Abstract

Laser metal deposition (LMD) is an additive manufacturing process used in manufacturing freeform geometries, repair applications, coating and surface modification, fabrication of functionally graded materials. It has a broad range of applications in various industries, including aviation, space, defence, automotive, tooling, etc. In this work, a multi-physics model of the LMD process was developed to rapidly predict the geometrical characteristics of the single clad track using the commercial software package Flow-3D. The volume of fluid (VOF) method was integrated to differentiate the interface between the metallic and gaseous cells. To validate the numerical model single bead tracks were deposited, and cross-sections of the beads were analysed. Mathematical formulae to predict different aspects of the single clad track (height, width, and depth) were derived using regression analysis. The influence of the process parameters on the geometrical characteristics of the single clad track was analysed in detail using analysis of variance (ANOVA). Both multi-physics model and mathematical regression model results were compared to the experimental measurements. The results were in good agreement with the experimental results.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

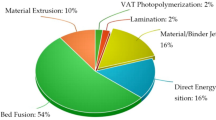

Additive manufacturing (AM) technologies are growing in significance because of their ability to provide design freedom, consolidate and customize components, manufacture on-demand, reduce weight [1], and minimize human interaction [2]. Applications of AM technologies exist in various sectors, including aerospace, energy, oil and gas, automotive, medical and dental, tool and die, consumer goods [3]. Directed energy deposition (DED) is one of the subcategories of AM technologies. DED processes manufacture components by melting the feedstock material as it is deposited [4]. DED technologies are used to manufacture near net-shaped components, repair and remanufacture high-value components, add new features on already existing parts, functionally graded materials (FGM) and coating applications to enhance surface properties.

Laser metal deposition (LMD) is an additive manufacturing process under the DED umbrella. For the LMD process, metal powder is the feedstock material and the laser beam is the heat source. An inert carrier gas delivers powder particles via multiple powder feeding nozzles (see Fig. 1). The heat from the laser beam melts the substrate and creates a melt pool. The powder particles are fed into the melt pool and melt. Certain powder particles interact with the laser beam mid-air and undergo phase transformation. As the laser beam moves ahead, the melt pool solidifies, creating a track of metal. The primary process parameters in the LMD process include laser power, laser scanning speed, powder feeding rate, shielding gas flow rate and laser beam diameter. Various combinations of process parameters influence the geometry, microstructure, mechanical properties, and formation of defects.

The size and geometry (height, width and depth) are critical in determining the quality of the deposited track. It is necessary to optimize the process parameters to achieve the desired geometry. Trial and error experimentation is generally used to optimize the process parameters for single tracks. An experimental investigation is an expensive and time-consuming process. It is necessary to develop a method to precisely predict the geometry of the single track. Numerical models, regression models and analytical models are used to predict single track geometries.

Several researchers [5,6,7,8,9] proposed physics numerical simulation models to predict the geometry of the track. LMD is a complex process with multiple physical phenomena taking place simultaneously. Bayat et al. [5] developed a multiphysics numerical model based on the Finite Volume Method (FVM) for the DED process to study the effect of powder particles velocities on the melt pool conditions and the final track geometry. The Lagrangian framework modelled the powder particle dynamics. The thermal camera performed In-situ monitoring, whereas ex-situ observations were carried out using an optical microscope. The simulated melt pool evolution follows the same trend as viewed by the thermal camera. The simulated track morphology was also in good agreement with the experimental data. Lee et al. [6] used a transient 3D transport model to understand the influence of convection flow on the solidification condition and the melt pool formation. The simulation showed that the deepest region formed at the back of the melt pool ahead of the solidification boundary due to Marangoni convection. The predicted clad geometry at various parameters was comparable to the experimental measurements. Wang et al. [7] employed a powder scale multiphysics model applying FVM to predict the track geometry. The authors also developed the Gaussian process regression (GPR) model based on the simulation results. The results showed a good agreement between the multiphysics simulation and experimental results for the track geometrical characteristics. The GPR model was also able to predict the track geometrical characteristics accurately. Ur Rehman et al. [8] presented a computational model taking into account the volume of fluid (VOF) and discrete element modelling techniques to model the flow behaviour of the melt pool for the laser metal deposition of AISI 304 Stainless Steel Single Tracks. The authors correlated the simulated layer geometry with the experimental results. The experimental and simulated results deviated between 1 and 3%. Zhang et al. [9] proposed a computational fluid dynamics model that incorporated the VOF method to simulate the clad formation and melt pool generation for the LMD process. The proposed model accurately predicted the melt pool behaviour and mass addition during the process. The simulated geometry showed good accuracy in comparison with the experimental measurements.

Some researchers [10,11,12,13] developed empirical (statistical) regression models to predict the track geometry. Lee et al. [10] investigated the effect of process parameters on the track geometry. The authors developed a mathematical model to predict the track geometry using Response surface methodology (RSM). The developed model was verified by comparing the predicted values with the experimental data. The error margin did not exceed 10%. Liu et al. [11] used the Taguchi method to optimize the LMD process parameters to maximize relative density. The authors performed analysis of variance (ANOVA) to identify the most significant parameters influencing the relative density of the deposit. A regression equation was developed to predict relative density. The percentage error between predicted and experimental values was less than 1%. Onwubolu et al. [12] used RSM to establish an exponential model to predict the track angle for the LMD process. The predictive model was satisfactory. Paulo Davim et al. [13] applied a multiple regression analysis (MRA) model to predict the effect of process parameters on the geometry of the clad based on the experimental results. The predicted values were validated experimentally and, the confirmation test showed good accuracy except for the track depth.

Certain researchers [14, 15] used machine learning (ML) techniques to predict single track geometry. Caiazzo et al. [14] developed a machine learning approach based on an artificial neural network to correlate the process parameters with the geometry of the single track deposited by LMD. The artificial neural network model estimated the process parameters for a track geometry with minimal absolute error. D.R. Feenstra et al. [15] effectively used an artificial neural network to model the interactions between critical process parameters and single track cross-sections or Inconel 625, Hastelloy X, and stainless steel 316 L. This study confirms that artificial neural network models can accurately predict cross-sectional track geometry.

Physics-based numerical simulation models use boundary conditions and make certain assumptions to derive the results. These models are highly accurate when the model assumptions closely match the physical system. The error in the predicted result may increase due to variability in the process. However, empirical-statistical models use direct measurements to create process maps to predict untested results. Experimental trials for direct measurements are costly and time-consuming. No information is available regarding the physical phenomenon of the process that can help in understanding and controlling the process. This paper aims to predict single track geometry deposited via the LMD process using numerical and empirical (statistical) models. The authors used the Taguchi method to develop process parameter combinations in a predefined range. A multiphysics numerical model was developed based on the VOF method for the LMD process. Single tracks were deposited, cut and, the cross-sections were analyzed under the microscope. Mathematical formulas were derived using the Taguchi method to predict the track geometry. Percentage error was calculated by comparing the predicted geometries for the multiphysics and statistical models with the experimental measurements. ANOVA was used to identify the most significant process parameters and their contribution towards each geometrical variable.

2 Materials and Methods

2.1 Taguchi-Based Design of Experiment

Researchers use statistical tools such as the design of the experiment (DOE) to collect essential technical information while performing minimum experimental trials. The Taguchi method is a DOE technique used in engineering applications because of its usability [16]. The factors, levels and responses are defined. Factors are any variable analyzed in the DOE. Levels are predefined values to be used for each factor. DOE response is a measurable result that we are interested in improving. A three-level Taguchi’s orthogonal array was used to minimize experimental trials. In this study, three factors: laser power, laser scanning speed, powder feed rate were varied at three levels. Table 1 shows the selected ranges for the variable process parameters. Minitab statistical software was used to obtain the L9 orthogonal array, as shown in Table 2.

2.1.1 Analysis of Variance (ANOVA)

Analysis of variance (ANOVA) is a statistical method generally used to identify the percentage contribution of individual factors and the most significant factors for the response. Equations (1–6) [17] were used to calculate the degree of freedom (DF), Sum of Squares for Total(SST), the sum of squares for each factor(SSF), mean squares for each factor(MSF), percentage of contribution(%)(C)and F-test values (Ftest) for the ANOVA.

Degree of freedom for each factor

where n is the number of levels.

Sum of Squares for Total

where z is the total number of experiments, and \(\eta_{i}\) is the signal to noise ratio of ith test.

Sum of squares for each factor

where F is one of the tested factors, y is the level number of the factor F, x is the repetition of each level of the factor F and, \(S_{{\eta_{y} }}\) is the sum of S/N ratio.

Mean squares for each factor

where \(SS_{F}\) sum of squares for each factor, DF is the degree of freedom.

Percentage of contribution (%),

where \(SS_{F}\) is sum of squares for each factor, \(SS_{T}\) is sum of squared for total.

F-test values

where \(MS_{F}\) is mean squares for each factor, \(MS_{E}\) is mean squares error.

2.2 Computational Fluid Dynamics (CFD) Modelling

The deposited material undergoes rapid melting and solidification during the LMD process. LMD is a complex process with multiple physical phenomena occurring simultaneously, such as powder particles-laser interaction, melt pool flow, heat transfer etc. [7]. A multiphysics numerical model was developed to simulate the deposition process of 316L-Si stainless steel powder particles on 1050 stainless steel. The model was developed using the commercial software package Flow 3D. The assumptions made are as follows:

-

(a)

The flow in the melt pool is assumed to be incompressible [8];

-

(b)

Metal evaporation is not considered [8];

-

(c)

Blown powder particle distribution is assumed to be Gaussian [9].

The mass, momentum and energy conservation expressions were used to model the melt pool region and substrate as expressed in Eqs. (7–9).

where k is the heat conductivity, \(h\) is specific enthalpy, \(\rho\) is density, \(\alpha\) is the coefficient of thermal expansion, \(\overrightarrow{g}\) is gravity function, \(\mu\) is viscosity, \(\overrightarrow{P}\) is pressure, and \(v\) is the velocity profile. Temperature-dependent heat conductivity was taken from commercial material properties software JMatPro for the deposited material (316L-Si) and substrate material (1050 stainless steel). The temperature range used was between 25 and 1600 °C. For very high energy densities where melt pool temperature exceeds 1600 °C, the accuracy of the numerical simulation model may decrease. For higher accuracy, additional information shall be fed into the simulation model. The volume of fluid (VOF) model was obtained via the free surface [18]. It is used to simulate melt pool shape and size. VOF method is expressed by the following equation:

where VF stands for metal volume fraction in the cell. VF = 0 indicates that there is no fluid in the cell. VF = 1 shows that the cell is completely occupied by the fluid. VF between 0 and 1 indicates that the cell is located on the surface between the empty and fluid regions. The laser beam has a ‘‘Gaussian’’ distribution for the energy density. Equations (11) [8] shows the energy density at constant scanning speed

where q is the energy density, A is powder particles laser beam absorption coefficient, p is laser power, \({R}_{b}\) is the radius of laser beam, \(v\) is the rate of scanning, and \({x}_{0}, {y}_{0}\) are the central location of laser beam. The LMD process was simulated in a three-dimensional Cartesian system. The size of the computational domain was 18 mm in length (x-direction) × 12 mm in width (y-direction) × 19 mm in height (z-direction) as shown in Fig. 2(a). The simulation domain was discretized into 547,822 mesh of size 0.1 mm each. Figure 3(b) shows the meshed VOF model. The blue region represents the substrate and, the yellow region shows the shielding gas region. The initial temperature for the material and the surrounding was set at 298 K. The material used for cladding was 316 l-Si and for substrate was 1050 stainless steel. Table 2 shows the simulated parameters. The shape of the laser beam is ‘‘top-hat’’ with the focus radius of 1.75 mm.

2.3 Experimental conditions

ERLASER HARD + CLAD system manufactured by Erlas (Germany) was used in the experiment. The system includes a robotic arm (KUKA KR90 R3100 extra), laser source (Laserline [LDF 4000–100]), coaxial water-cooled nozzle, and multi hopper powder delivery system. 60 mm long single tracks were deposited with 316L-Si metal powder on 1050 stainless steel substrate. The shielding gas used was argon. Figure 3a shows the experimental setup and, Fig. 3b shows the deposited tracks. Oerlikon Metco supplied the 316L-Si powder and, the powder particles ranged between 45 and 106 μm. Table 3 shows the chemical composition of the powder. Table 2 shows the process parameters used for the experimental trials.

316L is an austenitic, nickel–chromium stainless steel. It exhibits high impact resistance and tensile strength at elevated temperatures and provides great corrosion and erosion protection. The material is in high demand for applications in the oil, gas and marine industries. 316L with higher silicon content was used because silicon acts as a fluxing agent that produces cleaner single track deposits. In other words, higher silicon content makes the material more suited for Additive Manufacturing.

The tracks were cut at the cross-section using wire electric discharge machining. Cross-sectional geometry was investigated using an optical microscope. The height, width and depth of the tracks were measured as shown in Fig. 4. The light coloured region shows the melt pool region. The darker region shows the heat affected zone (HAZ). Straight and curved interface shapes were observed. The variation in interface shape can be attributed to irregular powder flow rate because of the difficulties with powder mass flow control and fluctuations in laser power caused by optical and thermal instability during laser radiation [10]. The height and width were measured once at maximum point, whereas depth was measured at 5 equidistant points and averaged out. Two additional combined process parameters: specific energy density, SED (J/mm2), and powder feeding density, PFD (g/mm2), were defined to examine their influence on the single track geometry. Equations (12) and (13) [10] define the combined parameters.

where SED is the specific energy density, LP is laser power, d is laser beam diameter and, SS is laser scanning speed.

where PFD is the powder feeding density, PF is powder flow rate, d is laser beam diameter and, SS is laser Scanning Speed. Another parameter that was defined was Dilution (%). It is a dimensional parameter and is defined by the ratio between the melt pool penetration depth below the substrate and the sum of melt pool penetration depth and deposited height for a single track. It is calculated as shown in Eqs. (14):

where D (%) is the dilution percentage, d is melt pool penetration depth below the substrate, and h is deposited single height.

3 Results and Discussions

3.1 Effects of the Process Parameters on the Single Bead Track Geometry

3.1.1 Effects of Specific Energy Density

Figure 5a and b show that the track height and width increase along with SED.

The powder deposition efficiency increases with SED because of the increased heat input [10]. The increase in the powder deposition efficiency results in more powder getting melted hence the increase in track heights. The track height ranges from 0.54 to 0.88 mm. The increase in heat input influences the size and shape of the melt pool, increasing the track widths. The width ranges from 3.03 to 3.14 mm. The fluctuations in the bead height and width can be attributed to the varying powder flow rate (see Fig. 5f).

Figure 5c and d show that the track depth and dilution % decrease along with the increase in the SED. With the increase in SED, the track depth and dilution % is generally expected to increase at a constant powder flow rate due to the increased heat transfer from the substrate surface to the inner section. The decreasing trend can be attributed to the varying and increasing powder feed rate (See Fig. 5f). With increased powder flow, the mid-air interaction between the powder cloud and laser beam increases reducing, the SED incident on the substrate. The track depth ranges from 0.04 to 0.12 mm, and the dilution % ranges from 5.24 to 16.44%. Figure 5e shows that the width to height ratio shows a decreasing trend along with the increase in the SED. This is because the increase in height is comparatively higher than the increase in width with the increasing SED. The width to height ratio ranges from 3.57 to 5.74. The variation in the depth, dilution % and, width to height ratios can be attributed to the varying powder flow rate (See Fig. 5f).

3.1.2 Effects of Powder Feeding Density

Figure 6a shows that the track height shows an increasing trend along with powder feeding density.

With the increase in PFD, more powder gets delivered in the melt pool region and get melted explaining the increase in height. In contrast, the track width does not show any significant change but shows a slight decreasing trend with the increasing PFD, as shown in Fig. 6b. The increase in PFD influences the melt pool shape and size, slightly reducing the track width. The fluctuations in height and width can be attributed to the variation in the laser power (see Fig. 6f).

Figure 6c and d show the track depth and dilution % tend to decrease along with the increase in the PFD. As the PFD increases, more powder particles interact with the laser beam mid-air and, relatively less heat from the laser interacts with the substrate, hence the decreasing trend. The fluctuations in the dilution % and track depth are because of the variation in the laser power (see Fig. 6f). The width to height ratio also shows a decreasing trend with the increase in PFD, as seen in Fig. 6e. The increase in height is relatively greater than the increase in width with the increasing PFD hence the decreasing trend.

3.1.3 Covariance

Table 4 shows covariance between the input parameter vectors and the track geometry vectors.

A positive covariance value indicates a positive relationship between the input factor and the response variable. A negative value indicates a negative relationship. Table 5 shows that the track height increases with laser power and powder feeding rate but decreases with laser scanning speed. As the laser power increases, SED increases, more powder particles get melted, resulting in increased track height. As powder feed rate increases, PFD increases. More powder particles get delivered in the melt pool region and get melted, resulting in increased track height. As the laser scan speed increases, SED decreases. The melt pool size and powder catchment efficiency decrease, resulting in reduced track height.

Table 5 shows that the track width increases with laser power but decreases with laser scanning speed and powder feed rate. The melt pool width determines the width of the track. As the laser power increases, SED increases, influencing the melt pool size and shape, increasing the track width. With the increase in scan velocity, SED decreases. The interaction time between the substrate and laser beam gets reduced, which influences the melt pool shape and size, reducing the track width. As the powder feeding rate increases, more powder particles interact with the laser beam mid-air. The amount of heat energy that interacts with the substrate reduces, influencing the melt pool shape and size, reducing the track width.

Table 5 shows that the track depth increases along with laser power and laser scanning speed but decreases with powder feed rate. With the increase in laser power, SED increases. The melt pool penetration depth below the substrate increases resulting in increased track depth. As the laser scanning speed increases, SED decreases, reducing the melt pool depth below the substrate. A negative correlation generally exists between laser scanning speed and track depth, given all other conditions remain unchanged. However, a positive correlation is observed in this study. As for the powder feeding rate, an increase results in an increased powder particles interaction with the laser beam mid-air, reducing the SED incident on the substrate decreasing track depth.

3.2 Prediction of Single-Track Geometry Via Multi-Physics Simulation

3.2.1 Cladding Track Geometry: Experiment versus Simulation

Figure 7a shows the detailed simulation results of the single track formation process (laser power: 1400 W, laser scanning speed: 9 mm/s, powder feeding rate: 4 rev/min, shielding gas flow rate: 8 L/min). Figure 7b shows the cross-sectional geometry measurements of the single track. The shape of the track cross-section roughly remains an arc because of the effect of the surface tension [7]. Fluctuations in depth are observed in the simulated cross-section. These fluctuations can be attributed to irregular powder flow or laser power fluctuations due to thermal and optical instabilities [10].

Table 5 shows the simulated track geometry, the experimental measurements and the % error. For illustration purposes, Fig. 8 compares the simulated and experimental results. Table 6 shows that the % error for track height ranges from 2.73 to 15.82%, and for track width, it ranges from 8.25 to 14.79%. This shows that the simulation model can accurately predict the heights and widths. For track depth, the error ranges from 10.37 to 131.76%. The simulations were very time-intensive, taking up to 2 days.

It must be noted that the simulation incorporates mass transfer, heat transfer, and phase transfer and helps predict the geometrical characteristics of the single tracks without doing experimental trials. The process parameters influence the track geometry. It is necessary to initially know the track geometry for desirable parameter ranges in order to choose a suitable overlapping between tracks which generally varies between 45 and 65% of track width. Choosing suitable overlaps may not be possible without initially knowing the track width itself. Improper overlaps may result in lack of fusion porosity.

The inputs for simulation include temperature-dependent material properties, particle size distribution, nozzle properties, laser source properties (flux distribution, wavelength), and process parameters. Because the simulation takes into account nozzle characteristics and chemical composition, it can be used to predict the bead geometry of almost any material and machine accurately, given correct information is used as input. Experimental trials for different materials may not be needed, except for validation of certain parameter combinations that look promising.

3.3 Prediction of Single-Track Geometry Via Taguchi Design

3.3.1 Cladding Track Geometry: Experiment versus Mathematical Model

Mathematical models were derived using the measured experimental data. Equations (15–17) show the regression equations for the output variables (Height, Width and Depth) based on the input process parameters (Laser Power, Laser Scanning Speed and Powder Feeding Rate).

Table 6 shows the predicted track geometry, the experimental measurements and the % error. The input process parameters were substituted in the regression equations to obtain the predicted values. For illustration purposes, Fig. 9 compares the predicted and experimental results. Table 6 shows that the % error for track height and width does not exceed 10% proving that the mathematical model can accurately predict the heights and widths. In terms of track depth, the % error is higher, with the maximum error reaching 43.40%. The high % error for the depth does not mean that the mathematical model prediction for the track depth is not as good as the height or width. The high % error can be explained by the fact that the melt pool depth is a small numerical value. A slight deviation results in a relatively large error.

It must be noted that, for Iron-based alloys with chemical compositions close to 316L-Si stainless steel, the mathematical model can predict the bead geometry with relatively low error. In the case of other alloys, such as Titanium alloys, the error may increase. This is because of the difference in the densities of the materials. For the same specific energy density less dense material will melt more in comparison with the denser material. It creates a relatively larger melt pool than what the model may predict, increasing the error. The chemical composition also impacts the flows inside the melt pool, for example, with the addition of sulphur which acts as a surface-active element [19]. This influences the surface tension inside the melt pool, impacting the flows inside the melt pool. Radially outward flow makes the melt pool wider, whereas radially inward flow makes the melt pool deeper. The variation in the chemical composition may reduce the accuracy of the mathematical model.

In terms of equipment it must be noted that wide variety of equipment is available in the open market which includes gantry style CNC machines, robotic arms with deposition heads, hybrid machines (Depositon + Milling). The nozzles in LMD can be off-axis, coaxial continuous and coaxial discrete. The mathematical model was created for equipment defined in Sect. 2.3. For the LMD equipment similar to the one used in the experiment, the mathematical regression model can give very accurate predictions for the bead geometry. The error in prediction may increase as the differentiation in the equipment increases.

The accuracy of the mathematical regression model decreases as the material chemical composition changes and differentiation in the equipment used increases. Nevertheless, the mathematical regression model can be used as a starting point for different materials and LMD equipment. The model can provide reasonable initial bead geometry estimates to researchers. Researchers can fine-tune the process parameter ranges they can work with, significantly reducing the number of experimental trials, hence, saving time and resources.

3.3.2 Analysis of Variance (ANOVA)

ANOVA was performed to compare the contribution of each parameter on the height, width and depth of the track geometry. 95% level of confidence was used for the analysis. Lee et al. [20] suggested that the parameter with the higher F value has a higher impact on the output. Tables 7, 8 and 9 show the ANOVA for the height, width and, depth. Table 7 shows that the powder feeding rate is the most significant parameter influencing the track height. Figure 6a shows a sharp increase in the track height along with PFD. As the powder feeding density increases, more powder gets delivered in the melt pool region. Consequently, more powder melts, causing a height increase. Table 8 shows that Laser power is the most significant parameter influencing the track width. Figure 5b also shows an increase in track width along with SED. As the SED increases, the melt pool size increases resulting in the increased width. Table 9 shows that the powder feeding rate is the most significant parameter influencing the track depth closely followed by laser power. Both laser power and powder feeding rate influence the SED incident on the substrate impacting the track depth below the substrate.

4 Conclusions

In this work, a multiphysics numerical model of the LMD process of stainless steel 316L-Si was developed to predict the geometrical characteristics of the single clad track using Flow-3D software. In the model, the volume of fluid method was incorporated to differentiate the interface between the gaseous and metallic cells. Single tracks were deposited, and the cross-sections were analyzed. Based on the experimental measurements (height, width and depth), mathematical formulae were derived to predict different geometrical aspects of the single clad track. The multi-physics model and mathematical regression model results were compared to the experimental measurements. For the simulation model, there were deviations of 2.73%–15.82% for track height, 8.25%–14.79% for track width and 10.37%–131.76% for track depth. For the mathematical model, the deviation does not exceed 10% for the track height and width, and the maximum deviation for track depth was 43.40%. The error in the mathematical model is expected to increase with the change in material composition, and if a different set of equipment is used. Nevertheless, researchers can use the mathematical model as a starting point, to fine tune the parameter ranges they can work with. This will reduce the number of experimental trials required, hence saving time and resources. According to the ANOVA results, powder feeding rate has the most significant effect on the track height and laser power on the track width. For track depth, both laser power and powder feeding rate were critical because they influenced the specific energy density incident on the substrate. The results from this work suggest that both multi-physics and mathematical regression models can almost precisely predict the geometry of single bead tracks each having its advantages and disadvantages.

References

O. Diegel, A. Nordin, D. Motte, A Practical Guide to Design for Additive Manufacturing (Springer, Singapore, 2019)

Y. Zhang, W. Jarosinski, Y.G. Jung, J. Zhang, in Additive Manufacturing: Materials, Processes, Quantifications and Applications, ed. by J. Zhang, Y.-G. Jung (Butterworth-Heinemann, Oxford, 2018), pp. 39–51

J.O. Milewski, Additive Manufacturing of Metals: From Fundamental Technology to Rocket Nozzles, Medical Implants, and Custom Jewelry, 1st edn.(Springer, Cham, 2017)

I. Gibson, D. Rosen, B. Stucker, M. Khorasani, Additive Manufacturing Technologies, 3rd edn. (Springer, Cham, 2021)

M. Bayat, V.K. Nadimpalli, F.G. Biondani, S. Jafarzadeh, J. Thorborg, N.S. Tiedje, G. Bissacco, D.B. Pedersen, J.H. Hattel, Addit. Manuf. 43, 102021 (2021). https://doi.org/10.1016/j.addma.2021.102021

Y. Lee, M. Nordin, S. Babu, D. Farson, Weld. J. 93, 292s (2014). http://files.aws.org/wj/supplement/WJ_2014_08_s292.pdf

S. Wang, L. Zhu, J.Y.H. Fuh, H. Zhang, W. Yan, Opt. Lasers Eng. 127, 105950 (2020). https://doi.org/10.1016/j.optlaseng.2019.105950

A. Ur Rehman, M.A. Mahmood, F. Pitir, M.U. Salamci, A.C. Popescu, I.N. Mihailescu, Metals 11, 1569 (2021). https://doi.org/10.3390/met11101569

Y.M. Zhang, C.W.J. Lim, C. Tang, B. Li, Int. J. Therm. Sci. 165, 106954 (2021). https://doi.org/10.1016/j.ijthermalsci.2021.106954

E.M. Lee, G.Y. Shin, H.S. Yoon, D.S. Shim, J. Mech. Sci. Technol. 31, 3411 (2017). https://doi.org/10.1007/s12206-017-0239-5

Y. Liu, C. Liu, W. Liu, Y. Ma, S. Tang, C. Liang, Q. Cai, C. Zhang, Opt. Laser Technol. 111, 470 (2019). https://doi.org/10.1016/j.optlastec.2018.10.030

G.C. Onwubolu, J. Paulo Davim, C. Oliveira, A. Cardoso, Opt. Laser Technol. 39, 1130 (2007). https://doi.org/10.1016/j.optlastec.2006.09.008

J. Paulo Davim, C. Oliveira, A. Cardoso, Mater. Design 29, 554 (2008). https://doi.org/10.1016/j.matdes.2007.01.023

F. Caiazzo, A. Caggiano, Materials 11, 444 (2018). https://doi.org/10.3390/ma11030444

D.R. Feenstra, A. Molotnikov, N. Birbilis, Mater. Design 198, 109342 (2021). https://doi.org/10.1016/j.matdes.2020.109342

Methods and formulas for Analyze Taguchi Design - Minitab. (n.d.). (C) Minitab, LLC. All Rights Reserved. 2019. https://support.minitab.com/en-us/minitab/18/help-and-how-to/modeling-statistics/doe/how-to/taguchi/analyze-taguchi-design/methods-and-formulas/methods-and-formulas/

S.K. Ghosh, K. Bandyopadhyay, P. Saha, Mater. Charact. 93, 68 (2014). https://doi.org/10.1016/j.matchar.2014.03.021

Y.S. Lee, W. Zhang, Addit. Manuf. 12, 178 (2016). https://doi.org/10.1016/j.addma.2016.05.003

W. Pitscheneder, T. Debroy, K. Mundra, R. Ebner, Weld. J. 75, 71s (1996). https://app.aws.org/wj/supplement/WJ_1996_03_s71.pdf

H.-K. Lee, J. Mater. Process. Tech. 202, 321 (2008). https://doi.org/10.1016/j.jmatprotec.2007.09.024

Funding

This work was supported by the Tubitak and Coşkunöz Holding [2244 Industrial Doctorate Programme No. 119C059]; and by Tubitak, Eureka, Eureka Smart Cluster and Coşkunöz Holding [Grant Agreement No. 9190007].

Author information

Authors and Affiliations

Contributions

TM: Investigation, data curation, writing—original draft, writing—review and editing, formal analysis, visualization. MB: conceptualization, methodology, software, formal analysis, visualization. MC: conceptualization, methodology. TK: conceptualization, methodology, validation. FO: writing—review and editing, supervision. AB: writing—review and editing, supervision. AO: writing—review & editing, supervision.

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Biyikli, M., Karagoz, T., Calli, M. et al. Single Track Geometry Prediction of Laser Metal Deposited 316L-Si Via Multi-Physics Modelling and Regression Analysis with Experimental Validation. Met. Mater. Int. 29, 807–820 (2023). https://doi.org/10.1007/s12540-022-01243-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-022-01243-3