Abstract

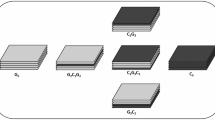

The morphology and nanostructure of carbon and glass fiber are investigated by using XRD, SEM and TEM analysis. The composites are divided into three groups which consists of “without post-curing”, “post-cured at 80 °C for 6 hrs” and “post-cured at 120 °C for 3 hrs” to investigate curing temperature effect. The mechanical properties of composites are tested in the indentation, tensile, and flexural machine with ASTM standard. According to the results, the hardness of post-curing of carbon fiber reinforced polymer (CFRP) and glass fiber reinforced polymer (GFRP) are increased approximately three-times and 5 % compared to with and without post-curing process. The tensile strength of CFRP and GFRP are approximately 458 MPa and 385 MPa, while post-cured at 120 °C for the three-hour results are 490 MPa and 433 MPa respectively. In contrast, composites of treated fiber are not improved mechanical strength significantly for CFRP, while GFRP are slightly increased by 7 %. On the other hand, the flexural strength of treated carbon and glass fiber of composite are increased to 3 % and 15 % respectively. Higher temperature and treated fiber composites of carbon fiber are not significantly improved because high temperature curing and treated fiber created more porous to occur fracture internally.

Similar content being viewed by others

References

Anderson, D. P. (1989). Carbon fiber morphology: wide-angle X-ray studies of pitch- and pan-based carbon fibers. WRDC-TR-89-4072, US Air Force Technical Report, Ohio, USA.

Anghelina, V. F., Popescu, I. O., Gaba, A., Popescu, I. N., Despa, V. and Ungureanu, D. (2010). Structural analysis of PAN fiber by X-ray diffraction. J. Science and Arts 1, 1, 89–94.

Bascom, W. D. and Drzal, L. T. (1987). The surface properties of carbon fibers and their adhesion to organic polymers. NASA Contractor Report 4084.

Campana, C., Leger, R., Sonnier, R., Ferry, R. and Ienny, P. (2018). Effect of post curing temperature on mechanical properties of a flax fiber reinforced epoxy composite. Composites Part A: Applied Science and Manufacturing, 107, 171–179.

Dwight, D. (2000). Glass Fiber Reinforcements. Comprehensive Composite Materials, 1, 231–261.

Karin, P., Boonsakda, J., Siricholathum, K., Saenkhumvong, E., Charoenphonphanich, C. and Hanamura, K. (2017). Morphology and oxidation kinetics of CI engine’s biodiesel particulate matters on cordierite diesel particulate filters using TGA. Int. J. Automotive Technology 18, 1, 31–10.

Kim, Y., Choi, C., Kumar, S. K. S., Kim, C., Kim, S. and Lim, J. H. (2017). Thermo-gravimetric analysis method to determine the fiber volume fraction for PAN-based CFRP considering oxidation of carbon fiber and matrix. Composites Part A: Applied Science and Manufacturing, 102, 40–17.

Maurin, R., Davies, P., Baral, N. and Baley, C. (2008). Transverse properties of carbon fibres by nano-indentation and micro-mechanics. Applied Composite Materials 15, 2, 61–73.

Morgan, P. (2005). Carbon Fibers and Their Composites. CRC Press Taylor & Francis Group. Boca Raton.

Sharma M., Gao, S., Mäder, E., Sharma, H., Wei, L. Y. and Bijwe, J. (2014). Carbon fiber surfaces and composite interphases. Composites Science and Technology, 102, 35–50.

Somani, P. R. and Umeno, M. (2007). Importance of transmission electron microscopy for carbon nanomaterials research. Modern Research and Educational Topics in Microscopy. FORMATEX, 634–642.

Tiwari, S. and Bijwe, J. (2014). Surface treatment of carbon fibers — A review. Procedia Technology, 14, 505–512.

Volkova, V. K. and Kalistratova, L. F. (2015). X-ray diffraction analysis of structure of composite materials based on polytetrafluoroethylene during thermal exposure. Inorganic Materials: Applied Research, 6, 411–413.

Wang, C. R., Gu, Y. Z., Zhang, K. M., Li, M. and Zhang, Z. G. (2013). Rapid curing epoxy resin and its application in carbon fibre composite fabricated using VARTM moulding. Polymers and Polymer Composites, 21, 315–324.

Wang, X., Wang, Q., Gao, L. and Jia, Y. (2017). Effect of heat treatment on curing uniformity of fiber composite laminates. Polymers and Polymer Composites, 25, 29–33.

Wu, S., Liu, Y., Ge, Y., Ran, L. R., Peng, K. and Yi, M. (2016). Surface structures of PAN-based carbon fibers and their influences on the interface formation and mechanical properties of carbon-carbon composites. Composites Part A: Applied Science and Manufacturing, 90, 480–488.

Yun, Y. M., Seo, M. W., Koo, G. R., Ra, H. W., Yoon, S. J., Kim, Y. K., Lee, J. G. and Kim, H. (2014). Pyrolysis characteristics of GFRP (glass fiber reinforced plastic) under non-isothermal conditions. Fuel, 137, 321–327.

Acknowledgement

This work is supported by King Mongkut’s Institute of Technology Ladkrabang (2562-0111006), Tokyo Institute of Technology, Somboon Advance Technology Co., Ltd., Polyplastic Co., Ltd., and National Science and Technology Development Agency.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Man, T.C., Karin, P., Lin, Y.H. et al. A Study on Curing Temperature and Fracture Mechanism of Carbon and Glass Fiber Reinforced Polymers Using an Electron Microscopy. Int.J Automot. Technol. 22, 687–700 (2021). https://doi.org/10.1007/s12239-021-0064-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12239-021-0064-9