Abstract

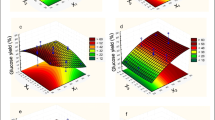

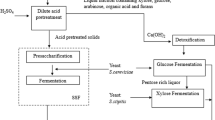

Pulverized sugarcane bagasse consists of 37 ± 0.29 % cellulose, 28 ± 0.26 % hemicellulose, and 21 ± 0.28 % lignin on dry solid basis. About 11.58 % xylose, 6.39 % glucose, and 4.56 % fructose were liberated in hydrolysate when bagasse was treated with 1 % HNO3, under steam explosion. Simultaneous saccharification and fermentation of pretreated bagasse by cellulase and Pachysolen tannophilus MTCC 1077 were investigated in the present study. Important process variables for ethanol production from pretreated bagasse were optimized using response surface methodology based on central composite design (CCD) experiments. A three-level CCD experiments with central and axial points was used to develop a statistical model for the optimization of process variables. Data obtained from RSM on ethanol production were further subjected to the analysis of variance, and contour plots were used to study the interactions among three relevant variables (incubation temperature, inoculum concentration, and nutrient factors) of the fermentation process. Maximum ethanol concentration 9.15 g/l was obtained after 72-h incubation with P. tannophilus MTCC 1077 at the optimized process conditions in anaerobic batch fermentation when optimum values for temperature (34 °C), inoculum level (6 %), and fermentation medium (ammonium sulfate, KH2PO4, peptone, and yeast extract) were applied.

Similar content being viewed by others

References

Abdulla, E., T. Feanov, S. Costa, M.K. Robra, C.A. Paulo, and M.G. Gubitz. 2000. Decolorization and detoxification of textile dyes with a laccase from Trametes hirsute. Applied and Environmental Microbiology 66: 3357–3362.

Basavaraj, G., P.P. Rao, K. Basu, R. Reddy, A.A. Kumar, P.S. Rao, and B.V.S. Reddy. 2013. Assessing viability of bio-ethanol production from sweet sorghum in India. Energy Policy 56:501–508. doi:10.1016/j.enpol.2013.01.012.

Berlin, A., V. Maximenko, N. Gilkes, and J.N. Saddler. 2007. Optimization of enzyme complexes for lignocellulose hydrolysis. Biotechnology Bioengineering 97: 287–296.

Betancur, G.J.V., and N. Pereira Jr. 2010. Sugarcane bagasse as feedstock for second generation ethanol production. Part I: Diluted acid pretreatment optimization. Electronic Journal of Biotechnology. doi:10.2225/vol13-issue3-fulltext-3.

Bhatia, L., and S. Paliwal. 2011. Ethanol producing potential of Pachysolen tannophilus from sugarcane bagasse. International Journal of Biotechnology and Bioengineering Research 2(2): 271–276.

Carmen, S. 2009. Lignocellulosic residues: Biodegradation and bioconversion by fungi. Biotechnology Advances 27: 185–194.

Carvalheiro, F., L.C. Duarte, S. Lopes, J.C. Parajo, H. Pereira, and F.M. Girio. 2005. Evaluation of the detoxification of brewery’s spent grain hydrolysate for xylitol production by Debaryomyces hansenii CCMI 941. Process Biochemistry 40: 1215–1223.

Chandel, A.K., F.A. Antunes, and V. Anjos. 2013a. Ultra-structural mapping of sugarcane bagasse after oxalic acid fiber expansion (OAFEX) and ethanol production by Candida shehatae and Saccharomyces cerevisiae. Biotechnology for Biofuels 6: 4. doi:10.1186/1754-6834-6-4.

Chandel, A.K., S.S. da Silva, and O.V. Singh. 2013b. Detoxification of lignocellulose hydrolysates: Biochemical and metabolic engineering towards white biotechnology. Bioengineering Research 6: 388–401.

Chandel, A.K., M.L. Narasu, G. Chandrasekhar, A. Manikyam, and L.V. Rao. 2009. Use of Saccharum spontaneum (wild sugarcane) as biomaterial for cell immobilization and modulated ethanol production by thermotolerant Saccharomyces cerevisiae VS3. Bioresource technology 100: 2404–2410.

Chandel, A.K., S.S. Silva, W. Carvalho, and O.V. Singh. 2012. Sugarcane bagasse and leaves: Foreseeable biomass of biofuel and bio-products. Journal of Chemical Technology and Biotechnology 87: 1–20.

Cheung, S.W., and B.C. Anderson. 1997. Laboratory investigation of ethanol production from municipal primary wastewater. Bioresource technology 59: 81–96.

Giovanni, M. 1983. Response surface methodology and product optimization. Journal of Food Technology 37: 41–45.

Haagensen, F., and B.K. Ahring. 2002. Enzymatic hydrolysis and glucose fermentation of wet oxidized sugarcane bagasse and rice straw for cellulosic ethanol production. Riso-R-1517 (EN) 1: 184–195.

Huang, X.L., and M.H. Penner. 1991. Apparent substrate inhibition of the Trichoderma reesei cellulase system. Journal of Agriculture Food Chemistry 39: 2096–2100.

Kaar, W.E., C.V. Gutierrez, and C.M. Kinoshita. 1998. Steam explosion of sugarcane bagasse as a pretreatment for conversion to ethanol. Biomass and Bioengineering 14(3): 277–287.

Kapoor, R.K., A.K. Chandel, S. Kuhar, R. Gupta, and R.C. Kuhad. 2006. Cellulosic ethanol from crop residues, production forecasting and economics: An Indian perspective. In Lignocellulose biotechnology: Current and future prospects, ed. R.C. Kuhad, and A. Singh, 32–45. New Delhi: I.K. International.

Kim, T.H., F. Taylor, and K. Hicks. 2008. Cellulosic ethanol production from barley hull using SAA (soaking in aqueous ammonia) pretreatment. Bioresource technology 99: 5694–5702.

Kristensen, J.B., J. Borjesson, M.H. Bruun, F. Tjerneld, and H. Jorgensen. 2007. Use of surface active additives in enzymatic hydrolysis of wheat straw lignocelluloses. Enzyme and Microbial Technology 40: 888–895.

Kristensen, J.B., L.G. Thygesen, C. Felby, H. Jorgensen, and T. Elder. 2008. Cell-wall structural changes in wheat straw pretreated for cellulosic ethanol production. Biotechnology Biofuels 1(5): 1–9.

Miller, G.L. 1959. Use of dinitrosalicylic acid reagent for determination of reducing sugar. Analytical Chemistry 31: 426–428.

Mitchell, D. 2008. In: A note of rising food prices. Policy research working paper 4682. Development Prospects Group. The World Bank, Washington DC pp. 1–21.

Pasha, C., N. Valli, and L.V. Rao. 2007. Lantana camara for fuel ethanol production using thermotolerant yeast. Letter of Applied Microbiology 44: 666–672.

Penner, M.H., and E.T. Liaw. 1994. Kinetic consequences of high ratios of substrate to enzyme saccharification systems based on Trichoderma cellulase. In Enzymatic conversion of biomass for fuels production, ed. M.E. Himmel, J.O. Baker, and R.P. Overend, 363–371. Washington, DC: American Chemical Society.

Perlack, R.D., L.L. Wright, A.F. Turhollow, R.L. Graham, B.J. Sotcks, and D.C. Erbach. 2005. In: Biomass as feedstock for a bioenergy and bioproducts industry: The technical feasibility of a billion-ton annual supply. DOE/GO-10 2005-2135, April. US. Department of Energy and US. Department of Agriculture. Oak Ridge National laboratory. USA, pp. 1–78.

Ray, S., A. Goldar, and S. Miglani. 2012. The ethanol blending policy in India. Economic and Political Weekly 1: 23–25.

Rezende, C.A., M.A. de Lima, P. Maziero, E.R. deAzevedo, W. Garcia, and I. Polikarpov. 2011. Chemical and morphological characterization of sugarcane bagasse submitted to a delignification process for enhanced enzymatic digestibility. Biotechnology for Biofuels 4: 54. doi:10.1186/1754-6834-4-54.

Saha, B.C., L.B. Iten, M.A. Cotta, and Y.V. Wu. 2005. Dilute acid pretreatment, enzymatic saccharification and fermentation of wheat straw to ethanol. Process Biochemistry 40: 3693–3700.

Santos, V.T.O., P.J. Esteves, A.M.F. Milagres, and W. Carvalho. 2011. Characterization of commercial cellulases and their use in the saccharification of a sugarcane bagasse sample pretreated with dilute sulfuric acid. Journal of Indian Microbiology and Biotechnology 38: 1089–1098.

Sasikumar, E., and T. Viruthagiri. 2010. Simultaneous saccharification and fermentation (SSF) of sugarcane bagasse: Kinetics and modeling. International Journal of Chemical and Biological Engineering 3(2): 57–64.

Singh, A., A.B. Abidi, N.S. Darmwal, and A.K. Agarwal. 1990. Saccharification of cellulosic substrates by Aspergillus niger cellulase. World Journal of Microbiology & Biotechnology 6: 333–336.

Singhania, R.R., R.K. Skumaran, A. Pillai, P. Prema, G. Szakacs, and A. Pandey. 2006. Solid-state fermentation of lignocellulosic substrates for cellulase production by Trichoderma reesei NRRL 11460. Indian Journal of Biotechnology 5: 332–336.

Smidsrod, O., and G. Skjak-Braek. 1990. Alginate as an immobilization matrix for cells. Trends in Biotechnology 8(3): 71–78.

Szczodrak, J., and J. Fiedurek. 1996. Technology for conversion of lignocellulosic biomass to ethanol. Biomass and Bioengineering 10: 367–375.

Tappi Test Methods. 1992. Technical Association of the Pulp and Paper Institute (TAPPI), Test Methods 1992–1993. Atlanta: TAPPI Press.

Tu, M., R. Chandra, and J.N. Saddler. 2007. Evaluating the distribution of cellulases and recycling of free cellulases during the hydrolysis of lignocellulosic substrates. Biotechnology Progress 23: 398–406.

Wang, F.S., and J.W. Sheu. 2000. Multiobjective parameter estimation problems of fermentation processes using a high ethanol tolerance yeast. Chemical Engineering Sciences 55: 3685–3695.

Wheals, A.E., L.C. Basso, M. Denise, G. Alves, and H. Amorim. 1999. Fuel ethanol after 25 years. Trend in Biotechnology 17: 482–487.

Zaldivar, J., J. Nielsen, and L. Olsson. 2001. Fuel ethanol production from lignocellulose: A challenge for metabolic engineering and process integration. Applied Microbiology and Biotechnology 56: 17–34.

Zheng, Y., Z. Pan, R. Zhang, and D. Wang. 2009. Enzymatic saccharification of dilute acid pretreated saline crops for fermentable sugar production. Applied Energy 86: 2459–2467.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bhatia, L., Johri, S. Optimization of Simultaneous Saccharification and Fermentation Parameters for Sustainable Ethanol Production from Sugarcane Bagasse by Pachysolen tannophilus MTCC 1077. Sugar Tech 18, 457–467 (2016). https://doi.org/10.1007/s12355-015-0418-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12355-015-0418-6