Abstract

Mold oscillations, widely used in continuous casting for infiltrating the mold flux between the mold and the solidified shell, change periodically the heat flux from the meniscus to mold. These variations of the heat flux affect the solidification behavior near an initial solidification position. Because the surface shape of the solidified shell is influenced by the initial solidification behavior, it is important to understand the relation between the mold oscillation, the heat flux and initial solidification behavior. In the present study, we developed a numerical model that simulates the flow and thermal behavior of the mold flux near the meniscus. Using this model, we analyze the effects of the variations of the heat flux from the meniscus on the initial solidification position and suggest the formation mechanism of the oscillation marks (OMs) and the hooks. Also, we will present quantitative results about the depth of the OMs and the length of the hooks at the conditions used in the present study. The factors that influence the hooks’ types and the causes of the irregularity of the shell surface are also discussed.

Graphic Abstract

Similar content being viewed by others

References

H.-J. Shin, S.-H. Kim, B.G. Thomas, G.-G. Lee, J.-M. Park, J. Sengupta, Measurement and prediction of lubrication, powder consumption, and oscillation mark profiles in ultra-low carbon steel slabs. ISIJ Int. 46(11), 1635–1644 (2006)

H. Todoroki, T. Ishii, K. Mizuno, A. Hongo, Effect of crystallization behavior of mold flux on slab surface quality of a Ti-bearing Fe–Cr–Ni super alloy cast by means of continuous casting process. Mater. Sci. Eng. A 413–414, 121–128 (2005)

K.C. Mills, A.B. Fox, Z. Li, R.P. Thackray, Performance and properties of mould fluxes. Ironmak. Steelmak. 32(1), 26–34 (2013)

J. Cho, T. Emi, H. Shibata, M. Suzuki, Heat transfer across mold flux film in mold during initial solidification in continuous casting of steel. ISIJ Int. 38(8), 834–842 (1998)

Y.A. Meng, B.G. Thomas, Modeling transient slag-layer phenomena in the shell/mold gap in continuous casting of steel. Metall. Mater. Trans. B 34(5), 707–725 (2003)

A. Badri et al., A mold simulator for the continuous casting of steel: part II. the formation of oscillation marks during the continuous casting of low carbon steel. Metall. Mater. Trans. B 36B, 373–383 (2005)

P.E. Ramirez-Lopez, K.C. Mills, P.D. Lee, B. Santillana, A Unified mechanism for the formation of oscillation marks. Metall. Mater. Trans. B 43B(1), 109–122 (2012)

K. Schwerdtfeger, H. Sha, Depth of oscillation marks forming in continuous casting of steel. Metall. Mater. Trans. B 31B, 813–826 (2000)

E. Takeuchi, J.K. Brimacombe, The formation of oscillation marks in the continuous casting of steel slabs. Metall. Trans. B 15B, 493–509 (1984)

H. Yamamura, Y. Mizukami, K. Misawa, Formation of a solidified hook-like structure at the subsurface in ultra low carbon steel. ISIJ Int. 36, S223–S226 (1996)

J. Sengupta, B.G. Thomas, H.J. Shin, G.G. Lee, S.H. Kim, A new mechanism of hook formation during continuous casting of ultra-low-carbon steel slabs. Metall. Mater. Trans. A 37(5), 1597–1611 (2006)

C. Ojeda, J. Sengupta, B.G. Thomas, J. Barco, J.L. Arana, Mathematical modeling of thermal-fluid flow in the meniscus region during an oscillation cycle. AISTech Proc. 1, 1017–1028 (2006)

M. Alizadeh, A. Jenabali Jahromi, O. Abouali, New analytical model for local heat flux density in the mold in continuous casting of steel. Comput. Mater. Sci. 44(2), 807–812 (2008)

H. Tomono, W. Kurz, W. Heinemann, The liquid steel meniscus in molds and its relevance to the surface quality of castings. Metall. Trans. B 12B, 409–411 (1981)

H. Tomono, P. Ackermann, W. Kurz, W. Heinemann, Elements of surface mark formation in continuous casting of steel (Solidification Technology in the Foundry and Cast House) (The Metals Society, Warwick, 1983), pp. 524–531

A. Matsushita, K. Isogami, M. Temma, T. Ninomiya, K. Tsutsumi, Direct observation of molten steel meniscus in CC mold during casting. Trans. Iron Steel Inst. Jpn. 28(7), 531–534 (1988)

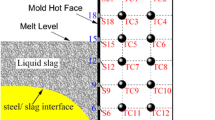

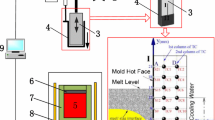

J.-Y. Park, E.-Y. Ko, J. Choi, I. Sohn, Characteristics of medium carbon steel solidification and mold flux crystallization using the multi-mold simulator. Met. Mater. Int. 20(6), 1103–1114 (2014)

CFD-ACE + V2017.5. ESI Group, Paris, FRANCE. www.esi-group.com

J.J. Bikerman, Physical surface (Academic Press Inc, New York, 1970), pp. 1–13

E.-Y. Ko, K.-W. Yi, J.-K. Park, J.-W. Cho, H.-J. Shin, Numerical modeling and analysis of the thermal behavior of copper molds in continuous casting. Met. Mater. Int. 16(2), 281–288 (2010)

J. Cho, H. Shibata, T. Emi, M. Suzuki, Radiative heat transfer through mold flux film during initial solidification in continuous casting of steel. ISIJ Int. 38(3), 268–275 (1998)

K.C. Mills, S. Karagadde, P.D. Lee, L. Yuan, F. Shahbazian, Calculation of physical properties for use in models of continuous casting process-part 1: mould slags. ISIJ Int. 56(2), 264–273 (2016)

FactSage 7.2. CRCT-ThermoFact.inc and GTT-Technologies, Montreal, Canada and Aachen, Germany. www.factsage.com

A. Yamauchi, T. Emi, S. Seetharaman, A mathematical model for prediction of thickness of mould flux film in continuous casting mould. ISIJ Int. 42(10), 1084–1093 (2002)

Y. Meng, B.G. Thomas, Heat-transfer and solidification model of continuous slab casting: CON1D. Metall. Mater. Trans. B 34B, 685–705 (2003)

J. Sengupta, H.J. Shin, B.G. Thomas, S.H. Kim, Micrograph evidence of meniscus solidification and sub-surface microstructure evolution in continuous-cast ultralow-carbon steels. Acta Mater. 54(4), 1165–1173 (2006)

Thomas BG, Lui D, Ho B (1997) Effect of transverse depressions and oscillation marks on heat transfer in the continuous casting mold. In: TMS annual meeting, pp. 117–142

J.-Y. Lee, Y.-T. Kim, K.-W. Yi, Analysis of the origin of periodic oscillatory flow in the continuous casting mold. Met. Mater. Int. 21(2), 295–302 (2015)

H. Nakato et al., Improvement of surface quality of continuous cast slabs by high frequency mold oscillation. Steelmak. Conf. Proc. 68, 361–365 (1985)

T.-H. Park, J.-H. Kim, J. Choi, B.-J. Ye, The analysis of dynamic pressure in the molten flux near the meniscus during mold oscillation for the continuous casting of steel. J. Korea Found. Soc. 24(1), 26–33 (2004). (in Korean)

Acknowledgements

The authors would like to express their gratitude to the Center for Iron and Steel Research at Research Institute of Advanced Materials (RIAM) in Seoul National University for their financial support of this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kim, Yt., Yi, Kw. Effects of Variation of Heat Flux Released from the Meniscus on the Surface Shape of the Solidified Shell During Continuous Casting. Met. Mater. Int. 27, 5346–5359 (2021). https://doi.org/10.1007/s12540-020-00860-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00860-0