Abstract

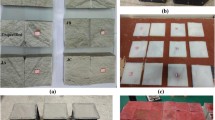

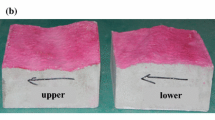

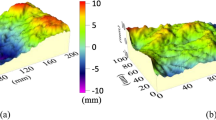

In present study, 144 direct shear tests are performed on mated rock joint replicas under constant normal load condition (CNL). For these tests, three natural roughness of joint surface are transferred to the RTV silicon rubber molds. On these molds, mixture of cement, sand, and water in the ratio of 1:1.5:0.45 by weight is poured and joint replicas are made. In this study, the experimental shear strength is corrected with gross contact area (Ac) and incremental dilation angle (i). Further, the peak dilation angle is determined by Barton’s and incremental dilation (dv/dh) approaches and compared. The results showed that Barton’s approach underestimates the peak dilation angle. The roughness quantification of joint surface is done using 3D noncontact type profiler, and morphological parameters of joint surface are determined in each shearing direction as described by Grasselli and Egger (Int J Rock Mech Min Sci 40:25–40, 2003). A new predictive model for joint roughness coefficient (JRC) is developed and Barton’s model is modified. It is observed that modified Barton’s model provides good approximation of shear strength in desired shear direction. Moreover, modified Barton peak shear strength (τPre) is compared with Barton and Grasselli’s experimental peak shear strength, and it is observed that τPre matches closely with Barton’s peak shear strength.

Similar content being viewed by others

Abbreviations

- σ n :

-

Normal stress

- ϕ b :

-

Basic friction angle

- τ i :

-

Dilation corrected shear stress

- τ ip :

-

Dilation corrected peak shear stress

- τ or τexp :

-

Experimental or uncorrected shear stress

- τ A :

-

Gross contact area corrected shear stress

- τ Pre :

-

Modified Barton peak shear strength

- τ B :

-

Barton’s peak shear strength

- τ p :

-

Uncorrected peak shear stress

- τ GE :

-

Grasselli’s experimental shear strength

- A :

-

Amplitude of profile

- CNL :

-

Constant normal load

- D :

-

Fractal dimension

- JRC :

-

Joint roughness coefficient

- JCS :

-

Joint wall compressive strength

- L :

-

Length of sample

- RTV :

-

Room temperature vulcanizing

- Z 2 :

-

Root mean square of first derivative of profile

- dy/dx :

-

Slope of profile

- A C :

-

Gross contact area

- \( {A}_{\theta^{\ast }} \) :

-

Normalized potential contact area

- A 0 :

-

Maximum potential contact area

- θ max :

-

Maximum asperity angle

- θ ∗ :

-

Threshold dip angle

- C :

-

Dimensionless fitting parameters

- i :

-

Incremental dilation angle

- r :

-

Radius of sample

- dv/dh :

-

Rate of dilation

- d n :

-

Dilation angle

- d na :

-

Actual peak dilation angle

- SSE :

-

Sum of square error

- MSE :

-

Mean square error

- N :

-

No. of data

References

Amadei B, Wibowo J, Sture S, Price RH (1998) Applicability of existing models to predict the behavior of replicas of natural fractures of welded tuff under different boundary conditions. Geotech Geol Eng 16:79–128. https://doi.org/10.1023/A:1008886106337

Asadollahi P, Tonon F (2010) Constitutive model for rock fractures: revisiting Barton’s empirical model. Eng Geol 113:11–32. https://doi.org/10.1016/j.enggeo.2010.01.007

Barton N (1973) Review of a new shear-strength criterion for rock joints. Eng Geol 7:287–332. https://doi.org/10.1016/0013-7952(73)90013-6

Barton N, Choubey V (1977) The shear strength of rock joints in theory and practice. Rock Mech 10:1–54. https://doi.org/10.1007/BF01261801

Barton N, Bandis S, Bakhtar K (1985) Strength, deformation and conductivity coupling of rock joints. Int J Rock Mech Min Sci Geomech Abstr 22:121–140. https://doi.org/10.1016/0148-9062(85)93227-9

Brown SR, Scholz CH (1985) Broad bandwidth study of the topography of natural rock surfaces. J Geophys Res 90:12575. https://doi.org/10.1029/JB090iB14p12575

Ghazvinian AH, Azinfar MJ, Geranmayeh Vaneghi R (2012) Importance of tensile strength on the shear behavior of discontinuities. Rock Mech Rock Eng 45:349–359. https://doi.org/10.1007/s00603-011-0207-9

Grasselli G, Egger P (2003) Constitutive law for the shear strength of rock joints based on three-dimensional surface parameters. Int J Rock Mech Min Sci 40:25–40. https://doi.org/10.1016/S1365-1609(02)00101-6

Grasselli G, Wirth J, Egger P (2002) Quantitative three-dimensional description of a rough surface and parameter evolution with shearing. Int J Rock Mech Min Sci 39:789–800. https://doi.org/10.1016/S1365-1609(02)00070-9

Hencher SR, Richards LR (1989) Laboratory direct shear testing of rock discontinuities. Ground Eng 22(2):24–31

Hencher SR, Lee SG, Carter TG, Richards LR (2011) Sheeting joints: characterisation, shear strength and engineering. Rock Mech Rock Eng 44:1–22. https://doi.org/10.1007/s00603-010-0100-y

Homand F, Belem T, Souley M (2001) Friction and degradation of rock joint surfaces under shear loads. Int J Numer Anal Methods Geomech 25:973–999. https://doi.org/10.1002/nag.163

Huang SL, Oelfke SM, Speck RC (1992) Applicability of fractal characterization and modelling to rock joint profiles. Int J Rock Mech Min Sci Geomech Abstr 29:89–98. https://doi.org/10.1016/0148-9062(92)92120-2

Huang et al (1993) An Investigation of the Mechanics of Rock Joints Part I . Laboratory investigation. Int J Rock Mech Min Sci Geomech Abstr 30:257–269

ISRM (1978) International Society for Rock Mechanics commission on standardization of laboratory and field tests: suggested methods for the quantitative description of discontinuities in rock masses. Int J Rock Mech Min Sci Geomech Abstr 15(6):319–368

Indraratna, Haque (2000) Shear behaviour of rock joint. Balkema, Rotterdam

Jing L, Nordlund E, Stephansson O (1992) An experimental study on the anisotropy and stress-dependency of the strength and deformability of rock joints. Int J Rock Mech Min Sci Geomech Abstr 29:535–542. https://doi.org/10.1016/0148-9062(92)91611-8

Khosravi A, Sadaghiani MH, Khosravi M, Meehan CL (2013) The effect of asperity inclination and orientation on the shear behavior of rock joints. Geotech Test J 36:404–417

Kulatilake PHSW, Um J (1999) Requirements for accurate quantification of self-affine roughness using the roughness-length method. Int J Rock Mech Min Sci 36:5–18. https://doi.org/10.1016/S1365-1609(98)00170-1

Kulatilake PHSW, Shou G, Huang TH, Morgan RM (1995) New peak shear strength criteria for anisotropic rock joints. Int J Rock Mech Min Sci Geomech Abstr 32:673–697. https://doi.org/10.1016/0148-9062(95)00022-9

Kumar R, Verma AK (2016) Anisotropic shear behavior of rock joint replicas. Int J Rock Mech Min Sci 90:62–73. https://doi.org/10.1016/j.ijrmms.2016.10.005

Ladanyi B, Archambault G (1970) Simulation of shear behavior of jointed rock mass. In: 11th U.S. symposium on rock mechanics: theory and practice, Berleley, California. pp. 105–125

Li Y, Huang R (2015) Relationship between joint roughness coefficient and fractal dimension of rock fracture surfaces. Int J Rock Mech Min Sci 75:15–22. https://doi.org/10.1016/j.ijrmms.2015.01.007

Maerz NH, Franklin JA, Bennett CP (1990) Joint roughness measurement using shadow profilometry. Int J Rock Mech Min Sci Geomech Abstr 27:329–343. https://doi.org/10.1016/0148-9062(90)92708-M

Maksimović M (1992) New description of the shear strength for rock joints. Rock Mech Rock Eng 25:275–284. https://doi.org/10.1007/BF01041808

Maksimović M (1996) The shear strength components of a rough rock joint. Int J Rock Mech Min Sci Geomech Abstr 33:769–783. https://doi.org/10.1016/0148-9062(95)00005-4

Milinverno A (1990) A simple method to estimate the fractal dimension of self-affine series. Geophys Res Lett 17:1953–1956

Muralha J, Grasselli G, Tatone B, Blümel M, Chryssanthakis P, Yujing J (2014) ISRM suggested method for laboratory determination of the shear strength of rock joints: revised version. Rock Mech Rock Eng 47:291–302. https://doi.org/10.1007/s00603-013-0519-z

Odling NE (1994) Natural fracture profiles, fractal dimension and joint roughness coefficients. Rock Mech Rock Eng 27:135–153. https://doi.org/10.1007/BF01020307

Patton FD (1966) Multiple modes of shear failure in rock. In: Proceedings of the 1st congress of the international society of rock mechanics. Lisbon, Portugal, pp. 509–513

Plesha ME, Ballarini R, Parulekar A (1989) Constitutive model and finite element procedure for dilatant contact problems. J Eng Mech 115(12):2649–2668

Power WL, Tullis TE (1991) Euclidean and fractal models for the description of rock surface roughness. J Geophys Res 96:415. https://doi.org/10.1029/90JB02107

Reeves MJ (1985) Rock surface roughness and frictional strength. Int J Rock Mech Min Sci Geomech Abstr 22:429–442. https://doi.org/10.1016/0148-9062(85)90007-5

Sakellariou M, Nakos B, Mitsakaki C (1991) On the fractal character of rock surfaces. Int J Rock Mech Min Sci Geomech Abstr 28:527–533

Tatone BSA (2009) Quantitative characterization of natural rock discontinuity roughness in-situ and in the laboratory. University of Toronto, Toronto

Tatone BSA, Grasselli G (2010) A new 2D discontinuity roughness parameter and its correlation with JRC. Int J Rock Mech Min Sci 47:1391–1400. https://doi.org/10.1016/j.ijrmms.2010.06.006

Tse R, Cruden DM (1979) Estimating joint roughness coefficients. Int J Rock Mech Min Sci Geomech Abstr 16:303–307. https://doi.org/10.1016/0148-9062(79)90241-9

Wang JG, Ichikawa Y, Leung CF (2003) A constitutive model for rock interfaces and joints. Int J Rock Mech Min Sci 40:41–53. https://doi.org/10.1016/S1365-1609(02)00113-2

Wibowo J, Amadel B, Sture S, Price RH (1994) Effect of boundary conditions on the strength and deformability of replicas of natural fractures in welded tuff : data analysis (No. SAND-93-7079). Sandia National Labs., Albuquerque, NM (United States); Colorado Univ., Boulder, CO (United States). Dept. of Civil, Environmental, and Architectural Engineering

Xia CC, Tang ZC, Xiao WM, Song YL (2014) New peak shear strength criterion of rock joints based on quantified surface description. Rock Mech Rock Eng 47:387–400. https://doi.org/10.1007/s00603-013-0395-6

Xie H, Wang JA, Kwaśniewski MA (1999) Multifractal characterization of rock fracture surfaces. Int J Rock Mech Min Sci 36:19–27. https://doi.org/10.1016/S1365-1609(98)00172-5

Yang Z, Chiang D (2000) An experimental study on the progressive shear behavior of rock joints with tooth-shaped asperities. Int J Rock Mech Min Sci 37:1247–1259. https://doi.org/10.1016/S1365-1609(00)00055-1

Yang ZY, Di CC (2001) A directional method for directly calculating the fractal parameters of joint surface roughness. Int J Rock Mech Min Sci 38:1201–1210. https://doi.org/10.1016/S1365-1609(02)00006-0

Yang ZY, Lo SC, Di CC (2001) Reassessing the joint roughness coefficient (JRC) estimation using Z2. Rock Mech Rock Eng 34:243–251. https://doi.org/10.1007/s006030170012

Yu X, Vayssade B (1991) Joint profiles and their roughness parameters. Int J Rock Mech Min Sci Geomech Abstr 28:333–336. https://doi.org/10.1016/0148-9062(91)90598-G

Zhao J (1997a) Joint surface matching and shear strength. Part a: joint matching coefficient (JMC). Int J Rock Mech Min Sci Geomech Abstr 34:173–178. https://doi.org/10.1016/S0148-9062(96)00062-9

Zhao J (1997b) Joint surface matching and shear strength. Part B: JRC-JMC shear strength criterion. Int J Rock Mech Min Sci Geomech Abstr 34:179–185. https://doi.org/10.1016/S0148-9062(96)00063-0

Acknowledgments

The laboratory facilities, support, and suggestions of technical staff of Rock Mechanics Laboratory, IIT Kharagpur, India, for conducting necessary experiments is duly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible Editor: Zeynal Abiddin Erguler

Rights and permissions

About this article

Cite this article

Kumar, R., Verma, A.K. Corrections applied to direct shear results and development of modified Barton’s shear strength criterion for rock joints. Arab J Geosci 13, 1019 (2020). https://doi.org/10.1007/s12517-020-06030-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-020-06030-1