Abstract

Forming nickel-based superalloy aero-engine components is a challenging process, largely because of the risk of high degree of springback and issues with formability. In the forming tests conducted on alloy 718 at room temperature, open fractures are observed in the drawbead regions, which are not predicted while evaluating the formability using the traditional forming-limit diagram (FLD). This highlights the importance of an accurate prediction of failure during forming as, in some cases, may severely influence the springback and thereby the accuracy of the predicted shape distortions, leading the final shape of the formed component out of tolerance. In this study, the generalised incremental stress-state dependent damage model (GISSMO) is coupled with the isotropic von Mises and the anisotropic Barlat Yld2000-2D yield criteria to predict the material failure in the forming simulations conducted on alloy 718 using LS-DYNA. Their effect on the predicted effective plastic strains and shape deviations is discussed. The failure and instability strains needed to calibrate the GISSMO are directly obtained from digital image correlation (DIC) measurements in four different specimen geometries i.e. tensile, plane strain, shear, and biaxial. The damage distribution over the drawbeads is measured using a non-linear acoustic technique for validation purposes. The numerical simulations accurately predict failure at the same regions as those observed in the experimental forming tests. The expected distribution of the damage over the drawbeads is in accordance with the experimental measurements. The results highlight the potential of considering DIC to calibrate the GISSMO in combination with an anisotropic material model for forming simulations in alloy 718.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Currently, the reductions in fuel consumption and carbon dioxide emissions are key factors for the aviation industry because of major concerns regarding climate change and more restrictive environmental laws. One of the methods of reducing both fuel consumption and CO2 emissions is by significantly decreasing the weight of vehicles while increasing the efficiency of the engine. According to the Advisory Council for Aeronautics Research in Europe (ACARE), the aviation industry has set targets for 2050 to reduce CO2 emissions by 75% and NOx by 90% compared to levels observed in 2000 [1]. To meet these requirements, the European aero-engine industry is continuously focusing on improved engine designs and alternative manufacturing methods for load-carrying structures in advanced materials, such as titanium and nickel-based superalloys. Unlike conventional large-scale single castings, new manufacturing methods involve sheet-metal parts, small castings, and forgings assembled using welding. The new manufacturing methods imply possibilities to achieve flexible designs, where each part is made of the most suitable material state with advantages such as reduced product cost, lower weight, and increased engine efficiency.

Presently, nickel-based superalloys are mainly employed in the hot sections of gas-turbine engines in military and civil aircraft [2]. In this study, an outer case sheet-metal component made of alloy 718 is analysed. It is located in the rear part of the jet engine, called the turbine exhaust case (TEC), with working temperatures up to 650 °C, see Fig. 1. The geometry of the component is shown in Fig. 2. In the forming tests to produce the component at room temperature, micro-cracks and open fractures were observed in the drawbead regions c.f. Fig. 3a, b, which could not be predicted while evaluating the formability using the forming-limit diagram as depicted in Fig. 3c. Even though the size and position of these cracks are not expected to severely influence the amount of shape deviation over the part, the presence of large-open fractures may affect the springback greatly. Therefore, it is of the most importance to accurately predict failure during forming and consider the history of the material in every step of the manufacturing process.

a Non-linear acoustic technique test setup on a drawbead, b Detailed view of micro-cracks found on the upper drawbead of the double-curved component in alloy 718 at room temperature, and c FLD (middle shell layer) of the alloy 718 showing no risk of cracks in the formed part at the end of the forming process

The generalised incremental stress-state dependent damage model (GISSMO) is a model used to predict the ductile damage, which is implemented into the finite element (FE) code LS-DYNA and it can be coupled with existing elasto–plastic material models such as von Mises (*MAT_024), Barlat Yld2000-2D (*MAT_133), or Barlat ‘89 (*MAT_226) for both metal forming and crashworthiness simulations. In the model, the failure is assumed to occur because of the plastic-deformation history of the material, implying that the damage in the material is accumulated and fracture is expected when the damage reaches a critical value. To calibrate the GISSMO model, the fracture and instability strains versus triaxiality curves are required for different stress states which, in this study, are obtained through testing four different geometries until fracture using the digital image correlation system ARAMIS™. This approach has also been used by other authors in different materials such as Anderson [3] in the dual-phase steel sheet grade DP780, Till [4] in the HCT980C complex-phase steel or Huang [5] in an USIBOR steel grade. Another approach consisting of calibrating the GISSMO by inverse modelling has also been applied by Andrade [6] in DP800. Heibel [7] combined these two approaches and calibrated the GISSMO in DP1000 using both experimental data together with DIC measurements and inverse modelling. No previous applications of the GISSMO in nickel-based superalloys have been found in literature. A subsequent parameter calibration is performed using LS-OPT considering the smallest element length to obtain both the damage and fading exponents and to evaluate the hardening after the necking process. The mesh-size independence of the damage model is captured through the regularisation factors versus element size curve. It is determined after simulating a uniaxial tensile test with varying mesh sizes from 1 to 5 mm.

In this study, the GISSMO is calibrated using DIC and employed to predict the damage and failure in the forming simulation of the outer case component in alloy 718. The damage distribution over the part is measured using the NAW® method with the help of non-linear ultrasounds [8, 9]. The predicted FEA results are compared with both experimental forming tests and damage measurements at room temperature.

Material

The material studied in this work is the alloy 718 (UNS N07718) with a sheet thickness of 2.6 mm in the solution-annealed condition. The chemical composition extracted from the material certificate is listed in Table 1.

Experimental procedure

This section briefly describes the experimental procedures followed to determine the mechanical properties of the material and the experimental reference data for the calibration of the material models used. It also includes the non-linear acoustic technique used to compare the predicted damage values with experimental measurements.

Material-characterization tests

Uniaxial tensile tests were conducted in three different directions with respect to the rolling direction: longitudinal (L), transverse (T), and diagonal (D) according to the SS-EN ISO 6892-1:2009 standard using an MTS tensile test equipment with a load capacity of 100 kN c.f. Fig. 4a. The tests were performed at a strain rate of 0.0014 s−1 up to an engineering strain of 0.2% followed by a strain rate of 0.004 s−1 until fracture. The deformation of every test was continuously monitored using a facet size/step of 19 × 15 in the ARAMIS™ digital image correlation system after applying a stochastic pattern on the surface of the specimens. This facet was equivalent to the smallest element size of 1 mm in the forming simulation. Fig. 5 shows the geometry of the tensile specimens.

A viscous bulge test [10] was performed at room temperature using a Wemhöner hydraulic press with a stamping force capability of 1300 tons at 5 mm/s to induce a balanced biaxial stress state in the specimen and determine the equibiaxial yield stress without the influence of friction. The diameter of the blank is 200 mm. The ARAMIS™ cameras were mounted on the upper die as depicted in Fig. 4b.

The results from the tests are presented in Figs. 9 and 10 while the experimental yield stresses, R-values, and anisotropic parameters of the Barlat Yld2000-2D material model are listed in Table 2.

Four different geometries are considered to calibrate the damage and failure model GISSMO. Tensile (A10), plane strain (PS), and shear (S45) specimens were tested using the MTS equipment whereas the biaxial (B) specimens were tested using the hydraulic press with the help of a hemispherical punch by adhering to the Nakazima [11] test procedure. The specimens were laser cut with respect to the longitudinal rolling direction. Fig. 6 shows the specimen geometries used. The diameter of the B specimens is 260 mm. The A10, PS, and S45 specimens were tested at a strain rate of 0.003 s−1 up to an engineering strain of 0.2% followed by a strain rate of 0.0065 s−1 until fracture. The B specimens were tested at a strain rate of 0.003 s−1. Both the instability and failure strains were measured and evaluated using DIC with a facet size/step of 15 × 12 (A10), 18 × 14 (PS), and 15 × 12 (B) equivalent to a 1 mm element size. The S45 geometry was evaluated with a facet size/step of 10 × 7 which corresponded to an element size of 0.5 mm.

Non-linear acoustic technique

The Nonlinear Acoustic Wavemodulation (NAW®) is a non-linear acoustic method used to measure the damage distribution over the drawbeads after forming. The method detects nonlinearities in the material by analysing the distortion of a low-amplitude wave which is introduced into the specimen through a transducer and by tapping a hammer on 47 different measurement points, therefore inspecting the material locally, see Fig. 3a. Cracks and other defects distort the acoustic waves generated when propagating over the drawbeads in a non-linear manner. The receiver acquires the signal and analyses de nonlinearity content of the propagated waves, as shown in Fig. 7a. The obtained signal shows the total value of the imperfections in the measured part, herein referred to as the damage value. For an undamaged specimen, a single frequency sinusoid is transmitted through the material. The signal is received without any distortion and the response from the transmitted signal is then the same undistorted sinusoid, see Fig. 7b. On the other hand, for a damaged specimen, nonlinearities such as higher harmonics appear in the received signal as depicted in Fig. 7c. The number and amplitude of nonlinearities is proportional to the amount of damage or defects in the specimen investigated. A damage value is obtained for each measurement point c.f. Fig. 17c.

Numerical procedure

The Barlat Yld2000-2D [12] material model is applied in the forming simulation. It is a non-quadratic plane-stress yield function for anisotropic materials, which is formulated based on Eqs. 1–3 as follows:

where f is the yield function, Φ′ and Φ′′ are two isotropic convex functions with respect to the three principal stresses, s1 and s2 are the principal deviatoric stresses, \( \overline{\sigma} \) is the effective stress, and a is a material coefficient based on the crystallographic structure of the material. The exponent a is suggested in the Barlat and Lian [13] yield criterion to be equal to six for materials with a BCC crystal structure and eight for materials with an FCC crystal structure.

By applying the linear transformation X = C ∙ s to each of the isotropic functions defined by Eqs. 2 and 3, the following equations are obtained:

where s is the deviatoric stress tensor, C′ and C′′ are the linear transformations, and X′1, 2 and X ′ ′1, 2 are the principal values of the linearly transformed stress tensors.

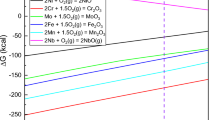

The Barlat Yld2000-2D material model comprises eight material parameters which are determined, in this study, by conducting uniaxial tensile tests in three different directions with respect to the rolling direction and an equi-biaxial test wherein a balanced biaxial stress state is obtained. From these tests, the yield stresses and R-values are determined and used as inputs to the material model. The von Mises is represented using the Barlat material model. In this case, the yield stresses correspond to SIG00 in Table 2 and the R-values are set to one. For alloy 718, the exponent a is assumed eight for the Barlat and two for the von Mises yield criteria. Fig. 10 shows the calibrated yield surfaces for both yield criteria at room temperature along with the experimental yield stresses in the three different rolling directions, and for the biaxial yield stress state. In addition, the matrices C′ and C′′ can be expressed in terms of the eight anisotropy parameters as listed in Table 2.

The blank is meshed in LS-PrePost using fully integrated shell elements (type 16) with seven integration points through the thickness. An h-adaptive method of mesh refinement is used to locally increase the density of the mesh in the areas with the largest deformations where the initial mesh size describes the geometry less accurately. For the forming simulation, the tool surfaces are modelled as rigid with a pre-determined velocity profile. The die travels in the negative z direction towards the punch at a speed of 25 mm/min with a blank-holder force of 2400 kN. The contact between the tool and the blank is modelled as a contact interface using a friction model assumed to follow the Coulomb’s friction law [14]. The friction coefficient is set to 0.275 based on the comparison between the predicted with the experimental draw-in in both x and y directions. The FE model of the forming tool includes the punch, die, binder with drawbeads, and blank as shown in Fig. 8a. The drawbeads have a radius of 4 mm and a total height from the surface of the binder of 8 mm c.f. Fig. 8b.

Damage and fracture model

The GISSMO was developed by Daimler AG and DYNAmore GmbH for prediction of ductile fracture based on incremental damage accumulation, including softening and failure [15]. In this model, the fracture is assumed to occur because of the plastic-deformation history, implying that the material (gaussian point) fails when the damage parameter D reaches a critical value i.e. D = 1. Based on the study by Kachanov [16], the damage could be defined as the reduction in the nominal section area in a representative volume element due to micro-cracks and micro-voids as follows:

where A0 is the reference cross-sectional area, and Aeff is the effective cross-sectional area after subtracting the areas of the micro-cracks and micro-voids from the reference area. The formulation of the GISSMO is based on the damage model proposed by Johnson and Cook [17] where the linear accumulation of the damage D depends on the ratio of the failure strain εf to the actual equivalent plastic strain increment dεp [18]:

When the damage reaches the value of 1, ultimate fracture is expected. The failure strain is defined as:

where d1…d5 are material constants, \( {\dot{\varepsilon}}_p \) is the rate of the von Mises equivalent plastic strain, \( {\dot{\varepsilon}}_0 \) is the reference strain rate, η is the stress triaxiality, and T is the temperature. As adiabatic heating usually does not play an important role in crash situations, the temperature dependency can be neglected, and Eq. 8 [18] can be rewritten as:

Using Equation 7, a power-law function can be used to describe the accumulation of damage as a function of plastic strain if εf is constant [18]:

By differentiating Equation 10, an incremental formulation is obtained for the non-linear damage evolution as proposed by Neukamm [15] as follows:

The equation can be rewritten as the expression for the GISSMO [19] as:

where D is the damage value (0 ≤ D ≤ 1), n is the damage exponent, εf(η) is the fracture strain as a function of the triaxiality η, and Δεp is the plastic-strain increment. Assuming plane stress conditions (σ3 = 0), the triaxiality is defined as the ratio of the mean stress to the equivalent stress [15]:

Here, σm is the hydrostatic stress, σv is the equivalent von Mises stress, and σ1 and σ2 are the two principal stresses. The plastic deformation occurs when σv reaches the yield strength of the material. Nonetheless, the failure strains are input in this work as a weighing function defined as the curve of failure strain vs. triaxiality.

The GISSMO model incorporates a path-dependent instability criterion to define the onset of diffuse necking. The equation for the same is similar to the damage accumulation expressed in Equation 12:

where F is the forming intensity, n is the new accumulation exponent, εp, loc is the equivalent plastic strain for localisation, and Δεp is the increment in the current equivalent plastic strain. The forming intensity parameter F is then accumulated in a manner similar to that of the damage parameter D; however, a different weighting function is employed, which is defined as the curve of the instability strain vs. triaxiality. The forming intensity represents the onset of material instability and marks the beginning of the need for regularisation of different mesh sizes. The basic idea is to regularise the amount of energy dissipated during crack development and propagation. When F reaches unity, the coupling of the accumulated damage to the stresses is initiated by modifying the effective-stress concept proposed by Lemaitre [20]:

where σ∗ is the stress coupled to the damage, and σ is the current stress. By combining the process of material instability, a damage threshold could be defined [19]. As soon as the damage parameter D reaches this value, the damage and flow stresses will be coupled. The current implementation helps in either entering the damage threshold as a fixed input parameter or using the damage value corresponding to the instability point. After reaching the post-critical range of the deformation or beyond the point of instability, a critical damage DCRIT is determined and is used to calculate the effective stress tensor as follows:

where m is the instability exponent governing the rate of stress fading, which directly influences the amount of energy dissipated during the element fade out. Both the damage exponent n (dmgexp) and fading exponent m (fadexp) control the way in which the true plastic stress–strain curve decreases (softening). When the material is fully damaged (D = 1), the stress in the integration point will be zero. When a user-defined number of integration points have failed, the element is deleted.

Calibration

The GISSMO is implemented into the LS-DYNA using the keyword *MAT_ADD_EROSION and is activated using the first flag IDAM = 1. When DMGTYP = 1, the damage is accumulated, and element failure occurs when D reaches unity in each of its seven integration points through the thickness. To calibrate the model, the inputs of the two load curves are required: the failure curve LCSDG, which defines the equivalent plastic strain required for failure vs. triaxiality, and the instability curve ECRIT, which defines the critical equivalent plastic strain vs. triaxiality. The experimental strain data is obtained after testing the geometries of the four specimens (A10, PS, S45, and B) corresponding to different stress states, ranging from shear to biaxial. Seventeen specimens are tested: 3 (A10), 5 (PS), 7 (S45), and 2 (B). The fracture and instability strains in each test are directly obtained using DIC at the instability point (maximum force) and at the last stage prior to the fracture, respectively. The stress triaxiality values are calculated using the algorithm proposed by Marth [21], which is used to export the local deformation gradients from ARAMIS™ to the algorithm and obtain the true stress–strain relationship beyond the point of necking until fracture. Using the von Mises yield criterion, the local strain state is used to calculate the local stress state while assuming a plane-stress condition. Fig. 11a shows the strain paths as a function of the triaxiality of the specimens tested for each geometry. Each strain path has been smoothed using the smoothing-spline function in Matlab R2014b. The average values of the failure and instability strains and their corresponding stress triaxiality are obtained for each specimen geometry. The failure and instability curves are obtained after fitting a grade 5 polynomial through the average experimental points in Matlab R2014b, as depicted in Fig. 11b.

The dmgexp and fadexp exponents are determined through an optimisation procedure in LS-OPT along with the FE-solver LS-DYNA by employing the A10, PS, and S45 geometries. The parameter identification is performed by simulating the tests conducted on the three geometries using the smallest considered element size in the forming simulation i.e. 1 mm. Because of the small evaluation area between the notches, the S45 geometry is simulated with an element size of 0.5 mm. The instability strains for each geometry are set as constant, whereas the failure strains (A10epsf, PSepsf, and S45epsf) are optimised within a failure strain of ±5%. The dmgexp and fadexp are allowed to vary between 0.1 and 5. After every iteration, the softening part of the simulated force vs. displacement curve for each geometry is compared to the corresponding experimental one, as depicted in Fig. 12. Fig. 13 shows the punch force vs. displacement curves for the two biaxial specimens tested. The experimental force vs. displacement curve is obtained by averaging the curves of the specimens tested for each specific geometry. The objective function is set to minimise the sum of least square errors between the simulation and the experiment whereas the failure displacement is used as a constraint. Table 3 lists the results of the optimisation.

To obtain mesh-size independence, the fracture strain is scaled using a factor that depends on the element size. The scale factor, or regularisation factor, is determined after simulating the A80 uniaxial tensile test specimen with different mesh sizes varying from 1 to 5 mm. The last input for calibrating the GISSMO is a load curve termed the regularisation curve, or LCREGD, wherein the abscissa and ordinate represent the element size and regularisation factors, respectively, as shown in Figs. 14 and 15.

Results

The flow curve for alloy 718 shown in Fig. 9 corresponds to the uniaxial tensile test in the longitudinal rolling direction. The curve is extended after evaluation of the small area measured by means of DIC where the strains localize before fracture. The calibrated yield surfaces for alloy 718 at room temperature are depicted in Fig. 10a. The variations in the yield stresses and R-values as a function of the rolling direction validate the anisotropic properties of this material c.f. Fig. 10b. The experimental references used to calibrate the yield criteria and the anisotropic parameters for alloy 718 at room temperature are listed in Table 2.

a Calibrated yield surfaces with experimental yield stresses for alloy 718 at room temperature for different values of shear stress \( {\upsigma}_{12}/\overline{\upsigma} \), where σ12 is the shear stress and \( \overline{\upsigma} \) is the effective stress, and b Measured and predicted R-values and initial yield stresses depending on rolling direction at room temperature

Figure 11 shows the strain paths as a function of the triaxiality for the four geometries tested and the failure and instability curves.

The experimental force vs. displacement curves are compared to the predicted ones in Fig. 12. The punch force vs. displacement curves for the two biaxial specimens tested are depicted in Fig. 13. The results of the optimisation procedure in LS-OPT i.e. damage and fading exponents, failure effective plastic strains (epsf) and failure displacements (zf) are listed in Table 3.

Figure 14 shows the effective plastic strain distributions prior element deletion for different element sizes. The scale factors to construct the regularisation curve in Fig. 15 are calculated from the predicted failure strains for each mesh size.

Figure 16 compares the effective plastic strains at the end of the forming process considering the isotropic von Mises and the anisotropic Barlat Yld2000-2D material models together with the GISSMO. The contours of the outer case geometry are included for both cases. Owing to the representation of the von Mises yield criteria using the Barlat material model, the damage distribution is stored in the history variable number 8 in LS-PrePost for both cases. Fig. 17a and b depict the damage distribution over the upper drawbead at the onset of element deletion considering the isotropic and anisotropic material models, respectively. Fig. 17c illustrates the measured damage distribution over the upper drawbead for comparison purposes.

Damage distribution over the double-curved part at the onset of element deletion for the a von Mises, and b Barlat yield criteria, and c Measured damage distribution on the upper drawbead c.f. Fig. 3a based on the number and amplitude of the nonlinearities in the acoustic waves acquired at every measurement point

After trimming to the outer case geometry, the effective plastic strain field of the two cases studied is shown in Fig. 18. The predicted amount of springback considering the two material models and the GISSMO is compared to the measured one in Fig. 19.

Discussion

The uniaxial tensile tests conducted in the three different directions with respect to the rolling direction give similar yield stresses, with the variation between the maximum (SIG00) and the minimum (SIG90) being less than 5%. The difference between the highest (R90) and lowest (R00) Lankford coefficients increases up to 21%, see Fig. 10b and Table 2. These results indicate that the specific batch of alloy 718 can be considered anisotropic in strain yet quite isotropic in stress. Therefore, the anisotropic Barlat Yld2000-2D material model is chosen for the forming simulations.

The A10, PS, and S45 tests do not follow a strain path of constant triaxiality during the loading, see Fig. 11a. Effelsberg [19] concluded that this behaviour is largely because of the geometrical changes in the section during deformation. The experimental strain paths are in good agreement with the theoretical stress triaxiality values found in literature by Haufe [22]. A strain path of constant triaxiality is used in the B geometry tests because of the inability of the algorithm proposed by Marth [21] in calculating the stress triaxiality values from the biaxial test. The LCSDG and ECRIT curves in Fig. 11b are bounded by equivalent plastic strains greater than zero.

The accuracy of the fracture strains measured on the surface of the specimens via optical strain measurements such as ARAMIS™ has been extensively discussed by other authors. On the one hand, Till [4] concluded for the complex phase steel that failure strains should be obtained using thickness measurements since surface strain measurements may underestimate the real failure strains. On the other hand, Heibel [7] found that the failure onset is overestimated for every stress state when the failure strains are obtained from tactilely measured thickness in a DP1000 steel sheet. However, the onset of fracture initiation could be accurately predicted when the experimental points of the fracture curve in GISSMO were inversely determined based on optically-measured equivalent plastic strains at fracture and then optimized based on force-displacement curves. A similar conclusion was reached by Huang [5] in a USIBOR steel grade where they validated the accuracy of the surface strain measurements using DIC after comparison with the measured thinning from equibiaxial tests. In this work, the failure strains measured on the surface of the GISSMO specimens are considered to be accurate enough to calibrate the model.

In the present calibration, the identified damage and fading exponents are listed in Table 3. The force vs. displacement curves in Fig. 12 reproduce fairly accurate the behaviour of the geometries tested. For the PS and S45 geometries, the simulated softening part of the force vs. displacement curve (PS_OPT and S45_OPT) fit reasonably well with the experimental one (PS_avg and S45_avg) after parameter identification in LS-OPT. In contrast, the simulated (A10_OPT) curve for the A10 geometry exhibits an earlier softening compared to the experimental one (A10_avg). The predicted failure strains for the three considered geometries (A10epsf, PSepsf, and S45epsf) are slightly lower than the experimental ones but within less than 4%. The simulated failure displacements (A10zf, PSzf, and S45zf) have a maximum error of 5.56% compared to the experiments.

The regularisation curve is calibrated only considering uniaxial loading (η = 1/3). The effect of using the regularisation curve but for different triaxialities is not studied in this work. The A80 geometry is chosen because it allows to run the simulations with varying mesh sizes from 1 to 5 mm while maintaining a great accuracy of the geometry of the specimen. Other geometries such as the PS (η = 1/√3), and S45 (η = 0) contain smaller measurement areas than the A80, making the highest element size of 5 mm too large to accurately represent the correct geometry of the measurement area i.e. radii of the notches.

With respect to the forming simulations, the isotropic von Mises predicts slightly higher effective plastic strains over the outer case geometry compared to the anisotropic Barlat Yld2000-2D material model, see Fig. 16a and b, respectively. The measured damage distribution over the upper drawbead in Fig. 17c is in better agreement with the predicted damage values considering the anisotropic material model c.f. Fig. 17b where the highest damage values (presented in red) correspond to the first elements deleted from the centre of the drawbead. The alternation of high and low damage values along the drawbead, as well as higher damage values on the right-hand side of the drawbead compared to those on the left-hand side where the damage values are lower are also captured.

The predicted effective plastic strains for the trimmed outer case geometry are also lower when considering the anisotropic Barlat compared to the isotropic von Mises, as depicted in Fig. 18. Overall, the predicted distribution of shape deviation considering both material models is in good agreement with the measured one c.f. Fig. 19. The anisotropic Barlat model predicts the shape deviations over the part more accurately than the von Mises, especially along the lower-left edge and around the hole. The open fractures observed in the drawbead regions could influence the behaviour of the material and therefore the resulting shape distortions.

Conclusions

In this study, the GISSMO is coupled with the isotropic von Mises and the anisotropic Barlat Yld2000-2D yield criteria to simulate the behaviour of alloy 718 in a forming procedure at room temperature using LS-DYNA. The effect of using both models in the predicted amount of shape deviation and the distribution of damage over the part is discussed. The calibration procedure of the GISSMO is also evaluated. The strain paths for the geometries tested are in good agreement with the theoretical stress triaxiality values found in literature. The parameter-optimisation procedure yields close results with the failure strains measured with DIC. The use of the damage model is found to be of major importance in predicting localisation and failure. The GISSMO can predict fracture in the forming process studied whereas the traditional FLD does not indicate any risk of failure. The predicted shape distortions are compared to the 3D-scanned measurements showing a closer agreement when considering the anisotropic model. The NAW® method can determine the distribution of the damage over the part with great accuracy. These measurements correlate best with the predicted distribution of the damage using the anisotropic yield criterion. Finally, the industry can benefit from the use of DIC to calibrate the GISSMO in forming simulations in order to design successful forming procedures without risk of material failure and enhance the accuracy of the prediction of springback of sheet-metal forming processes of interest to the aviation industry.

References

LIGHTer (2013) Lightweight solutions strengthen Swedish competitiveness and growth – for a sustainable society. Strategic research and innovation agenda for lightweight 2013-2033. http://www.lighterarena.com/media/152731/lattviktsagenda_eng_141107.pdf. Accessed 3 April 2018

Reed RC (2006) The Superalloys. Fundamentals and Applications. Cambridge University Press, New York

Anderson D, Butcher C, Pathak N, Worswich MJ (2017) Failure parameter identification and validation for a dual-phase 780 steel sheet. Int J Solids Struct 124:89–107. https://doi.org/10.1016/j.ijsolstr.2017.06.018

Till ET, Hackl B, Schauer H (2011) Crash simulation of roll formed parts by damage modelling taking into account performing effects. In: Proceedings of the 8th international conference and workshop on numerical simulation of 3D sheet metal forming processes (NUMISHEET 2011). Seoul

Huang G, Zhu H, Sriram S (2014) Fracture prediction and correlation of AlSi hot stamped steels with different models in LS-DYNA. In: Proceedings of the 13th international LS-DYNA users conference. Dearborn

Andrade FXC, Feutch M, Haufe A, Neukamm F (2016) An incremental stress state dependent damage model for ductile fracture prediction. Int J Fract 200:127–150. https://doi.org/10.1007/s10704-016-0081-2

Heibel S, Nester W, Clausmeyer T, Tekkaya AE (2017) Failure assessment in sheet metal forming using a phenomenological damage model and fracture criterion: experiments, parameter identification and validation. Procedia Eng 207:2066–2071. https://doi.org/10.1016/j.proeng.2017.10.1065

Haller KCE, Andersson SAK, Martinsen H (2012) Crack detection in cast stainless steel valve utilizing nonlinear acoustics. In: Proceedings of the 6th european workshop on structural health monitoring. Dresden

Hedberg CM, Johnson E, Andersson SAK, Haller KCE, Kjell G, Hellbratt SE (2012) Ultrasonic monitoring of a fiber reinforced plastic-steel composite beam during fatigue. In: Proceedings of the 6th european workshop on structural health monitoring. Dresden

Sigvant M, Mattiasson K, Vegter H, Thilderkvist P (2009) A viscous pressure bulge test for the determination of a plastic hardening curve and equibiaxial material data. Int J Mater Form 2:235–242. https://doi.org/10.1007/s12289-009-0407-y

Nakazima K, Kikuma T, Hasuka K (1968) Study on the formability of steel sheets. Yawata Tech Rep 264:8517–8530

Barlat F, Brem J, Yoon J, Chung K, Dick R, Ledge D, Pourgoghrat F, Choi S, Chu E (2003) Plane stress yield function for aluminum alloy sheets – part 1: theory. Int J Plast 19:1297–1319. https://doi.org/10.1016/S0749-6419(02)00019-0

Barlat F, Lian J (1989) Plasticity behaviour and strechability of sheet metals. Part I: a yield function of orthotropic sheets under plane stress condition. Int J Plast 5:51–56. https://doi.org/10.1016/0749-6419(89)90019-3

Odenberger EL, Jansson M, Thilderkvist P, Gustavsson H, Oldenburg M (2008) A short lead time methodology for design, compensation and manufacturing of deep drawing tools for inconel 718. In: Proceedings of the international deep drawing research group (IDDRG) 2008 international conference. Olofström

Neukamm F, Feucht M, Haufe A, Roll K (2008) On closing the constitutive gap between forming and crash simulation. In: Proceedings of the 10th international LS-DYNA users conference. Dearborn

Kachanov M (1999) Rupture time under creep conditions. Int J Fract 97:11–18

Johnson GR, Cook WH (1985) Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng Fract Mech 21:31–48. https://doi.org/10.1016/0013-7944(85)90052-9

Neukamm F, Feucht M, Haufe A (2008) Consistent damage modelling in the process chain of forming to crashworthiness simulations. In: Proceedings of the 2008 German LS-DYNA Forum. Bamberg

Effelsberg J, Haufe A, Feucht M, Neukamm F, Du Bois P (2012) On parameter identification for the GISSMO damage model. In: Proceedings of the 12th international LS-DYNA users conference. Detroit

Lemaitre J (1985) A continuous damage mechanics model for ductile fracture. J Eng Mater Technol 107:83–89. https://doi.org/10.1115/1.3225775

Marth S, Häggblad HÅ, Oldenburg M, Östlund R (2016) Post necking characterisation for sheet metal materials using full field measurement. J Mater Process Technol 238:315–324. https://doi.org/10.1016/j.jmatprotec.2016.07.036

Haufe A, Du Bois P, Neukamm F, Feucht M (2011) GISSMO – Material modeling with a sophisticated failure criteria. In: Proceedings of the german LS-DYNA forum. Stuttgart

Acknowledgements

The support given by GKN Aerospace Sweden AB, ITE Fabriks AB, Acoustic Agree AB, VINNOVA – Swedish Governmental Agency for Innovation Systems NFFP6 program for SME, Swedish Armed Forces, and Swedish Defence Materiel Administration is gratefully appreciated. Grant No. 2013-01173.

Funding

This study was funded by VINNOVA – Swedish Governmental Agency for Innovation Systems NFFP6 program for SME, Swedish Armed Forces, and Swedish Defence Materiel Administration (grant no. 2013-01173).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Pérez Caro, L., Schill, M., Haller, K. et al. Damage and fracture during sheet-metal forming of alloy 718. Int J Mater Form 13, 15–28 (2020). https://doi.org/10.1007/s12289-018-01461-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-018-01461-4