Abstract

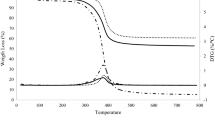

Currently, there is still no knowledge of the potential uses of the increasing post-industrial fiberglass fabric waste generated from wind turbine manufacturing industries. The present work proposes reusing this fiberglass fabric waste as reinforcement in new thermosetting polymer composites. Polyester composites with different numbers and stacking sequences of stitched and random scraps of fiberglass fabrics were prepared using a resin transfer molding process. Moreover, their thermal stability, flexural and tensile properties were evaluated. Results of the statistical analysis performed according to Tukey’s methodology indicated that the number of fiberglass layers is the decisive factor influencing the mechanical properties of the developed composites, whereas their stacking sequence does not have a significant influence. The composites with four layers of fiberglass fabric waste showed promising mechanical properties with flexural and tensile strengths higher than 205 and 115 MPa, respectively, and Young’s Modulus higher than 2700 MPa, enabling their use in numerous applications. On the other hand, the number of fiberglass fabric layers had only a small influence on the thermal stability of the composites of around 335 °C. Overall results showed that reusing fiberglass fabric waste as reinforcement in new polymer composites is a feasible way to valorize this waste from wind turbine industries.

Similar content being viewed by others

References

N. Andersen, O. Eriksson, K. Hillman, and M. Wallhagen, Energies, 9, 999 (2016).

P. Liu and C. Y. Barlow, Waste Manag., 62, 229 (2017).

S. Djunisic, 3GWEC sees 330 GW of New Wind Globally by 2023, https://renewablesnow.com/news/gwec-sees-330-gw-of-new-wind-globally-by-2023-668140/ (Accessed January 24, 2020).

J. Chen, J. Wang, and A. Ni, J. Reinf. Plast. Compos., 38, 567 (2019).

Y. Noorollahi, S. M. Bina, and K. Rahmani, Int. J. Energy Policy Manag., 3, 8 (2018).

R. Cherrington, V. Goodship, J. Meredith, B. M. Wood, S. R. Coles, A. Vuillaume, A. Feito-Boirac, F. Spee, and K. Kirwan, Energy Policy, 47, 13 (2012).

H. Albers, S. Greiner, H. Seifert, and U. Kühne, DEWI Mag., 34, 32 (2009).

S. Huysman, J. De Schaepmeester, K. Ragaert, J. Dewulf, and S. De Meester, Resour. Conserv. Recycl., 120, 46 (2017).

A. V. Oskouei, M. Bazli, H. Ashrafi, and M. Imani, Polym. Test., 69, 417 (2018).

E. E. Theotokoglou and G. A. Balokas, J. Reinf. Plast. Compos., 34, 101 (2015).

A. Rahimizadeh, J. Kalman, K. Fayazbakhsh, and L. Lessard, Compos. Part B Eng., 175, 107101 (2019).

D. S. Cousins, Y. Suzuki, R. E. Murray, J. R. Samaniuk, and A. P. Stebner, J. Clean. Prod., 209, 1252 (2019).

D. Åkesson, Z. Foltynowicz, J. Christéen, and M. Skrifvars, J. Reinf. Plast. Compos., 31, 1136 (2012).

S. Job, Reinf. Plast., 57, 19 (2013).

J. Beauson, H. Lilholt, and P. Brøndsted, J. Reinf. Plast. Compos., 33, 1542 (2014).

H. Rodin III, S. Nassiri, K. Englund, O. Fakron, and H. Li, Constr. Build. Mater., 187, 738 (2018).

S. H. Mamanpush, H. Li, K. Englund, and A. Tavousi Tabatabaei, Waste and Biomass Valorization, 11, 3853 (2020).

K. Larsen, Renew. Energy Focus, 9, 70 (2009).

P. C. Guerrero, S. D. Mancini, and C. M. Toubia, HOLOS Environ., 147, 1519 (2011).

A. Yazdanbakhsh, L. C. Bank, K. A. Rieder, Y. Tian, and C. Chen, Resour. Conserv. Recycl., 128, 11 (2018).

N. Singh, D. Hui, R. Singh, I. P. S. Ahuja, L. Feo, and F. Fraternali, Compos. Part B Eng., 115, 409 (2017).

C. A. Mucelin and M. Bellini, Soc. Nat., 20, 111 (2008).

T. P. Sathishkumar, S. Satheeshkumar, and J. Naveen, J. Reinf. Plast. Compos., 33, 1258 (2014).

D. K. Rajak, D. D. Pagar, P. L. Menezes, and E. Linul, Polymers, 11, 1667 (2019).

W. R. Stahel, Nature, 531, 435 (2016).

N. J. Pagano and R. B. Pipes, J. Compos. Mater., 5, 50 (1971).

H. P. S. A. Khalil, C. W. Kang, A. Khairul, R. Ridzuan, and T. O. Adawi, J. Reinf. Plast. Compos., 28, 1123 (2009).

M. Koziol, J. Compos. Mater., 46, 1067 (2011).

R. Potluri, R. S. Dheeraj, and G. V. V. N. G. Vital, Mater. Today Proc., 5, 5876 (2018).

M. Bazli, H. Ashrafi, A. Jafari, X.-L. Zhao, R. K. S. Raman, and Y. Bai, Polymers, 11, 1401 (2019).

K. Herbuś and P. Ociepka, MATEC Web of Conf., doi: https://doi.org/10.1051/matecconf/201711204022 (2017).

A. Karimzadeh, M. Y. Yahya, M. N. Abdullah, and K. J. Wong, Fiber. Polym., 21, 1583 (2020).

ASTM D790-03, “Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials”, ASTM International, West Conshohochen, PA, 2003.

ASTM D3039-02, “Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials”, ASTM International,West Conshohochen, PA, 2002.

E. O. Ogunsona, M. Misra, and A. K. Mohanty, Compos. Part A Appl. Sci. Manuf., 98, 32 (2017).

F. Anjum, N. Gull, S. M. Khan, M. A. Munawar, A. Islam, S. I. Niazi, S. Zia, M. Shafiq, M. T. Z. Butt, and T. Jamil, Adv. Polym. Technol., 37, 929 (2018).

N. C. Pereira, Rev. Mackenzie Eng. e Comput., 11, 23 (2012).

D. A. Jesson and J. F. Watts, Polym. Rev., 52, 321 (2012).

F. A. López, M. I. Martín, I. García-Díaz, O. Rodríguez, F. J. Alguacil, and M. Romero, J. Environ. Prot., doi: https://doi.org/10.4236/jep.2012.38088 (2012).

S. R. Naqvi, H. M. Prabhakara, E. A. Bramer, W. Dierkes, R. Akkerman, and G. Brem, Resour. Conserv. Recycl., 136, 118 (2018).

N. Guermazi, N. Haddar, K. Elleuch, and H. F. Ayedi, Mater. Des., 56, 714 (2014).

F. Rubino, A. Nistic, F. Tucci, and P. Carlone, J. Mar. Sci. Eng., 8, 26 (2020).

M. Kara, M. Uyaner, and A. Avci, Compos. Struct., 123, 1 (2015).

M. E. Hossain, J. Compos. Mater., 45, 2133 (2011).

C. P. Pantelides, M. Asce, J. Nadauld, and L. Cercone, J. Compos. Constr., 7, 118 (2003).

M. Shamsuddoha, L. P. Djukic, M. M. Islam, T. Aravinthan, and A. Manalo, J. Compos. Mater., 51, 1605 (2016).

K. B. Katnam, A. J. Comer, D. Roy, L. F. M. Da Silva, and T. M. Young, J. Adhes., 91, 113 (2015).

Acknowledgments

The authors gratefully appreciate the financial support by the Coordination for the Improvement of Higher Education Personnel (CAPES) [funding code 001 and grant number 88887.464432/2019-00]. The authors are grateful to Wobben Windpower Indústria e Comércio Ltda. and Ashland Polímeros do Brasil S.A. for providing some of the materials used in the composites, and to Sinctronics for performing the thermogravimetric analysis of the composites.

Author information

Authors and Affiliations

Corresponding author

Additional information

Conflict of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Rights and permissions

About this article

Cite this article

Fernandes, A.P., Prado, K.S., Castanho, M.N. et al. Preparation and Characterization of Polymeric Composites Assembled from Fiberglass Fabric Waste from the Wind Blades Manufacturing Process. Fibers Polym 23, 3606–3614 (2022). https://doi.org/10.1007/s12221-022-4425-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-022-4425-4