Abstract

We present a detailed analysis of the chemical alloying data (Cu, Sn, Pb) on the bronzes recovered from the Late Shang capital at Yinxu, revealing a complex pattern which varies by social status and object typology, and which also changes over time. The preference for higher tin in the bronze vessels and weapons for the elites during Yinxu Phase II gives way to a more binary pattern (with weapons being preferentially alloyed with lead) for the lower elites of phase II, which becomes prevalent in subsequent phases. These changes are interpreted in terms of different ‘alloying practices’, which attempts to reconstruct the way in which the alloys are created at the point of casting. The alloy type described here as A1/A2 (11–24% tin, 0 to 3–5% lead) seems most likely to have been created by mixing together three components, corresponding to mixing relatively pure copper, tin and lead. This contrasts with the suggestion in the Kaogong Ji, several hundred years later, that binary pre-prepared alloys were used. It is now important to determine when such a change might have occurred. The suggestion that alloy type B (low tin, variably high lead) could have been made by combining pure copper with a slightly impure lead (95%Pb/5%Sn) hints that such practices might have started during the Shang, but requires more work, especially on the intervening Western and Eastern Zhou periods.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

In a previous paper (Liu et al. 2020), we discussed differences in alloying element patterns (Cu, Sn, Pb) in bronzes from Yinxu (殷墟: 36°07′36″N 114°18′50″E) near Anyang (安阳), the capital of Shang China between c. 1250 and 1046 BCE, according to tomb status and phase. The four recognised phases of Yinxu (Anyang) are dated slightly differently according to different protocols (including traditional king lists, the Xia-Shang-Zhou radiocarbon chronology (XSZCP Group 2000), and the oracle bone radiocarbon chronology (Liu et al. 2021)), and are still subject to discussion. For the purposes of this paper, we have adopted the following approximate dates:

-

Yinxu Ic. 1250–c. 1210 BCE

-

Yinxu IIc. 1210–c. 1180 BCE

-

Yinxu IIIc. 1180–c. 1110 BCE

-

Yinxu IV1121–1046 BCE

In an earlier paper, Zhao (2004) considered the evolution of bronze metal composition at Anyang through these four phases, showing the dominance of the Cu-Pb-Sn system, but with an increase in lead and a decrease of tin over time. However, her data was drawn only from elite tombs, and Liu et al. (2020) extended this analysis to include data from the tombs of the lesser elites at Anyang, with the aim of investigating differences in access to metal supply according to status. The conclusion of this was that particularly during Yinxu II the top elites at Anyang used ‘designed’ alloys for their vessels, characterised by high tin (c. 15%) and low lead (<5%), whereas those objects of the lower elites generally had more lead, and more variable tin contents. The interpretation was that the higher elites were able to command metal of higher purity which was alloyed during the casting stage in carefully controlled quantities, and probably using little or no recycled metal. In contrast, the objects in the lower elite tombs were generally made from less pure metals, with less control over alloying practices, and probably using some recycled materials.

The aim of this paper is to look in more detail at this variation during Yinxu Phases II–IV, in particular to compare between tombs, and between different typological forms — at least as far as comparing between weapons and vessels. Here we have ignored the data from Yinxu I, since to date only 10 objects have been analysed from this phase. The overall intention is to better understand the variation in the range of alloying practices at Anyang according to time, status and typology, with a view to subsequently comparing these patterns with earlier and later Chinese dynasties, in order to work towards a more comprehensive picture of the evolution of Chinese bronze casting practices. It is clear that alloying practice at the point of bronze casting is a consequence of many factors, such as changes to metal supply and procurement over time (extensively discussed by many authors, e.g. Liu et al. 2019) and access according to status (e.g. Liu et al. 2020), but also reflects the skills of the artisans in controlling metallurgical properties according to the constraints of metal supply and the requirements of the final product. To some extent, therefore, it reflects the perceptions of metal at that time, both in terms of its nature as a material and a commodity.

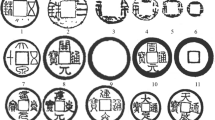

The tombs of Yinxu Phases II–IV containing analysed bronzes

A total of approximately 500 analyses of bronzes from all phases of Yinxu have been published, as listed in Table 1. The location of the tombs is shown in Fig. 1. For convenience, these analyses are collected together in the online appendix. There are a number of issues with this combined dataset, apart from the obvious problems associated with comparing data acquired by different analytical techniques over a period of time. These are primarily twofold — the occasionally poor individual analytical totals, and the possible duplication of samples. The analyses with totals outside the range 95–102% are highlighted in the appendix. We have, however, chosen not to filter them out, unless the compositions are obviously incomplete, in order to maintain the largest number of samples in the analyses. We felt that this was preferential to normalising the data, and would not unduly affect the overall conclusions. Possible duplications, either within a single published dataset, or between datasets, as indicated by duplicated object numbers, are also noted, but again have not been filtered out, not least because it is not always obvious that duplicated object numbers necessarily imply duplicate analyses of the same object.

Yinxu II tomb M5 Fu Hao (top elite) (data from Li 1982; Zhao 2004)

Yinxu Phase II is generally taken to be from the later part of the reign of Wu Ding (武丁) to that of Zu Jia (祖甲) (c. 1210–1180 BCE). The most celebrated tomb (M5) of this period is that of Lady Fu Hao (妇好), the second of three consorts of Wu Ding, but also a military leader in her own right. She died c. 1200 BCE, and her tomb is the only one of the Shang royal tombs to survive intact. On excavation in 1976, it was found to be relatively small (the central chamber was only 5 × 3.5 × 1.3 m, whereas the robbed Shang kingly tombs were up to seven times larger), but contained 468 bronze objects (with a combined weight of 1.6 tonnes), along with 755 jades and 564 bone objects, but only 11 pottery objects. She was accompanied by 16 human sacrifices and six dogs (Institute of Archaeology 1980). Of the 468 bronze objects from Fu Hao’s tomb (M5), approximately 146 have been chemically analysed. The majority of the analysed objects are ritual vessels. The classification of the analysed objects by typology for all the tombs considered here is shown in online Table 1.

Yinxu II tomb M54 (top elite) (data from Liu et al. 2007)

Tomb M54 is approximately 500 m from that of Fu Hao, at Huayuanzhuang, northeast of Anyang, and is slightly smaller (the central wooden chamber measures c. 3.7 × 2.2 × 1.8 m). Excavated in 2000, it contained 200 bronze objects (including 43 ritual bronzes and musical instruments), and approximately 200 jades, along with 21 pottery vessels. The owner (a male aged 35, with blade injuries to his bones) was accompanied by 15 sacrificial victims and 15 dogs. It is dated to Yinxu II on the basis of the ceramics, and the owner is assumed to have been a member of the top elite class on the basis of the tomb contents (Institute of Archaeology 1998). The chemical analysis of 48 objects, mostly ritual vessels, have been published (Liu et al. 2007).

Yinxu II tomb M1004 (top elite) (Tian et al. 2010; Uchida and Iizuka 2015)

M1004 is a Phase II tomb located in Xibeigang, north of Anyang, where the majority of the Shang royal tombs were found (Liang and Gao 1970). It is much larger than M5 and M54 — the burial pit was measured as 23.8 m (northeastern corner to southwestern corner) and 24 m (northwestern corner to southeastern corner). Although heavily robbed in antiquity, one corner was left intact, and in the excavations carried out in 1934–1935, a total of 889 metal objects were recovered, the majority of which were copper/bronze spearheads (731), followed by 72 ge blades and 66 helmets. Only two Ding were found — the well-known ox and deer square ding, which have not yet been analysed as far as we know. It is widely assumed to have been a kingly tomb, possibly that of Wu Ding himself, husband of Fu Hao. Most of the extant bronzes are currently held by the Academia Sinica in Taiwan, but a small group (the contents of two boxes lost at the time of transfer) remain in Beijing. There are two publications relating to the analyses of these objects — Tian et al. (2010) on the material in Beijing, and Uchida and Iizuka (2015) on the objects in Taiwan. A total of 57 analyses of helmets are available.

Yinxu II M18, M25, M29, M663 (middle elite) (Zhao 2004)

Tomb M18 was excavated in 1976 by the Chinese Academy of Social Sciences (CASS) and contained 43 bronze objects, four ceramics, 11 jades, 28 bone objects and four seashells (Zheng 1981). The owner was accompanied by five human sacrifices and two dogs. Based on the characteristics of the human bones, the excavators thought that the owner of this tomb might have been a woman aged around 35–40 years old. However, two of the bronze objects were inscribed Zi Yu (子渔), who was the son of Wu Ding. The original excavators were uncertain about the occupant, but more recently it has been asserted that the owner of M18 is Zi Yu (Yan 2022). We have classified this tomb as ‘middle elite’ on the basis of the number of bronzes found, but if it is Zi Yu’s tomb then it could be ‘top elite’. A total of 20 objects were analysed (Zhao 2004).

M25 and M29 were both excavated in 1986 by CASS (Gu 1989) in the south of Dasikong county, just north of Anyang. The size of M25 is 3.14 × 1.9 × 4.0 m. The burial objects included 11 bronzes and nine jades. M29 is a little smaller than M25, with dimensions 2.4 × 1.1 × 3.95 m. This tomb contained 13 bronze objects, two jades and one pottery object. The unknown owners of these two tombs were not accompanied by any human sacrifices or dogs. Zhao (2004) analysed eight objects from M25 and five from M29.

M663 is a small rectangular vertical pit with dimensions 3.3 × 2 × 4 m which was excavated by CASS in 1983, located in the southeast of Dasikong county. The owner was accompanied by four human sacrifices and one dog. The tomb contained 44 bronzes (of which 13 have been analysed (Zhao 2004)), 10 ceramics and 10 stone objects (Xu 1988).

Yinxu II Western Area (lower elite) (Li et al. 1984; Zhao 2004)

There are a large number of lower status tombs in the Western Area of Yinxu. The majority of tombs have yielded only one or two objects each; analyses are reported from M91, M391, M413, M515, M604, M618, M619, M627, M642 and M918. The maximum number analysed per tomb is five each from M234 and M269. Dating such tombs is somewhat more difficult than the elite tombs, which contain inscriptions and inscribed objects.

Yinxu III M160 (top elite) (Ji 1997; Liu 1998; Zhao 2004)

Tomb M160 in Guojiazhuang is the only elite tomb from Yinxu III which contains analysed bronzes. This tomb located in the west of Guojiazhuang and was excavated by CASS in 1990 (Institute of Archaeology 1998). It is a rectangular vertical pit, with dimensions of approximately 4.5 × 2.8 × 8 m (Liu 1998). The occupant is assumed to have been a high-ranking military individual, who was buried with four human sacrifices and three dogs. The tomb contained 291 bronze objects including 41 ritual vessels and three musical instruments. Most of vessels and instruments were decorated with inscriptions or symbols. Of the bronze objects with inscriptions, 33 were inscribed with ‘Yazhi (亚址)’. Ya (亚) refers to a military position. Zhi (址) is a name of a person or a clan. Accordingly, the owner was probably a high-ranking military individual. The total number of burial objects is 353 which includes 9 groups of arrowheads. The total number of arrowheads is 906. Fifty objects have been analysed, possibly including some duplicates (Ji 1997; Liu 1998; Zhao 2004).

Yinxu III Western Area (lower elite) (Li et al. 1984; Zhao 2004)

There are 35 analyses of bronze objects from the Western Area of Anyang dated to Yinxu III, namely from tombs M1, M1102, M1126, M125, M198, M271, M294, M355, M777, M819, M907 and M976. From the inventory numbers, it is possible that some of these analyses are duplicated.

Yinxu IV M1046 (top elite) (Zhao et al. 2008)

Tomb M1046 in Liujiazhuang was excavated in 1999. It consisted of a shaft 10.2 m deep, of dimensions 4.25 × 2.15 m, and contained the remains of six humans and one dog. A total of 123 bronzes, 6 jades and 14 ceramics were recovered. It was assigned to Yinxu Phase IV during the reign of Di Xin, the last King of Shang (1075–1046 BCE). Nine objects, all vessels, have been analysed (Zhao et al. 2008).

Yinxu IV Western Area (lower elite) (Li et al. 1984; Zhao 2004)

There are 69 analyses from the Western Area of Anyang attributed to Yinxu IV, from a large number of different contexts (chariot pit A, chariot pit B, AGM7, AKM7, HGH10, M2, M3, M11, M18, M41, M54, M71, M89, M92, M94, M100, M152, M234, M261, M263, M268, M269, M270, M279, M284, M621, M640, M692, M825, M1080, M1090, M1102, M1116 and M1118).

Alloying practices during Yinxu II

The data from Yinxu II have been allocated to three social layers on the basis of tomb size and the richness of the grave goods — top elite (M5 Fu Hao, M54 and M1004), middle elite (M18, M25, M29 and M663) and lower elite (Western Area). Figure 2 shows a plot of %Sn vs %Pb for the vessels from the top elite tombs (M1004 does not appear because no vessels have been analysed). The majority of the vessels from M5 and M54 contain between 11 and 24% tin, and the majority have between 0 and 3–5% lead, with all having less than 8%. We label this compositional pattern as A. Although it is not completely clear in Fig. 2, in order to compare these data with later periods, it is useful to divide this group (labelled A) into a lower lead group (A1) (with lead below c. 4%) and a higher lead group A2 (up to c. 8% in the case of vessels). There is a suggestion in Fig. 2 that the vessels from M54 have a slightly higher level of tin than do those of Fu Hao (average c. 19% (±4.2) for M54, c. 16.2% (±2.6) for Fu Hao), but the differences in analytical techniques between the two datasets (ICP for M54, wet chemistry for some of Fu Hao) counsel some caution in this respect. Figure 2 also seems to show that a higher percentage of vessels from Fu Hao’s tomb fall into group A2 (i.e. have higher lead) but this is a consequence of the difference in numbers between the two groups — as shown in Table 2, the percentage of vessels in A2 for Fu Hao is approximately 16% (20/122) whereas for M54 it is 11% (3/27). The average %Pb for Fu Hao vessels is 1.8% (±1.9%) compared to 2% (±1.9%), so in neither measure is the difference particularly significant. Several of the vessels from Fu Hao’s tomb have inscriptions, but, contrary to the suggestion by Zhao (2004), there is no clear chemical patterning in terms of the presence or absence of an inscription (discussed further below).

Figure 3 shows the vessels from the middle elite tombs (M18, M25, M29 and M663). The boxes show approximately the two compositional groups identified above as A1 and A2. It is clear that the bronzes of the middle elites correspond partially to those of the top elites — this applies particularly to M663 (12 out of 13 analysed vessels), and less so to M29 (4/5) and M25 (2/3) — but both of these tombs also have objects with higher lead than the top elite objects. M18 is more scattered, with 11/19 corresponding to the top elite, but having some with higher lead and also some with less tin.

Yinxu II middle elite vessels, %Sn vs %Pb. The box shows the approximate distribution of elite vessel compositions from Fig. 2 (A1/A2), and the vertical line at 5% Sn indicates a lower tin composition (B)

Figure 4 shows the weapons and vessels from the lower elite tombs from the Western Area. All of the vessels correspond in composition to the vessels of the top elites — more specifically, they correspond to the lower lead group (A1). This could reflect the burial in the lower elite tombs of vessels gifted by the higher elites. The weapons and tools, however, mainly form a new compositional pattern (labelled B), of low tin (<5%), with lead variable between 0 and 22%. The higher levels of lead might have rendered these objects as functionally poor tools and weapons, raising the question of whether they were created specifically for burial.

Yinxu II lower elite (Western Area) weapons and vessels %Sn vs %Pb. The boxes show the approximate distribution of compositions from Fig. 3

A few of the tools and weapons from the lower elites conform to the A1 pattern postulated for the higher elites. Figure 5 shows the composition of tools and weapons from the top and middle elite tombs in Yinxu II, and again the majority fall approximately into the box A1, although for the weapons and tools this might be extended to lower tin levels — perhaps from 7.5 to 22%.

Yinxu II top and middle elite weapons and tools, %Sn vs %Pb. The boxes show the approximate distribution of compositions from Fig. 3

In summary, for Yinxu II, we can describe the majority of vessel compositions as either A1 or A2, with the weapons and tools of the top and middle elites conforming approximately to A1. Whilst the vessels deposited in the tombs of the lower elites also conform to A1, the weapons and tools are distinctly different, having lower tin and generally higher but also very variable lead content (group B).

Alloying practices during Yinxu III and IV

For these later phases, we have divided the tombs only into top elite and lower elite. Figure 6 shows a plot of %Sn vs %Pb for the vessels and weapons from the top elite tomb M160. The split between the composition of the vessels and weapons seen in Fig. 4 (Yinxu II lower elite) is again apparent. Nearly all of the vessels have between 11 and 20% tin, apart from a small group of nearly pure copper. The lead concentration is, as shown in Fig. 7, mostly above 3.5% lead, corresponding to composition A2 in Yinxu II. Only a small group of three Gu have lower lead, around 2%. Figure 8 shows the same plot as Fig. 6 for the bronzes of the lower elites in Yinxu III. It is apparent that the structured differentiation between weapons and vessels seen in the elite tomb no longer applies. The reduced tin and trend towards increasing lead suggest that metal recycling and/or dilution might be taking place.

Yinxu III top elite vessels and weapons, %Pb vs %Sn. The boxes show the approximate distribution of compositions from Fig. 3

Expanded Yinxu III top elite vessels by typology, %Pb vs %Sn. The boxes show the approximate distribution of compositions from Fig. 3

Yinxu III lower elite vessels and weapons, %Pb vs %Sn. The boxes show the approximate distribution of compositions from Fig. 3

A very different compositional picture is presented in Fig. 9, where the vessels from the Yinxu IV top elite tomb (M1046) are plotted. The data represent a tight group of approximately 5% tin and 25% lead, quite unlike the vessels from the earlier periods. Although it is dangerous to speculate from such a small sample, it looks like, perhaps for the first time, there is a single target composition for all of the bronze vessels.

Yinxu IV top elite vessels by typology, %Pb vs %Sn. The boxes show the approximate distribution of compositions from Fig. 3

There are no weapons or tools analysed from tomb M1046, but Fig. 10 shows a plot of the vessels and weapons/tools from the lower elite area of Yinxu IV. The specific composition seen for the vessels from the elite tomb is not represented here, suggesting a strong division between top elite and lower elites metal production. The lower elite vessels have two broad distributions — one of between 10 to 20% tin and up to 20% lead, and the other of less than 5% tin but between 0 and 45% lead (excepting two vessels of virtually pure lead). This suggests some patterning exists which is analogous to that seen in earlier periods, but not exactly the same.

Yinxu IV lower elite vessels and weapons, %Pb vs %Sn. The boxes show the approximate distribution of compositions from Fig. 3

Comparison of alloying practices across periods

The changes in alloying practice from Yinxu II to Yinxu IV are summarised in Table 2, in terms of allocation of samples to compositional types A1, A2, B and other.

The vessels in the top elite tombs of Yinxu II (Fu Hao and M54) are all of the type described above as A1 or A2 — both have high tin, with a somewhat arbitrary differentiation between lower (<4%, A1) and higher lead (4–8%, A2). Assuming these groups represent a composition reserved for elites, it is interesting to note that the tools and weapons included in these tombs are also almost exclusively made from this metal — in fact predominantly from A1, which, because it has lower lead, might be assumed to be the most prestigious alloy. This might imply that the tools and weapons for these elite tombs during Yinxu II were made specifically for burial rather than for use, using the same metal as that used for the vessels, and perhaps in the same workshops. Tomb M1004, from which only helmets have been analysed, also conforms very largely to this composition. The middle elite tombs of Yinxu II (M18, M25, M29 and M663) have a slightly less well-defined composition. The vessels of tomb M18 have a high proportion in A1, but also a number in category B and also some classified as other (note that ‘other’ could include samples with compositions close to those of defined types, but falling slightly outside the arbitrarily defined limits). The vessels of these middle elite tombs are largely of A1/A2 composition, but with four samples from tomb M18 showing a group B composition (low tin, variably high lead: M18:30; M18:9; M18:31; M18:32), with M18:12 and M18:37 classified as ‘other’. The vessels of the lower elite tombs during Yinxu II are of composition A1 (similar to those of the elites — possibly gifts from higher elites? M391:3; M391:5; M618:13; M627:3). The weapons and tools, however, are all type B alloys, showing that this metal first appears in the currently available dataset in the tools and weapons of the lower elites, and a few vessels of the middle elites.

A similar pattern is also visible in the composition of the copper alloys in the elite tomb of Yinxu III (M160), but with one striking difference — the vessels are largely of type A1/A2, but, unlike the equivalent alloys of Yinxu II, the majority are A2 rather than A1. This implies that the metal available to the top elites of Yinxu III had high tin, but also higher levels of lead. The tools and weapons, however, deposited in M160 are almost exclusively of alloy type B — similar to that used in Yinxu II for the tools and weapons of the lower elites. There is thus considerable continuity in alloying practice from Yinxu II to Yinxu III in the weapons, and also to some extent in the vessels, but with a slight shift to higher lead in Yinxu III vessels. The lower elites of Yinxu III have access to much less well-controlled alloys, with the majority of vessels being either of type B, or other, and the tools and weapons almost exclusively other.

This less well-controlled patterning (in comparison to the controlled alloys of early phases) is visible in Yinxu IV, albeit with relatively few samples. However, the elite tomb M1046 has a very specific composition for the vessels, irrespective of typology. This looks like a very simple target composition of 70% Cu, 25% Pb and 5% Sn. The vessels and weapons of the lower elites are similar to those of Yinxu III, i.e. largely either type B or ‘other’.

Alloying practices

We can broadly see two copper alloying patterns during the later Shang at Anyang — one identified as A1/A2, and the other being B. In a previous publication (Liu et al. 2020), we have commented on the relatively symmetrical distribution of alloying elements (specifically of tin) in vessels from the top elites of Yinxu II, and contrasted this with the much broader elemental distributions in the vessels of the lesser elites. This we interpreted as a socially differentiated access to metal, with the upper elites commanding alloys of more restricted (targeted) compositions, reflecting the use of primary metal resources with little or no contribution from recycled metal. This contrasts with the less-controlled compositions of the lesser elites, reflecting (we proposed) the incorporation of a higher content of recycled metal.

This more detailed analysis of the data supports this conclusion, but also raises some interesting questions. Figure 2 defines a range of 11–24% for the tin content of upper elite vessels in Yinxu II (although the actual distribution of these data is approximately normal — see Fig. 11). Although we still assert that this relatively broad distribution represents a targeted composition, it does not compare to the precision of composition shown in Fig. 9 for the (admittedly) small number of vessels from elite tomb M1046 in Yinxu IV (4%<Sn<6%, 24%<Pb<28%). Perhaps more importantly, nor does it correspond to the consistency of composition of the weapons found in Fu Hao’s tomb, when disaggregated by typology (Fig. 12). This shows discrete compositional groups for Ge (dagger-axes: average Cu = 87.1 (±1.82%, Sn = 11.1 (±1.5)%, Pb = 0.84 (±0.29 (±%), and arrowheads/knives (average Cu = 80.1 (±2.6)%, Sn = 18.1 (±2.3)%, Pb = 0.59 (±0.44)%). Not only do these appear to be distinct compositions according to function, they also form coherent compositional groups. This implies that the craftsmen of Fu Hao could make targeted compositions according to typology, but they appear to have been less prescriptive for the vessels. This is indeed slightly puzzling. It could indicate the use of scrap metal, but the relative ‘cleanness’ of the metal in terms of trace elements as compared to other assemblages suggests otherwise, as discussed in Liu et al. 2020 (unless the recycling is taking place within a very closed metal system — which is possible).

We suspect that this difference may be due to alloying practice at the point of casting the objects. As noted above, the vessels of Yinxu IV seem to correspond to an alloy made simply by directly mixing metallic copper, metallic lead and metallic tin in the ratio of 70:25:5. Both tin and lead ingots of reasonably high purity have been recovered from Yinxu (Zhao 2004). So what alloying practice do these earlier elite vessel compositions represent? Figure 11 shows the distribution of tin in the 123 vessels from the elite tomb of Fu Hao (M5) during Yinxu II. As noted above, it is approximately Gaussian, with an average of 16.2% Sn and a standard deviation of 2.6%, but it is not as narrow as we would expect if it represents a specific target composition for the combination of copper and tin. It is possible that this scatter arises from the fact that the vessels originated from different workshops — perhaps gifted to Fu Hao, or looted from elsewhere, and thereby lacking a single clearly defined target composition. In this context, however, it is worth noting that there appears to be no systematic difference between the vessels with inscriptions related to Fu Hao’s name and those bearing no inscription (Fig. 13). Moreover, this suggests that the objects bearing an inscription of Fu Hao do not represent a specific compositional group, contrary to the suggestion of Zhao (2004), who based her conclusion on a comparison with a relatively limited number of non-inscribed samples.

It is worth testing whether this scatter arises not from mixing pure metallic ingredients in specified ratios, but from the mixing of pre-prepared alloys at the point of casting (Pollard and Liu 2023). This idea has been proposed as an explanation for the interpretation of the famous ‘six recipes’ for bronze casting from the Kaogong Ji incorporated into the Zhou Li (Rites of Zhou, 周礼), dating to about the third century BCE (Pollard and Liu 2022). These recipes give combinations of two ingredients (Jin (金) and Xi (锡)) to make different categories of bronze objects, but the finished bronzes are ternary copper-tin-lead alloys, which could not therefore be made by mixing two pure metals. The proposal in Pollard and Liu (2022) was that Jin and Xi represent two pre-prepared alloys, mixed at the time of casting. Modelling suggested that Jin could be a leaded bronze of approximately 80%Cu/15%Sn/5%Pb diluted with Xi, modelled as 50/50 Cu/Pb. Naturally, such a model only reflects the broad compositional trends in the data, and one would expect some variation around the starting compositions of the two alloys between casting campaigns. Thus, it would be possible for some objects to be made with a ternary alloy containing more than 15% tin, giving rise to alloys of higher tin. The key point to appreciate is that, although the compositions are expected to vary around the trend lines identified, the actual practice of the metal caster involved mixing two components, both of which could be binary or ternary alloys, rather than starting with three relatively pure ingredients. This is the implication of the Kaogong Ji during the Warring States period, and it is an as yet unaddressed question as to whether this reflects earlier practices, possibly even during the Shang.

In order to test this hypothesis, Fig. 14 shows a comparison of the composition of the vessels recovered from Fu Hao’s tomb (M5, Yinxu II) with the predicted values of a model consisting of diluting pure copper with increasing quantities of a binary 80Sn/20Pb mixture, in the range of 0 to 50% of the original weight of copper. Although the model fits very well when %Sn is plotted against %Cu, and performs passably for %Pb vs %Cu, it fails completely when %Pb is plotted against %Sn. The fact that %Sn does not correlate positively with %Pb in Fu Hao’s data precludes the dilution of pure copper by a binary Sn/Pb alloy, and the relative independence of %Pb from %Cu strongly suggests that in this case the vessels are indeed constructed from an alloy prepared from three independent ingredients (copper, tin and lead). The proportions seem to be approximately 4Cu:1Sn:0.25Pb, but, as noted above, the proportions do not seem to be very carefully controlled.

Type B alloys, as seen particularly in Figs. 4 and 6, seem to parallel this ternary recipe, but with tin and lead reversed. For example, for the weapons from tomb M160 (Yinxu III: Fig. 15), a recipe of diluting pure copper with increasing quantities of pure lead replicates the main feature of the observed correlation — the strong negative relationship between lead and copper. If the model is modified slightly to be diluting pure copper with a 95%Pb/5%Sn, then the correlation between %Sn and %Cu can also be replicated for the majority of samples. It also replicates the relationship between %Sn and %Pb to some degree (for the majority), so it is possible that type B alloys represent a dilution of pure copper with increasing amounts of a binary 95Pb/5Sn alloy. It is also possible that it is a binary combination of copper containing low amounts of tin (<3%) with pure lead. Unlike the alloys of A1/A2 compositions, it is unlikely that the intention was to introduce small amounts of tin into the alloy, so it seems most likely that the tin is unintentionally introduced into type B alloys with the added lead.

Conclusions

This detailed analysis of the data on the bronzes recovered from Late Shang capital at Yinxu has revealed a complex alloy patterning which varies by social status and object typology, and which also changes over time. The preference for higher tin in the bronze vessels and weapons for the elites during Yinxu Phase II gives way to a more binary pattern (having weapons preferentially alloyed with lead) for the lower elites of phase II, which becomes prevalent in subsequent phases. These changes are interpreted in terms of different ‘alloying practices’, which attempts to reconstruct the way in which the alloys are created at the point of casting. Importantly, the alloy type described as A1/A2 seems most likely to have been created by mixing together three components, corresponding to relatively pure copper, tin and lead. This contrasts with the suggestion in the Kaogong Ji, several hundred years later, that binary pre-prepared alloys were used. It is now important to determine when such a change might have occurred. The suggestion alloy type B could have been made by combining pure copper with a slightly impure lead (95%Pb/5%Sn) hints that such practices might have started during the Shang, but this requires considerably more work, especially on the intervening Western and Eastern Zhou periods.

We suggest here that bronze vessels with specific inscriptions do not appear to form particularly coherent compositional groups, which if true would have important consequences for our reconstruction of the workshop organisation during the Shang, but this requires further detailed examination.

These interpretations about alloying practices are relatively robust, because they are based on relationships between the major alloying elements (copper, tin and lead), but are inherently limited by the quality of the analytical data, which is not always as good as might be desired. The important analytical database studied here requires some further refinement — either by elimination of the less reliable data, or, preferably, by re-analyses of some or all of the objects.

Data availability

All the data used in this paper has been previously published by other authors and its sources are fully acknowledged. For convenience, these data have been drawn together into the online appendix with full acknowledgement.

Code availability

Not applicable

References

Gu F 谷飞 (1989). 1986 nian anyang dasikong cun nandi de liangzuo yin mu 1986年安阳大司空南地的两座殷墓 (Two tombs in Dasikong nandi, Anyang, found in 1986). Kaogu 考古 1989(07), 591-597+675-677

Institute of Archaeology, Chinese Academy of Social Sciences中国社会科学院考古所 (1980). Yinxu Fu Hao Mu 中国社会科学院考古所 (Tomb of Lady Fu Hao at Yinxu in Anyang). 文物出版社 (Cultural Relics Publishing House), 北京 (Beijing)

Institute of Archaeology, Chinese Academy of Social Sciences 中国社会科学院考古所 (1998). Anyang Yinxu Guojiazhuang Shangdai muzang 1982-1992 nian kaogu fajue baogao 安阳殷墟郭家庄商代墓葬1982-1992年考古发掘报告 (Excavation report of Shang tombs in Guojiazhuang, Yinxu, Anyang from 1982 to 1992). 中国大百科全书出版社 (Encyclopedia of China Publishing House), 北京 (Beijing)

Ji L 季连琪 (1997). Henan Anyang Guojiazhuang 160 hao mu chutu tongqi d chengfen fenxi yanjiu 河南安阳郭家庄160号墓出土铜器的成分分析研究 (Compositional analysis of bronzes excavated from Tomb 160 in Guojiazhuang in Anyang, Henan). Kaogu 考古 1997(2), 80-84+92

Li M 李敏生 (1982). Yinxu jinshu qiwu chengfen de ceding baogao yi 殷墟金属器物成分的测定报告 (一) (Scientific analysis of bronzes from Yinxu, the first part). Kaoguxue jikan考古学集刊2, 181-193

Li M 李敏生, Huang S 黄素英 and Ji L 季连琪 (1984). Yinxu jinshu qiwu chengfen de ceding baogao er 殷墟金属器物成分的测定报告 (二) (Scientific analysis of bronzes from Yinxu, the second part). Kaoguxue jikan考古学集刊 4, 328-375

Liang S 梁思永 and Gao Q 高去寻 (1970). Houjiazhuang diwuben 1004 hao damu 侯家庄第五本1004号大墓 (Houjiazhuang Volume 5 Tomb M1004). 中央研究院歷史語言研究所 (Institute of history and philology, Academia Sinica), 臺北 (Taipei)

Liu Y 刘一曼 (1998). Yinxu Guojiazhuang 160 hao mu de faxian ji zhuyao shouhuo 殷墟郭家庄160号墓的发现及主要收获 (Findings of tomb 160 in Guojiazhuang, Yinxu). Kaogu考古 1998(09), 64-74

Liu R, Pollard AM, Rawson J, Tang X, Zhang C (2019) Panlongcheng, Zhengzhou and the movement of metal in Early Bronze Age China. J World Prehistory 32:393–428

Liu R, Pollard AM, Cao Q, Liu C, Sainsbury V, Howarth P, Bray P, Huan L, Bohao Y, Fu Y, Tang J (2020) Social hierarchy and the recycling of metal at Anyang, the capital of Bronze Age China. Sci Rep 10:18794

Liu K, Wu X, Guo Z, Yuan S, Ding X, Fu D, Pan Y (2021) Radiocarbon dating of oracle bones of Late Shang period in Ancient China. Radiocarbon 63:155–175

Liu Y 刘煜, He Y何毓灵 and Xu G 徐广德 (2007). M54 ji M60 chutu qingtongqi de chengfen fenxi M54及M60 出土青铜器的成分分析 (Compositional analysis of bronzes excavated from M54 and M60). In 中国社会科学院考古研究所 (Institute of Archaeology, Chinese Academy of Social Sciences) (eds.) Anyang Yinxu Huayuanzhuang Dongdi Shangdai Muzang 安阳殷墟花园庄东地商代墓葬 (Shang Tombs in Huayuangzhuang Dongdi in Yinxu, Anyang), pp. 289-296. 科学出版社 (Science Press), 北京 (Beijing)

Pollard AM, Liu R (2022) The six recipes of Zhou – a new perspective on Jin (金) and Xi (锡). Antiquity 96:1200–1213

Pollard AM, Liu R (2023) Predicting bronze casting recipes in Ancient China: ternary copper-lead-tin alloys and the ‘Unit Sum Problem.’ Archaeol Anthropol Sci 15:55

Tian J, Jin Z, Li R, Yan L, Cui J (2010) An elemental and lead-isotopic study on bronze helmets from royal tomb No.1004 in Yin ruins. Archaeometry 52:1002–1014

Uchida J 内田純子, Iizuka Y 飯塚義之 (2015) 中央研究院收藏殷墟青銅器的冶金學研究 Zhongyang yanjiuyuan shoucang Yinxu qingtongqi de yejinxue yanjiu (Metallurgical research on the Yin Ruins bronze wares collected by Academia Sinica). In Li Yongdi李永迪 (ed.), Jinian Yinxu fajue basi zhounian xueshu yantaohui 紀念殷墟發掘八十週年學術研討會 (Symposium Commemorating the 80th Anniversary of the Yin Ruins Excavation), pp. 109-130. 中央研究院歷史語言研究所 (Institute of history and philology, Academia Sinica), 臺北 (Taipei)

XSZCP Group (2000), 夏商周断代工程1996—2000年阶段成果报告: 简本 (The Xia-Shang-Zhou Chronology Project Report for the years 1996–2000 (abridged)). 世界图书出版公司, Beijing

Xu G 徐广德 (1988) Anyang Dasikong cun dongnan de yizuo yinmu安阳大司空村东南的一座殷墓 (A Yin tomb in the southeast of Dasikong county in Anyang). Kaogu 考古 1988(10): 865-874+961-962

Yan Z 严志斌 (2022). Yinxu Shangmu tongqi zuhe yu muzhu guishu wenti殷墟商墓铜器组合与墓主归属问题 (Research on the owners of bronze sets in Shang tombs in Yinxu). Wenwu 文物 2022(11), 34-45

Zhao C 赵春燕 (2004). Anyang Yinxu chutu qingtongqi huaxue chengfen fenxi yu yanjiu. 安陽殷墟出土青銅器化學成分分析與研究 (Analysis and research on chemical composition of bronze ware unearthed from Yinxu, Anyang). Kaoguxue jikan 考古學集刊15, 243-277

Zhao C 赵春燕, Yue Z 岳占伟 and Xu G 徐广德 (2008) Anyang Yinxu Liujiazhuang bei 1046 hao mu chutu tongqi de huaxue zucheng fenxi安阳殷墟刘家庄北1046号墓出土铜器的化学组成分析 (Compositional analysis of bronzes excavated from tomb 1046 in the north of Liujiazhuang in Yinxu, Anyang). Wenwu 文物 2008(1), 92-94

Zheng Z 郑振香 (1981). Anyang Xiaotuncun bei de liangzuo yindai mu 安阳小屯村北的两座殷代墓 (Two tombs of the Yin Dynasty in the north of Xiaotun Village, Anyang). Acta Archaeologica Sinica 考古学报 1981(04), 491-518

Acknowledgements

We acknowledge the support of the European Research Council Horizon 2020 (ERC advanced project FLAME, Flow of Ancient Metal Across Eurasia, 670010).

Funding

This work was funded in part by the European Research Council Horizon 2020 (ERC advanced project FLAME, Flow of Ancient Metal Across Eurasia, 670010).

Author information

Authors and Affiliations

Contributions

All authors contributed to the writing, figure preparation and review of the manuscript.

Corresponding author

Ethics declarations

Ethics approval

Not applicable

Consent to participate

Not applicable

Consent for publication

Not applicable

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Pollard, A.M., Zhang, Y. & Liu, R. Bronze alloying recipes at Anyang during the Shang Dynasty. Archaeol Anthropol Sci 15, 156 (2023). https://doi.org/10.1007/s12520-023-01853-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12520-023-01853-x