Abstract

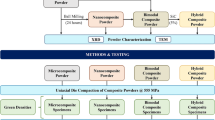

Hybrid aluminum matrix composites containing particles of boron carbide and quasicrystals were manufactured to explore the combined effect of reinforcements on microstructural evolution and mechanical performance of the composites. The particles were incorporated at a loading of 6 wt% each making a total of 12 wt% reinforcement in pure aluminum. For comparison, two composites containing individually reinforced 12 wt% particles were also prepared along with a reference specimen of pure aluminum. Ball milling technique was employed to mix the composite constituents. The green bodies of composite powders were prepared by uniaxial pressing at room temperature followed by consolidation by pressureless sintering under inert atmosphere. The microstructural characterization was performed using scanning electron microscopy while phase identification was carried out by X-ray diffraction. The mechanical characterization was performed by Vickers hardness and compression tests. Hybrid composites showed increased compressive properties while the composites containing solely quasicrystals demonstrated improved hardness. The increase in mechanical performance was related to the microstructural evolution due to the presence and uniform dispersion of binary particles.

Similar content being viewed by others

References

A. Mortensen and J. Llorca, Annu. Rev. Mater. Res. 40, 243 (2010).

M. Khakbiz and F. Akhlaghi, J. Alloy. Compd. 479, 334 (2009).

A. R. Kennedy, J. Mater. Sci. 37, 317 (2002).

R. Harichandran and N. Selvakumar, Arch. Civ. Mech. Eng. 16, 147 (2016).

B. Ravi, B. B. Naik, and J. U. Prakash, Mater. Today 2, 2984 (2015).

I. Topcu, H. O. Gulsoy, N. Kadioglu, and A. N. Gulluoglu, J. Alloy. Compd. 482, 516 (2009).

H. Kwon, M. Saarna, S. Yoon, A. Weidenkaff, and M. Leparoux, Mat. Sci. Eng. A 590, 338 (2014).

A. Abdollahi, A. Alizadeh, and H. R. Baharvandi, Mater. Design 55, 471 (2014).

X.-F. Tan, F.-H. Zeng, S.-Q. Wang, F. Zhou, and X. Xiong, T. Nonferr. Metal. Soc. 4, 2359 (2014).

R. G. Vogt, Z. Zhang, T. D. Topping, E. J. Lavernia, and J. M. Schoenung, J. Mater. Process. Tech. 209, 5046 (2009).

Q. Shen, C. Wu, G. Luo, P. Fang, C. Li, Y. Wang, et al. J. Alloy. Compd. 588, 265 (2014).

N. Yuvaraj, S. Aravindan, and Vipin, J. Mater. Process. Tech. 4, 398 (2015).

E. Ghasali, M. Alizadeh, and T. Ebadzadeh, J. Alloy. Compd. 655, 93 (2015).

D. Levine and P. J. Steinhardt, Phys. Rev. Lett. 53, 2477 (1984).

E. Huttunen-Saarivirta, J. Alloy. Compd. 363, 154 (2004).

A. P. Tsai, K. Aoki, and A. Inoue, J. Mater. Res. 8, 5 (1993).

V. V. Cherdyntsev, S. D. Kaloshkin, I. A. Tomilin, E. V. Shelekhov, A. I. Laptev, A. A. Stepashkin, et al. Phys. Met. Metallogr. 104, 497 (2007).

E. Fleury, S. M. Lee, G. Choi, W. T. Kim, and D. H. Kim, J. Mater. Sci. 36, 963 (2001).

M. Y. Zheng, X. G. Qiao, S. W. Xu, K. Wu, S. Kamado, and Y. Kojima, J. Mater. Sci. 40, 2587 (2005).

F. Ali, S. Scudino, M. S. Anwar, R. N. Shahid, V. C. Srivastava, V. Uhlenwinkel, et al. J. Alloy. Compd. 607, 274 (2014).

B. N. Mordyuk, M. O. Iefimov, G. I. Prokopenko, T. V. Golub, and M. I. Danylenko, Surf. Coat. Tech. 204, 1590 (2010).

G. Laplanche, A. Joulain, J. Bonneville, V. Gauthier-Brunet, and S. Dubois, Mat. Sci. Eng. A 527, 4515 (2010).

S. D. Kaloshkin, V. V. Tcherdyntsev, A. I. Laptev, A. A. Stepashkin, E. A. Afonina, A. L. Pomadchik, et al. J. Mater. Sci. 39, 5399 (2004).

Q. Hu, H. Zhao, and J. Ge, Mat. Sci. Eng. A 650, 478 (2016).

J. Singh and A. Chauhan, J. Mater. Res. Technol. 5, 159 (2016).

T. S. M. Babu, M. S. A. Sugin, and N. Muthukrishnan, Procedia Eng. 38, 2617 (2012).

A. Baradeswaran, S. C. Vettivel, A. E. Perumal, N. Selvakumar, and R. Franklin Issac, Mater. Design 63, 620 (2014).

J. U. Prakash, T. V. Moorthy, and J. M. Peter, Procedia Eng. 64, 1344 (2013).

T. Subhani, M. Latif, I. Ahmad, S. A. Rakha, N. Ali, and A. A. Khurram, Mater. Design 87, 436 (2015).

B. Yazdani, Y. Xia, I. Ahmad, and Y. Zhu, J. Eur. Ceram. Soc. 35, 179 (2015).

J. C. Viala, J. Bouix, G. Gonzalez, and C. Esnouf, J. Mater. Sci. 32, 4559 (1997).

A. L. Ortiz and L. Shaw, Acta Mater. 52, 2185 (2004).

M. Peel, A. Steuwer, M. Preuss, and P. J. Withers, Acta Mater. 51, 4791 (2003).

Y. Mazaheri, M. Meratian, R. Emadi, and A. R. Najarian, Mat. Sci. Eng. A 560, 278 (2013).

M. F. Ibrahim, H. R. Ammar, A. M. Samuel, M. S. Soliman, and F. H. Samuel Compos. Part B-Eng. 79, 83 (2015).

R. Zheng, X. Hao, Y. Yuan, Z. Wang, K. Ameyama, and C. Ma, J. Alloy. Compd. 576, 291 (2013).

E. Mohammad Sharifi, F. Karimzadeh, and M. H. Enayati, Mater. Design 32, 3263 (2011).

R. M. Mohanty, K. Balasubramanian, and S. K. Seshadri, Mater. Sci. Eng. A 498, 42 (2008).

E. Fleury, S. M. Lee, W. T. Kim, and D. H. Kim Met. Mater. Int. 6, 415 (2000).

L. Lityńska-Dobrzyńska, J. Dutkiewicz, K. Stan-Głowińska, W. Wajda, L. Dembinski, C. Langlade, et al. J. Alloy. Compd. 643, S114 (2015).

T. A. Passos, R. M. Gomes, T. A. de A. Melo, and S. J. G. de Lima, Mater. Sci. Forum 643, 125 (2010).

F. Schurack, J. Eckert, and L. Schultz, Acta Mater. 49, 1351 (2001).

S. M. Lee, J. H. Jung, E. Fleury, W. T. Kim, and D. H. Kim, Mat. Sci. Eng. A 294-296, 99 (2000).

F. Tang, I. E. Anderson, and S. B. Biner, Mat. Sci. Eng. A 363, 20 (2003).

F. Tang, I. E. Anderson, T. Gnaupel-Herold, and H. Prask, Mat. Sci. Eng. A 383, 362 (2004).

T. El Kabir, A. Joulain, V. Gauthier, S. Dubois, J. Bonneville, and D. Bertheau, J. Mater. Res. 23, 904 (2008).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khan, M., Zulfaqar, M., Ali, F. et al. Microstructural and mechanical characterization of hybrid aluminum matrix composite containing boron carbide and Al-Cu-Fe quasicrystals. Met. Mater. Int. 23, 813–822 (2017). https://doi.org/10.1007/s12540-017-6619-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-017-6619-7