Abstract

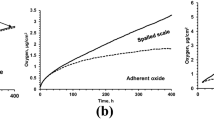

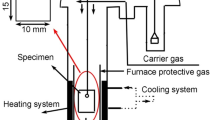

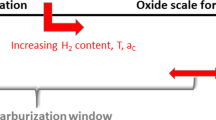

The in-situ blistering phenomena of the scale ‘surface’ was investigated on three carbon steels with respect to carbon and silicon concentrations, such as 0.05 wt%C, 0.2 wt%C, and 0.2 wt%C-0.2 wt%Si. The oxidation and blistering kinetics and blister area fraction during high temperature oxidation were analyzed. The average thickness of the surface scale by oxidation during isothermal holding from 800 to 1200 °C in dry air was observed to decrease when the amount of carbon increased and/or when Si was inserted additionally. Thus, the blistering behavior depended primarily on a change in oxidation temperature (T ox ) as well as amounts of carbon and silicon in the matrix. It is also revealed that such blister formation would be triggered by growth of internal stress and active generations of CO and/or CO2 gases at the interface between the scale and matrix since carbon would result in an increase in the blister formation by generating CO and/or CO2 gas. In addition, silicon might play an important role in preventing the blister formation at T ox below 900 °C by reducing the thickness of the surface scale whilst silicon might enhance the blister formation by means of the appreciable micro-void formation in the scale layer at T ox higher 900 °C.

Similar content being viewed by others

References

Y. Oike, J. Sato, K. Minami, K. Yoshitake, and S. Yamanaka, ISIJ Int. 32, 1211 (1992).

C. S. Li, J. Z. Xu, X. M. He, X. H. Liu, and G. D. Wang, J. Mater. Process. Tech. 116, 201 (2001).

K. Min, K. Kim, S. K. Kim, D.-J. Lee, Met. Mater. Int. 18, 341 (2012).

H. Okada, T. Fukagawa, H. Ishihara, A. Okamoto, M. Azuma, and Y. Matsuda, ISIJ Int. 35, 886 (1995).

H. Utsunomiya, K. Hara, R. Matsumoto, and A. Azushima, CIRP Ann.-Manuf. Techn. 63, 261 (2014).

H. Seki, T. Hiruta, M. Yamashita, T. Imae, K. Tominaga, and M. Koide, CAMP ISIJ 9, 972 (1996).

R. Rolls, Metallurgie 7, 53 (1967).

T. Kizu, Y. Nagataki, T. Inazumi, and Y. Hosoya, ISIJ Int. 41, 1494 (2001).

F. Matsuno, T. Iron Steel. I. Jpn. 20, 413 (1980).

Y. Kondo, H. Tanei, K. Ushioda, and M. Maeda, ISIJ Int. 52, 2254 (2012).

Y. Kondo, H. Tanei, N. Suzuki, K. Ushioda, and M. Maeda, ISIJ Int. 51, 1696 (2011).

Y. Kondo, H. Tanei, K. Ushioda, M. Maeda, and Y. Abe, ISIJ Int. 52, 1644 (2012).

R. Y. Chen, Oxi. Met. 59, 433 (2003).

M. Krzyzanowski, J. H. Beynon, and C. J. Farrugia, Oxide Scale Behavior in High Temperature Metal Processing, pp. 29, WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim, Germany (2010).

I. Svedung and N. G. Vannerburg, Corros. Sci. 14, 391 (1974).

A. A. Mouayd, A. Koltsov, E. Sutter, and B. Tribollet, Mater. Chem. Phys. 143, 996 (2014).

N. B. Pilling and R. E. Bedworth, J. I. Met. 29, 529 (1923).

A. S. Khanna, Introduction to High Temperature Oxidation and Corrosion, p. 103, ASM International, USA (2002).

X. Cheng, Z. Jiang, D. Wei, J. Zhao, B. J. Monaghan, R. J. Longbottom, et al. Met. Mater. Int. 21, 251 (2015).

D. B. Lee and P. Yadav, Korean J. Met. Mater. 53, 859 (2015).

G. E. Kim, Y. D. Kim, S. Noh, and T. K. Kim, Korean J. Met. Mater. 54, 533 (2016).

C. S. Giggins, B. H. Kear, F. S. Pettit, and J. K. Tien, Metall. Mater. Trans. A 5, 1685 (1974).

J. K. Tien and F. S. Pettit, Metall. Mater. Trans. A 3, 1587 (1972).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, DJ., Lee, JS. & Koo, YM. Influences of carbon and silicon on blister formation in scale surface during high temperature oxidation of carbon steels. Met. Mater. Int. 23, 715–719 (2017). https://doi.org/10.1007/s12540-017-6741-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-017-6741-6