. Jenko, D. Steiner–Petrovic, B. Breskvar, F. Marinšek, Steel Res. 68, 80–86 (1997). https://doi.org/10.1002/srin.199700546

T. Nguyen-Minh, J.J. Sidor, R.H. Petrov, L.A.I. Kestens, IOP Confer. Ser. Mater. Sci. Eng. 82, 012023 (2015). https://doi.org/10.1088/1757-899X/82/1/012023

S.S.F. de Dafé, S.da Costa Paolinelli, A.B. Cota, J. Magn. Magn. Mater. 323, 3234–3238 (2011). https://doi.org/10.1016/j.jmmm.2011.07.015

E.J. Gutiérrez Castañeda, C.N. Palafox Cantú, A.A. Torres Castillo, A. Salinas Rodríguez, R. Deaquino Lara, F. Botello Rionda, F. Márquez Torres, S. García Guillermo, Mater. Sci. Eng. B 243, 8–18 (2019). https://doi.org/10.1016/j.mseb.2019.03.016

M. Mehdi, Y. He, E.J. Hilinski, L.A.I. Kestens, A. Edrisy, Acta Mater. 185, 540–554 (2020). https://doi.org/10.1016/j.actamat.2019.12.024

T. Nguyen-Minh, J.J. Sidor, R.H. Petrov, L.A.I. Kestens, Scripta Mater. 67, 935–938 (2012). https://doi.org/10.1016/j.scriptamat.2012.08.017

L.-Z. An, Y. Ping Wang, H.-Y. Song, G.-D. Wang, H.-T. Liu, J. Magn. Magn. Mater. 491, 165636 (2019). https://doi.org/10.1016/j.jmmm.2019.165636

F. Rumiche, J.E. Indacochea, M.L. Wang, J. Mater. Eng. Perform. 17, 586–593 (2008). https://doi.org/10.1007/s11665-007-9184-2

F.J.G. Landgraf, J.R.F. da Silveira, D. Rodrigues Jr., J. Magn. Magn. Mater. 323, 2335–2339 (2011). https://doi.org/10.1016/j.jmmm.2011.03.034

K. Karami Nezhad, S. Kahrobaee, I. Ahadi Akhlaghi, J. Magn. Magn. Mater. 477, 275–282 (2019). https://doi.org/10.1016/j.jmmm.2019.01.074

M.J. Sablik, J. Appl. Phys. 89, 5610–5613 (2001). https://doi.org/10.1063/1.1359167

S. Tripathy, S. Ghosh Chowdhury, Sci. Rep. 11, 4912 (2021). https://doi.org/10.1038/s41598-021-84360-0

G. Lin, F. Zhao, X. Yu, Z. Zhang, J. Xie, J. Magn. Magn. Mater. 504, 166699 (2020). https://doi.org/10.1016/j.jmmm.2020.166699

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Babapour, A., Hosseinipour, S.J., Jamaati, R. et al. Effect of Sb and Initial Annealing on the Microstructure, Texture, and Magnetic Behavior of Low Silicon Steel Produced by Single-Roll Drive Rolling. Met. Mater. Int. 29, 1815–1824 (2023). https://doi.org/10.1007/s12540-022-01337-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-022-01337-y