Abstract

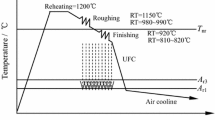

Oil country tubular goods (OCTG) steels with a low yield ratio (yield strength/tensile strength) and excellent impact toughness have recently been demanded to ensure mining performance and safety. From this viewpoint, the optimization of the manufacturing conditions is important because they influence the microstructure and mechanical properties of the steels; in particular, in the case of OCTG steels with carbon contents greater than 0.2 wt%, the finishing mill temperature (FMT) and coiling temperature (CT) strongly affect the microstructure of the final products, which are generally composed of ferrite and pearlite phases. In this study, 0.39C-0.23Si-1.56Mn-0.11Cr steel plates were fabricated under various FMT and CT conditions and their yield strength, tensile strength, and impact energy were investigated. In addition, pipes with diameters of 244 and 508 mm were manufactured via an electric resistance welding method using two of these strips fabricated under two different optimized conditions [(1) FMT = 880 °C and CT = 630 °C and (2) FMT = 800 °C and CT = 690 °C] to analyze the change in mechanical properties induced by the work-hardening effect during the piping process. The results revealed that the FMT and CT are closely related to the volume fraction of the ferrite phase, the grain size and lamellar spacing of the pearlite phase, and the tensile and impact properties of the steel strips; the variations in the microstructure and mechanical properties with the FMT and CT were also discussed in detail.

Graphic Abstract

Similar content being viewed by others

References

Oil Country Tubular Goods (OCTG) Market in North America - Forecast, 2012-2019 (Micro-Market Moniter, 2014), http://www.micromarketmonitor.com/market/north-america-oil-country-tubular-goods-octg-9739477780.html

M. Katsumi, N. Yutaka, J.F.E. Tech, Rep. 7, 1 (2006)

H. Brauer, H. Löbbe, in Oil and Gas Pipelines, ed. By R.W. Revie (John Wiley & Sons, New Jersey, 2015), p. 203

N. Y. Ghodsi, in Oil and Gas Pipelines, ed. By R.W. Revie (John Wiley & Sons, New Jersey, 2015), p. 37

M. Mitsuya, S. Sakanoue and H. Motohashi, in Proceedings of the ASME 2012 Pressure Vessels and Piping Conference, vol 8 (2012), p. 95

M. Hardy, Proc. Energy Mater. 2014, 673 (2014)

Y. Hu, X. Zuo, R. Li, Z. Zhang, Mater. Res. 15(2), 317 (2012)

C.C. Tasan, M. Diehl, D. Yan, M. Bechtold, F. Roters, L. Schemmann, C. Zheng, N. Peranio, D. Ponge, M. Koyama, K. Tsuzaki, D. Raabe, Ann. Rev. Mater. Res. 45, 391 (2015)

X.S. Du, W.B. Cao, C.D. Wang, S.J. Li, J.Y. Zhao, Y.F. Sun, Mater. Sci. Eng. A 642, 181 (2015)

M.A.M. Bonab, M. Eskandari, J.A. Szpunar, J. Mater. Res. 31, 3390 (2016)

M.A.M. Bonab, H.G. Kucheki, Met. Mater. Int. 25, 1109 (2019)

J. Zhou, D. Horsley, B. Rothwell, in Proceedings of the International Pipeline Conference (2006), p. 899

W. Mohr, in Proceedings of the International Pipeline Conference (2006), p. 899

S. Igi, T. Sakimoto, in Proceedinsg of the 20th International Offshore and Polar Engineering Conference (2010), p. 489

M. Lower, ORNL/TM-2014/106 of US DOE, p. 1 (2014)

A.J. Abdalla, L.R.O. Hein, M.S. Pereira, T.M. Hashimoto, Mater. Sci. Technol. 15, 1167 (1999)

L. Himmel, K. Goodman, W.L. Haworth, Fundamentals of Dual Phase Steels (AIME, New York, 1981), p. 305

S. Gunduz, Mater. Sci. Eng. A 486, 63 (2008)

R.G. Davies, R.A. Kot, B.L. Bramfitt, Fundamentals of Dual Phase Steels (AIME, New York, 1981), p. 265

S. Gunduz, A. Tosun, Mater. Des. 29, 1914 (2008)

API specification 5CT 9th ed. (American Petroleum Institute, 2012), https://www.api.org/~/media/files/certification/monogram-apiqr/program-updates/5ct-9th-edition-purch-guidelines-r1-20120429.pdf

C.G. Andre, F.G. Caballero, C. Capdevila, L.F. Lvarez, Mater. Charact. 48, 101 (2002)

K.B. Matus, G. Altamirano, A. Salinas, A. Flores, F. Goodwin, Metals 8(9), 674 (2018)

Z. Cui, Ph.D. Thesis, The University of Sheffield (2016)

E.J. Palmiere, C.I. Garcia, A.J. Deardo, Metall. Mater. Trans. A 27, 951 (1996)

S. Vervynckt, K. Verbeken, B. Lopez, J.J. Jonas, Int. Mater. Rev. 57, 187 (2012)

L. Sun, Ph.D. Thesis, University of Sheffield (2012)

H. Tamotsu, S. Takeaki, O. Hiroo, Tetsu-to-Hagane 65(9), 1425 (1979)

K. Maeda, T. Zhou, H.S. Zurob, Proc. TMS 2014, 927 (2014)

K. Mukherjee, S.S. Hazra, M. Militzer, Metall. Mater. Trans. A 40, 2145 (2009)

F. Boratto, R. Barbosa, S. Yue, J.J. Jonas, Proc. THERMEC 88, 383 (1988)

J. Trzaska, L.A. Dobrazanski, J. Mater. Process. Technol. 192–193, 504 (2007)

J.P. Houin, A. Simon, G. Beck, Trans. Iron Steel Inst. Jpn 21(10), 726 (1981)

R. Mizuno, H. Matsuda, Y. Funakawa, Y. Tanaka, Tetsu-to-Hagané 96(6), 414 (2010)

N. Tsuchida, T. Inoue, H. Nakano, T. Okamoto, Mater. Lett. 160, 117 (2015)

T.L. Russell, D.S. Wood, D.S. Clark, Acta Metall. 9, 1054 (1961)

R. Song, D. Pong, D. Raabe, J.G. Speer, D.K. Matlock, Mater. Sci. Eng. A 441, 1 (2006)

R. Song, D. Ponge, D. Raabe, Scr. Mater. 52(11), 1075 (2005)

J.J. Kramer, G.M. Pound, R.F. Mehl, Acta Metall. 48(6), 763 (1958)

A.S. Pandit, Ph.D. Thesis, University of Cambridge (2011)

M. Avrami, J. Chem. Phys. 7, 1103 (1939)

M. Avrami, J. Chem. Phys. 8, 212 (1940)

M. Avrami, J. Chem. Phys. 9, 177 (1941)

A.N. Kolmogorov, Izv Acad Nauk SSSR. Ser Mat. 3, 355 (1937)

W.A. Johnson, R.F. Mehl, Trans. AIME 135, 416 (1939)

O. Kwon, K.J. Lee, K.B. Kang, J.K. Lee, P.J. Lee, Y.S. Park, E.K. Ro, K.J. Min, J.D. Lee, K.C. Yoo, J. Korean Inst. Met. Mater. 30(11), 1335 (1992)

J.M. Hyzak, I.M. Bernstein, Metall. Trans. A 7(8), 1217 (1976)

T. Gladman, I. Mclvor, F. Pickering, J. Iron Steel Inst. 210, 916 (1972)

V.I. Izotov, V.A. Pozdnyakov, E.V. Lukyanenko, O.Y. Usanova, G.A. Filippov, Phys. Met. Metallogr. 103, 519 (2007)

Acknowledgements

This work was supported by National Research Foundation of Korea (NRF) Grants funded by the Korean government (MSIP, South Korea) (Nos. 2017R1A4A1015628 and 2019R1A2C1085272).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kim, H.L., Bang, S.H., Choi, J.M. et al. Effect of Rolling and Coiling Temperatures on Microstructure and Mechanical Properties of Medium-Carbon Pipeline Steel. Met. Mater. Int. 26, 1757–1765 (2020). https://doi.org/10.1007/s12540-019-00500-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00500-2