Abstract

Mechanisms of grain refinement under multidirectional isothermal forging (MIF) at 325 °C (~ 0.65 Tm) and the strain rate 10− 4 s− 1 of the Al–Mg-based alloy with complex additions of transition metals were investigated. The starting alloy had an equiaxed grain structure with grain size 25 µm and a uniform distribution of coherent Al3(Sc,Zr) dispersoids of 20–50 nm. A distinguished structural feature in the early MIF stage was the formation of high strain- and misorientation gradients, followed by deformation banding. Due to the sequential changes of the loading axis, such bands were developed in various directions and fragmented the original grains. The number of bands and misorientation of their boundaries gradually rose with strain, resulting in formation of (ultra)fine grain structure with the grain size 2 µm. New grain formation was concluded to occur via continuous dynamic recrystallization and controlled by the nanosized precipitates, which preferably remained stable and coherent with the surrounding matrix.

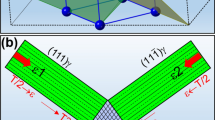

Graphic Abstract

Similar content being viewed by others

References

R.Z. Valiev, R.K. Islamgaliev, I.V. Alexandrov, Prog. Mater Sci. 45, 103 (2000)

R.Z. Valiev, T.G. Langdon, Prog. Mater Sci. 51, 881 (2006)

M.V. Markushev, Lett. Mater. 1, 36 (2011)

F.J. Humphreys, M. Hatherly, Recrystallization and Related Annealing Phenomena, 2nd edn. (Elsevier Ltd., New York, 2004), p. 605

K. Nakashima, Z. Horita, M. Nemoto, T.G. Langdon, Acta Mater. 46, 1589 (1998)

P.B. Berbon, M. Furukawa, Z. Horita, M. Nemoto, T.G. Langdon, Metall. Mater. Trans. A 30, 1989 (1999)

A. Yamashita, D. Yamaguchi, Z. Horita, T.G. Langdon, Mater. Sci. Eng. A 287, 100 (2000)

C. Pithan, T. Hashimoto, M. Kawazoe, J. Nagahora, K. Higashi, Mater. Sci. Eng. A 280, 62 (2000)

R.M. Imayev, G.A. Salishchev, O.N. Senkov, V.M. Imayev, N.K. Gabdullin, M.R. Shagiev, A.V. Kuznetsov, F.H. Froes, Mater. Sci. Eng. A 300, 263 (2001)

A. Belyakov, T. Sakai, H. Miura, K. Tsuzaki, Phios. Mag. A 81, 2629 (2001)

Y.C. Chen, Y.Y. Huang, C.P. Chang, P.W. Kao, Acta Mater. 51, 2005 (2003)

O. Sitdikov, T. Sakai, A. Goloborodko, H. Miura, Scr. Mater. 51, 175 (2004)

P.J. Apps, M. Berta, P.B. Prangnell, Acta Mater. 53, 499 (2005)

I. Mazurina, T. Sakai, H. Miura, O. Sitdikov, R. Kaibyshev, Mater. Trans. 50, 101 (2009)

O. Sitdikov, T. Sakai, E. Avtokratova, R. Kaibyshev, Y. Kimura, K. Tsuzaki, Mater. Sci. Eng. A 444, 18 (2007)

R.R. Mulyukov, R.M. Imayev, A.A. Nazarov, M.F. Imayev, V.M. Imayev, Superplasticity of Ultrafine Grained Alloys: Experiment, Theory, Technologies (Nauka, Moscow, 2014), p. 284 (in Russian)

O. Sitdikov, E. Avtokratova, T. Sakai, J. Alloys Compd. 648, 195 (2015)

O. Sitdikov, R. Kaibyshev, Mater. Sci. Eng. A 328, 147 (2002)

Y.A. Filatov, V.I. Yelagin, V.V. Zacharov, Mater. Sci. Eng. A 280, 97 (2000)

Y. Zeng, Y. Chao, Z. Luo, Y. Cai, R. Song, High Temp. Mater. Process. 37, 603 (2018)

Channel 5, User Manual, O. Instruments HKL (2007). http://web.archive.org/web/20200807101801/https://aarc.ua.edu/wp-content/uploads/docs/JEOL-7000FOxford_Channel_5_User_Manual.pdf

ISO Standard 13067, Microbeam Analysis—Electron Backscatter Diffraction—Measurement of Average Grain Size (2011)

P.B. Hirsch, A. Howie, R.B. Nicholson, D.W. Pashley, M.J. Whelan, Electron Microscopy of Thin Crystals (Butter Worths, London, 1965), p. 549

O.N. Senkov, M.R. Shagiev, S.V. Senkova, D.B. Miracle, Acta Mater. 56, 3723 (2008)

E. Avtokratova, O. Sitdikov, M. Markushev, R. Mulyukov, Mater. Sci. Eng. A 538, 386 (2012)

H.J. McQueen, S. Spigarelli, M.E. Kassner, E. Evangelista, Hot Deformation and Processing of Aluminum Alloys (CRC Press, Taylor & Francis Group, Boca Raton, 2011), p. 564

J.P. Poirier, Creep of Crystals: High-Temperature Deformation Processes in Metals, Ceramics and Minerals (Cambridge University Press, Cambridge, 1985), p. 260

M.E. McMahon, The Variation of Subgrain Misorientation in Aluminum with Large Steady-State Creep Strain. Thesis (M.S. in Mechanical Engineering), (Naval Postgraduate School, 1986), p. 72

P.J. Hurley, F.J. Humphreys, Acta Mater. 51, 1087 (2003)

C. Kobayashi, T. Sakai, A. Belyakov, H. Miura, Phil. Mag. Lett. 87, 751 (2007)

T. Sakai, A. Belyakov, H. Miura, Metal. Mat. Trans. A 39, 2206 (2008)

O. Sitdikov, T. Sakai, H. Miura, C. Hama, Mater. Sci. Eng. A 516, 180 (2009)

T. Takeshita, U.F. Kocks, H.-R. Wenk, Acta Metall. 37, 2595 (1989)

S. Aris, R.V. Martins, V. Honkimaki, A. Pyzalla, Comput. Mater. Sci. 19, 116 (2000)

M. Hatherly, A.S. Malin, Scr. Met. 18, 449 (1984)

D.A. Hughes, N. Hansen, Metall. Trans. A 24, 2021 (1993)

U. Chakkingal, P.F. Thomson, J. Mater. Process. Technol. 117, 169 (2001)

I. Mazurina, T. Sakai, H. Miura, O. Sitdikov, R. Kaibyshev, Mater. Sci. Eng. A 486, 662 (2008)

J. Čadek, Creep in Metallic Materials (Elsevier, New York, 1988), p. 372

E. Avtokratova, O. Sitdikov, O. Mukhametdinova, M. Markushev, S.V.S.N. Murty, M.J.N.V. Prasad, B.P. Kashyap, J. Alloys Compd. 673, 182 (2016)

O. Sitdikov, E. Avtokratova, O. Mukhametdinova, R. Garipova, M. Markushev, Phys. Met. Metallogr. 118, 1215 (2017)

H.J. McQueen, Metal Forum (Australia) 4, 81 (1981)

O. Sitdikov, Inorg. Mater. Appl. Res. 7, 149 (2016)

A. Russell, K.L. Lee, Structure—Property Relations in Nonferrous Metals (Wiley, New York, 2005), p. 440

Acknowledgements

The work was supported by the Russian Science Foundation under Grant No. 16-19-10152-P and the Ministry of Science and Higher Education of Russia in accordance to the state assignment of IMSP RAS under Grant АААА-А19-119021390107-8 (composition analyses of intermetallic phases). The authors are grateful to Dr. M. Shagiev for the useful discussions and Mr. B. Atanov for help in experimental work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sitdikov, O., Avtokratova, E. & Markushev, M. Development of Ultrafine Grain Structure in an Al–Mg–Mn–Sc–Zr Alloy During High-Temperature Multidirectional Isothermal Forging. Met. Mater. Int. 27, 2743–2755 (2021). https://doi.org/10.1007/s12540-020-00842-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00842-2