Abstract

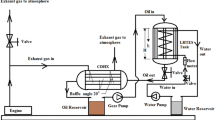

A novel design process for a parallel multi-flow type air-cooled condenser of a dual-loop waste heat recovery system with Rankine steam cycles, for improving the fuel efficiency of gasoline automobiles, has been investigated, focusing on reduction of the pressure drop inside the micro-tubes. The low temperature condenser plays a role in dissipating heat from the system, by sufficiently condensing the low temperature loop working fluid. However, the refrigerant has low enough evaporation temperature to recover the waste heat from engine coolant of about 100°C, but has small saturation enthalpy, so that excessive mass flow rate of the LT working fluid, e.g. over 150 g/s, causes an enormously large pressure drop of the working fluid, to maintain the heat dissipation performance of more than 20 kW. This paper has dealt with a scheme to design a low temperature condenser that has reduced the pressure drop, while ensuring the required thermal performance from the waste heat recovery system. The number of passes, arrangement of the tubes of each pass, and positions of the inlet and outlet pipes on the header are the most critical parameters affecting flow uniformity through all the tubes of the condenser. For the purpose of the performance predictions and parametric study for the LT condenser, we have developed a 1-dimensional userfriendly performance prediction program that feasibly calculates the phase change of the working fluid in the tubes. The proposed design process enables design engineers to find the optimum values of the numbers of passes and tubes of the multiflow condenser, for the reduction of the pressure drop sustaining the heat exchange performance. An example is presented through the proposed design process, and compared with an experiment.

Similar content being viewed by others

Abbreviations

- σ:

-

flow uniformity

- N:

-

number of tubes per pass

- Q:

-

mass flow rate of working fluid, kg/s

- S.C.:

-

subcool, °C

- S.H.:

-

superheat, °C

References

Bae, S. J., Heo, H. S., Lee, H. K., Lee, D. H., Kim, T. J., Park, J. S., Lee, H. Y. and Kim, C. J. (2011). Performance characteristics of a rankine steam cycle and boiler for engine waste heat recovery. SAE Paper No. 2011-28-0055.

Bae, S. J., Heo, H. S., Park, J. S., Lee, H. Y. and Kim, C. J. (2012). Design and performance evaluation of low temperature condenser of waste heat recovery system for fuel economy improvement. Spring Conf. Proc., Korean Society of Automotive Engineers, 250–255.

Endo, T., Kawajiri, S., Kojima, Y., Takahashi, K., Baba, T., Ibaraki, S., Takahashi, T. and Shinohara, M. (2007). Study on maximizing energy in automotive engines. SAE Paper No. 2007-01-0257.

Freymann, R., Ringler, J., Seifert, M. and Horst, T. (2012). The second generation turbosteamer. MTZ Worldwide, 2012, 2, 18–28.

Heo, H. S. and Bae, S. J. (2010). Technology trends of rankine steam cycle for engine waste heat recovery. Auto J. KSAE 32, 5, 23–32.

Ringler, J., Seifert, M., Guyotot, M. and Hubner, M. (2009). Rankine cycle for waste heat recovery of IC engines. SAE Paper No. 2009-01-0174.

Teng, H., Regner, G. and Cowland, C. (2007). Waste heat recovery of heavy-duty diesel engines by organic rankine cycle part II: Working fluids for WHR-ORC. SAE Paper No. 2007-01-0543.

Ye, L., Tong, M. W. and Zeng, X. (2009), Design and analysis of multiple parallel-pass condensers. Int. J. Refrigeration 32, 6, 1153–1161.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bae, S.J., Heo, H.S., Kim, C.J. et al. Design of an air-cooled condenser for engine coolant waste heat recovery. Int.J Automot. Technol. 16, 17–26 (2015). https://doi.org/10.1007/s12239-015-0002-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12239-015-0002-9