Abstract

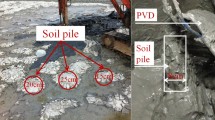

During a vacuum consolidation, due to the faster consolidation rate at the zone near the prefabricated vertical drain (PVD), a lower-permeability zone will be formed around the PVD, reducing the radial propagation rate of the vacuum pressure. Thus, a vacuum-dynamic drainage consolidation method was proposed to alleviate the clogging effect of a “soil column” produced in the vacuum preloading process. A series of model tests for different tamping modes (a combination of tamping sequence and energy) are conducted in this study. The vacuum pressure, water discharge, excess pore water pressure, surface settlement, intergranular pore, and soil shear strength changes were also analyzed. The results indicate that, under the vacuum-dynamic drainage consolidation, which uses low energy to tamp the soil near the PVD after using high energy to tamp the ground near the periphery of the model, the water discharge amount increased faster, and the final discharge volume was more significant than that obtained under the other methods. The relative settlement of the vacuum-dynamic drainage consolidation method is about 1.47 times that of the traditional vacuum preloading method. At the same time, the pore size results between the soil particles prove that the relatively high-energy tamping energy is used to ram the soil around the model barrel, and then the low-energy tamping energy is used to ram the soil near the PVD unit, which can be more effective in strengthening. Wenzhou hydraulic fills the ground to make it suitable for a broader range of construction land requirements.

Similar content being viewed by others

References

Barrington SF, Moueddeb KE, Jazestani J, Dussault M (1998) The clogging of nonwoven geotextiles with cattle manure slurries. Geosynth Int 5(3):309–325

Bing B (2006) Consolidation characteristics and undrained strength of saturated soft clay under repeated impact loading. Geotech Test J 29(4):289–297

Chang TT, Lou XM, Xu SL, Wang JC, Guo LL (2010) Innovative soft soil stabilization using simultaneous high-vacuum dewatering and dynamic compaction. Transp Res Rec J Transp Res Board 2186(1):138–146

Chen PS, Dong ZL, Zhang GX (2012) Mechanism and numerical simulation of the “soil piles” in the fresh hydraulic mud fill treated by surface-layer improvement technique. Port Waterway Eng 462(1):158–163

Fu HT, Chai JC (2020) Performance of a winged PVD (WPVD) for vacuum consolidation of soft clayey deposits. Transp Geotech 24:100370

Gong XN, Cen YR (2002) Mechanism of vacuum preloading. J Harbin Univ Civil Eng Archit 35(2):7–10 (in Chinese)

Han X, Zhu J, Wang L, Zhu Y, Zhao X (2006) Research on the impact energy dispersion of dynamic vacuum consolidation on the saturated dredger mucky. J Eng Geol 14:355–369

Hui W, Hu L (2012) Analytical and numerical solutions for vacuum preloading considering a radius-related strain distribution. Mech Res Commun 44:9–14

Jiang YB, Ning HE, Xu BH, Zhou YZ, Zhang ZL (2017) Model tests on negative pressure distribution in vacuum preloading. Chin J Geotech Eng 39(10):1874–1883

Kianfar K, Indraratna B, Rujikiatkamjorn C (2013) Radial consolidation model incorporating the effects of vacuum preloading and non-darcian flow. Geotechnique 12:163

Kjellman K (1952) Consolidation of clay soil by means of atmospheric pressure. Proc. conf. on Soil Stabilization

Lee S, Jeon JS, Kim WY (2000) Radial consolidation characteristics of soft clay. Chem Eng Sci 66(12):2864–2871

Lei HY, Hu Y, Liu JJ, Liu X, Li CY (2021) Consolidation behavior of Tianjin dredged clay using two air-booster vacuum preloading methods. Journal of Zhejiang University-SCIENCE A 22(2):147–164. https://doi.org/10.1631/JZUS.A2000133. (in Chinese)

Li LH (2002) The feasibility study of three-dimensional vacuum precipitation method to strengthen dredger fill in layers. Chin J Geotech Eng 24(4):522–524 ((in Chinese))

Li SL (2008) Analysis of action mechanism of treating soft foundation with vacuum preloading. Rock Soil Mech 29(2):479–482

Liang RY, Xu SL (2012) High vacuum densification method for soft soil improvement. in: GeoCongress 2012: State of the Art and Practice in Geotechnical Engineering (Oakland, California, United States,25–29 March 2012). 1928–1937

Liu AM, Ye GL, Zhu YT (2016) Research on consolidation characteristics of ultra-soft clay. Japanese Geotechnical Society Special Publication 2(11):469–472

Palmeira EM, Gardoni MG (2000) The influence of partial clogging and pressure on the behaviour of geotextiles in drainage systems. Geosynth Int 7(4–6):403–431

Pang Y, Gu C, Wang J, Cai Y (2020) Strain evolution of saturated clays under cyclic loadings in three-dimensional stress condition. Eng Geol 278:105824

Qian J, Zhao W, Cheung Y, Lee P (1992) The theory and practice of vacuum preloading. Comput Geotech 13(2):103–118

Sun LQ, Yan SW, Li W, Wu KB (2011) Study of super-soft soil vacuum preloading model test. Rock Soil Mech 32(4):984–990

Tang T, Liu J, Liu P, Cai X, Zhang J, Sun S et al (2017) Experimental study of new technology of multi-channel vacuum drainage dynamic compaction. Journal of Hohai University (natural Ences) 45(4):324–331. (in Chinese)

Tang Y, Jie Z, He X, Ping Y, Wang J (2012) Theoretical and experimental study of consolidation settlement characteristics of hydraulic fill soil in Shanghai. Environ Earth Sci 67(5). https://doi.org/10.1007/s12665-012-1584-4

Thilakasiri HS, Gunaratne M, Mu Llins G, Stinnette P, Jory B (1996) Investigation of impact stresses induced in laboratory dynamic compaction of soft soils. Int J Numer Anal Methods Geomech 20(10). https://doi.org/10.1002/(SICI)1096-9853199610)20:10<753::AID-NAG846>3.0.CO;2-R

Wang J, Cai Y, Ma J, Chu J, Fu H, Wang P et al (2016) Improved vacuum preloading method for consolidation of dredged clay-slurry fill. J Geotech Geoenviron Eng 142(11). https://doi.org/10.1061/(ASCE)GT.1943-5606.0001516

Wang J, Cai Y, Fu H et al (2018) Experimental study on a dredged fill ground improved by a two-stage vacuum preloading method. Soils Found 58(3):766–775

Wang J, Ni J, Cai Y, Fu H, Wang P (2017) Combination of vacuum preloading and lime treatment for improvement of dredged fill. Eng Geol 227. https://doi.org/10.1016/j.enggeo.2017.02.013

Wang J, Cai Y, Liu F, Li Z, Hu X (2020) Effect of a vacuum gradient on the consolidation of dredged slurry by vacuum preloading. Can Geotech J. https://doi.org/10.1139/cgj-2019-0666

Wang J (2013) Application of the vacuum preloading technique in foundation treatment. Int J Pharm 287(2004):113–121

Wang S (2010) Research on indoor experimental model for dynamic consolidation of dredged clay. J Eng Geol 18(6):906–912

Sterpejkowicz-Wersocki W (2014) Problem of clogging in drainage systems in the examples of the Zur and Podgaje dams. Archives of hydroengineering and environmental mechanics 61(3–4). https://doi.org/10.1515/heem-2015-0012

Wu YJ, Qin P, Zou DM, Sun DA (2013) In-situ tests and numerical simulation of soft soil consolidation using vacuum preloading method under various loading. Port Waterway Eng 8:165–172

Xu BH, He N, Jiang YB, Zhou YZ, Zhan XJ (2020) Experimental study on the clogging effect of dredged fill surrounding the PVD under vacuum preloading. Geotextiles and Geomembranes 48(5). https://doi.org/10.1016/j.geotexmem.2020.03.007

Yang AW, Yan SW, Du DJ, Lu LQ, Wang JH (2011) Partly improved technology of vacuum preloading in foundation treatment of soft dredger fill. J Tianjin Univ Sci Technol 44(6):477–483. (in Chinese)

Zhou K, Jian Z, Jia M (2009) Test study on dredger fill foundation reinforcement with low-energy dynamic consolidation method. Construction Technology 38(9):98–100

Zhou Y, Cai Y, Yuan G, Wang J, Jin H (2020) Effect of tamping interval on consolidation of dredged slurry using vacuum preloading combined with dynamic consolidation. Acta Geotech 4:1–13

Funding

This research was supported by the National Key R&D Program of China (2016YFC0800200), the National Natural Science Foundation of China (grant nos. 51778500, 51778501, 51878512), the Zhejiang Province Natural Foundation Projects of China (grant nos. LR18E080001, LY20E080029), and the Key Research and Development Program of Zhejiang Province (grant no. 2018C03038). This financial support is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Responsible Editor: Zeynal Abiddin Erguler

Rights and permissions

About this article

Cite this article

Li, X., Li, J., Yuan, G. et al. The influence of the tamping mode on the clogging effect of the vacuum-dynamic drainage consolidation method. Arab J Geosci 15, 148 (2022). https://doi.org/10.1007/s12517-021-09421-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-021-09421-0