Abstract

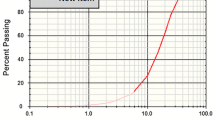

During quarry design, most of the crushers selected at this stage are not appropriate for the muck-pile size ranges produced after rock fragmentation. Therefore, fragmentation performance, quality rating, and fragment size distribution prediction for suitable crusher selection were investigated to bridge the gap of mismatched crushers in quarries. Bulk density and P-wave velocity were determined in the laboratory. In situ rebound hardness values were obtained for the different case study sites. Also, rock quality designation (RQD) and rock mass rating (RMR) were determined. Field data obtained includes geometrical parameters, crusher specifications and information, a digital image of the muck pile, and crusher data. Particle distribution cumulative curves for 183 digital blast images were utilized to determine the 80% passing size using WipFrag. Models for crusher selection were developed using artificial neural network soft computing techniques with nine parameters (5 uncontrollable parameters and 4 controllable parameters) as inputs, and thereafter, the performance of the models was evaluated. The results of mean bulk density, rebound hardness value, P-wave velocity, RQD, and RMR are 2886.4 kg/m3, 46.1, 4153.4 m/s, 64%, and 71, respectively. The muck-pile particle size distribution analysis revealed that 80% passing size and Uniformity Index are 387.2 mm and 1.78, respectively. In addition, the relationship between Uniformity Index and powder factor suggests that a high powder factor can result in an increased Uniformity Index. The result of crusher classification is in the range of 1–5 unique classification identifier (UCI) for large and small crusher gaps. Three models were developed, and it was discovered that the third model, trained with eighteen (18) inputs and fifteen (15) neurons using a hybrid transfer function, has the highest prediction accuracy based on the model correlation coefficient. This model will select a suitable crusher that will match the resulting muck-pile particle distribution, thereby eliminating mismatches in crushers in quarries.

Similar content being viewed by others

Data availability

Data used in this study is available on request.

References

Adebayo B, Bolariwa HT (2023) Determination of suitable explosives for dolomitic marble and granodiorite using blastability characteristics. Aspects Min Min Sci 11(1):1209–1211

Adebayo B, Mukoya JGM (2019) Rock properties and machine parameters evaluation at Rössing uranium mine for optimum drill performance. Southern African Instit Min Metallurg 119:459–464

Adebayo B, Taiwo BO, Afeni TB, Aderoju RO, Faluyi JO (2023) Improvement of drill bit-button performance and efficiency during drilling: an application of LSTM model to Nigeria Southwest Mines. J Min Environ 14(4):1121–1139

Adebayo B, Adeniyi PR, Agbalajobi SA (2015) Blastability characteristics of ewekoro limestone using rock mass classification. In: Proceedings 24th International Mining Congress of Turkey. IMCET, pp 867–873

Afeni TB, Lawal AI, Adeyemi RA (2020) Re-examination of Itakpe iron ore deposit for reserve estimation using geostatistics and artificial neural network techniques. Arab J Geosci. https://doi.org/10.1007/s12517-020-05644-9

Aladejare AE, Onifade M, Lawal AI (2020b) Application of metaheuristic based artificial neural network and multilinear regression for the prediction of higher heating values of fuels. Int J Coal Prep Util. https://doi.org/10.1080/19392699.2020.1768080

Aladejare AE, Kärenlampi K, Lawal AI (2020a) Application of artificial intelligence for characterization of rocks from Otanmäki, Finland. In: ARMA US Rock Mechanics/Geomechanics Symposium 2020 Jun 28. ARMA

Amoako R, Jha A, Zhong S (2022) Rock fragmentation prediction using an artificial neural network and support vector regression hybrid approach. Mining 2(2):233–247. https://doi.org/10.3390/mining2020013

ASTM (2016) ASTM D5731–16 standard test method for determination of Point Load Strength Index, of rock and application to rock strength classification. ASTM International, West Conshocken, PA, USA

Babaeian M, Ataei M, Sereshki F, Sotoudeh F, Mohammadi S (2019) A new framework for evaluation of rock fragmentation in open-pit mines. J Rock Mech Geotech Eng 11(2019):325–336

Bahrami A, Monjezi M, Goshtasbi K, Ghazvinian A (2011) Prediction of rock fragmentation due to blasting using artificial neural network. Eng Comp 27:177–181

Bamford T, Esmaeili K, Schoellig AP (2021) A deep learning approach for rock fragmentation analysis. Int J Rock Mech Min Sci 145(2021):1–13

Chandrahas NS, Choudhary BS, Teja MV, Venkataramayya MS, Prasad NK (2022) XG boost algorithm to simultaneous prediction of rock fragmentation and induced ground vibration using unique blast data. Appl Sci 12(10):5269

Ebrahimi E, Monjezi M, Khalesi MR, Armaghani DJ (2016) Prediction and optimization of back-break and rock fragmentation using an artificial neural network and a bee colony algorithm. Bull Eng Geol Env 75:27–36. https://doi.org/10.1007/s10064-015-0720-2

Elahi TA, Hosseini M (2017) Analysis of blasted rocks fragmentation using digital image processing (case study: limestone quarry of Abyek Cement Company). Intl J Geo-Eng 8:1–11

Esmaeili M, Salimi A, Drebenstedt C, Abbaszadeh M, Bazzazi AA (2014) Application of PCA, SVR, and ANFIS for modeling of rock fragmentation. Arab J Geosci 14:1–13

Hasanipanah M, Jahed Armaghani D, Monjezi M, Shams S (2016) Risk assessment and prediction of rock fragmentation produced by blasting operation: a rock engineering system. Environ Earth Sci 75:1–12. https://doi.org/10.1007/s12665-016-5503-y

Hosseini S, Mousavi A, Monjezi M, Khandelwal M (2022a) Mine-to-crusher policy: planning of mine blasting patterns for environmentally friendly and optimum fragmentation using Monte Carlo simulation-based multi-objective grey wolf optimization approach. Resour Policy 79:103087

Hosseini S, Poormirzaee R, Hajihassani M (2022) An uncertainty hybrid model for risk assessment and prediction of blast-induced rock mass fragmentation. Intl J Rock Mech Min Sci 160:105250. https://doi.org/10.3390/app12105269

ISRM (2007) Rock characterization testing and monitoring. In: Brown ET (ed) International Society for Rock Mechanics Commission. Pergamon Press, pp 75–105

Jasmin, J., Stjepan S., Mario G. and Boris K. (2017). Fragment size distribution of blasted rock mass, World Multidisciplinary Earth Sciences Symposium, IOP Conf. Series: Earth and Environmental Science 95 (2017) 042013, pp. 1 – 9.

Kahraman E, Kilic AM (2023) Determination of the effective blasting region by using fragmentation analysis: a field study. Iran J Sci 47(3):791–799

Karami A, Afiuni-Zadeh S (2013) Sizing of rock fragmentation modeling due to bench blasting using adaptive neuro-fuzzy inference system (ANFIS). Int J Min Sci Technol 23(6):809–813. https://doi.org/10.1016/j.ijmst.2013.10.005

Lawal AI (2020) An artificial neural network-based mathematical model for the prediction of blast-induced ground vibration in granite quarries in Ibadan, Oyo State, Nigeria. Sci Afr 8:e00413

Lawal AI, Akande JM (2013) Effects of controllable blasting variables on number of boulders generated after blasting in Ratcon and NSCE quarries, Ibadan, Oyo State, Nigeria. Intl J Eng Technol Sci Publishing Corp Germany 2(2):105–112

Lawal AI, Aladejare EA, Onifade M, Bada S, Idris MA (2020b) Predictions of elemental composition of coal and biomass from their proximate analyses using ANFIS ANN and MLR. Intl J Coal Sci Technol. https://doi.org/10.1007/s40789-020-00346-9

Lawal A. I., Onifade M., Abdulsalam J., Aladejare A. E., Gbadamosi A. R., Said K. O. (2020b). On the performance assessment of ANN and spotted hyena optimized ANN to predict the spontaneous combustion liability of coal. Combust Sci Technol , https://doi.org/10.1080/00102202.2020.1815196

Lawal, A. I., Adebayo, B, Afeni, T. B., Okewale, I. A. Ajaka, E. O., Amigun, J. O., Akinbinu, V. A. and Apena, W. O. (2023). Soft computing applications for optimum rock fragmentation: an advanced overview, Geotech Geol Eng pp. 1–26, https://doi.org/10.1007/s10706-023-02594-3

Michaux S, Djordjevic N (2005) Influence of explosive energy on the strength of the rock fragments and SAG mill throughput. Miner Eng 18(4):439–448

Monjezi M, Rezaei M, Varjani AY (2009) Prediction of rock fragmentation due to blasting in Gol-E-Gohar iron mine using fuzzy logic. Int J Rock Mech Min Sci 46(8):1273–1280

Said KO, Onifade M, Lawal AI, Githiria JM (2020b) Computational intelligence-based models for predicting the spontaneous combustion liability of coal. Int J Coal Prep Util. https://doi.org/10.1080/19392699.2020.1741558

KO Said M Onifade AI Lawal JM Githiria 2020a An artificial intelligence-based model for the prediction of spontaneous combustion liability of coal based on its proximate analysis Combust SciTechnol https://doi.org/10.1080/00102202.2020.1736577

Sayadi A, Monjezi M, Talebi N, Khandelwal M (2013) A comparative study on the application of various artificial neural networks to simultaneous prediction of rock fragmentation and backbreak. J Rock Mech Geotech Eng 5(4) Geosci 8:10819–10832. https://doi.org/10.1007/s12517-015-1952-y

Sereshki F, Hoseini M, Ataei M (2016) Fragmentation measurement using image processing. Intl J Min Geo-Eng 50(2):211–228

Shams S, Monjezi M, Majd VJ, Armaghani DJ (2015) Application of fuzzy \inference system for prediction of rock fragmentation induced by blasting. Arab J Geosci 8:10819–10832. https://doi.org/10.1007/s12517-015-1952-y

Taiwo BO, Adebayo B (2022) Improvement of blast-induced fragmentation using artificial neural network and BlastFrag© optimizer software. Mater Geoenviron 69(1):1–13

Taiwo BO, Ajibona AI, Idowu K, Babatunde AS, Ogunyemi BO (2023a) Improvement of small scale mine blast operation: a comparative application of hunter-point artificial neural network, support vector machine, and regression analysis models. Intl J Min Geo-Eng 57(2):205–213

Taiwo BO, Fissha Y, Palangio T, Palangio A, Ikeda H, Cheepurupalli NR, Kawamura Y (2023b) Assessment of charge initiation techniques effect on blast fragmentation and environmental safety: an application of WipFrag Software. Mining 3(3):532–551

Taiwo BO, Yewuhalashet F, Adamolekun LB, Bidemi OO, Famobuwa OV, Victoria AO (2023c) Development of artificial neural network based mathematical models for predicting small scale quarry powder factor for efficient fragmentation coupled with uniformity index model. Artif Intell Rev 56(12):14535–14556

Türker H, Özge A (2020) Investigation of blast fragmentation models in a sandstone quarry. Sci Min J 59(3):145–156

Acknowledgements

We also thank all the managers of selected quarries for free access to the different quarry faces.

Funding

The financial support for this work was provided by the TETFUND National Research Fund (NRF) with code (TETF/DR&D-CE/NRF 2020/SETI/30).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethical statement

The authors state that the research was conducted according to ethical standards.

Conflicts of interest

The authors declare no competing interests.

Additional information

Responsible Editor: Zeynal Abiddin Erguler

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Adebayo, B., Ajaka, E.O., Afeni, T.B. et al. Enhancing downstream operation through run-of-mine crusher selection model: an application of edge detection software and soft computing algorithms. Arab J Geosci 17, 123 (2024). https://doi.org/10.1007/s12517-024-11933-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-024-11933-4