Abstract

Sugarcane juice (SGJ) has been known to possess nutritious, curative, and preventive properties. However, its use and marketing have been greatly limited due to issues such as preservation difficulty and short shelf life, which come into play due to enzymes and microbial activity. The conversion of the juice into powder has been shown to retain the nutrients of the juice as well as be a sustainable solution to its preservation problems. This study is a review of the documented observations of various researchers on the production of SGJ powder. This study critically analysed for similarities, differences, and trends in reported studies, as well as gave some recommendations to improve the quality of the powder. It was observed that for the production of the powder, the most successful and utilized drying technique is the spray drying technique. Operating parameters such as the choice and concentration of the drying agent, inlet and outlet air temperature, presence of additives, total soluble solids of feed solution, and the atomizer disc rotational speed were observed to affect the yield and the powder properties. Maltodextrin, a drying agent, was observed to give the highest yield and the best sensory and non-sensory properties in relation to other drying agents that have been utilized. The highest yield of SGJ powder obtained is 91.19% of the total solids of the feed material. It is expected that this study would lay the foundation to educate future researchers interested in the production of quality SGJ powder.

Reproduced from Shishir and Chen (2017) with permission from Elsevier

Similar content being viewed by others

References

Afiomah, C.S., and K.O. Iwuozor. 2020. Nutritional and phytochemical properties of beta vulgaris Linnaeus (Chenopodiaceae)—A review. Nigerian Journal of Pharmaceutical and Applied Science Research 9 (4): 38–44.

Arif, S., A. Batool, W. Nazir, R.S. Khan, and N. Khalid. 2019. Physiochemical characteristics nutritional properties and health benefits of sugarcane juice. In Non-alcoholic beverages, 227–257. London: Elsevier.

Bao, T., Y. Xu, V. Gowd, J. Zhao, J. Xie, W. Liang, and W. Chen. 2016. Systematic study on phytochemicals and antioxidant activity of some new and common mulberry cultivars in China. Journal of Functional Foods 25: 537–547. https://doi.org/10.1016/j.jff.2016.07.001.

Bernard, C., S. Regnault, S. Gendreau, S. Charbonneau, and P. Relkin. 2011. Enhancement of emulsifying properties of whey proteins by controlling spray-drying parameters. Food Hydrocolloids 25 (4): 758–763. https://doi.org/10.1016/j.foodhyd.2010.08.011.

Cai, Y.-Z., and H. Corke. 2000. Production and properties of spray-dried Amaranthus betacyanin pigments. Journal of Food Science 65 (7): 1248–1252. https://doi.org/10.1111/j.1365-2621.2000.tb10273.x.

Carr, R.L., Jr. 1965. Evaluating flow properties of solids. Chemical Engineering 72: 163–168.

Chegini, G., and B. Ghobadian. 2005. Effect of spray-drying conditions on physical properties of orange juice powder. Drying Technology 23 (3): 657–668.

Chen, W., J. Zhao, T. Bao, J. Xie, W. Liang, and V. Gowd. 2016. Comparative study on phenolics and antioxidant property of some new and common bayberry cultivars in China. Journal of Functional Foods 27: 472–482.

Cheng, M.H., H. Huang, B.S. Dien, and V. Singh. 2019. The costs of sugar production from different feedstocks and processing technologies. Biofuels, Bioproducts and Biorefining 13 (3): 723–739.

Dal Magro, C., R. Bulegon, and G. de Almeida Gomes. 2019. Development of freeze dried sugarcane juice powder. Journal of the South Brazilian Congress of Food Engineering 4 (1): 21–23. https://doi.org/10.5965/24473650412018023.

Dalmoro, A., A.A. Barba, G. Lamberti, and M. d’Amore. 2012. Intensifying the microencapsulation process: Ultrasonic atomization as an innovative approach. European Journal of Pharmaceutics and Biopharmaceutics 80 (3): 471–477.

Desai, K.G.H., and H. Jin Park. 2005. Recent developments in microencapsulation of food ingredients. Drying Technology 23 (7): 1361–1394.

Đorđević, V., A. Paraskevopoulou, F. Mantzouridou, S. Lalou, M. Pantić, B. Bugarski, and V. Nedović. 2016. Encapsulation technologies for food industry. In Emerging and traditional technologies for safe, healthy and quality food, 329–382. Switzerland: Springer.

Duke, J.A. 2017. Handbook of phytochemical constituents of GRAS herbs and other economic plants. New York: CRC Press.

Fazaeli, M., Z. Emam-Djomeh, A. Kalbasi-Ashtari, and M. Omid. 2012a. Effect of process conditions and carrier concentration for improving drying yield and other quality attributes of spray dried black mulberry (Morus nigra) juice. International Journal of Food Engineering 8 (1): 1–20.

Fazaeli, M., Z. Emam-Djomeh, A.K. Ashtari, and M. Omid. 2012b. Effect of spray drying conditions and feed composition on the physical properties of black mulberry juice powder. Food and Bioproducts Processing 90 (4): 667–675.

Finney, J., R. Buffo, and G. Reineccius. 2002. Effects of type of atomization and processing temperatures on the physical properties and stability of spray-dried flavors. Journal of Food Science 67 (3): 1108–1114.

Gallo, L., J.M. Llabot, D. Allemandi, V. Bucalá, and J. Piña. 2011. Influence of spray-drying operating conditions on Rhamnus purshiana (Cáscara sagrada) extract powder physical properties. Powder Technology 208 (1): 205–214.

Goula, A.M., and K.G. Adamopoulos. 2008. Effect of maltodextrin addition during spray drying of tomato pulp in dehumidified air: II. Powder properties. Drying Technology 26 (6): 726–737.

Goula, A.M., K.G. Adamopoulos, and N.A. Kazakis. 2004. Influence of spray drying conditions on tomato powder properties. Drying Technology 22 (5): 1129–1151.

Hammami, C., and F. René. 1997. Determination of freeze-drying process variables for strawberries. Journal of Food Engineering 32 (2): 133–154.

Hari, S., R. Jebitta, and K. Sivaraman. 2013. Production and characterization of sugarcane juice powder. Journal of Sugarcane Research 3 (1): 20–34.

Hong, J.H., and Y.H. Choi. 2007. Physico-chemical properties of protein-bound polysaccharide from Agaricus blazei Murill prepared by ultrafiltration and spray drying process. International Journal of Food Science and Technology 42 (1): 1–8.

Islam, M., Y. Kitamura, Y. Yamano, and M. Kitamura. 2016. Effect of vacuum spray drying on the physicochemical properties, water sorption and glass transition phenomenon of orange juice powder. Journal of Food Engineering 169: 131–140.

Islam, M., Y. Kitamura, M. Kokawa, K. Monalisa, F.-H. Tsai, and S. Miyamura. 2017. Effects of micro wet milling and vacuum spray drying on the physicochemical and antioxidant properties of orange (Citrus unshiu) juice with pulp powder. Food and Bioproducts Processing 101: 132–144.

Iwuozor, K.O. 2019. Qualitative and quantitative determination of anti-nutritional factors of five wine samples. Advanced Journal of Chemistry-Section A 2 (2): 136–146.

Iwuozor, K.O., L.A. Ogunfowora, and I.P. Oyekunle. 2021a. Review on sugarcane-mediated nanoparticle synthesis: A green approach. Sugar Tech 24: 1186–1197. https://doi.org/10.1007/s12355-021-01038-7.

Iwuozor, K.O., I.P. Oyekunle, I.O. Oladunjoye, E.M. Ibitogbe, and T.S. Olorunfemi. 2021b. A review on the mitigation of heavy metals from aqueous solution using sugarcane bagasse. Sugar Tech 24: 1167–1185. https://doi.org/10.1007/s12355-021-01051-w.

Iwuozor, K.O., E.C. Emenike, M. Abdulkadir, S. Ogunniyi, and A.G. Adeniyi. 2022a. Effect of salt modification on biochar obtained from the thermochemical conversion of sugarcane bagasse. Sugar Tech. https://doi.org/10.1007/s12355-022-01166-8.

Iwuozor, K.O., V.U. Anyanwu, B.O. Olaniyi, P.S. Mbamalu, and A.G. Adeniyi. 2022b. Adulteration of sugar: A growing global menace. Sugar Tech 24: 914–919. https://doi.org/10.1007/s12355-022-01122-6.

Iwuozor, K.O., E.C. Emenike, J.O. Ighalo, S. Eshiemogie, P.E. Omuku, and A.G. Adeniyi. 2022c. Valorization of sugar industry’s by-products: A perspective. Sugar Tech 24: 1052–1078. https://doi.org/10.1007/s12355-022-01143-1.

Iwuozor, K.O., P.S. Mbamalu, B.O. Olaniyi, V.U. Anyanwu, E.C. Emenike, and A.G. Adeniyi. 2022d. Fortification of sugar: A call for action. Sugar Tech 24: 1284–1294. https://doi.org/10.1007/s12355-022-01183-7.

Jayasundera, M., B. Adhikari, T. Howes, and P. Aldred. 2011. Surface protein coverage and its implications on spray-drying of model sugar-rich foods: Solubility, powder production and characterisation. Food Chemistry 128 (4): 1003–1016.

Jinapong, N., M. Suphantharika, and P. Jamnong. 2008. Production of instant soymilk powders by ultrafiltration, spray drying and fluidized bed agglomeration. Journal of Food Engineering 84 (2): 194–205.

Kaavya, R., R. Pandiselvam, A. Kothakota, E. Banuu Priya, and V. Arun Prasath. 2019. Sugarcane juice preservation: A critical review of the state of the art and way forward. Sugar Tech 21 (1): 9–19.

Karthikeyan, J., and S.S. Samipillai. 2010. Sugarcane in therapeutics. Journal of Herbal Medicine and Toxicology 4 (1): 9–14.

Khare, A., A. Behari Lal, A. Singh, and A. Pratap Singh. 2012. Shelflife enhancement of sugarcane juice. Hrvatski Časopis Za Prehrambenu Tehnologiju, Biotehnologiju i Nutricionizam 7 (3): 179–183.

Khuenpet, K., N. Charoenjarasrerk, S. Jaijit, S. Arayapoonpong, and W. Jittanit. 2016. Investigation of suitable spray drying conditions for sugarcane juice powder production with an energy consumption study. Agriculture and Natural Resources 50 (2): 139–145.

Kong, K.W., A. Ismail, C.P. Tan, and N.F. Rajab. 2010. Optimization of oven drying conditions for lycopene content and lipophilic antioxidant capacity in a by-product of the pink guava puree industry using response surface methodology. LWT-Food Science and Technology 43 (5): 729–735.

Largo-Avila, E., M. Cortés Rodríguez, and H.J. Ciro-Velasquez. 2014. The adsorption thermodynamics of sugarcane (Saccharum officinarum l.) powder obtained by spray drying technology. Vitae 21 (3): 165–177.

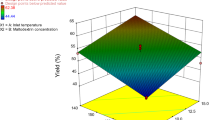

Largo Avila, E., M. Cortes Rodríguez, and H.J. Ciro Velásquez. 2015. Influence of maltodextrin and spray drying process conditions on sugarcane juice powder quality. Revista Facultad Nacional De Agronomía Medellín 68 (1): 7509–7520.

León-Martínez, F., L.L. Mendez-Lagunas, and J. Rodriguez-Ramirez. 2010. Spray drying of nopal mucilage (Opuntia ficus-indica): Effects on powder properties and characterization. Carbohydrate Polymers 81 (4): 864–870. https://doi.org/10.1016/j.carbpol.2010.03.061.

Longvah, T., and I. An̲antan̲, K. Bhaskarachary, K. Venkaiah, and T. Longvah. 2017. Indian food composition tables. New Delhi: National Institute of Nutrition Press.

Maa, Y.-F., H.R. Costantino, P.-A. Nguyen, and C.C. Hsu. 1997. The effect of operating and formulation variables on the morphology of spray-dried protein particles. Pharmaceutical Development and Technology 2 (3): 213–223.

Maury, M., K. Murphy, S. Kumar, L. Shi, and G. Lee. 2005. Effects of process variables on the powder yield of spray-dried trehalose on a laboratory spray-dryer. European Journal of Pharmaceutics and Biopharmaceutics 59 (3): 565–573.

Miller, D.A., and M. Gil. 2012. Spray-drying technology. In Formulating poorly water soluble drugs, 363–442. New York: Springer.

Mishra, P., S. Mishra, and C.L. Mahanta. 2014. Effect of maltodextrin concentration and inlet temperature during spray drying on physicochemical and antioxidant properties of amla (Emblica officinalis) juice powder. Food and Bioproducts Processing 92 (3): 252–258.

Murali, S., A. Kar, D. Mohapatra, and P. Kalia. 2015. Encapsulation of black carrot juice using spray and freeze drying. Food Science and Technology International 21 (8): 604–612.

Nishad, J., S.A. Mir, and K. Walia. 2019. Optimization of spray drying technology for sugarcane juice using natural and synthetic encapsulating agents. Sugar Tech 21 (5): 749–755.

Nishad, J., C.J. Selvan, S.A. Mir, and S.J.D. Bosco. 2017. Effect of spray drying on physical properties of sugarcane juice powder (Saccharum officinarum L.). Journal of Food Science and Technology 54 (3): 687–697.

Panigrahi, C., A.E.Y. Shaikh, B.B. Bag, H.N. Mishra, and S. De. 2021. A technological review on processing of sugarcane juice: Spoilage, preservation, storage, and packaging aspects. Journal of Food Process Engineering. https://doi.org/10.1111/jfpe.13706.

Quek, S.Y., N.K. Chok, and P. Swedlund. 2007. The physicochemical properties of spray-dried watermelon powders. Chemical Engineering and Processing: Process Intensification 46 (5): 386–392.

Rajendran, P., R. Bharathidasan, and K. Sureshkumar. 2017. GC-MS analysis of phyto-components in raw and treated sugarcane juice. International Journal of Current Microbiology and Applied Sciences 6 (7): 51–61.

Rodríguez-Hernández, G., R. González-García, A. Grajales-Lagunes, M. Ruiz-Cabrera, and M. Abud-Archila. 2005. Spray-drying of cactus pear juice (Opuntia streptacantha): Effect on the physicochemical properties of powder and reconstituted product. Drying Technology 23 (4): 955–973.

Salazar Alzate, B.C., M. Cortés Rodríguez, and O. Montoya Campuzano. 2015. The impact of storage conditions on the stability of sugarcane powder biofortified with kefir grains. Revista Facultad Nacional De Agronomía Medellín 68 (2): 7703–7712.

Sankhla, S., A. Chaturvedi, A. Kuna, and K. Dhanlakshmi. 2012. Preservation of sugarcane juice using hurdle technology. Sugar Tech 14 (1): 26–39.

Santhalakshmy, S., S.J.D. Bosco, S. Francis, and M. Sabeena. 2015. Effect of inlet temperature on physicochemical properties of spray-dried jamun fruit juice powder. Powder Technology 274: 37–43.

Santivarangkna, C., U. Kulozik, and P. Foerst. 2007. Alternative drying processes for the industrial preservation of lactic acid starter cultures. Biotechnology Progress 23 (2): 302–315.

Santos, LCd., R. Condotta, and Md.C. Ferreira. 2018. Flow properties of coarse and fine sugar powders. Journal of Food Process Engineering. https://doi.org/10.1111/jfpe.12648.

Shishir, M.R.I., and W. Chen. 2017. Trends of spray drying: A critical review on drying of fruit and vegetable juices. Trends in Food Science and Technology 65: 49–67.

Singh, J. 2019. Value added products from cane juice for food and nutritional security in India. RASSA Journal of Science for Society 1 (1): 13–17.

Singh, S., K. Gaikwad, and P. More. 2014. Spoilage of sugarcane juice: A problem in sugarcane industry. International Journal of Agricultural Engineering 7 (1): 259–263.

Sobulska, M., and I. Zbicinski. 2021. Advances in spray drying of sugar-rich products. Drying Technology 39 (12): 1774–1799.

Souza, A.S., S.V. Borges, N.F. Magalhães, H.V. Ricardo, M.P. Cereda, and E.R. Daiuto. 2009. Influence of spray drying conditions on the physical properties of dried pulp tomato. Food Science and Technology 29: 291–294.

Tatar Turan, F., A. Cengiz, D. Sandıkçı, M. Dervisoglu, and T. Kahyaoglu. 2016. Influence of an ultrasonic nozzle in spray-drying and storage on the properties of blueberry powder and microcapsules. Journal of the Science of Food and Agriculture 96 (12): 4062–4076.

Tee, L.H., L. Chuah, K.Y. Pin, A.A. Rashih, and Y.A. Yusof. 2012. Optimization of spray drying process parameters of Piper betle L.(Sirih) leaves extract coated with maltodextrin. Journal of Chemical and Pharmaceutical Research 4 (3): 1833–1841.

Tonon, R.V., C. Brabet, D. Pallet, P. Brat, and M.D. Hubinger. 2009. Physicochemical and morphological characterisation of açai (Euterpe oleraceae Mart.) powder produced with different carrier agents. International Journal of Food Science and Technology 44 (10): 1950–1958.

Tontul, I., and A. Topuz. 2017. Spray-drying of fruit and vegetable juices: Effect of drying conditions on the product yield and physical properties. Trends in Food Science and Technology 63: 91–102.

Uscategui, D.C.R., H.J.C. Velásquez, and J.U.S. Valencia. 2018. Concentrates of sugarcane juice and whey protein: Study of a new powder product obtained by spray drying of their combinations. Powder Technology 333: 429–438.

Wong, C., L. Pui, and J. Ng. 2015. Production of spray-dried Sarawak pineapple (Ananas comosus) powder from enzyme liquefied puree. International Food Research Journal 22 (4): 1631–1636.

Yadav, R., and S. Solomon. 2006. Potential of developing sugarcane by-product based industries in India. Sugar Tech 8 (2): 104–111.

Yousefi, S., Z. Emam-Djomeh, and S. Mousavi. 2011. Effect of carrier type and spray drying on the physicochemical properties of powdered and reconstituted pomegranate juice (Punica Granatum L.). Journal of Food Science and Technology 48 (6): 677–684.

Funding

This work received no external funding.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that there are no conflicts of interest.

Ethics Approval and Consent to Participate

Not applicable.

Consent for Publication

The authors have unanimously decided that this manuscript be sent for possible publication.

Consent to Publish

Not applicable.

Ethical Approval

This article does not contain any studies involving human or animal subjects.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Iwuozor, K.O., Adeniyi, A.G., Emenike, E.C. et al. Sugarcane Juice Powder Produced from Spray Drying Technology: A Review of Properties and Operating Parameters. Sugar Tech 25, 497–507 (2023). https://doi.org/10.1007/s12355-022-01211-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12355-022-01211-6