Abstract

To explore the distribution of flow field inside the swirl nozzle under different inlet pressure conditions, the model and numerical simulation analysis of the nozzle are carried out by fluid analysis softwares named STAR-CCM+ and ANSYS CFX, and the cloud chart of velocity and pressure distribution in the swirl nozzle during spinning is obtained. The results show that the flow mechanism of air into the swirl nozzle through inlet follows the vortex flow effect, and the swirling flow to both sides can slightly untwist the yarn and further paste the hairiness. The flow field inside the nozzle under different inlet pressure conditions was obtained. It is concluded that the inlet pressure has no effect on the distribution of yarn stress, but the fluctuation amplitude of air pressure increases with the increase of inlet pressure. The larger the fluctuation amplitude is, the better the fuzzy yarn is wrapped, but the excessive air pressure will cause more fiber loss.

Similar content being viewed by others

Data availability

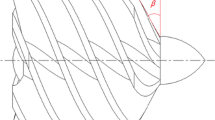

The description here is about the rotational state of the airflow, which is difficult to characterize numerically.

References

X.J. Liu, X.Z. Su, Fiber. Polym. 17, 940 (2016)

Lawrence, Fundamentals of Spun Yarn Technology (CRC Press, Boca Raton, 2003), pp.1–5

X.Z. Lan, H. Qiu, Y. Zhang, Fiber. Polym. 13, 104 (2012)

M. Li, M.G. Li, STAR-CCM+ and Flow Field Calculation (Mech. Indus. Press, Beijing, 2011)

J.C. Lee, K.Y. Kim, G.S. Jung, L. Ye, Fiber. Polym. 19, 1102 (2018)

J. Yan, H. Qiu, Adv. Text. Tech. 25, 87 (2017)

J.L. Mou, H. Qiu, M.Q. Ge, Tex. Res. J. 11, 36 (2009)

N. Chen, M. Wu, H. Qiu et al., Tex. Res. J. 35, 142 (2014)

Y.Y. Fu, H. Qiu, M.Q. Ge, Tex. Res. J. 35, 124 (2014)

J. Yan, H. Qiu, R.R. Cui, J. Cloth. Res. 1, 455 (2016)

A. Patnaik, R.S. Rengasamy, V.K. Kothari, M.Q. Ge, J. Text. Inst., Part 3 97, 89 (2006)

J.H. Lim, J.S. Kim, Y. Huh, Fiber. Polym. 19, 219 (2018)

J.S. Pan, Fundamentals of Aerodynamics (Natl. Def. Indus. Press, Beijing, 2012)

K. Ramachandralu, B.S. Dasaradan, J. Ind. Text. 43, 26 (2004)

Y. Guo, C. Wassgren, B. Hancock, Powder Technol. 249, 386 (2013)

Acknowledgements

This work was supported by “the Fundamental Research Funds for the Central Universities under Grant No. JUSRP52007A.”

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xi, C., Hua, Q. Flow Simulations of Swirl Nozzle Under Different Inlet Pressure Conditions. Fibers Polym 24, 2343–2355 (2023). https://doi.org/10.1007/s12221-023-00238-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-023-00238-0