Abstract

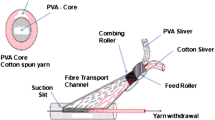

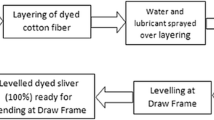

Polypropylene spun yarn is very widespread as filtration media to manufacture candle filters. The porosity of the yarn plays a vital role in deciding the performance characteristics of filters wound from it. Since the DREF spinning system is used to produce string from which the wound filters are constructed, the spinning parameters also strongly influence the resultant yarn properties. This study aimed to understand the impact of the speed ratio, spinning drum speed, and suction pressure on the yarn properties and porosity. Design Expert13® was used to find the main spinning process parameters that influenced yarn properties. Suction pressure was the most prominent factor influencing the yarn porosity, followed by the speed ratio, while spinning drum speed did not affect significantly.

Similar content being viewed by others

Data availability

All necessary data is already shared.

References

A. J. Sonagra, B. Mait, C. R. Prayag, S. R. Vengsarkar, ATIRA Comm. Text. 41, 47 (2007)

S. Dhameja, K.R. Salhotra, R. Chattopadhyay, R.C.D. Kaushik, Ind. J. Fib. Text. Res. 27, 33 (2002)

S.M. Ishtiaque, A. Das, P. Vishnoi, Ind. J. Fib. Text. Res. 36, 152 (2011)

P.S. Kanade, M.V. Koranne, T.A. Desai, Alexandria Engg. J. 56, 9 (2016). https://doi.org/10.1016/j.aej.2016.09.012,Sept.2016

W. Klein, 2nd ed., Vol. 6, pp 17–20, Text. Inst., United Kingdom, 1998

H. Abo-Taleb, H. El-Fowaty, A. Sakr, J. Text. Sci. Engg 5, 217 (2015). https://doi.org/10.4172/2165-8064.1000217

R. Chattopadhya, K.R. Salhotra, S. Dhameja, R.C.D. Kaushik, Ind. J. Fib. Text. Res. 23, 131 (1998)

Acknowledgements

This work received a grant from the Research and Consultancy Cell (RCC/Dir/2017/335/28), The Maharaja Sayajirao University of Baroda, INDIA. The author is grateful to Mr. Siddharth Patel of Ashutosh Spinning Mills for permitting to use their spinning facility, providing the raw material, and allowing the staff members to spare their valuable time and give their valuable inputs. The author would like to thank Ms. Smita Trivedi from Management studies, The Maharaja Sayajirao University of Baroda, for giving valuable inputs in the statistical analysis.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The author declares that there is no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kanade, P. Role of Spinning Machine Process Variables on Porosity of DREF Spun Yarn. Fibers Polym 24, 2521–2527 (2023). https://doi.org/10.1007/s12221-023-00241-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-023-00241-5