Abstract

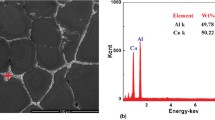

The microstructures and mechanical properties of Al-2.8 wt%Cu-1.4 wt%Li-T87 alloy after thermal exposure at 125, 150 and 175 °C were measured and characterized by universal testing machine, scanning electron microscope and transmission electron microscope. The thermal stability of microstructures and mechanical properties of T87 heat-treated Al-2.8 wt%Cu-1.4 wt%Li alloy was investigated. The results show that the tensile strength of Al-2.8 wt%Cu-1.4 wt%Li-T87 alloy increased first and then decreased with the increase of thermal exposure temperature, which is due to the change of the number and size of precipitates. After thermal exposure at 125 °C, the alloy exhibited higher strength due to further precipitation of θ′ phase and stable size of T1 phase. After thermal exposure at 175 °C, the mechanical properties of Al-2.8 wt%Cu-1.4 wt%Li-T87 alloy decreased obviously, which was related to the dissolution of θ' phase and thickening of T1 phase.

Graphic abstract

Similar content being viewed by others

Data Availability

The raw/processed data required to reproduce these findings cannot be shared at this time due to technical or time limitations.

References

L. Zhong, W. Gao, Z. Feng, Z. Lu, C. Zhu, J. Mater. Sci. Technol. 35, 2409 (2019)

T. Dursun, C. Soutis, Mater. Design 56, 862 (2014)

R.J. Rioja, J. Liu, Metall. Mater. Trans. A 43, 3325 (2012)

Yong Li, Zhusheng Shi, Jianguo Lin, Mater. Design 183, 108121 (2019)

Y. Lin, Z. Zheng, S. Li, X. Kong, Y. Han, Mater. Charact. 84, 88 (2013)

S. Mishra, M. Suresh, A.M. More, A. Bisht, N. Nayan, S. Suwas, Mater. Sci. Eng. A 799, 140047 (2021)

A.A. El-Aty, Y. Xu, X. Guo, S. Zhang, Y. Ma, D. Chen, J. Adv. Res. 10, 49 (2018)

I.J. Polmear, G. Pons, Y. Barbaux, H. Octor, C. Sanchez, A.J. Morton, W.E. Borbidge, S. Rogers, Mater. Sci. Technol. 15, 861 (1999)

E. Gumbmann, W. Lefebvre, F. De Geuser, C. Sigli, A. Deschamps, Acta Mater. 115, 104 (2016)

P. Donnadieu, Y. Shao, F. De Geuser, G.A. Botton, S. Lazar, M. Cheynet, M. de Boissieu, A. Deschamps, Acta Mater. 59, 462 (2011)

C. Zhu, Q. Liu, Wu. Z. Wu, W. Gao, Mater. Charact. 167, 110530 (2020)

S.Y. Duan, C.L. Wu, Z. Gao, L.M. Cha, T.W. Fan, J.H. Chen, Acta Mater. 129, 352 (2017)

K.S. Kumar, F.H. Heubaum, Acta Mater. 45, 2317 (1997)

B. Noble, S.J. Harris, K. Dinsdale, Acta Mater. 45, 2069 (1997)

V.G. Davydov, I.N. Fridlyander, M.V. Samarina, A.I. Orozov, L.B. Ber, V.I. Yelagin, R. Lang, T. Pfannenmüller, Mater. Sci. Forum 331–337, 1049 (2000)

D. Ortiz, J. Brown, M. Abdelshehid, P. De Leon, R. Dalton, L. Mendez, J. Soltero, M. Pereira, M. Hahn, E. Lee, J. Ogren, R. Clark, J. Foyos, O.S. Es-Said, Eng. Fail. Anal. 13, 170 (2006)

S. Katsikis, B. Noble, S.J. Harris, Mater. Sci. Eng. A 485, 613 (2008)

E. Balducci, L. Ceschini, S. Messieri, S. Wenner, R. Holmestad, Mater. Design 119, 54 (2017)

J. Jabra, M. Romios, J. Lai, E. Lee, M. Setiawan, J. R. Ogren, R. Clark, T. Oppenheim, O. S. Es-Said, E. W. Lee, N. Abourialy, W. E. Frazier, J. Witters , J. Mater. Eng. Perform. 15, 601 (2006)

B. Jiang, F. Cao, H. Wang, D. Yi, Y. Jiang, F. Shen, B. Wang, H. Liu, Mater. Sci. Eng. A 740–741, 157 (2019)

N.E. Prasad, A.A. Gokhale, R.J.H Wanhill, Aluminum-Lithium Alloys: Processing, Properties, and Applications (Butterworth-Heinemann, Oxford, 2013), pp. 503–535

A. Deschamps, M. Garcia, J. Chevy, B. Davo, F. De Geuser, Acta Mater. 122, 32 (2017)

S. Duan, F. Guo, D. Wu, T. Wang, T. Tsuchiya, K. Matsuda, Y. Zou, J. Mater. Res. Tech. 15, 2379 (2021)

R. Yoshimura, T.J. Konno, E. Abe, K. Hiraga, Acta Mater. 51, 4251 (2003)

H. Liu, B. Bellón, J. LLorca, Acta Mater. 132, 611 (2017)

H.Y. Li, D.S. Huang, W. Kang, J.J. Liu, Y.X. Ou, D.W. Li, J. Mater. Sci. Technol. 32, 1049 (2016)

J. Zhang, C. Wang, Y. Zhang, Y. Deng, J. Alloy. Compd. 764, 452 (2018)

H. Li, Y. Tang, Z. Zeng, Z. Zheng, F. Zheng, Mater. Sci. Eng. A 498, 314 (2008)

Z. Gao, J.-H. Chen, S.-Y. Duan, X.-B. Yang, C.-L. Wu, Acta Metall. Sin. Engl. Lett. 29, 94 (2016)

K. Chen, X. Wu, Y. Cao, Z. Wang, X. Zhang, C. Wu, M. Chen, Mater. Sci. Eng. A 811, 141092 (2021)

S. Ahmadi, H. Arabi, A. Shokuhfar, J. Alloy. Compd. 484, 90 (2009)

B.M. Gable, M.A. Pana, G.J. Shiflet, E.A. Jr. Starke, Mater. Sci. Forum 396–402, 699 (2002)

J.F. Nie, B.C. Muddle, I.J. Polmear, Mater. Sci. Forum 217–222, 1257 (1996)

C. Fan, L. Ou, Z. Hu, S. Wang, J. Wang, T. Nonferr. Metal. Soc. 30, 2590 (2020)

H.M. Flower, P.J. Gregson, Mater. Sci. Technol. 3, 81 (1987)

M.J. Kerr, E.D. Sweet, C.G. Bennett, B.C. Muddle, Mater. Sci. Forum 217–222, 1079 (1996)

X. Gao, J.F. Nie, B.C. Muddle, in Aluminum Alloys: Their Physical and Mechanical Properties. Vol.2: Proceedings of The 6th International Conference on Aluminum Alloys, ICAA-6, ed. by T. Sato, S. Kumai, T. Kobayashi, Y. Murakami. Toyohashi, 5-10 July 1998 (The Japan Institute of Light Metals (JILM), Tokyo, 1998), p. 651

N. ÜnlÜ, B.M. Gable, G.J. Shiflet, E.A. Starke Jr., Metall. Mater. Trans. A 34, 2757 (2003)

C.R. Hutchinson, X. Fan, S.J. Pennycook, G.J. Shiflet, Acta Mater. 49, 2827 (2001)

Acknowledgements

This work was supported by National Natural Science Foundation of China (No. 51474101) and the equipment pre-research project of China (Nos. 41422060204).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhu, C., Li, G., Hao, S. et al. Thermal Stability of Precipitates in Al-2.8 wt%Cu-1.4 wt%Li Alloy. Met. Mater. Int. 28, 2898–2906 (2022). https://doi.org/10.1007/s12540-022-01187-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-022-01187-8