Abstract

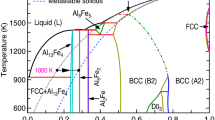

Aluminum/magnesium (Al/Mg) alloys have good metallurgical compatibility as well as similar melting and recrystallization temperatures. Therefore, the formation of deleterious IMCs is considered as a major problem in dissimilar Al/Mg alloys joining. In this paper, the metallurgical reaction behavior and atomic diffusion in Al/Mg solid state joining interface are studied. Based on the thermodynamic, kinetic and crystallographic characteristics of ordered phase transformation and atomic diffusion database, a phase field calculation framework of the polycrystalline β–Al3Mg2 and γ–Al12Mg17 evolution is developed. Diffusivity, D and interface mobility, M, which significant kinetic parameters are defined as alloy compositions and joining conditions dependent. By a series of simulation, it is proved the simulated interdiffusion microstructural characteristics and element distribution across the joining interface are in coincidence with the corresponding experimental data. The thermally activated IMC evolution in diffusion bonding is in thermodynamic equilibrium, while accelerated IMC evolution in friction stir welding results from thermomechanically activated D and M. The present study contributes to the understanding of interfacial microstructures evolution in solid state joining of dissimilar alloys.

Graphical abstract

Similar content being viewed by others

Data availability

The data sets supporting the results of this article are included within the article.

References

Z.B. Dong, Q. Song, X.X. Ai, Z. Lv, J. Manuf. Process. 42, 106 (2019)

Y.M. Baqer, S. Ramesh, F. Yusof, S.M. Manladan, Int. J. Adv. Manuf. Technol. 95, 4353 (2018)

Y.J. Fang, X.S. Jiang, D.F. Mo, D.G. Zhu, Z.P. Luo, Int. J. Adv. Manuf. Technol. 102, 2845 (2019)

H.A. Derazkola, F. Khodabakhshi, Int. J. Adv. Manuf. Technol. 100, 2401 (2019)

Y. Zhao, S. Jiang, S.F. Yang, Z.P. Lu, K. Yan, Int. J. Adv. Manuf. Technol. 83, 673 (2016)

L.H. Shah, A. Gerlich, Y. Zhou, Int. J. Adv. Manuf. Technol. 94, 2667 (2018)

U. Suhuddin, V. Fischer, F. Kroeff, J.F. Dos Santos, Mater. Sci. Eng. A 590, 384 (2014)

H. Shi, K. Chen, Z. Liang, F. Dong, T. Yu, X. Dong, L. Zhang, A. Shan, J. Mater. Sci. Technol. 33, 359 (2017)

X.Q. Wang, K. Chou, Int. J. Adv. Manuf. Technol. 100, 2147 (2019)

C.L. Yang, C.S. Wu, L. Shi, Sci. Technol. Weld. Joi. 25, 345 (2020)

W.J. Zheng, Y.M. He, J.G. Yang, Z.B. Dong, J. Mech. Eng. 54, 62 (2018)

T.Z. Gong, Y. Chen, S.S. Li, Y.F. Cao, D.Z. Li, X.Q. Chen, G. Reinhart, H. Nguyen-Thi, J. Mater. Sci. Technol. 74, 155 (2021)

D. Mukherjee, H. Larsson, J. Odqvist, Comput. Mater. Sci. 184, 109914 (2020)

A. Bhattacharya, K. Mondal, C.S. Upadhyay, S. Sangal, Comput. Mater. Sci. 173, 109428 (2020)

J.Y. Huh, K.K. Hong, Y.B. Kim, K.T. Kim, J. Electron. Mater. 33, 1161 (2004)

K.K. Hong, J.Y. Huh, J. Electron. Mater. 35, 56 (2006)

M.S. Park, S.L. Gibbons, R. Arróyave, Acta. Mater. 60, 6278 (2012)

M.S. Park, R. Arróyave, Acta. Mater. 58, 4900 (2010)

W. Wang, J.L. Murray, S.Y. Hu, L.Q. Chen, H. Wei, J. Phase. Equilib. Diff. 28, 258 (2007)

G.M. Han, Z.Q. Han, A.A. Luo, B.C. Liu, Metall. Mater. Trans. A 46, 948 (2015)

R.R. Mohanty, A. Leon, Y.H. Sohn, Comput. Mater. Sci. 43, 301 (2008)

A. Panteli, J.D. Robson, I. Brough, P.B. Prangnell, Mater. Sci. Eng. A 556, 31 (2012)

J. Robson, A. Panteli, P.B. Prangnell, Sci. Technol. Weld. Joi. 17, 447 (2012)

W. Zhong, M.S. Hooshmand, M. Ghazisaeidi, W. Windl, J.C. Zhao, Acta. Mater. 189, 214 (2020)

L. Wang, Y. Wang, P. Prangnell, J. Robson, Metall. Mater. Trans. A 46, 4106 (2015)

J.C. Liu, J. Hu, X.Y. Nie, H.X. Li, Q. Du, J.S. Zhang, L.Z. Zhuang, Mater. Sci. Eng. A 635, 70 (2015)

K.N. Kulkarni, A.A. Luo, J. Phase. Equili. Diff. 34, 104 (2013)

M. Jafarian, A. Khodabandeh, S. Manafi, Mater. Design 65, 160 (2015)

A. Azizi, H. Alimardan, Trans. Nonferrous. Met. Soc. China 26, 85 (2016)

M. Rezaei, A.H. Jabbari, M. Sedighi, Weld. World 64, 949 (2020)

Z.A. Zhu, R.H. Shi, A.D. Klarner, A.A. Luo, Y.Q. Chen, J. Magnes. Alloy 8, 578 (2020)

L.P. Long, W.S. Liu, Y.Z. Ma, L. Wu, S.W. Tang, High Temp. Mater. Proc. 36, 985 (2016)

A.H. Plaine, U.F.H. Suhuddin, C.R.M. Afonso, N.G. Alcântara, J.F. dos Santos, Mater. Design 93, 224 (2016)

U. Suhuddin, V. Fischer, J.F. dos Santos, Scripta Mater. 68, 87 (2013)

F. Foadian, M. Soltanieh, M. Adeli, M. Etminanbakhsh, Metall. Mater. Trans. A 45A, 1823 (2014)

S.D. Ji, Z.W. Li, Met. Mater. Int. 23, 1158 (2017)

H. Shakeri, M.A. Mofid, Met. Mater. Int. 27, 4132 (2021)

H.–S. Shin, M. de Leon, Met. Mater. Int. 23, 554 (2017)

P.Q. Gao, Y. Zhang, K.P. Mehta, Met. Mater. Int. 27, 3085 (2021)

J. Yang, J.P. Oliveira, Y.L. Li, C.W. Tan, C.K. Gao, Y.X. Zhao, Z.S. Yu, J. Mater. Process. Tech. 301, 117443 (2022)

Funding

The authors received financial support from the National Natural Science Foundation of China (No. 51905143) and National Magnetic Confinement Fusion Energy Research Program of China (Grant No. 2019YFE03100400).

Author information

Authors and Affiliations

Contributions

KS and XL implemented the phase field modeling and drafted the manuscript. YJ, YW and JL carried out the welding experiments, participated in the sample preparation and analysis. FL, DL and ZZ conceived the study and participated in its design and coordination. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethics approval

Not applicable.

Consent for publication

Written informed consent for publication of this paper was obtained from Hefei University and Technology and all authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Song, K., Liu, X., Ji, Y. et al. Intermetallic Compounds (IMCs) Formation in Al/Mg Dissimilar Alloy Solid State Joining: Experimental Study and Phase Field Modeling. Met. Mater. Int. 29, 1165–1180 (2023). https://doi.org/10.1007/s12540-022-01292-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-022-01292-8