Abstract

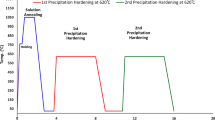

We studied the effects of secondary phases on the mechanical properties of joints formed by transient liquid-phase bonding in nitrogen-containing duplex stainless steel UNS S32750. Transient liquid-phase bonding was carried out using Fe–B–Si amorphous insert metal over the temperature range of 1423–1473 K for 0–1000 s under a vacuum of 5 × 10−5 Torr. Area fraction of austenite (γ) in the joint region decreased with increasing bonding temperature and holding time. In particular, when the holding time was sufficiently prolonged, γ phase-depleted region were observed in the base metal adjacent to the joint. Secondary phases formed at the joint after short holding times were predominantly chromium borides. For specimens bonded with longer holding times (up to 1000 s), boron nitrides were formed at the interface with the joint. Formation of secondary phases in a joint area during the bonding process was expressed by diffusion equation. Tensile strength was improved in accordance with increase of bonding temperature and holding time. Especially, the bonding efficiency was over 98% for the specimen held for 1000 s at 1473 K. Tensile strength of the joint after short holding times was affected by brittle residual eutectic constituents and borides, whereas tensile strength after longer holding time was influenced by boron nitride formed at the joint interface. The results showed that the mechanical properties were strongly related to the secondary phases (CrB, BN) formed during the bonding process.

Similar content being viewed by others

References

J.O. Nilsson, Mater. Sci. Technol. 8, 685–700 (1992)

J.P. Hoffman, J. S. Afr. Inst. Min. Metall. 86(11), 433 (1986)

K. Ravindranath, S.N. Mailhotra, Corros. Sci. 37(1), 121 (1995)

H.D. Solomon, T.M. Devine, in: ed. by R.A. Lula. Duplex Stainless Steels (ASM, Metals Park, 1982), pp. 693–756

N. Lopez, M. Cid, M. Puiggali, Corros. Sci. 41, 1615–1631 (1999)

D.J. Kotccki, Weld. J. 68, 431s–441s (1989)

J. Hilkes, K. Bekkers, Weld. J. 74, 51–54 (1995)

H. Matsunaga, Y.S. Sato, H. Kokawa, T. Kuwana, Sci. Technol. Weld. Join. 3, 225–232 (1998)

Y.S. Sato, H. Kokawa, T. Kuwana, Sci. Technol. Weld. Join. 4, 41–49 (1999)

R.A. Walker, Mater. Sci. Technol. 4, 78–84 (1988)

T. Zacharia, S.A. David, J.M. Vitek, T. Debroy, Metall. Trans. A 20, 957–967 (1989)

J.H. Potgieter, Br. Corros. J. 27(3), 219 (1992)

J.C. Lippold, W. Lin, S. Brandi, I. Varol, W.A. Baeslack, in Proceedings of Duplex Stainless Steels Conference, Glasgow, Scotland (1994)

E.I. Kivineva, N.E. Hannerz, in Proceedings of Duplex Stainless Steels Conference, Glasgow, Scotland (1994)

M.F. Islam, N. Ridley, Scr. Mater. 38, 1187 (1998)

L.H. Chiu, W.C. Hsieh, C.H. Wu, Mater. Sci. Eng. A 354, 82–91 (2003)

T. Padron, T.I. Khan, M.J. Kabir, Mater. Sci. Eng. A 385, 220–228 (2004)

X. Yuan, M.B. Kim, Y.H. Cho, C.Y. Kang, Metall. Mater. Trans. A 43, 1989–2001 (2012)

T.I. Khan, M.J. Kabir, R. Bulpett, Mater. Sci. Eng. A 372, 290–295 (2004)

T.I. Khan, E.R. Wallach, J. Mater. Sci. 31, 2937–2943 (1996)

H. Ikawa, Y. Nakao, Trans. Jpn. Weld. Soc. 8, 3–8 (1977)

Y. Nakao, K. Nishimoto, et al., in Proceedings Superalloys’89 (Metallurgical Society of AIME, 1989), pp. 775–783

W.F. Gale, S.V. Orel, Metall. Trans. A 27A, 1925–1931 (1996)

H.Y. Liou, R.I. Hsieh, W.T. Tsai, Corros. Sci. 44, 2841–2856 (2002)

O. Kubaschewski, C.B. Alcock, Metallurgical Thermochemistry, 5th edn. (Pergmon Press, Oxford, 1979), pp. 336–356

J. Crank, The Mathematics of Diffusion (Oxford University Press, Oxford, 1975), pp. 13–16

The Japan Institute of Metals, Metals Data Book (Maruzen, Tokyo, 1993), pp. 21–22

B.H. Rhee, S.J. Roh, D.H. Kim, Mater. Trans. 44, 1014–1023 (2003)

Acknowledgements

This research was supported by the Development of Space Core Technology initiative of the National Research Foundation of Korea (NRF) and Innopolis Foundation of Korea funded by the Ministry of Science and ICT (NRF-2016M1A3A3A04017836, ACC-2016-DDI-00793 and 1711063546-2017K000601). The authors would also like to thank VITZRONEXTECH Research Institute for financially supporting this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Roh, S., Lee, C. Formation of Secondary Phases and Their Effect on the Mechanical Properties of Joints Formed by TLP Bonding Using Fe–B–Si Insert Metal in Duplex Stainless Steel. Met. Mater. Int. 25, 425–438 (2019). https://doi.org/10.1007/s12540-018-0186-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-018-0186-4