Abstract

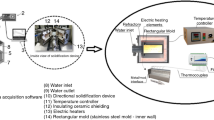

In this work, solidification and T6-heat treatment experiments were performed with the Al7Si0.3Mg alloy in order to investigate the effect of processes parameters on the microstructure and microhardness (HV). A directional solidification device was used, and the solidification thermal parameters investigated were the growth and cooling rates (VL and TR). The heat treatment applied was the T6 (T6-HT), under the following conditions: solution treatment for 3 h at 520 ± 2 °C, followed by quenching in warm water (70 ± 20 °C), aging for 1, 2, 3 and 4 h at 155 ± 2 °C and air-cooling. The microstructure observed in both as-cast and T6-heat treated samples is composed of a primary phase consisting of an Al-rich dendritic network and secondary eutectic phases, located within the interdendritic regions, formed by Si and Mg2Si particles and Fe-intermetallic phases. The dendritic microstructure was characterized by secondary dendritic spacing (λ2) and, for both investigated samples, a single mathematical expression was proposed on the λ2 dependence with the position in the ingot. Spheroidized-like eutectic Si particles have been found in both analyzed samples for finer microstructures. Elements quantitative and qualitative microanalysis by SEM/EDS as well as HV measurement at the dendritic and interdendritic regions attest to the effectiveness of the T6-heat treatment. It is highlighted in this work that mathematical expressions have been proposed to characterize the HV dependence on aging time.

Graphical Abstract

Similar content being viewed by others

References

D.B. Carvalho, E.C. Guimarães, A.L. Moreira, D.J. Moutinho, J.M. Dias Filho, O.L. Rocha, Mat. Res. 16, 874–888 (2013)

D.L.B. Carvalho, T.A. Costa, A.L.S. Moreira, M.A.P.S. Silva, M. Dias, D.J.C. Moutinho, O.L. Rocha, Rev. Esc. Minas 67, 265–270 (2014)

U. Patakham, C. Limmaneevichitr, J. Alloy. Compd. 616, 198–207 (2014)

R. Chen, Y. Shi, Q. Xu, B. Liu, Trans. Nonferrous Met. Soc. China 24, 1645–1652 (2014)

R. Chen, Q. Xu, H. Guo, Z. Xia, Q. Wu, B. Liu, Mater. Sci. Eng., A 685, 391–402 (2017)

M. Costa, F. Souza, I. Magno, C. Loayza, J. Nascimento, A. Barros, O. Rocha, Mater. Sci. 23, 124–128 (2017)

T.A. Costa, M. Dias Filho, L.G. Gomes, O.L. Rocha, A. Garcia, J. Alloy. Compd. 683, 485–494 (2016)

T.A. Costa, A.L. Moreira, D.J. Moutinho, M. Dias, I.L. Ferreira, J.E. Spinelli, O.L. Rocha, A. Garcia, Mat. Sci. Tech. 31, 1103–1112 (2015)

H. Kaya, E. Çadırlı, U. Böyük, N. Maraşlı, Appl. Surf. Sci. 255, 3071–3078 (2008)

G. Gustafsson, T. Thorvaldsson, G.L. Dunlop, Metall. Mater. Trans. A 17, 45–52 (1986)

S.G. Shabestari, H. Moemeni, J. Mater. Process. Tech. 153, 193–198 (2004)

G. García-García, J. Espinoza-Cuadra, H. Mancha-Molinar, Mater. Des. 28, 428–433 (2005)

E. Çadırlı, Met. Mater. Int. 19, 411–422 (2013)

E. Acer, E. Çadırlı, H. Erol, Mat. Sci. Eng. A. 662, 144–156 (2016)

L. Zhen, W.D. Fei, S.B. Kang, H.W. Kim, J. Mater. Sci. 32, 1895–1902 (1997)

A.K. Gupta, D.J. Lloyd, S.A. Court, Mater. Sci. Eng., A 316, 11–17 (2001)

A.K. Gupta, D.J. Lloyd, S.A. Court, Mater. Sci. Eng., A 301, 140–146 (2001)

W.F. Miao, D.E. Laughlin, Scr. Mater. 40, 873–878 (1999)

M. Tash, F.H. Samuel, F. Mucciardi, H.W. Doty, Mater. Sci. Eng., A 443, 185–200 (2007)

H. Demir, S. Gunduz, Mater. Des. 30, 1480–1483 (2009)

M. Tash, F.H. Samuel, F. Mucciardi, H.W. Doty, S. Valtierra, Mater. Sci. Eng., A 434, 207–217 (2006)

Y. Zedan, F.H. Samuel, A.M. Samuel, H.W. Doty, J. Mater. Process. Tech. 210, 245–257 (2010)

L. Pedersen, L. Arnberg, Metall. Mater. Trans. A 32, 525–532 (2001)

E. Sjölander, S. Seifeddine, J. Mater. Process. Tech. 210, 1249–1259 (2010)

E.A. Elsharkawi, E. Samuel, A.M. Samuel, F.H. Samuel, J. Mater. Sci. 45, 1528–1539 (2010)

S. Mohsen Sadrossadat, S. Johansson, Mater. Sci. For. 649, 505–510 (2010)

L. Hurtalová, E. Tillová, M. Chalupová, Acta Metall. Slovaca Conf. 3, 65–74 (2013)

H. Yang, S. Ji, Z. Fan, Mater. Des. 85, 823–832 (2015)

J. Jang, D. Nam, Y. Park, I. Park, Trans. Nonferrous Met. Soc. China 23, 631–635 (2013)

A.I. Luna, M.H. Molinar, C.M.J. Roma, E.J.C. Bocardo, H.M. Trejo, Mater. Sci. Eng., A 561, 1–6 (2013)

M. Merlin, G. Timelli, F. Bonollo, G.L. Garagnania, J. Mater. Process. Tech. 209, 1060–1073 (2009)

Y. Birol, J. Alloy. Compd. 484, 164–167 (2009)

A.S. Barros, I.A. Magno, F.A. Souza, C.A. Mota, A.L. Moreira, M.A. Silva, O.L. Rocha, Met. Mater. Int. 21, 429–439 (2015)

I.A.B. Magno, F.V.A. Souza, A.S. Barros, M.O. Costa, J.M. Nascimento, T.A.P.S. Costa, O.F.L. Rocha, Mat. Res. 20, 2–5 (2017)

D. Carvalho, J. Rodrigues, D. Soares, J. Aviz, A. Barros, M. Silva, O. Rocha, I. Ferreira, A. Moreira, Mat. Sci. 24, 18–23 (2018)

F. Souza, J. Lima, C. Rizziolli, I. Magno, A. Barros, A. Moreira, O. Rocha, Mat. Sci. Tech. 34, 1–13 (2018)

C.A.P. Silva, L.R.M. Leal, E.C. Guimarães, P.M. Júnior, A.L. Moreira, O.L. Rocha, A.P. Silva, Adv. Mater. Sci. Eng. 2018, 1–12 (2018)

H.M. Azevedo, G.H. Machado, C.R. Barbosa, F.S. Rocha, R.B. Costa, T.A. Costa, O.L. Rocha, Metall. Mater. Trans. A 49, 4722–4735 (2018)

J.O. Lima, C.R. Barbosa, I.A.B. Magno, J.M. Nascimento, A.S. Barros, M.C. Oliveira, F.A. Souza, O.L. Rocha, Trans. Nonferrous Met. Soc. China 28, 1073–1083 (2018)

O.L. Rocha, T.A. Costa, M. Dias, A. Garcia, Trans. Nonferrous Met. Soc. China 28, 1679–1686 (2018)

I.L. Ferreira, A.L.S. Moreira, J.A.S. Aviz, T.A. Costa, O.L. Rocha, A.S. Barros, A. Garcia, J. Manuf. Process. 35, 634–650 (2018)

P. Ouellet, F.H. Samuel, J. Mat. Sci. 34, 4671–4697 (1999)

X.Y. Wu, H.R. Zhang, Z. Ma, L.N. Jia, H. Zhang, J. Mater. Eng. Perform. 27, 483–491 (2018)

H.R. Ammar, A.M. Samuel, F.H. Samuel, A.M.A. Al-Ahmari, J. Mat. Sci. 47, 1331–1338 (2011)

F.A. Souza, I.A. Magno, M.O. Costa, A.S. Barros, J.M. Nascimento, D.B. Carvalho, O.L. Rocha, Met. Mater. Int. 25, 18–33 (2019)

S.G. Shabestari, Mat. Sci. Eng. 383, 289–298 (2004)

Q.G. Wang, D. Apelian, D.A. Lados, J. Light Met. 1, 85–97 (2001)

X. Wu, H. Zhang, Z. Ma, T. Tao, J. Gui, W. Song, B. Yang, H. Zhang, J. Alloy. Compd. 786, 205–214 (2019)

E. Ozbakir, Development of Aluminum Alloys for Diesel-Engine Applications (McGill University, Montreal, 2008)

A. Barros, C. Cruz, A.P. Silva, N. Cheung, A. Garcia, O. Rocha, A. Moreira, Acta Metall. Sin. (Engl. Lett.). 32, 695–709 (2018)

A.V. Rodrigues, T.S. Lima, T.A. Vida, C. Brito, A. Garcia, N. Cheung, Met. Mater. Int. 24, 1058–1076 (2018)

I.A. Magno, F.A. Souza, M.O. Costa, J.M. Nascimento, A.P. Silva, T.S. Costa, O.L. Rocha, Mater. Sci. Tech. 35(7), 791–806 (2019)

C.R. Barbosa, J.O.M. Lima, G.M.H. Machado, H.A.M. Azevedo, F.S. Rocha, A.S. Barros, O.F.L. Rocha, Mat. Res. 22, 1–12 (2018)

A.M. Samuel, J. Gauthier, F.H. Samuel, Metall. Mater. Trans. A 27, 1785–1798 (1996)

M. Djurdjevic, T. Stockwell, J. Sokolowski, Int. J. Cast Metal. Res. 12, 67–73 (1999)

Z. Li, A.M. Samuel, F.H. Samuel, C. Ravindran, S. Valtierra, J. Mater. Sci. 38, 1203–1218 (2003)

P. Mikolajczak, Metals 7(3), 89–104 (2017)

Acknowledgements

The authors acknowledge the financial support provided by IFPA—Federal Institute of Education, Science and Technology of Pará, UFPA—Federal University of Pará, and CNPq—The Brazilian Research Council (Grants 302846/2017-4 and 400634/2016- 3) and CAPES—Coordenação de Aperfeiçoamento de Pessoal de Nível Superior – Brasil – Finance Code 001.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Barbosa, C.R., Machado, G.H., Azevedo, H.M. et al. Tailoring of Processing Parameters, Dendritic Microstructure, Si/Intermetallic Particles and Microhardness in As-cast and Heat-Treated Samples of Al7Si0.3Mg Alloy. Met. Mater. Int. 26, 370–383 (2020). https://doi.org/10.1007/s12540-019-00334-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00334-y