Abstract

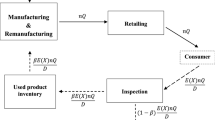

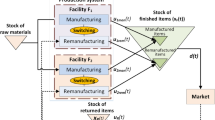

In this paper, we develop a closed-loop supply chain model to determine an appropriate strategy to be implemented in management practices. We consider a manufacturing–remanufacturing system to produce fresh product as well as recycled product maintaining equal quality. Inventories of the manufacturer and the retailer are managed by consignment stock policy. The return of used products is assumed to be random. The collected used products undergo an inspection process which is subject to learning and forgetting. A crucial inclusion of this paper gives a thought to greenhouse gas emission at the time of production. The proposed model is demonstrated with a numerical example followed by a sensitivity analysis. Our numerical study shows that about \(35\%\) cost reduction is achievable against the no learning–forgetting case. A higher learning effect in manufacturing results in a higher acquisition of the system profit, which is a key factor for the managers to be taken into consideration. Utilization of discarded items has also an impressive impact on the system; about \(6\%\) cost saving is experienced when \(50\%\) of used materials is utilized.

Similar content being viewed by others

References

Alfares HK, Attia AM (2017) A supply chain model with vendor-managed inventory, consignment, and quality inspection errors. Int J Prod Res 55(19):5706–5727

Asadkhani J, Mokhtari H, Tahmasebpoor S (2021) Optimal lot-sizing under learning effect in inspection errors with different types of imperfect quality items. Oper Res. https://doi.org/10.1007/s12351-021-00624-7

Batarfi R, Jaber MY, Glock CH (2019) Pricing and inventory decisions in a dual-channel supply chain with learning and forgetting. Comput Ind Eng 136:397–420

Ben-Daya M, As’ad R, Nabi KA (2019) A Single-vendor multi-buyer production remanufacturing inventory system under a centralized consignment arrangement. Comput Ind Eng 135:10–27

Braglia M, Zavanella L (2003) Modelling an industrial strategy for inventory management in supply chains: the Consignment Stock case. Int J Prod Res 41:3793–3808

Carlson JG, Rowe AJ (1976) How much does forgetting cost. Ind Eng 8:40–47

Chakraborty A, Maiti T, Giri BC (2021) Consignment stock policy in a closed-loop supply chain. RAIRO Oper Res 55:S1913–S1934

Çömez-Dolgan N, Moussawi-Haidar L, Jaber MY (2021) A buyer-vendor system with untimely delivery costs: traditional coordination vs. VMI with consignment stock. Comput Ind Eng 154:107009

Dey O, Giri BC (2019) A new approach to deal with learning in inspection in an integrated vendor–buyer model with imperfect production process. Comput Ind Eng 131:515–23

Gautam P, Kishore A, Khanna A, Jaggi CK (2019) Strategic defect management for a sustainable green supply chain. J Clean Prod 233:226–241

Giri BC, Glock CH (2017) A closed-loop supply chain with stochastic product returns and worker experience under learning and forgetting. Int J Prod Res 55:6760–6778

Giri BC, Masanta M (2019) Optimal production policy for a closed-loop supply chain with stochastic lead time and learning in production. Sci Iran 26(5):2936–2951

Giri BC, Masanta M (2020) A closed-loop supply chain model with uncertain return and learning–forgetting effect in production under consignment stock policy. Oper Res. https://doi.org/10.1007/s12351-020-00571-9

Giri BC, Chakraborty A, Maiti T (2017) Effectiveness of consignment stock policy in a three-level supply chain. Oper Res 17(1):39–66

Hemmati M, Fatemi Ghomi SMT, Sajadieh MS (2017) Vendor managed inventory with consignment stock for supply chain with stock-and price-dependent demand. Int J Prod Res 55(18):5225–5242

Hemmati M, Fatemi Ghomi SMT, Sajadieh MS (2018) Inventory of complementary products with stock-dependent demand under vendor-managed inventory with consignment policy. Sci Iran 25(4):2347–2360

Hill RM (1999) The optimal production and shipment policy for the single-vendor single-buyer integrated production-inventory problem. Int J Prod Res 37:2463–2475

Jaber MY, Bonney M (1996) Production breaks and the learning curve: the forgetting phenomenon. Appl Math Model 20:162–169

Jaber MY, Bonney M (1997) A comparative study of learning curves with forgetting. Appl Math Model 21(8):523–531

Jaber MY, Givi ZS, Neumann WP (2013) Incorporating human fatigue and recovery into the learning–forgetting process. Appl Math Model 37:7287–7299

Jaber MY, Zanoni S, Zavanella LE (2014) A consignment stock coordination scheme for the production, remanufacturing and waste disposal problem. Int J Prod Res 52:50–65

Kazemi N, Modak NM, Govindan K (2019) A review of reverse logistics and closed loop supply chain management studies published in IJPR: a bibliometric and content analysis. Int J Prod Res 57(15–16):4937–4960

Konstantaras I, Skouri K, Jaber MY (2012) Inventory models for imperfect quality items with shortages and learning in inspection. Appl Math Model 36:5334–5343

Liu Z, Chen J, Diallo C, Venkatadri U (2021) Pricing and production decisions in a dual-channel closed-loop supply chain with (re) manufacturing. Int J Prod Econ 232:107935

Lolli F, Messori M, Gamberini R, Rimini B, Balugani E (2016) Modelling production cost with the effects of learning and forgetting. IFAC PapersOnLine 49(12):503–508

Mondal C, Giri BC, Biswas S (2021) Integrating Corporate Social Responsibility in a closed-loop supply chain under government subsidy and used products collection strategies. Flex Serv Manuf J. https://doi.org/10.1007/s10696-021-09404-z

Savaskan RC, Bhattacharya S, Van Wassenhove LN (2004) Closed-loop supply chain models with product remanufacturing. Manag Sci 50:239–252

Schrady DA (1967) A deterministic inventory model for reparable items. Naval Res Logist 14:391–398

Sen N, Bardhan S, Giri BC (2021) Effectiveness of consignment stock policy under space limitations and deterioration. Int J Prod Res 59(6):1834–1851. https://doi.org/10.1080/00207543.2020.1727040

Shi J, Zhou J, Zhu Q (2019) Barriers of a closed-loop cartridge remanufacturing supply chain for urban waste recovery governance in China. J Clean Prod 167:108–118

Taleizadeh AA, Moshtagh MS (2019) A consignment stock scheme for closed loop supply chain with imperfect manufacturing processes, lost sales, and quality dependent return: Multi Levels Structure. Int J Prod Econ 217:298–316

Tharani S, Uthayakumar R (2020) A comparative study on stock dependent production model for deteriorating items with carbon emission, rework and multiple production setups. AIP Conf Proc 2261(1):030–065

Wright T (1936) Factors affecting the cost of airplanes. J Aeronaut Sci 3:122–128

Wu G, Yuan K (2020) Differential pricing models on a remanufacturing supply chain considering product quality upgrade under carbon trading mechanism. J Phys Conf Ser 1624(2):022–027

Xu L, Wang C (2018) Sustainable manufacturing in a closed-loop supply chain considering emission reduction and remanufacturing. Resour Conserv Recycl 212:1544–1553

Zahran SK, Jaber MY (2017) Investigation of a consignment stock and a traditional inventory policy in a three-level supply chain system with multiple-suppliers and multiple-buyers. Appl Math Model 44:390–408

Zanoni S, Jaber MY, Zavanella LE (2012) Vendor managed inventory (VMI) with consignment considering learning and forgetting effects. Int J Prod Econ 140:721–730

Zavanella LE, Zanoni S (2009) A one vendor multi-buyer integrated production-inventory model: the ‘Consignment Stock’ case. Int J Prod Econ 118:225–232

Acknowledgements

Authors are sincerely thankful to the esteemed reviewers for their comments and suggestions based on which the manuscript has been improved. Research support from Department of Science and Technology, Government of India (IF160066) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Masanta, M., Giri, B.C. A manufacturing–remanufacturing supply chain model with learning and forgetting in inspection under consignment stock agreement. Oper Res Int J 22, 4093–4117 (2022). https://doi.org/10.1007/s12351-021-00662-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12351-021-00662-1