Abstract

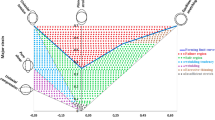

An accurate description of the material behaviour is the most important part to generate precise results in sheet metal forming simulation. The main parameters for the plastic material behaviour are the yield curve, the anisotropy and the strain rate sensitivity, which can be determined by various tests, e.g. tensile test, hydraulic bulge test or the compression test. For sheet metal forming the tensile test is the most common procedure to determine the yield curve, simple yield loci and the strain rate sensitivity. The main advantages of the tensile test are the frictionless behaviour and the simple control of the strain rate in analogy to the test velocity, nevertheless only uniaxial material behaviour can be described. For the determination of yield curves under biaxial stress and up to high strains the hydraulic bulge test, which is standardized in ISO-16808 (ISO copyright office 2013 [2]), is applied. In this paper the dependence of the strain rate sensitivity upon the applied stress state for a mild steel is investigated. To realize constant strain rates up to 0.1 s−1 in the hydraulic bulge test the punch velocity was adjusted instantaneously depending on the forming state. For prediction of the required velocity curve an inverse method using FE simulations is established. The results show a decrease of the strain rate sensitivity for increasing plastic equivalent strain up to 0.7 for uniaxial and biaxial stress conditions. However a high deviation of the level of strain rate sensitivity, which depends on the stress state, was observed. These dependencies are taken into account in a yield curve approach.

Similar content being viewed by others

References

Larour P, Bäumer A, Kirsten D, Bleck W (2012) Influence of strain rate, temperature, plastic strain, and microstructure on the strain rate sensitivity of automotive sheet steels. Steel Res Int 83:426–442

ISO copyright office (2013) Metallic Materials-Sheet and strip- determination of biaxial true stress-true strain curve using hydraulic bulge test with optical measurement system. ISO/DIS 16808:2013

Panknin W (1964) Die Bestimmung der Fließkurve und der Dehnungsfähigkeit von Blechen durch den hydraulischen Tiefungsversuch. Industrie-Anzeiger 49:915–991

Gutscher G, Wu HC, Ngaile G, Altan T (2004) Determination of flow stress for sheet metal forming using the viscous pressure bulge (VPB) test. Int J Mater Process Technol 146:1–7. doi:10.1016/S0924-0136(03)00838-0

Santos AD, Teixeira P, Barlat F (2010) Flow stress determination using hydraulic bulge test and a mechanical measurement system. Proceedings of the 10th International Conference on Numerical Methods in Industrial Forming Processes. 10:845–852

Keller S, Hotz W, Friebe F (2009) Yield curve determination using the bulge test combined with optical measurements. IDDRG 2009:319–330

Volk W, Heinle I (2010) New approach for the evaluation of plastic flow curves for large strains with Bulge test. In IV European Conference on Computational Mechanics 2010

Lipp A, Heinle I, Craighero P, Friebe H (2012) Improved flow curve determination using the bulge test combined with optical measurement systems and compensation strategies. IDDRG 2012:224–231

Min J, Stoughton T, Carsley J, Carlson B, Lin J, Gao X (2016) Accurate characterization of biaxial stress-strain response of sheet metal from bulge testing. Int J Plast. doi:10.1016/j.ijplas.2016.02.005

Volk W, Heinle I, Grass H (2011) Accurate determination of plastic yield curves and approximation point for the plastic yield locus with bulge test. In Proceedings of the 10th ICTP 2011:799–804

Mutrux A, Hochholdinger B, Hora P (2008) A procedure for the evaluation and validation of the hydraulic biaxial experiment. Numisheet 2008:67–71

Vuvetjc M, Hallfeldt T, Leppin C, Friebe H, Keller S, Till E, Heinle I, Gerlach J, Hotz W, Kuppert A, Merklein M, Behrens BA (2014) Round robin test on determination of biaxial true stress-true strain curves from bulge test. IDDRG 2014:54–58

Ramezani M, Ripin ZM, Ahmad R, Akil HM, Damghani-Nouri M (2010) High strain-rate bulge forming of sheet metals using a solid bulging medium. Int J Eng Manuf 224:257–270. doi:10.1243/09544054JEM1550

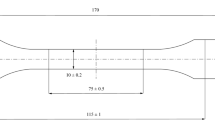

DIN copyright office (2009) Testing of metallic materials - tensile test pieces. DIN 50125:2009–07

Hoffmann H, Vogl C (2003) Determination of true stress-strain-curves and normal anisotropy in tensile tests with optical strain measurement. CIRP Ann Manuf Technol 52:217–220

Siebel E, Schwaigerer S (1948) Zur Mechanik des Zugversuchs. Archiv für das Eisenhüttenwesen 19:145–152

Vogl C (2003) Erweiterte Beschreibung des Umformverhaltens von Blechwerkstoffen. Dissertation, Technische Universität München, Utg-Forschungsberichte 23

Larour P (2010) Strain rate sensitivity of automotive sheet steels: influence of plastic strain, strain rate, temperature, microstructure, bake hardening and pre-strain. Dissertation, Berichte aus dem Institut für Eisenhüttenkunde. RWTH Aachen

Hill R (1948) A theory of the yielding and plastic flow of anisotropic metals. Proc R Soc A 193:281–297

Swift MW (1952) Plastic instability under plane stress. J Mech Phys Solids 1:1–18

Hockett JE, Sherby OD (1975) Large strain deformation of polycrystalline metals at low homologous temperatures. J Mech Phys Solids 23:87–98

Johnson GR, Cook WH (1983) A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures, Proceedings of the 7th International Symposium on Ballistics, 54:541–547

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jocham, D., Norz, R. & Volk, W. Strain rate sensitivity of DC06 for high strains under biaxial stress in hydraulic bulge test and under uniaxial stress in tensile test. Int J Mater Form 10, 453–461 (2017). https://doi.org/10.1007/s12289-016-1293-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-016-1293-8