Abstract

Objectives

Doping of halloysite nanotubes (HNTs) with γ-methacryloxypropyltrimethoxysilane (γ-MPS) as a silane coupling agent has sparked the interest of researchers. The objective of the study was to design, characterize and critically optimize γ-MPS–doped HNTs by homogenization technique to achieve uniform dispersion and homogenous mixture of clay minerals.

Methods

Optimization of doped HNTs was performed by applying custom design using JMP software 16.1, by considering 2 levels and 3 factors, to determine the impact of independent variables such as concentration of γ-MPS (X1), HNTs (X2) and ethanol (X3) on the response variables diffraction angle (Y1) and zeta potential (Y2).

Results

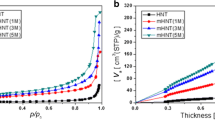

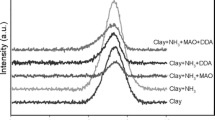

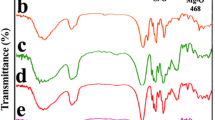

The results showed that γ-MPS was successfully doped on the surface of HNTs. Existence of characteristic peaks in Fourier-transform infrared analysis affirms the doping of pristine HNTs. From the x-ray diffraction patterns, it was observed that upon doping there was slight shift in the interlayer distance signifying the intercalation of γ-MPS onto the layers of HNTs. Scanning electron microscopic analysis revealed that the doped HNTs showed reduced aggregation as compared to pristine HNT. DHNT F3 and DHNT F7 exhibited higher zeta potential values indicating the excellent stability and dispersibility of the formulation. The predicted R2 values for diffraction angle (2θ) (0.94) and zeta potential (mv) (0.95) were close to 1. The optimal values of the independent variables were obtained to measure the desirability of independent variables (X1, X2 and X3) at the concentration of 9 ml, 37.5 g and 87.5 ml, respectively. The overall desirability D = 0.998, indicates the efficiency of custom design for the studied responses.

Conclusion

The present study concluded that HNTs were successfully doped with γ-MPS using ultra-turrax homogenizer and the results of statistical analysis indicate that the application of custom design proves to be an ideal tool for optimizing the doping of HNTs.

Similar content being viewed by others

Abbreviations

- PHNTs:

-

Pristine Halloysite nanotubes

- γ-MPS:

-

γ-methacryloxypropyltrimethoxysilane

- DHNTs F1:

-

Doped HNT Formulation 1

- DHNTs F2:

-

Doped HNT Formulation 2

- DHNTs F3:

-

Doped HNT Formulation 3

- DHNTs F4:

-

Doped HNT Formulation 4

- DHNTs F5:

-

Doped HNT Formulation 5

- DHNTs F6:

-

Doped HNT Formulation 6

- DHNTs F7:

-

Doped HNT Formulation 7

- DHNTs F8:

-

Doped HNT Formulation 8

References

Eveline B, Tales D, Douglas AS, Henri SS, Susana AL, Raquel SM. Organosilane-functionalized halloysite for high performance halloysite/heterophasic ethylene–propylene co-polymer nanocomposites. Appl Clay Sci. 2015;112:68–74. https://doi.org/10.1016/j.clay.2015.04.020.

Sagare RD, Dasankoppa FS, Sholapur HN, Buruga K. Halloysite nanotubes: design, characterization and applications. A review. Farmacia. 2021;69(2):218–14. https://doi.org/10.31925/farmacia.2021.2.3.

Bediako E, Nyankson E, Arhin D, Tuffour B, Lukowiec D, Tomiczek B, et al. Modified halloysite nanoclay as a vehicle for sustained drug delivery. Heliyon. 2018;4(7):1–22. https://doi.org/10.1016/j.heliyon.2018.e00689.

Satish S, Tharmavaram M, Rawtani D. Halloysite nanotubes as a nature’s boon for biomedical applications. Nanobiomedicine. 2019;6:1–16.

Saif MJ, Asif HM. Escalating applications of halloysite nanotubes. J Chil Chem Soc. 2015;60(2):2949–53. https://doi.org/10.4067/S0717-97072015000200019.

Yuan P, Tan D, Bergaya F. Properties and applications of halloysite nanotubes: recent research advances and future prospects. Appl Clay Sci. 2015;112:75–93. https://doi.org/10.1016/j.clay.2015.05.001.

Santos AC, Ferreira C, Veiga F, Ribeiro AJ, Panchal A, Lvov Y, Agarwal A. Halloysite clay nanotubes for life sciences applications: from drug encapsulation to bioscaffold. Adv Colloid Interface Sci. 2018;257:58–70. https://doi.org/10.1016/j.cis.2018.05.007.

Barry A. Hydrophobicity, hydrophilicity and silanes. Paint and Coatings Industry. 2006;22(10):114.

Yang Y, Chen Y, Leng F, Huang L, Wang Z, Tian W. Recent advances on surface modification of Halloysite nanotubes for multifunctional applications. Appl Sci. 2017;7:1215. https://doi.org/10.3390/app7121215.

Riza Erdogan A, Ilker A, Cevdet K. Influences of aminosilanization of halloysite nanotubes on the mechanical properties of polyamide-6 nanocomposites. Polym Compos. 2014;35(7):1350–61. https://doi.org/10.1002/pc.22787.

Ravichandran G, Rathnakar G, Santosh N. Effect of heat treated HNT on physico-mechanical properties of epoxy nanocomposites. Compos Commun. 2019;13:42–6. https://doi.org/10.1016/j.coco.2019.02.005.

Dhankar P. Homogenization fundamentals. IOSR J Eng. 2014;4(5):1–8.

Aziz DE, Abdelbary AA, Elassasy AI. Implementing central composite design for developing transdermal diacerein loaded niosomes: ex vivo permeation and in vivo deposition. Curr Drug Deliv. 2018;15(9):1330–42. https://doi.org/10.2174/1567201815666180619105419.

Buruga K, Kalathi J. Fabrication of γ-MPS modified HNT-PMMA nanocomposites by ultrasound assisted mini-emulsion polymerization. JOM. 2018;70(7):1307–12. https://doi.org/10.1007/s11837-018-2829-9.

Padhi S, Acharya PGR, Nayak NC. Mechanical and morphological properties of modified halloysite nanotubes filled ethylene-vinyl acetate copolymer nanocomposites. J Polym Eng. 2017;184(24):271–9. https://doi.org/10.1515/polyeng-2017-0075.

Yuan P, Southon P, Liu Z, Green MR, Hook J, Antill S, Kepert C. Functionalization of halloysite clay nanotubes by grafting with γ-aminopropyltriethoxysilane. J Phys Chem C. 2008;112(40):15742–51. https://doi.org/10.1021/jp805657t.

Jozanikohan G, Abarghooei M. The Fourier transform infrared spectroscopy (FTIR) analysis for the clay mineralogy studies in a clastic reservoir. J Petrol Explor Prod Technol. 2022;12:2093–106. https://doi.org/10.1007/s13202-021-01449-y.

Pasbakhsk P, Ismail H, Fauzi Ahmed MN, Bakar AA. EPDM/modified halloysite nanocomposites. Appl Clay Sci. 2010;48(3):405–13. https://doi.org/10.1016/j.clay.2010.01.015.

Zargarian SS, Haddadi-Asl, Hematpour H. Carboxylic acid functionalization of halloysite nanotubes for sustained release of diphenhydramine hydrochloride. J Nanopart Res. 2015;218(17):1–13. https://doi.org/10.1007/s11051-015-3032-3.

Yiu H, Botting CH, Botting NP, Wright P. Size selective protein adsorption on thiol-functionalized SBA-15 mesoporous molecular sieve. Phys Chem Chem Phys. 2001;3(15):2983–5. https://doi.org/10.1039/B104729A.

Sederidou I, Karabela M. Effect of the amount of 3-methacycloxypropyltrimethoxy silane coupling agent on physical properties of dental resin nanocomposites. Dent Mater. 2009; 25(11):1315–24. https://doi.org/10.1016/j.dental.2009.03.016.

Fouad H. Experimental and numerical studies of notch strengthening behavior of semi-crystalline ultra-high molecular weight polyethylene. Materials & Design. 2010;31(3):1117–29. https://doi.org/10.1016/j.matdes.2009.09.042.

Frost R, Mako E, Kristof J, Horvath E, Kloprogge JT. Modification of kaolonite surfaces by mechanochemical treatment. Langmuir. 2001;17(16):4731–8. https://doi.org/10.1021/la001453k.

Schaak R, Holder C. Tutorial on powder X-ray diffraction for characterizing nanoscale materials. ACS Nano. 2019;13:7359–65.

Albdiry MT, Yousif BF, Ku H, Lau KT. A critical review on the manufacturing processes in relation to the properties of nanoclay/polymer composites. J Compos Mater. 2013;47(9):1093–1115. https://doi.org/10.1177/2F0021998312445592.

Terzopoulou Z, Papageorgiou D, Papageorgiou G, Bikiaris D. Effect of surface functionalization of halloysite nanotubes on synthesis and thermal properties of poly (ε-caprolactone). J Mater Sci. 2018;53(9):6519–41. https://doi.org/10.1007/s10853-018-1993-1.

Zhou Z, Wang S, Lu L, Zhang Y, Zhang Y. Functionalization of multi-wall carbon nanotubes with silane and its reinforcement on polypropylene composites. Compos Sci Technol. 2008;68(7):1727–33. https://doi.org/10.1016/j.compscitech.2008.02.003.

Mu B, Zhao M, Liu P. Halloysite nanotubes grafted hyperbranched (co) polymers via surface -initiated self –condensing vinyl (co) polymerization. J Nanopart Res. 2008;10(5):831–8. https://doi.org/10.1007/s11051-007-9319-2.

Zhan W, Yi H, Song S, Zhao W, Rao F. Hydrophobic agglomeration behaviors of clay minerals as affected by siloxane structure. Colloids Surf A. 2019;568:36–42. https://doi.org/10.1016/j.colsurfa.2019.01.061.

Nguyen TC, Nguyen TD, Vu DT, Dinh DP, Nguyen AH, Li TN, Dao PH, Nguyen TL, Bach LG, Thai H. Modification of titanium dioxide nanoparticles with 3-(Trimethoxysilyl) propyl methacrylate silane coupling agent. J Chem. 2020;1–10. https://doi.org/10.1155/2020/1381407.

Akram W, Garud N. Design expert as a statistical tool for optimization of 5-ASA-loaded biopolymer-based nanoparticles using Box Beknken factorial design. Futur J Pharm Sci. 2021;146(7):1–17. https://doi.org/10.1186/s43094-021-00299-z.

Garg RK, Singhavi I. Optimization techniques: an overview for formulation development. Asian J Pharm Res. 2015;5(3):217–21.

Blum F, Young E, Smith G, Sitton O. Thermal analysis of adsorbed poly (methyl methacrylate) on silica. Langmuir. 2006;22(10):4741–4. https://doi.org/10.1021/la053098.

Wang DH, Baek JB, Tan LS. Grafting of vapor-grown carbon nanofibers (VGCNF) with a hyperbranched poly (ether-ketone). Mater Sci Eng B. 2006;132(1–2):103–7. https://doi.org/10.1016/j.mseb.2006.02.039.

Tafere C, Yilma Z, Abrha S, Yehualaw A. Formulation, in vitro characterization and optimization of taste masked orally disintegrating co-trimoxazole tablet by direct compression. PLoS One. 2021;16(3):1–35. https://doi.org/10.1371/journal.pone.0246648.

Acknowledgements

The authors are thankful to KLE College of Pharmacy, Belgaum for providing the facility to carry out zeta potential analysis. We also express special thanks to National Institute of Technology, Surathkal, Karnataka for XRD and SEM analysis, Jiwaji University, Gwalior for TGA, DSC and TEM analysis, Furthermore, we are also thankful to JMP support team to carry out optimization studies by using JMP software.

Funding

The research work was supported by funding agency AICTE - RPS Scheme, Government of India. Scheme sanctioned with file no: 8-89/FDC/RPS (POLICY-1) /2019-2020.

Author information

Authors and Affiliations

Contributions

All the authors have equal contribution and participation in this research work. RS and FD have structured the study design and carried out the optimization, experimentation, collection and interpretation of data. RS and FD contributed in drafting and revision of the manuscript. HS has contributed in interpretation of statistical data analysis. RS, FD and HS have read and approved the manuscript.

Corresponding author

Ethics declarations

Ethics Approval and Consent to Participate

Not applicable.

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sagare, R.D., Dasankoppa, F.S. & Sholapur, H.N. Design, Optimization and Characterization of γ-Methacryloxypropyltrimethoxysilane-doped Halloysite Clay Nanotubes Using Ultra-turrax Homogenizer. J Pharm Innov 18, 719–734 (2023). https://doi.org/10.1007/s12247-022-09680-8

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12247-022-09680-8