Abstracts

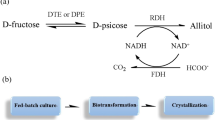

Tagatose is a rarely occurring sugar found in food and sweet fruits. It is a potential sweetener with low calories but a sweetness similar to that of sucrose. In this study, we developed a whole-cell biocatalyst using Corynebacterium glutamicum for direct bioconversion of fructose to tagatose. First, we constructed a biological conversion pathway for the conversion of fructose to tagatose by expressing tagatose 4-epimerase (TN) from Thermotoga neapolitana in C. glutamicum. Next, to increase the expression level of the enzyme, we engineered copy number of plasmid. Plasmid library was constructed by randomizing the cgrI antisense RNA region in the plasmid, and the plasmid with high-copy number was isolated using fluorescence-activated single cell sorting (FACS)-based high-throughput screening. The isolated plasmid, pHCP7, had 2-fold higher copy numbers than the original plasmid. A higher expression level and conversion yield could be achieved using pHCP7. Finally, we examined a novel tagatose 4-epimerase TN(KNF4E) isolated from Kosmotoga olearia. The gene expression level was further increased (33.9% of total fraction) through codon optimization and expression in pHCP7, and a conversion yield as high as 21.7% was achieved.

Similar content being viewed by others

References

Oh, D. K. (2007) Tagatose: properties, applications, and biotechnological processes. Appl. Microbiol. Biotechnol. 76: 1–8.

Levin, G. V. (2002) Tagatose, the new GRAS sweetener and health product. J. Med. Food 5: 23–36.

Roy, S., J. Chikkerur, S. C. Roy, A. Dhali, A. P. Kolte, M. Sridhar, and A. K. Samanta (2018) Tagatose as a potential nutraceutical: production, properties, biological roles, and applications. J. Food Sci. 83: 2699–2709.

Lu, Y., G. V. Levin, and T. W. Donner (2008) Tagatose, a new antidiabetic and obesity control drug. Diabetes Obes. Metab. 10: 109–134.

Espinosa, I. and L. Fogelfeld (2010) Tagatose: from a sweetener to a new diabetic medication? Expert Opin. Investig. Drugs 19: 285–294.

Beadle, J. R., J. P. Saunders, and T. J. Wajda Jr. (1992) Process for manufacturing tagatose. US Patent 5,078,796.

Jayamuthunagai, J., G. Srisowmeya, M. Chakravarthy, and P. Gautam (2017) d-Tagatose production by permeabilized and immobilized Lactobacillus plantarum using whey permeate. Bioresour. Technol. 235: 250–255.

Zhang, G., H. M. Zabed, J. Yun, J. Yuan, Y. Zhang, Y. Wang, and X. Qi (2020) Two-stage biosynthesis of D-tagatose from milk whey powder by an engineered Escherichia coli strain expressing L-arabinose isomerase from Lactobacillus plantarum. Bioresour. Technol. 305: 123010.

Henao-Velásquez, A. F., O. D. Múnera-Bedoya, A. C. Herrera, J. H. Agudelo-Trujillo, and M. F. Cerón-Muñoz (2014) Lactose and milk urea nitrogen: fluctuations during lactation in Holstein cows. Rev. Bras. Zootec. 43: 479–484.

Qi, X. and R. F. Tester (2019) Fructose, galactose and glucose — in health and disease. Clin. Nutr. ESPEN 33: 18–28.

Lee, S. H., S. H. Hong, K. R. Kim, and D. K. Oh (2017) High-yield production of pure tagatose from fructose by a three-step enzymatic cascade reaction. Biotechnol. Lett. 39: 1141–1148.

Shin, K.-C., T.-E. Lee, M.-J. Seo, D. W. Kim, L.-W. Kang, and D.-K. Oh (2020) Development of tagaturonate 3-epimerase into tagatose 4-epimerase with a biocatalytic route from fructose to tagatose. ACS Catal. 10: 12212–12222.

Wachtmeister, J. and D. Rother (2016) Recent advances in whole cell biocatalysis techniques bridging from investigative to industrial scale. Curr. Opin. Biotechnol. 42: 169–177.

Lin, B. and Y. Tao (2017) Whole-cell biocatalysts by design. Microb. Cell Fact. 16: 106.

Zhao, H. and W. A. van der Donk (2003) Regeneration of cofactors for use in biocatalysis. Curr. Opin. Biotechnol. 14: 583–589.

Baritugo, K.-A., J. Son, Y. J. Sohn, H. T. Kim, J. C. Joo, J. Choi, and S. J. Park (2021) Recent progress in metabolic engineering of Corynebacterium glutamicum for the production of C4, C5, and C6 chemicals. Korean J. Chem. Eng. 38: 1291–1307.

Wolf, S., J. Becker, Y. Tsuge, H. Kawaguchi, A. Kondo, J. Marienhagen, M. Bott, V. F. Wendisch, and C. Wittmann (2021) Advances in metabolic engineering of Corynebacterium glutamicum to produce high-value active ingredients for food, feed, human health, and well-being. Essays Biochem. 65: 197–212.

Jeong, S.-H., M. Kwon, and S.-W. Kim (2022) Advanced whole-cell conversion for D-allulose production using an engineered Corynebacterium glutamicum. Biotechnol. Bioprocess Eng. 27: 276–285.

Kallscheuer, N., M. Vogt, A. Stenzel, J. Gätgens, M. Bott, and J. Marienhagen (2016) Construction of a Corynebacterium glutamicum platform strain for the production of stilbenes and (2S)-flavanones. Metab. Eng. 38: 47–55.

Grigoriou, S., P. Kugler, E. Kulcinskaja, F. Walter, J. King, P. Hill, V. F. Wendisch, and E. O’Reilly (2020) Development of a Corynebacterium glutamicum bio-factory for self-sufficient transaminase reactions. Green Chem. 22: 4128–4132.

Son, J., I. H. Choi, C. G. Lim, J. H. Jang, H. B. Bang, J. W. Cha, E. J. Jeon, M. G. Sohn, H. J. Yun, S. C. Kim, and K. J. Jeong (2022) Production of cinnamaldehyde through whole-cell bioconversion from trans-cinnamic acid using engineered Corynebacterium glutamicum. J. Agric. Food Chem. 70: 2656–2663.

Son, J., J. H. Jang, I. H. Choi, C. G. Lim, E. J. Jeon, H. B. Bang, and K. J. Jeong (2021) Production of trans-cinnamic acid by whole-cell bioconversion from L-phenylalanine in engineered Corynebacterium glutamicum. Microb. Cell Fact. 20: 145.

Yang, S. J., Y. H. Kim, S. B. Kim, S. W. Park, I. H. Park, M. H. Kim, and Y. M. Lee (2020) Production method for tagatose. US Patent 10,745,720.

Yang, S. J., Y. M. Lee, I. H. Park, H. K. Cho, S. B. Kim, C. H. Lee, and E. J. Choi (2021) Composition for producing tagatose and method of producing tagatose using the same. US Patent 11,180,785.

Yim, S. S., J. W. Choi, R. J. Lee, Y. J. Lee, S. H. Lee, S. Y. Kim, and K. J. Jeong (2016) Development of a new platform for secretory production of recombinant proteins in Corynebacterium glutamicum. Biotechnol. Bioeng. 113: 163–172.

Yim, S. S., S. J. An, M. Kang, J. Lee, and K. J. Jeong (2013) Isolation of fully synthetic promoters for high-level gene expression in Corynebacterium glutamicum. Biotechnol. Bioeng. 110: 2959–2969.

Lee, C., J. Kim, S. G. Shin, and S. Hwang (2006) Absolute and relative QPCR quantification of plasmid copy number in Escherichia coli. J. Biotechnol. 123: 273–280.

Skulj, M., V. Okrslar, S. Jalen, S. Jevsevar, P. Slanc, B. Strukelj, and V. Menart (2008) Improved determination of plasmid copy number using quantitative real-time PCR for monitoring fermentation processes. Microb. Cell Fact. 7: 6.

Gruber, A. R., R. Lorenz, S. H. Bernhart, R. Neuböck, and I. L. Hofacker (2008) The Vienna RNA websuite. Nucleic Acids Res. 36(Web Server issue): W70–W74.

Kerpedjiev, P., S. Hammer, and I. L. Hofacker (2015) Forna (force-directed RNA): simple and effective online RNA secondary structure diagrams. Bioinformatics 31: 3377–3379.

Jeong, Y. J., J. W. Choi, M. S. Cho, and K. J. Jeong (2019) Isolation of novel exo-type β-agarase from Gilvimarinus chinensis and high-level secretory production in Corynebacterium glutamicum. Biotechnol. Bioprocess Eng. 24: 250–257.

Choi, J. W., S. S. Yim, and K. J. Jeong (2018) Development of a high-copy-number plasmid via adaptive laboratory evolution of Corynebacterium glutamicum. Appl. Microbiol. Biotechnol. 102: 873–883.

Ceroni, F., R. Algar, G. B. Stan, and T. Ellis (2015) Quantifying cellular capacity identifies gene expression designs with reduced burden. Nat. Methods 12: 415–418.

Bentley, W. E., N. Mirjalili, D. C. Andersen, R. H. Davis, and D. S. Kompala (1990) Plasmid-encoded protein: the principal factor in the “metabolic burden” associated with recombinant bacteria. Biotechnol. Bioeng. 35: 668–681.

Martinez, A., S. W. York, L. P. Yomano, V. L. Pineda, F. C. Davis, J. C. Shelton, and L. O. Ingram (1999) Biosynthetic burden and plasmid burden limit expression of chromosomally integrated heterologous genes (pdc, adhB) in Escherichia coli. Biotechnol. Prog. 15: 891–897.

He, L., F. Söderbom, E. G. H. Wagner, U. Binnie, N. Binns, and M. Masters (1993) PcnB is required for the rapid degradation of RNAI, the antisense RNA that controls the copy number of ColE1-related plasmids. Mol. Microbiol. 9: 1131–1142.

Okibe, N., N. Suzuki, M. Inui, and H. Yukawa (2010) Antisense-RNA-mediated plasmid copy number control in pCG1-family plasmids, pCGR2 and pCG1, in Corynebacterium glutamicum. Microbiology (Reading) 156: 3609–3623.

Venkova-Canova, T., M. Pátek, and J. Nesvera (2003) Control of rep gene expression in plasmid pGA1 from Corynebacterium glutamicum. J. Bacteriol. 185: 2402–2409.

Lee, Y. M., E.-S. Park, I. H. Park, S. M. Shin, S. J. Yang, R. Y. Yoon, E. J. Choi, S. B. Kim, and S. W. Park (2021) Novel fructose-4-epimerase and tagatose production method using same. US Patent 20,210,363,532.

Acknowledgements

This work was supported by research grants from CJ CheilJedang Institute of Biotechnology, and by the National Research Foundation of Korea (NRF) grant funded by the Ministry of Science and ICT (MSIT) [No. NRF-2020R1A2C2012537], Republic of Korea.

Author information

Authors and Affiliations

Contributions

EJJ designed the study, performed the experiments, analyzed the data and drafted the manuscript. EJC, YML, SBK participated in the execution of the experiments and data interpretation. KJJ initiated and supervised the study, and revised manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

EJJ, SBK, and KJJ declare no direct and indirect conflict of interest that relate to this manuscript. YMJ and EJC are full-time employees of CJ Cheiljedang, however the funding sponsors had no role in the performance of the experiments and in the collection, analysis and interpretation of the data. Neither ethical approval required nor informed consent was required for this study.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic Supplementary Material

Rights and permissions

About this article

Cite this article

Jeon, E.J., Lee, YM., Choi, E.J. et al. Production of Tagatose by Whole-cell Bioconversion from Fructose Using Corynebacterium glutamicum. Biotechnol Bioproc E 28, 419–427 (2023). https://doi.org/10.1007/s12257-022-0304-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12257-022-0304-5