Abstract

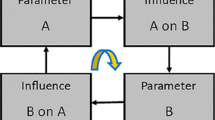

The main purpose of drilling and blasting (D&B) operations in mining and in a civil engineering project is rock mass fragmentation. Muck pile fragment size plays an important role in the efficiency of transportation and crushing and milling operations. Fragment size is a function of the characteristics of the rock mass, explosive type, and drilling and blasting pattern. The development of fragment size predictor models has been the output of many researches in the field of explosive engineering. In this research, a model for predicting the muck pile mean fragment size (X50) based on the response surface method (RSM) is presented. For this purpose, 97 data series from different cases are used for modeling. The purpose of this study is to model the X50 with regard to the individual impact of the effective factors and their interaction. In the suggested RSM-based model, the D&B pattern spacing to burden ratio, bench height to burden ratio, burden to hole diameter ratio, stemming to burden ratio, and a powder factor and two rock mass factors which included in situ block size and modulus of elasticity are used as effective factors on X50 as model response. The proposed RSM-based quadratic model consists of four quadratic, six linear, and 14 interaction terms. The statistical details of this model, conventional-related graphs, and RSM-specific analysis have satisfied the recommended model. For the X50, the bench height to burden ratio is more effective than the other independent factors; also, the most significant interaction is found to be between bench height to burden ratio and powder factor.

Similar content being viewed by others

References

Aler J, Du Mouza J, Arnould M (1996) Measurement of the fragmentation efficiency of rock mass blasting and its mining applications. Int J Rock Mech Min Sci Geomech Abstracts 33(2):125–139. https://doi.org/10.1016/0148-9062(95)00054-2

Alipour A, Mokharian M, Chehreghani S (2018) An application of fuzzy sets to the blastability index (BI) used in rock engineering. Periodica Polytechnica Civ Eng 62(3):580–589. https://doi.org/10.3311/PPci.11276

Alipour A, Mokhtarian M (2021) RSM-based model to estimate the V-cut drill and blast pattern specific charge in rock tunneling. Int J Geomech 21(11):06021030. https://doi.org/10.1061/(ASCE)GM.1943-5622.0002180

Alipour A, Mokhtarian M, Abdollahei Sharif J (2012) Artificial neural network or empirical criteria? A comparative approach in evaluating maximum charge per delay in surface mining — Sungun copper mine. J Geol Soc India 79(6):652–658. https://doi.org/10.1007/s12594-012-0102-3

Babanouri N, Asadizadeh M, Hasan-Alizade Z (2020) Modeling shear behavior of rock joints: a focus on interaction of influencing parameters. Int J Rock Mech Min Sci 134:104449. https://doi.org/10.1016/j.ijrmms.2020.104449

Bakhtavar E, Khoshrou H, Badroddin M (2015) Using dimensional-regression analysis to predict the mean particle size of fragmentation by blasting at the Sungun copper mine. Arab J Geosci 8(4):2111–2120. https://doi.org/10.1007/s12517-013-1261-2

Bhagade NV, Murthy VMSR, Ali MS (2021) Enhancing rock fragmentation in dragline bench blasts using near-field ground vibration dynamics and advanced blast design. Powder Technol 381:421–439. https://doi.org/10.1016/j.powtec.2020.12.046

Chakraborty AK, Raina AK, Ramulu M, Choudhury PB, Haldar A, Sahu P, Bandopadhyay C (2004) Parametric study to develop guidelines for blast fragmentation improvement in jointed and massive formations. Eng Geol 73(1):105–116. https://doi.org/10.1016/j.enggeo.2003.12.003

Chehreghani SH, Alipour A, Eskandarzade M (2011) Rock mass excavatability estimation using artificial neural network. J Geol Soc India 78(3):271. https://doi.org/10.1007/s12594-011-0087-3

Cunningham CVB (1983) The Kuz–Ram model for prediction of fragmentation from blasting. In: Proceedings of 1st international symposium on rock fragmentation by blasting. Luleå University of Technology, Sweden, pp 439–453

Cunningham CVB (2005) The Kuz–Ram fragmentation model – 20 years on. In: Proceedings of 3rd EFEE world confernce on explosives and blasting, pp 201–210

Da Gama CD (1995) A model for rock mass fragmentation by blasting. In: 8th ISRM Congress. OnePetro

Dimitraki L, Christaras B, Marinos V, Vlahavas I, Arampelos N (2019) Predicting the average size of blasted rocks in aggregate quarries using artificial neural networks. Bull Eng Geol Env 78(4):2717–2729. https://doi.org/10.1007/s10064-018-1270-1

Djordjevic N (1999) Two-component of blast fragmentation. In: Proceedings of 6th international symposium rock fragmentation by blasting, South African Institute of Mining and Metallurgy, Johannesburg, pp 213–219

Faramarzi F, Ebrahimi Farsangi MA, Mansouri H (2013) An RES-based model for risk assessment and prediction of backbreak in bench blasting. Rock Mech Rock Eng 46(4):877–887. https://doi.org/10.1007/s00603-012-0298-y

Farmer IW, Mojtabai N, Taylor DW (1997). An energy-based approach to blast design. In: Transactions of the institution of mining and metallurgy. Section A. Mining Industry, p 106

Ghaeini N, Mousakhani M, Amnieh HB, Jafari A (2017) Prediction of blasting-induced fragmentation in Meydook copper mine using empirical, statistical, and mutual information models. Arab J Geosci 10(18):409. https://doi.org/10.1007/s12517-017-3189-4

Gheibie S, Aghababaei H, Hoseinie SH, Pourrahimian Y (2009) Modified Kuz—Ram fragmentation model and its use at the Sungun copper mine. Int J Rock Mech Min Sci 46(6):967–973. https://doi.org/10.1016/j.ijrmms.2009.05.003

Hamdi E, du Mouza J, Fleurisson JA (2001) Evaluation of the part of blasting energy used for rock mass fragmentation. Fragblast 5(3):180–193. https://doi.org/10.1076/frag.5.3.180.7386

Hasanipanah M, Amnieh HB, Arab H, Zamzam MS (2018) Feasibility of PSO–ANFIS model to estimate rock fragmentation produced by mine blasting. Neural Comput Appl 30(4):1015–1024. https://doi.org/10.1007/s00521-016-2746-1

Hjelmberg H (1983) Some ideas on how to improve calculations of the fragment size distribution in bench blasting. Paper presented at the 1st international symposium on rock fragmentation by blasting

Hudaverdi T, Kulatilake PHSW, Kuzu C (2011) Prediction of blast fragmentation using multivariate analysis procedures. Int J Numer Anal Meth Geomech 35(12):1318–1333. https://doi.org/10.1002/nag.957

Hudaverdi T, Kuzu C, Fisne A (2012) Investigation of the blast fragmentation using the mean fragment size and fragmentation index. Int J Rock Mech Min Sci 56:136–145. https://doi.org/10.1016/j.ijrmms.2012.07.028

Kahraman E, Kilic AM (2020) Evaluation of empirical approaches in estimating mean particle size after blasting by using nondestructive methods. Arab J Geosci 13(14):613. https://doi.org/10.1007/s12517-020-05636-9

Kanchibotla SS, Valery W, Morrell S (1999) Modelling fines in blast fragmentation and its impact on crushing and grinding. In: Proceedings of Explo’99—a conference on rock breaking, Kalgoorlie, pp 137–144

Karami A, Afiuni-Zadeh S (2013) Sizing of rock fragmentation modeling due to bench blasting using adaptive neuro-fuzzy inference system (ANFIS). Int J Min Sci Technol 23(6):809–813. https://doi.org/10.1016/j.ijmst.2013.10.005

Koulli S, Rustan PA (1993) Computerized design and result prediction of bench blasting. In International symposium on rock fragmentation by blasting, pp 263–271

Kulatilake PHSW, Hudaverdi T, Wu Q (2012) New prediction models for mean particle size in rock blast fragmentation. Geotech Geol Eng 30(3):665–684. https://doi.org/10.1007/s10706-012-9496-3

Kulatilake PHSW, Qiong W, Hudaverdi T, Kuzu C (2010) Mean particle size prediction in rock blast fragmentation using neural networks. Eng Geol 114(3):298–311. https://doi.org/10.1016/j.enggeo.2010.05.008

Kuznetsov V (1973) The mean diameter of the fragments formed by blasting rock. Soviet Mining 9(2):144–148

Mehrdanesh A, Monjezi M, Sayadi AR (2018) Evaluation of effect of rock mass properties on fragmentation using robust techniques. Eng Computers 34(2):253–260. https://doi.org/10.1007/s00366-017-0537-7

Miller DM (1984) Reducing transformation bias in curve fitting. Am Stat 38(2):124–126

Mokhtarian Asl M, Alipour A (2020) A nonlinear model to estimate vibration frequencies in surface mines. Int J Min Geo-Eng 54(2):167–171. https://doi.org/10.22059/ijmge.2019.276445.594785

Monjezi M, Amiri H, Farrokhi A, Goshtasbi K (2010) Prediction of rock fragmentation due to blasting in Sarcheshmeh Copper Mine using artificial neural networks. Geotech Geol Eng 28(4):423–430. https://doi.org/10.1007/s10706-010-9302-z

Moomivand H, Vandyousefi H (2020) Development of a new empirical fragmentation model using rock mass properties, blasthole parameters, and powder factor. Arab J Geosci 13(22):1173. https://doi.org/10.1007/s12517-020-06110-2

Morin MA, Ficarazzo F (2006) Monte Carlo simulation as a tool to predict blasting fragmentation based on the Kuz-Ram model. Comput Geosci 32(3):352–359. https://doi.org/10.1016/j.cageo.2005.06.022

Myers RH, Montgomery DC, Anderson-Cook CM (2016) Response surface methodology: process and product optimization using designed experiments: John Wiley & Sons

Nourian A, Moomivand H (2020) Development of a new model to predict uniformity index of fragment size distribution based on the blasthole parameters and blastability index. J Min Sci 56(1):47–58. https://doi.org/10.1134/S1062739120016478

Ouchterlony F (2005) The Swebrec© function: linking fragmentation by blasting and crushing. Min Technol 114(1):29–44

Ouchterlony F, Niklasson B, Abrahamsson S (1990) Fragmentation monitoring of production blasts at MRICA. In: International symposium on rock fragmentation by blasting, 283–289. The Australian Institute of Mining and Metallurgy

Ozcelik Y (1998) Effect of discontinuities on fragment size distribution in open-pit blasting- a case study. In: Transactions of the institution of mining and metallurgy. Section A. Mining Industry, p 107

Raina A, Ramulu M, Choudhury P, Dudhankar A, Chakraborty A (2003) Fragmentation prediction in different rock masses characterised by drilling index. Int J Rock Frag Blasting-FRAGBLAST 7:117–121

Shams S, Monjezi M, Majd VJ, Armaghani DJ (2015) Application of fuzzy inference system for prediction of rock fragmentation induced by blasting. Arab J Geosci 8(12):10819–10832. https://doi.org/10.1007/s12517-015-1952-y

Shi X-Z, Zhou J, Wu B-B, Huang D, Wei W (2012) Support vector machines approach to mean particle size of rock fragmentation due to bench blasting prediction. Trans Nonferrous Metals Soc China 22(2):432–441. https://doi.org/10.1016/S1003-6326(11)61195-3

Spathis AT (2004) A correction relating to the analysis of the original Kuz-Ram model. Fragblast 8(4):201–205. https://doi.org/10.1080/13855140500041697

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Additional information

Responsible Editor: Murat Karakus

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Alipour, A., Asadizadeh, M. Rock fragment size prediction using RSM in bench blasting: a focus on the influencing factors and their interactions. Arab J Geosci 16, 61 (2023). https://doi.org/10.1007/s12517-022-11072-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-022-11072-8