Abstract

Since one of the aims of modern archaeometallurgy is to understand the processes carried out by ancient metalworkers, then ideally, we need to go beyond the traditional sources of evidence for such processes — physical investigation and chemical analysis of the objects themselves, and associated manufacturing debris. In order to understand the intentionality behind the decisions taken by these metalworkers (the ‘why’, in addition to the ‘how’), then we need to ‘see the world’ as the metalworkers themselves did. The key issue is how to traverse the gulf between ancient and modern perceptions of the natural world. Using ancient Chinese bronze metalwork as an example, we argue that many interesting glimpses of this world can be drawn from the contemporary and later literary sources. But it is crucial to note that these insights have to be supported by independent evidence, such as scientific data or archaeological information. Once verified, these findings can significantly improve our knowledge of the metaphysical perception of metal in the past and offer a heuristic and powerful tool to interpret the relationship between metallurgy and society. For the Chinese Bronze Age, metallurgy performed a crucial part in the political and ritual world. In particular, the different colours of metal objects provide important indicators of the social hierarchy as evidenced by burial practice.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

It is widely accepted that the rise and spread of metal across Eurasia was not simply driven by its novel functionality compared to that of lithic materials (Roberts et al. 2009; Pollard et al. 2018; Chernykh 2017; Linduff and Mei 2009), but that it also represented a new way to influence or respond to changed social settings (Killick 2004; Lechtman 1977; Roux 2010). In many cases, metallurgy was just one of many responses to these local issues, and the adoption of metallurgy was more of a cultural than a technological choice (Binford 1962; Bebber et al. 2019; Senna-Martinez and Luís, 2016; Liu et al. 2020). A vivid example of this comes from Bronze Age China (primarily Shang and Zhou periods, 1800–256 BC), where the primary use of metallurgy was to make bronze vessels for ancestral rituals designed to reinforce the lineage of the elite, rather than to provide the symbolic (e.g. ornaments) or practical (e.g. weapons) underpinnings of the warrior society (Rawson 2017; Bagley 1987). The rise of Erlitou (1800–1500 BC) marked the beginning of the Bronze Age in central China after the collapse at the end of the Neolithic period (Liu and Chen 2012; Zhang et al. 2019). It was natural for the Erlitou people to inherit a variety of the ritual and cultural practices from its powerful predecessor, the Longshan culture (2500–2000 BC), but also necessary to create some new social order to distinguish itself from other competing cultures (Jaang 2015). As a consequence, it chose to make these bronze ritual vessels by successfully combining the ancient tradition of pottery-making with the newly arrived technology of metallurgy (Linduff 2004; Mei 2009). In this context, the physical properties of the metal, though very important, were perhaps only a secondary consideration compared to its novel social characteristics in the minds of the Chinese elites and craftspeople.

For more than 200 years, archaeometallurgists have created a very strong and robust framework for the study of metal objects from the ancient world (e.g. Roberts and Thornton 2014). This has included the use of metallography to visualise the microstructure of the metal, and hence understand the manufacturing, finishing and use of the objects, as well as the corrosion behaviour and conservation needs (Scott 1996). More specifically, however, the art of chemical analysis has been applied to archaeological bronzes since at least 1777 (Pollard 2016), and isotopic methods, initially of lead, since 1967 (Brill and Wampler 1967). Naturally, apart from in the very earliest of this literature, where simple weights of the components are reported, the results of these chemical analyses of metals are invariably reported as weight percentages of pure elements. Whilst this is required by modern scientific practice, we suggest that an unintended consequence of adopting this protocol is that it structures to a high degree the way in which we interpret the data, and consequently limits our understanding of the actual intentionality of ancient craftspeople. It inevitably encourages archaeologists to think in terms of modern atomistic science, which is very unlikely to reflect the world view of the people who made the metals of antiquity (Killick and Fenn 2012). They would have been unaware of the modern periodic table with the pure elements, but would have had different ways of describing and thinking about the various raw materials, as well as the whole process necessary for making metallic alloys. The alchemy of many ancient eastern and western cultures sees metals as being compounds of ‘mercury’ and ‘sulfur’ (not the modern elements Hg and S, but the essences of metals and impurities). The different metals are characterised by different proportions of ‘mercury’ and ‘sulfur’, and therefore one metal can be converted into another by altering this balance. Gold, being the metal with the perfect balance (2:1 mercury to sulphur), can therefore be created from base metals by such purification (Holmyard 1957; Pollard 1988). This metaphysics works well as a description of various alloying processes and therefore provides an intellectual framework for thinking about alloys and impure metals, but is of course inconsistent with modern chemistry. To better understand the practice of creating copper alloy objects in the past, we need to reconfigure our data and perspectives into a framework which better represents the ways in which these materials would have been thought about in the past. This paper is an attempt to think through the implications of this approach, using both literary sources and chemical data.

This attempt immediately poses an interesting challenge to modern archaeometallurgists, by creating the following dilemma: how do we understand the underlying cognition of the practical procedures of ancient metallurgy, when the original practitioners themselves would not recognise the modern constituents and concepts which are used in modern science? We are essentially moving between two very different world views, without considering what might be inadvertently lost or created by such a transition. Specifically, we need to counter the subconscious tendency to assume that we are ‘right’ and they were ‘wrong’, and therefore it is justified to uncritically ignore any perspective which does not conform to modern scientific thinking. This cannot be a satisfactory position when the aim is to understand the practice of metallurgy in antiquity, and particularly in prehistory. The increased emphasis on the role of perception in archaeometallurgical studies — the view that physical and metallurgical properties as defined by modern science are not the only driving forces that need to be considered when explaining the changes seen in the archaeological material record — is a positive step in this direction, but perhaps needs to go even further (Killick and Fenn 2012; Pollard et al. 2019; Kuijpers 2018; Killick 2004; Martinon-Torres and Killick, 2015; Pollard et al. 2018; Liu et al. 2015). We suggest that, in addition to considering the many ways in which craftspeople interacted with metal, the entire world view of these craftspeople, including the metaphysics, social context and aesthetics of human beings, needs to be accounted for.

However, since most archaeometallurgists are trained in various aspects of modern chemistry and metallurgy, how can we avoid associating the scientific data with the artefacts without projecting modern concepts of natural philosophy into our interpretation? A simple illustration of this dilemma can be found in the long-running debate around the interpretation of the range of major alloying elements found in copper-based artefacts, in an attempt to understand the underlying intentionality of the original craftspeople. A fundamental question is to what degree the original craftspeople wanted or needed to control the addition of different sorts of metal to copper to achieve different alloys, and how they did it? In other words, was it some sort of selection process of ingredients in advance of smelting or casting, or was it post hoc selection of particular products for particular purposes, or neither, or both, or something else? The chemical analyses of alloying elements (tin, lead, zinc, arsenic, nickel, antimony, etc.) and the physical examination of metals and debris can help to illuminate some of these decisions (e.g. primary alloying practice or the use of speiss, Pollard et al. (2019); Rehren et al. (2012)), but can only partially reflect the way in which the original artisans and their patrons would have seen these metals and their raw materials. Such issues have of course been intensively discussed in the literature, and one indisputable consensus to emerge is the need for multiple lines of evidence from not only metallurgical materials but also contextual and literary evidence (Eaton and McKerrell 1976; Rehren and Pernicka 2008; Ponting and Levene 2015). Our argument here is that one crucial component which is frequently under-represented in this debate is the perception of the process as seen from the point of view of the original actors, framed in their own natural philosophy.

Bridging the ancient and modern: a critical perspective towards literary sources

One of the few ways of entering this world is to critically use the evidence from ancient texts, where these are available. Rarely, these texts specifically refer to ancient metallurgical processes, and such texts (e.g. Pliny, Theophilus, Agricola) have been the subject of intensive scholarly interpretation over several centuries. More often, however, the information is not specific but can still be used to piece together something of the world view within which these processes were embedded. Here is not the place to review or critique the use of ancient texts in the interpretation of contemporary technological processes — this has been done many times, in many different cultural areas and for a range of materials (Falkenhausen 1993). Suffice to say that there are many issues to be considered. Frequently, the texts are not contemporary with the craft processes described, although some later texts may reflect older processes and perceptions. Equally frequently (although there are exceptions), until the Early Modern world, the skills of literacy and those of the practical arts may not have resided in the same person — hence, there are question marks regarding the level of technical understanding of the person actually writing the description. Significantly too, the linguistic skills required to translate correctly the ancient texts are rarely to be found in modern scientists — perhaps the most notable exceptions to this rule in recent times have been Cyril Stanley Smith (1903–1992), Zhang Hongzhao (1877–1951) or Joseph Needham (1900–1995). And finally, as eloquently pointed out by Killick (2001), many modern ‘armchair archaeometallurgists’ are themselves insufficiently versed in practical archaeometallurgy to truly appreciate what is being described.

Nevertheless, ancient textual sources are often the closest, if not the only, way that modern archaeometallurgists can approach an understanding of the perceptions of ancient metalworkers, apart from the evidence gleaned from the objects themselves, and the associated production debris. It is often hard to know every detail of the social context in which these ancient documents were created. Common sources of uncertainty can include the precise date of the texts (including copies and commentaries), the purpose of the texts, the background of the writer(s) or the target audience. Uncertainty in translation and different versions of the transmitted texts also add unknown degrees of complexity to the interpretation. However, in spite of these potential difficulties, it is still possible to derive some interesting research hypotheses from such documents and, along with other lines of evidence, to create a broad pattern of how craftspeople perceived metal in antiquity, just as we often try to do with the chemical analyses from a group of objects, rather than focussing on an individual object. Furthermore, combining these two sources of evidence, derived from contrasting data sources, can offer new inspirations to investigate the contextual perception and manipulation of metal in antiquity. This is not, of course, easy to achieve, since until the medieval period we rarely if ever have any specifically technological texts (and certainly not from the Bronze Age) which can enable us to get into the minds of the original bronze casters. Nevertheless, using China as an example, we can begin to piece together evidence from later literary sources which, when combined with modern chemical data, might help us to begin to reconstruct how the mental world view of Bronze Age Chinese metalworkers influenced the practice of metallurgy.

Summary of ancient Chinese texts on metallurgy

Chinese archaeology has a strong tradition of associating archaeological discoveries with ancient documents, and therefore the study of ancient texts is extremely well developed. Largely thanks to the Chinese Text Project (https://ctext.org), the most comprehensive digital source of ancient Chinese literature so far, one can search for any Chinese character with specific metallurgical implications within a large group of transcribed texts in a very efficient manner (102 pieces of Han or pre-Han documents and 34 pieces of post-Han documents: the Han dynasty is 206 BC–220 AD). The objective here is to present a broad picture of what was mainly discussed in the texts about metallurgy. In doing so, we chose to search for the four most important Chinese metallurgical characters Jin (金), Tong (铜, copper), Xi (锡, tin) and Qian (铅, lead) to start with. The character Jin is the most complicated to interpret. It has the highest frequency of any metallurgical term in the narratives referring to the Bronze Age in the Han or pre-Han documents, but its exact meaning remains rather ambiguous. In modern Chinese, it corresponds to gold. Such a modern translation appears entirely unconvincing because gold was not common in the Chinese Bronze Age of the Shang (ca. 1500–1045 BC) and Western Zhou (ca. 1045–771 BC). A much more likely translation is either as metal in broad terms (Li and Li 2011) or as copper specifically (Zhou 1978; Zhang 1958; Liu et al. 2015; Chikashige 1936).

A systematic review of these four characters and their initial context in the documents dated to the Eastern Zhou to Han (771 BC–260 AD) and later suggests five major aspects of knowledge concerning metal and metallurgy, namely (1) the role of metallurgy in mythology, (2) the hierarchy of metals, (3) the manufacture of alloys, (4) the ambiguity between tin and lead, and (5) the available metals and their locality in early China. Considering the complexity embedded within these texts, as discussed above, it is always important to draw archaeological and scientific evidence for further verification.

Metallurgy and mythology

史记-封禅书: 秦始皇既并天下而帝, 或曰: “黄帝得土德, 黄龙地蚓见。夏得木德, 青龙止于郊, 草木畅茂。殷得金德, 银自山溢。周得火德, 有赤乌之符。今秦变周, 水德之时。昔秦文公出猎, 获黑龙, 此其水德之瑞。”.

Records of the Grand Historian (Shiji, written by Sima Qian (145–86 BC) during the Western Han dynasty) — Feng Shan: After the First Emperor of the Qin had united the world and proclaimed himself emperor, someone advised him, saying, ‘the Yellow Emperor ruled by the power of the element earth, therefore a yellow dragon and a great earthworm appeared in this time. The Xia dynasty ruled by the power of wood, and so a green dragon came to rest in its court and the grasses and trees grew luxuriantly. The Shang dynasty ruled by metal (金), and silver (银) flowed out of the mountains. The Zhou ruled by fire, and therefore it was given a sign in the form of a red bird. Now the Qin has replaced the Zhou, and the era of the power of water has come’ (Watson 1961).

Many records associated with metallurgy in the ancient Chinese documents are actually not only technologically relevant, but are also reflective of metal as being central to political legitimacy and collective memory. This is probably why these records of metal and metallurgy are often accompanied by mythological illustrations. As recorded by Sima Qian, Ying Zheng, the first emperor of Chinese Qin dynasty, who is also famously known as Qin Shi Huang Di in the historical documents and his terracotta warrior army excavated from the present-day Xianyang city, noted in his Fengshan sacrifice rites at the Mountain Tai that all the prosperous periods before the Qin dynasty (the Yellow Emperor, the Xia, Shang and Zhou dynasties) were empowered by one of the five elements in ancient Chinese philosophy. In particular, the rise of the Shang dynasty was underpinned by metal. It is intriguing that, stripping out these descriptions of ‘supernatural’ phenomena, the very first large-scale use of metal indeed happened during the Shang dynasty, as proved by decades of excavation, although based on copper, tin and lead. Consequently, this reference to silver in the Shang is somewhat anomalous, in that, although silver would have been known to Sima Qian in the Han dynasty, it is rare to absent in the Shang, as demonstrated by archaeological excavations. It is possible that silver is used here as an analogy for general metallic riches.

It appears that the ability to find and cast metal is often used in the ancient Chinese records to enhance heroic images of the early figures of Chinese prehistory. Examples can be found for well-known mythological figures in the creation of the Chinese civilisation, including the Yellow Emperor (黄帝) and Chi You (蚩尤), both of whom are dated prior to the first textually recorded Xia dynasty, possibly around 2000 BC, as well as Da Yu (大禹, the first emperor of the Xia dynasty) and Tang (汤, the first emperor of the Shang dynasty, ca. 1500–1045 BC). In accordance with a variety of records such as Shiji, the Yellow Emperor defeated Chi You (who later became associated with the God of War, and had a metal head and body), and also made bronze ritual vessels on the foothills of the Jin mountain with metal extracted from the Shou Mountain (Shiji-Fengshan: 黄帝采首山铜, 铸鼎于荆山下). More records derive from Guanzi-Shanquanshu (管子-山权数, Warring States to Han, 476–220 BC, 汤七年旱, 禹五年水, 民之无卖子者, 汤以庄山之金铸币, 而赎民之无卖子者; 禹以历山之金铸币, 而赎民之无卖子者). The seventh year of Tang’s reign period (early Shang) experienced severe drought, during which people who suffered from famine had to sell their children. Emperor Tang made coins using the metal from the Zhuang mountain to support them. In the seventh year of (Da) Yu, due to flooding, (Da) Yu made coins with the metal from the Li mountain and did the same. Whilst it is mythological that metal coins circulated during the pre-Shang or early Shang period of either (Da) Yu or Tang, the primary purpose of these records is to set up a model to be followed by later political leaders, establishing that it is their responsibility to save people from suffering. For the later political leaders in Chinese antiquity, the beneficial use of metal and metallurgy in society is central to following these successful predecessors, thereby creating collective identity and sustaining their administrative legitimacy.

A hierarchy of the metals

A clear hierarchical structure of metal was documented in the Yugong section of the Esteemed Documents (in Chinese Shangshu 尚书, the Spring and Autumn period, 770–465 BC), one of the earliest documents in China:

尚书-夏书-禹贡: 淮海惟扬州/荆及衡阳惟荆州…厥贡惟金三品

Shangshu-Xiashu-Yugong: The Huai Sea is the State of Yang/Jing and Hengyang are the State of Jing… where three levels of metal can be extracted and attributed.

More explanation regarding these three levels of metal (Jin) can be found in the Records of the Grand Historian. In the section of Shihuozhi (Treatise on Food and Commodities), it noted that ‘Jin has three levels, among which the highest is yellow Jin, middle the white Jin and lowest red Jin (金有三等, 黄金为上, 白金为中, 赤金为下)’. As shown in the example above, Shangshu, which is probably the earliest textual evidence on the perception of metal ranking in ancient China, dating from the Spring and Autumn period (771–476 BC), also refers to the same three colours as in Shiji. It is tempting, particularly from the perspective of the modern economic geology, to assume that yellow Jin is gold, white Jin is silver and red Jin is copper (since these metals would have been known to Sima Qian), but given that gold and silver are significantly less ubiquitous than copper and copper alloys in Bronze Age China, another possible interpretation is that these three terms originally referred to three different alloys of copper, identified primarily by colour.

A more complicated five-level colour-based ranking system is recorded in various other documents which are either contemporary with or later than Shiji (online supplementary material). This probably reflects the popularity of the five-colour system in China, namely black, red, blue/green, white and yellow, which reflect the five elements (water, fire, wood, metal and earth, respectively), which are at the heart of Chinese metaphysics. Each colour is associated with one of the five visible planets (Mercury, Mars, Jupiter, Venus and Saturn) and also with heavenly animals (black tortoise, vermilion bird, azure dragon, white tiger and yellow dragon). The famous sword Zhanlu (湛卢), once owned by the well-known He Lv, King of the Wu State, in the Spring and Autumn period (ca. 537 BC), was believed to have been cast from the essence of all five of these metals (一名湛卢,五金之英, Wu Yue Chun Qiu 吴越春秋, The Third Year of He Lv 阖闾三年). In Huainanzi Dixingxun (淮南子-墬形训, Western Han, 206 BC–9 AD), there is a very interesting section arguing that the different levels of metal, differentiated by the five colours, correspond to different ages of the local earth (yellow, 500 years; blue/green, 800 years; red, 700 years; white, 900 years; dark black, 600 years). This could be one of the earliest documented recognitions in China that different grades of metal come from different geological contexts, although of course the ages, if geological, are grossly underestimated.

It can be further learned from another Eastern Han document (Shuowen, 说文, written by Xu Shen (ca. 58 AD–148 AD), Eastern Han) that the five levels of metal represent gold, lead, copper, silver and iron, respectively, which links metals explicitly to colours (淮南子墬形训: 黄金金, 银白金, 铅青金, 铜赤金, 铁黑金). By the Eastern Han (25–220 AD), it is entirely likely that the main metallic elements of antiquity were distinguished and recognised primarily by colour in China, as elsewhere in Eurasia. The distinguished modern geologist Zhang Hongzhao (1877–1951), however, questioned why tin was not amongst these five metals, which is discussed in more detail below (Zhang, 1927). Despite the fragmentary nature of the evidence in these early texts, what can be concluded with certainty is that a sophisticated hierarchical system of metal must have existed in China before the Qin dynasty, and also that the perception of metal probably changed from the onset of the Bronze Age to the Han dynasty. Moreover, colour was probably the most important indicator of such ranking.

References to the colours of metal are also encountered in the inscriptions of bronzes dated to the Western Zhou, which are certainly earlier than the texts above and presumably closer to the craftsman’s perception of metal during the contemporary periods. Greatly thanks to the excellent summary of the terminology associated with metals published by Li and his colleagues (Li and Li 2011, 2010; Li 2020), we can now identify the characters dedicated to metals, such as Fu, Lv (铝), Liu (镠), La (镴), Qiao (鐈) or Jin (金). Whilst the meaning of Jin is broader and thus context-related, Fu, Lv, La and Qiao very likely refer to the specific types of metal ingots (Rong 1964; Guo 1957; Tang 1960; Hua 1989; Huang 1995; Pollard and Liu 2022). Moreover, a variety of colours, including yellow, red, black and white, are found in the bronze inscriptions to describe or differentiate metals, such as Xuan Liu Chi Lu (black Liu and red Fu). Even earlier literary evidence on metal and its colour can be found in the oracle bones at Anyang. So far, no systematic investigation has yet been published on the metal-related information seen in the oracle bones (Tang J. pers. comm.) but two examples are given in Huang (1995) . Both mention casting of the yellow Lv (铸黄吕) and one was actually ordered by the Shang king (王其铸黄吕). Whilst reconstructing the exact internal hierarchical structure amongst these metal colours appears impossible given these elusive records of very short length, it is reasonable to argue that the colour-based metal hierarchy is very likely to have been projected to earlier periods such as Shang and Western Zhou when complex social structures and bronze ritual system were already highly developed.

Alloying technology

The book Rites of Zhou (Zhou Li, 周礼, dated to late Eastern Zhou, 770–221 BC) has been a core text in the development of the study of archaeological bronzes in China. One section (Kao Gong Ji, 考工记, the Book of Diverse Crafts) talks about preparing the alloy for casting:

周礼-考工记: 凡铸金之状: 金与锡黑浊之气竭, 黄白次之; 黄白之气竭, 青白次之; 青白之气竭, 青气次之。然后可铸也。

The Rite of Zhou - Diverse Crafts: the state of casting: melting Jin and tin produces initially dense black smoke, followed by yellow-white smoke, blue-white smoke, cyan-blue smoke, in sequence, until the end. Then ready for casting.

The best-known (and most-discussed) section in the work is named the Record of Diverse Technology (Kao Gong Ji). It purports to give a series of ‘recipes’ for the manufacture of specific object type (bells/vessels, axes/hatchets, daggers/halberds, large knives, swords, reflective and concave mirrors; Table 1) in terms of a set of combinatorial ratios for two components Jin (金) and Xi (锡). Xi is conventionally interpreted as tin, but the true meaning of this character has been at the heart of the debate on the ‘six recipes’ for decades (Chikashige 1918, 1930, 1936; Dono 1930, 1932; Liang 1925; Zhang 1958; Sun 2011; Liu et al. 2015; Li et al. 1984; Hua 1990; Sun et al. 2018; Pollard and Liu 2022). Initially, interest in this text was focussed on using the chemistry of the objects to fix more precisely the date of the text, to ascertain whether the Rites of Zhou was created in the Zhou dynasty (ca. 1046–221 BC) or at a later period (Liang 1925). Subsequently, however, it was argued that these written records might help to establish the chronology of otherwise undated bronzes. However, the main issue here is that the interpretation of these ‘six recipes’ is extremely problematic, since they do not appear to correspond to the known compositions of the analysed named objects from the Zhou.

The Record of Diverse Technology was and continues to be referenced in an enormous number of publications concerned with the relationship between the typology of a vessel and the proportions of major elements in the metal, from Chikashige (1918) to Yang (2015). The rationale for adding to this corpus of literature here is that any reconciliation of this text with the evidence from the material record might help to create a link between the perception of the material and the objects.

The original form of the text refers to the two components mentioned above (Jin (金) and tin (锡)) and follows the formula ‘The Jin is divided into six, tin occupies one. This is the receipt for bells and tripod-vessels (钟鼑之齐: 六分其 “金”而锡居其一). The Jin is divided into five, tin occupies one (斧斤之齐: 五分其 “金”而锡居其一)…..’ and so on (Table 1). As noted above, there is ambiguity about whether Jin means metal generically, or copper specifically, and phrases such as ‘divided into parts, tin occupies one’ give rise to two possible (and intensively debated) interpretations of these recipes (see references above). Here we wish to explore some different ideas, including a third possibility for Jin — that it is a pre-formed alloy of copper, containing some tin and lead, but is not pure copper. Furthermore, we explore the idea that the combinatorial recipe might refer not to weight, but to liquid volume. This would be rational in a metallurgical environment which focusses almost exclusively on casting technology, and is an interpretation which might be consistent with the statement given above on preparing alloys for casting from the Book of Diverse Crafts. In this scenario, the liquid to be poured into the mould would need to be pre-mixed before casting (just as it would have to be pre-prepared if it was made by melting together weighed metal), but as a volume ratio — e.g. six crucibles of liquid copper to one of tin making up the casting liquid (Yang 2015). In practice, it is only a minor variation, but it would have been very difficult to control the precise composition, and could reflect a major difference in perception.

The two traditional interpretations of the six recipes focus on how to read the recipes themselves. Interpretation I (in the literature) assumes that Jin is a generic term, and refers to the total amount of metal present. In this case, the first formula (‘The Jin is divided into six, tin occupies one’) would translate as the overall alloy being divided into six parts, five of which are pure copper and one is tin (copper:tin = 5:1, or copper = 5/6 (83.3%), tin = 1/6 (16.7%)). The alternative interpretation (interpretation II in the literature, Table 1) argues that Jin in fact stands for copper alone, in which case for the first recipe copper comprises six parts (6/7 = 85.7%) and one part tin (1/7 = 14.3%). It is worth noting, however, that both interpretations equate Jin with copper and Xi with tin in the calculation.

In order to calculate the composition of a mixture by volume, we take the densities of pure copper and pure tin around their respective melting points to be approximately 8 g cm−3 and 7 g cm−3. Assuming no losses, Table 1 shows the chemical composition of objects made by volume combination, where liquid I and liquid II correspond to the two different ways of interpreting the combinatorial formulae, as before.

The main problem that all scholars have struggled with is that the predicted tin concentrations are uniformly higher than expected. It is not easy to compare the recipes with analytical data from objects, though this has been debated for nearly 100 years (see summary in Liu et al. 2015). This is largely because that the objects which were cast according to the six recipes, if there were any, were very likely distributed with other objects in circulation, and perhaps no longer identifiable in archaeology. The current alloying data already exhibits a huge variety. Even if some objects appear chemically consistent with the six recipes, it is still uncertain that they were intentionally alloyed based on these recipes. One interesting dataset is the analyses of 13 Ge (halberd) blades from the Shanghai Museum published by Zhao et al. (1992), which give an average composition of Cu = 79%, Sn = 16% and Pb = 3.9%. From the six recipes, the lowest tin prediction for halberds (ge) is that using the liquid combination model (I), which gives Cu = 82% and Sn = 18%. This is reasonably close in terms of copper and tin, but the key discrepancy is of course the presence of 3.9% lead, which is hard to explain if Jin (金) is taken to mean copper, and if Xi 锡 is uniquely tin. This level of lead is too high to have entered the alloy accidently (as a contaminant in the copper), and so we must either assume that Xi 锡 is not just tin, or that Jin 金 is not pure copper. The possibility that Jin refers to a pre-fabricated copper-rich alloy must be considered. In a study of the chemical composition of pre-Qin copper coinage (Pollard and Liu 2021), we have suggested that the best explanation for the alloy composition of these coins is that they fit a mixing line between two starting components — one containing copper, lead and tin (similar to the composition of the bronze used to cast contemporary ritual vessels), and one containing only copper and lead. The idea that Jin was a prepared alloy of some sort seems to be worth further consideration, and, although it is far from decisive, it is worth noting that the lowest set of tin concentrations from the six recipes is given by the liquid combination model under assumption I.

The existence of these six formulae has been extremely important in the interpretation of chemical data from Chinese bronzes, and no doubt discussion will continue for some time to come. Their principal significance, however, is not so much whether the recipes relate to reality, or how accurate they are, but more that they firstly indicate a systematic and regulated approach to metal production during the Zhou dynasty, and also that we still do not know what Jin and Xi mean.

The perception of lead and tin in Chinese antiquity

A lack of distinction, or at least some ambiguity, between lead and tin is historically common across many Eurasian cultures. Bassam (2002) notes that there is ambiguity between the terms for lead and tin in medieval Arabic alchemy. He states that Jābir ibn Hayyān, writing (probably) in the late 8th c. AD (and latinized as Geber), usually referred to both ‘rasas usrub’ and ‘rasus qala ‘i’ (terms thought to relate to tin and lead) as ‘rasasan’ because of the similarity between their properties. In the Roman world, Pliny the Elder (c. AD 23–79), in his Natural Philosophy, refers to tin as ‘white lead’ and lead as ‘black lead’ (Rackham 1952, Book XXXIV, p. 241). Elsewhere (Rackham 1952, Book XXXIV, p. 199), in his famous description of the manufacture of bronze statues, Pliny states:

The proper blend for making statues is as follows, and the same for tablets: at the outset the ore is melted, and then there is added to the melted metal a third part of scrap copper, that is copper or bronze that has been bought up after use. This contains a peculiar seasoned quality of brilliance that has been subdued by friction and so to speak tamed by habitual use. Silver-lead is also mixed with it in the proportion of twelve and a half pounds to every hundred pounds of the fused metal.

Interestingly, as well as making it clear that a third of the weight of the statue is scrap copper or bronze, the explicit justification for this practice is not economic, but the fact that it has a ‘seasoned quality’ of ‘subdued brilliance’. This suggests that in this case a bright and shiny appearance was not the desired property of metal. However, the term plumbum argentarium used by Pliny and translated by Rackham as ‘silver-lead’ is somewhat obscure. Rackham states that ‘Spanish silver lead’ consists of equal amounts of tin and lead. Other authors, however (e.g. Thomson 1830, 57), have asserted that plumbum argentarium is actually tin, citing the chemical analyses of Klaproth, and also referring to the terminological ambiguity between white lead and black lead. The analyses of Klaporth (1815) quoted by Thomson cannot, however, be used to support this conclusion, since the statues to which this refers contain both lead and tin (usually with more lead than tin). The true nature of plumbum argentarium therefore remains debatable, and perhaps not clearly definable in purely modern terminology. Picon et al. (1967, 161–162) have argued that argentarium does not relate directly to the metal silver, but is descriptive of colour, in the same way as plumbum nigrum and plumbum album refer to black and white lead, which we would interpret as Pb and Sn.

It is widely recognised that metal production in Bronze Age China was underpinned by copper, tin and lead (Mei et al. 2015; Liu 2016). However, there remains a controversy about whether tin and lead were differentiated in practical terms. The character tin (锡) often occurred together with Jin (金), as seen above in the six recipes (Table 1) and many other sources. But the character lead, or Qian (铅), was much less recorded in all the texts we have searched. Interestingly, even in much later documents, such as Yupian (玉篇, Jade Chapters, ca. sixth century AD) and Zhengzitong (正字通, Ming dynasty, 1368–1644 AD), lead was considered black tin, whereas tin is called white tin, which is the reverse of the nomenclature used by Pliny. Such ambiguity between tin and lead in China was perhaps first noted by Zhang Hongzhao in Shiya (石雅), who pointed out that in the earliest historical documents the five levels of metal did not include tin. Instead, tin was considered to be an intermediate between silver and lead (Zhang 1927), thereby also echoing the term plumbum argentarium used by Pliny. A different view was expressed by Erya (尔雅, 221 BC–9 AD), the earliest Chinese dictionary, which states that the best-quality tin is called lead. What is more intriguing is that tin was likely not to have been considered a metallic substance in early China. Wu Dawei suggested that the earliest form of the character tin did not contain the metal radical before the Ming dynasty (Zhang 1927). Whilst many of these textual records might appear ambiguous, contradictory or speculative, they do sound a note of caution for scholars interested in the alloying technology of ancient China, and elsewhere. If tin and lead were indeed used interchangeably, perhaps we have to reconsider all of our interpretations based on the chemical data.

However, it would seem reasonable from the chemical data to assume that, despite the apparent terminological ambiguity, in practice, tin and lead were distinguished, at least by their effects on the finished object. We have shown elsewhere (Liu et al. 2020) that the choice of alloy for the ritual bronze vessels at Anyang (ca. 1200–1046 BC), the capital of the late Shang dynasty, was strongly affected by the status of the individual for whom they were made. The ritual bronzes for the top elites at Anyang are most obviously illustrated by the contents of the tomb of Lady Fuhao, the consort of the King Wu Ding, dated to Anyang phase II (ca. 1230 BC–1190 BC; for the details of the Anyang chronology, see Fig. S1 in Liu et al. 2020). Her tomb, which remained intact throughout antiquity, has yielded the richest discoveries at Anyang, with over four hundred bronze objects adding up to 1.6 tonnes of metal, along with many other materials including jade, white pottery, ivory and human/animal sacrifices. Her ritual bronzes have a very narrow range of compositions (~ 15–20% for tin and lead ~ 0–6%, Fig. 1), whereas contemporary objects from lower elite contexts show a much wider range of compositions. During the succeeding phase III (ca. 1190–1120 BC) of Anyang, Zhao (2004) has shown that the alloying practice at Anyang changed completely, from one of high-tin low-lead to high-lead low-tin. It is highly unlikely that these systematic variations could have been achieved without the ability to distinguish between tin and lead.

This implies that those responsible for the casting knew how to produce specific alloys for particular patrons. It also seems likely that the patrons would have judged the quality of their efforts from the colour of the vessels. This may have been of particular importance in ritual bronzes, which were used as prescribed sets of vessels of similar or graded sizes, and where it is reasonable to assume that consistency of colour was also required (see the ‘A hierarchy of the metals’ section). Chase (1994), Fang and McDonnell (2011) and Mecking (2020) performed a series of simulated experiments to reveal the links between the alloying recipes and the final colour of the objects. This enables us to use their experimental results to predict the colour of the actual archaeological objects. Figure 1 plots the percentages of tin and lead for the bronze ritual vessels from the tombs of Fuhao, M54, M1046 and M18 from Anyang, specified by their vessel type (The Institute of Archaeology 1980; Zhao 2004; Liu et al. 2007; Zhao et al. 2008). The background colours are averaged results from the slow cooling experiments done by Chase (1994), Mecking (2020) and Fang and McDonnell (2011). Considering the variation of alloying elements in the casting process (e.g. tin vaporised at high temperature) and analytical uncertainty due to corrosion and variations in the instruments used, we choose to merge the colours of the objects into the same one (by averaging the results from the simulation experiments) if their tin variation is less than 5% and lead variation less than 2%. As expected from the highly controlled range of tin and lead, Fuhao’s bronze ritual vessels appear to present in only one colour. In a later period, in tomb M1046, which is that of a high military official from Anyang phase IV (ca. 1120–1045 BC), it appears that all these bronze ritual vessels also show the same colour, regardless of object type. Because of the high percentage of lead, which is very likely to have been intentionally added, it has been assumed that these objects in M1046 were made simply for burial. Whilst we do not have experimental data on what the exact colour would have been (because the composition is outside the range of all the published experimental compositions), it is reasonable to suggest that the colour of the Fuhao vessels would have been less red and more silver and golden than those of the M1046 assemblage. In contrast, ritual vessels from tombs M54 and M18 probably showed two or three different colours, which is ultimately due to their relatively less well-controlled alloying recipe or casting process. In M54, one Gu vessel contains tin up to 27.5% (with 2% lead). Such high-tin low-lead composition results in a highly silvery colour, which would appear rather different from the others. Tomb M18, the lowest socially ranked of the three, illustrates the most diverse picture. In addition to highly silvery vessels (e.g. one Jue with 25% tin and little lead), it also has a ding vessel which is red (almost pure copper without any alloying). It should bear in mind that the colour is not only defined by the alloying recipes. Other factors such as the cooling process and the degree of polishing should be taken into consideration. Whilst they are not very likely to change the result in Fig. 1, simulation experiments which have more alloying recipes and follow closely the ancient practice should be carried out (Dong and Su 2022).

All of this strongly indicates that lead and tin were individually identifiable, despite the ambiguity in the terminology used to describe different materials, in particular tin and lead. How do we reconcile this? A reasonable interpretation (which would also apply to other cultures) is that tin and lead were essentially viewed as the same material, but which could manifest itself as more like lead or more like tin (and possibly including silver, similar to mercury-sulphur in alchemy), depending on conditions. This would be entirely in keeping with the natural philosophy of the time, which emphasised the mutability of various materials. Base metals could be purified into gold by repeatedly processing to remove the ‘elemental’ properties responsible for their base nature. Consequently, it seems reasonable to assume that, in their minds, lead could be converted into tin, and vice versa.

A more practical interpretation is based on the observation that the physical properties of lead and tin are similar, and that some of their effects on copper are therefore broadly interchangeable. Superficially, this may be seen to be the case. Both metals in the pure state are soft pliable silvery white metals, with low melting points (Sn 232 °C; Pb 327 °C), although lead is nearly twice as dense (11.34 compared to 5.77 g cm−3), meaning that pure lead and tin are easily differentiated by specific gravity. More significantly, as shown in the phase diagrams of copper-tin (Copper Development Association 1992), both reduce the melting point of copper significantly, with concomitant effects on casting temperatures and energy requirements — in fact, tin is more effective in reducing melting temperature than lead on a weight-for-weight basis. It must be noted, however, that the colour of an alloy is highly sensitive to casting conditions and patination, deliberately induced or otherwise. It is well known that the addition of tin to copper between 4 and 16% increases the tensile strength and hardness of the alloy, but also causes the metal to become increasingly brittle (e.g. Evans 1923: vol. 4, 68–72). Above 19% Sn, the presence of the hard δ-phase renders the alloy too brittle for any mechanical purposes. The addition of lead above 4%, being largely insoluble in copper, normally produces globules of the soft lead-rich phase distributed throughout the structure, giving the alloy greater plasticity. All in all, we might deduce that, although the effects are not identical, the addition of tin and/or lead to copper does give at least some comparable practical results — a change in colour, increased hardness, lower melting point and increased fluidity.

In terms of the perception of metal, what seems clear is that there must have been an ambiguity in identifying and naming metals. The clearest example is the mutability of lead and tin — clearly understood to be different, but probably perceived as being different manifestations of the same substance. This could conceivably help in understanding the term Jin (金). The previous debate around this term has been around whether it refers to metal (generically) or to copper (specifically). It would seem reasonable to consider that it refers to a mutable alloy, primarily based on copper, but reflecting, at least in the earlier periods, the alloys referred to as ‘yellow copper’, ‘white copper’ and ‘red copper’.

The metals available to Bronze Age Chinese metalworkers and the social implications attached to their locality

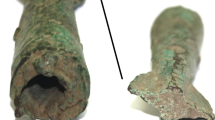

In terms of the work of the bronze founder, we need to think about metal, not in terms of simple chemical elements, but more in terms of the raw materials available at the time. For the foundry worker, this could be relatively pure metal, but perhaps also other forms of ingot in which the metal is circulated. The recent decades of excavation in China have yielded rich materials to address this question. It is unequivocal that the Erlitou period, at the beginning of the Bronze Age in Central China, already evidenced the existence of objects made primarily from lead. Archaeologists discovered a lead piece dated to Erlitou phase III and also a lead knife from phase IV, containing lead at 95.9% (with 1.97% Sn, 2.13% Cu) and 60.77% (3.76 Sn, 35.46% Cu) respectively (IA CASS 1999). In the subsequent period of Erligang (Zhengzhou, 1500–1300 BC), there is evidence for the existence of both lead and tin blocks, but without published chemical analyses. Significantly, all of them were discovered in the bronze workshop of Zijinshan at Zhengzhou. A few copper ores were also recovered from the same site (Henan Institute of Archaeology 2001). The subsequent major site of Anyang has seen over 500 lead objects recovered in a variety of forms, from weapons to ritual vessels, but again with no detailed chemical analyses published. They are also distributed in the tombs at various social levels (Nie 2019). It is worth noting that in 2015 a freshly discovered hoard of lead ingots came to light at Anyang. A total of 3.04 tonnes of lead ingots were excavated in the southern area of Anyang. They are all huge pieces in random shapes, with lead contents ranging from 75 to 98% and copper up to 20% and noticeable amounts of silver and antimony by SEM–EDS or ICP-MS (Tang et al. 2018). Compared to the number of lead objects, tin ingots/objects have been found only rarely during the Shang period, but are much more ubiquitous in the Western Zhou. A number of states such as Ying, Yu, Ji or Peng have yielded tens of tin objects, including various types of ritual vessels, weapons, tools and ornaments. Also, scholars have found the evidence of tinning for the weapons recovered from Zhouyuan (Nie 2019). This archaeological evidence leads us to conclude that (at least some) metalworkers in Bronze Age China had access to raw materials containing lead at greater than 75%, and probably also to tin-rich objects.

As noted above, the ancient Chinese literature contains many references to different metallic materials, usually referred to by colour. For example, Zhang (1927) refers to the five metals discussed above identified by colour (gold, silver, copper, lead and iron), but notes that they are not always specific names, and that in particular the three noble metals (gold, silver and copper) are not necessarily identified with the elements gold, silver and copper. He refers to metals such as red silver, yellow silver, red tin and yellow copper, which do not necessarily correspond to silver, tin or copper. Occasionally, these substances are identified with a geographical region. As quoted above, two of the nine states (Yang and Jing) in Yugong are said to have produced all three types of metal (yellow, white and red). A slightly more explicit record derives from the Book of Poetry (the earliest Chinese poetry collection, ca. eleventh to sixth century BC), which mentions capture of the southern metal (大赂南金). Similar descriptions can also be found in the inscriptions on bronze ritual vessels. Geologically, a majority of copper and tin mines are indeed along the Yangtze River in southern China, which seems to be consistent with the idea of the so-called southern metal as seen from the Central Plains.

A slightly flippant analogy might possibly be useful to help explore further the concept of the perception of metal in ancient China. In modern as well as historic times, tea has been bought in China on the basis of a number of qualities, but often geographical location is dominant. Thus, particular brands of ‘dragon’s well green tea’ are often sold at a premium, partly on the basis of where it comes from, the reputation and quality of the leaves, but also because of the spiritual character of the source in relation to some site of mythical significance. From the mythological literature quoted above, it is clear that in ancient times metal from specific mountains was seen as being of particular significance. It seems highly likely that, as with tea, a similar combination of geographical and spiritual significance, together with colour and other properties, might have been the way in which the sources of metal were described and identified, and also how the metal was procured and used.

Conclusions: the mental world view of metalworkers in Ancient China

One of the aims of modern archaeometallurgy is to understand the processes carried out by ancient metalworkers, which implies attempting to understand the intentionality behind the decisions taken by these metalworkers. This is a hard task, not least because there is a gulf of understanding between ancient and modern perceptions of the natural world. It is now axiomatic that the use of metal in the past was not only based on physical and material properties, but also on other characteristics such as colour and, above all, on social perceptions of metal (e.g. magic or religion in contrast to science — Gosden 2020). In order to better understand what they thought they were doing, ideally, we would like to be able to ‘see the world’ as the metalworkers did. Traditionally, and most powerfully, this is achieved by careful examination of the objects produced, alongside, where possible, the physical examination of the debris of the mining and manufacturing processes. However, this effectively only gives us a story written in a modern language. In order to ‘translate’ this into the ‘language’ used by the metalworkers themselves, we need to try to piece together the elements of this language from various other sources, including written sources. The difficulties of doing this are well rehearsed, but here we have attempted to combine evidence from chemical analyses and Chinese literary sources.

It is clear that many factors could affect the perception of metal evolved from the beginning of the Bronze Age to the Han dynasty and it is not feasible now to reveal all of them. One starting point might be the three ‘levels’ of metal identified by colour (yellow, white and red), through a set of five metals, increasingly identified with gold, silver, copper, iron and lead. Such a world view of metal is ultimately linked to the contemporary social context (Smith 1975), as well as to the dominant metaphysical paradigm. Bronze Age China, no matter in which phase, was a highly hierarchical society. It was underpinned by a ritual system which required not just a certain set of beliefs and narratives, but also distinctive materialisation. The distinctiveness of metal, deriving from its rarity and novelty (Smith 1970), can easily materialise the underlying social hierarchy and contribute to a unified social identity, particularly empowered by the mythological narratives. Therefore, the mental world view of the ancient Chinese craftspeople is defined to a large extent by the broad social settings and the technologies developed by them, such as different alloying recipes according to social status, or the regionality of metal, either as a raw material or finished objects, which can be employed to underpin the social functionality of metallurgy. Under this broad picture, the world view of ancient metallurgists needed to be fluid due to variations in the complicated practical situations, such as the requirements of people in different social strata, or the ever-changing political situation, giving rise to change or shortages in the metal supply system.

A better understanding of the worldview of the ancient craftspeople in relation to technological process might spark new inspiration on how to interpret not only the metal objects but also the literary records. In common with many other cultures, the Chinese literature shows ambiguity towards the nature of lead and tin, and also of silver. The analytical data, however, shows that the metalworkers themselves were more than capable of distinguishing between the different effects of lead and tin, as evidenced by the clear control exerted over the composition (and colour) of the vessels produced for people of different social status at Anyang. Whilst the bronze ritual vessels at Anyang were mostly used in sets (Bagley 1987; Rawson 1990), it is still intriguing to discover that the top-elite metal assemblages such as that of Fuhao show one colour. This suggests that although multiple sets of bronze ritual vessels, produced probably in different batches or workshops, were buried together, as demonstrated by the bronze inscriptions, these objects were all dedicated to her and subject to high standardisation. The chemical analysis and the predicted colour of the metal objects can offer an extra line of evidence for archaeologists to identify objects belonging to different sets in the future.

It also allows us to better appreciate the apparent contradiction posed by considering alchemical perceptions of all metals as being combinations of various ‘essences’, which can be varied (by nature or by human manipulation) to give particular materials. Using a more fluid view of the identity of metal might also help resolve the nature of Jin (金) as being at least an impure form of copper, if not an alloy with lead and perhaps tin, rather than elemental copper. Possibly the long-standing debate about the veracity of the ‘six recipes’ from the Rites of Zhou might be aided by such an interpretation.

References

Bagley RW (1987) Shang ritual bronzes in the Arthur M. Sackler Collections. Arthur M. Sackler Foundation

Bassam IE-E (2002) Lead and tin in Arabic alchemy. Arab Sci Philos 12:139–153

Bebber MR, Key AJM, Fisch M, et al (2019) The exceptional abandonment of metal tools by North American hunter-gatherers, 3000 B.P. Scientnfic Reports 9(5756)

Binford LR (1962) Archaeology as anthropology. Am Antiq 28(2):217–225

Brill RH, Wampler JM (1967) Isotope studies of ancient lead. Am J Archaeol 71(1):63–77

Cass IA (1999) Yanshi Erlitou. Zhongguo shehui dabaike quanshu press, Beijing (in Chinese)

Chase WT (1994) Chinese bronzes: casting, finishing, patination and corrosion. Ancient and historic metals: conservation and scientific research Los Angeles: Getty Museum

Chernykh EN (2017) Nomadic cultures in the megastructure of the Eurasian world (Trans. I. Savinetskaya and P. Hommel). Moscow: LRC press

Chikashige M (1918) Chemical analysis of ancient copper-based objects in East Asia. Shirin 3(2):177–211 (in Japanese)

Chikashige M (1930) Composition and reproduction of Han mirrors. Shirin 15(2):201–206 (in Japanese)

Chikashige M (1936) Alchemy and other chemical achievements of the ancient Orient: the civilization of Japan and China in early times as seen from the chemical point of view. Rokakuho Uchida.

Copper Development Association (1992) Equilibrium diagrams - selected copper alloy diagrams illustrating the major types of phase transformation. CDA Publication 94: 11/23

Dong Y, Su R (2022) New exploration of the Shang and Zhou bronzes. Nanfang Wenwu 3:235–242 (in Chinese)

Dono T (1930) Chemical studies on ancient Chinese coins. I Nippon Kagaku Kaishi 51(8):463–472

Dono T (1932) On the copper and ancient China. Bull Chem Soc Jpn 7(11):347–352

Eaton ER, McKerrell H (1976) Near Eastern alloying and some textual evidence for the early use of arsenical copper. World Archaeol 8(2):169–191

Evans UR (1923) Metals and metallic compounds. Edward Arnold, London

Falkenhausen LV (1993) On the historiographical orientation of Chinese archaeology. Antiquity 67:839–849

Fang J-L, McDonnell G (2011) The colour of copper alloys. Hist Metall 45:52–61

Gosden C (2020) A history of magic. Viking, London

Guo M (1957) Bronze inscriptions of Zhou dynasties Beijing: Science Press

Henan Institute of Archaeology (2001) Zhengzhou Shang site. Wenwu press, Beijing (in Chinese)

Holmyard EJ (1957) Alchemy. Penguin, Harmondsworth

Hua J (1989) The new exploration of Xuan Liu – the potential sources of tin in Shang and Zhou. Wenwu Baohu Yu Keji Kaogu 1:55–60 (in Chinese)

Hua J (1990) The chemical composition of Shang and Zhou bronzes and the interpretation of the six recipes. Science Press, The third international conference of Chinese history of Science. Beijing, pp 274–281

Huang X (1995) New discussion on Fu Lv inscription of Ge – the names of metal resorces in casting. Acad Seasonal Vol Forbidden City 1:63–74

Jaang L (2015) The landscape of China’s participation in the Bronze Age Eurasian network. J World Prehist 28:179–213

Killick D (2001) Science, speculation and the prigins of extractive metallurgy. In: Brothwell DR, Pollard AM (eds) Handbook of archaeological sciences. John Wiley, London, pp 483–492

Killick D (2004) Social constructionist approaches to the study of technology. World Archaeol 36(4):571–578

Killick D, Fenn T (2012) Archaeometallurgy: the study of preindustrial mining and metallurgy. Annu Rev Anthropol 41(1):559–575

Klaporth MH (1815) Chemische Abhandlungen Gemischten Inhalts. Berlin und Stettin Nicholaischen Buchhandlung

Kuijpers MH, (2018) A sensory update to the Chaîne Opératoire in order to study skill: perceptive categories for copper compositions in archaeometallurgy. J Archaeol Method Theory 25(3):863–891

Lechtman H (1977) Style in technology—some early thoughts. In: Lechtman H, Merrill R (eds) Material culture: styles, organization and dynamics of technology. West, New York, pp 3–20

Li J (2020) New interpretation of Fushou, Fuyue and Fuzhi – discussion of the evolution of the term copper. Wenbo 1:62–66 (in Chinese)

Li J, Li Y (2010) A study on Fulv: a kind of materials for bronze casting. Jianghan Kaogu 115:124–130 (in Chinese)

Li J, Li Y (2011) The concept of Jin and metal in the pre Qin texts. Stud Hist Nat Sci 30(4):460–471 (in Chinese)

Li Z, Hua J, Zhang H (1984) An investigation of the chemical composition of the Chinese bronze-alloy container in the Shang and Zhou dynasties. J Northwest Univ China 2:22–40 (in Chinese)

Liang L (1925) The alloying compositon in the Zhou Dynasty. In: Wang J, Zhang H, Liang L, et al. (eds) Ancient chemistry and alchemy of China. Chinese Scientific Book and Instrument Press pp.52–66 (in Chinese)

Linduff KM (2004) Metallurgy in ancient eastern Eurasia from the Urals to the Yellow River. Edwin Mellen Press, Lewiston, New York

Linduff KM, Mei J (2009) Metallurgy in ancient Eastern Asia: retrospect and prospects. J World Prehist 22:265–281

Liu R (2016) Capturing changes: applying the Oxford system to further understand the movement of metal in Shang China. University of Oxford, Unpublished

Liu L, Chen X (2012) The archaeology of China: from the late paleolithic to the early Bronze Age. Cambridge University Press, Cambridge

Liu R, Bray P, Pollard AM et al (2015) Chemical analysis of ancient Chinese copper-based objects: past, present and future. Archaeol Res Asia 3:1–8

Liu R, Pollard AM, Rawson J, Tang X, Bray P, Zhang C (2019) Panlongcheng, Zhengzhou and the movement of metal in Early Bronze Age China. J World Prehist 32(4):393–428

Liu R, Pollard AM, Cao Q et al (2020) Social hierarchy and the choice of metal recycling at Anyang, the last capital of Bronze Age Shang China. Sci Rep 10:18794

Liu Y, He Y and Xu G (2007) Chemical composition of bronze objects from M54 and M60 In: IA CASS (ed) Shang cemetery at Eastern Huayuanzhuang, Anyang. Beijing: Science Press, pp.289–296 (in Chinese)

Martinón-Torres M, Killick D (2015) Archaeological theories and archaeological sciences. The Oxford Handbook of Archaeological Theory. Oxford University Press. http://www.oxfordhandbooks.com. https://doi.org/10.1093/oxfordhb/9780199567942.001.0001

Mecking O (2020) The colours of archaeological copper alloys in binary and ternary copper alloys with varying amounts of Pb, Sn and Zn. J Archaeol Sci 121:105199

Mei J (2009) Early metallurgy and socio-cultural complexity: archaeological discoveries in Northwest China. In: Hanks BK, Linduff KM (eds) Social complexity in prehistoric Eurasia: monuments, metals, and mobility. Cambridge University Press, Cambridge, pp 2108–2118

Mei J, Wang P, Chen K et al (2015) Archaeometallurgical studies in China: some recent developments and challenging issues. J Archaeol Sci 56:221–232

Nie Z (2019) The study on lead and tin wares in Xia. Henan University Zhengzhou (in Chinese), Shang and Zhou dynasty

Picon M, Condamin J, Boucher S (1967) Recherches techniques sur des bronzes de Gaule romaine. II Gallia 25(1):153–168

Pollard AM (1988) Alchemy - a history of early technology. Sch Sci Rev 70:701–712

Pollard AM (2016) The first hundred years of archaeometallurgical chemistry: Pownall (1774) to von Bibra (1869). J Hist Metall 49(1):37–49

Pollard AM, Bray P, Hommel P et al (2018) Beyond provenance : new approaches to interpreting the chemistry of archaeological copper alloys. Leuven University Press, Belgium, Leuven

Pollard AM, Liu R, Rawson J et al (2019) From alloying composition to alloying practice: Chinese bronzes. Archaeometry 61(1):70–82

Pollard AM and Liu R (2021) Bronze alloying practice in ancient China - evidence from pre-Qin coin analyses. J Archaeol Sci 126: Online available

Pollard AM and Liu R (2022) The six receipts of Zhou – a new perspective on Jin (金) and Xi (锡). Antiquity accpted

Ponting M, Levene, D. (2015) Recycling economies, when efficient, are by their nature invisible. In: Geller MJ (ed) The archaeology and material culture of the Babylonian Talmud. Leiden: Brill pp.39–65

Rackham H (1952) Pliny. Natural History. Harvard University Press, Cambridge, MA

Rawson J (1990) Western Zhou ritual bronzes from the Arthur M. Sackler Collections. Arthur M. Sackler Foundation, Washington, D.C

Rawson J (2017) China and the Steppe: reception and resistance. Antiquity 91(356):375–388

Rehren T, Pernicka E (2008) Coins, artefacts and isotopes—archaeometallurgy and archaeometry. Archaeometry 50(2):232–248

Rehren T, Boscher L, Pernicka E (2012) Large scale smelting of speiss and arsenical copper at Early Bronze Age Arisman Iran. J Archaeol Sci 39(6):1717–1727

Roberts BW, Thornton CP, Pigott VC (2009) Development of metallurgy in Eurasia. Antiquity 83(322):1012–1022

Roberts BW and Thornton. CP (2014) Archaeometallurgy in global perspective: methods and syntheses. Springer Science & Business Media

Rong G (1964) Niaoshukao. Journal of Sun Yat-sen University 1 (in Chinese)

Roux V (2010) Technological innovations and developmental trajectories: social factors as evolutionary forces. In: O’Brien MJ, Shennan SJ (eds) Innovation in cultural systems. The MIT Press, Contributions from evolutionary anthropology Cambridge, Massachusetts London, England, pp 217–233

Scott DA (1996) A note on the metallographic preparation of ancient lead. Stud Conserv 41(1):60–62

Senna-Martinez JC and Luís E (2016) Technique and social complexity: development trajectories of peasant societies with metallurgy during the Bronze Age of Western Iberia. In: Soares J (ed) Social Complexity in a long term perspective, Session B15 of UISPP 17th Congres. Setúbal Arqueológica, 115–130

Smith CS (1970) Art, technology, and science: notes on their historical interaction. Technol Cult 11:493–549

Smith CS (1975) Metallurgy as a human experience. Metall Trans A 6A:603–623

Sun F (2011) Alloying compositions of bronze mirrors in the former museum of East Asian Art in Berlin and the spread of Kao gong Ji. J Naitonal Mus China 5(5):36–39 (in Chinese)

Sun W, Zhang L-P, Guo J et al (2018) Comment on ‘Did China import metals from Africa in the Bronze Age?’ Archaeometry 60(5):1036–1039

Tang L (1960) The preliminary study on the bronze agricultural tools in ancient China. J Forbiden City 2:10–34

Tang J, Jing Z, He Y et al (2018) The brief report on the hoard of lead ingots in North Liujiazhuang. Anyang Kaogu 10:32–41 (in Chinese)

The Institute of Archaeology C (1980) Fu Hao tomb Yinxu Fuhao Mu. Beijing: Cultural Relics Publishing House (in Chinese)

Thomson T (1830) The history of chemistry. Colburn and Bentley, London

Watson B (1961) Records of the grand historian (by Sima Qian). Columbia University Press, Hong Kong and New York

Yang H (2015) New discussion on the six recipes. Wenbo 1:35–38 (in Chinese)

Zhang H (1927) Shiya. China Geological Survey (in Chinese)

Zhang Z (1958) New discussion of the six recipes. Tsingua Univ (natural Science Edition) 4(2):159–166 (in Chinese)

Zhang C, Pollard AM, Rawson J, et al (2019) The rise and decline of China’s major late Neolithic centres and the rise of Erlitou Antiquity Accepted

Zhao C (2004) Chemical analysis of the bronzes from Anyang. Kaoguxue Jikan 15:243–268 (in Chinese)

Zhao K, Chen R, Zhou W et al (1992) A study of the alloy composition of the Warring States coins. Stud Hist Nat Sci 11(1):32–44 (in Chinese)

Zhao C, Yue Z, Xu G (2008) Chemical analysis of bronzes from North Liujiazhuang M1046. Anyang Wenwu 1:92–94 (in Chinese)

Zhou S (1978) The study of the six recipes. Bull Chem 3:54–57 (in Chinese)

Acknowledgements

We would like to thank the two anonymous reviewers for their insightful comments.

Funding

This research is funded by European Research Council advanced project FLAME (Flow of Ancient Metal Across Eurasia 670010).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Liu, R., Pollard, A.M. Squeezing mind out of metal: combining textual evidence with scientific data for metallurgy in early dynastic China. Archaeol Anthropol Sci 14, 117 (2022). https://doi.org/10.1007/s12520-022-01578-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12520-022-01578-3