Abstract

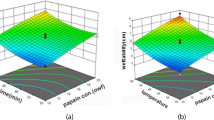

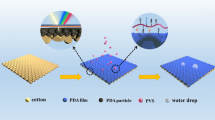

Water-based polyurethane (WPU) provides a number of benefits over typical solvent-based polyurethane. WPU is more environmentally friendly, safe, and reliable. The WPU with polycaprolactone diol/polycarbonate diol (PCL/PCDL) complex soft segment was developed using a prepolymer technique to enhance the color depth of cotton knitted fabrics dyed with reactive dyes. The appearance, particle size, zeta potential, and viscosity of WPU emulsions were analyzed. The chemical structure, thermal stability, phase change performance, and topography of WPU films were characterized by Fourier-transform infrared (FTIR), thermogravimetric analysis (TGA), differential scanning calorimetry (DSC), and atomic force microscopy (AFM), respectively. The tensile and hydrophilic properties of the WPU films were examined by an electronic universal testing machine and contact angle goniometer, respectively. The K/S value, rubbing fastness, washing fastness, and wearability of finished and unfinished dark cotton knitted fabrics were measured. Simultaneously, the chemical structure and morphology of fabrics were investigated using FTIR and scanning electron microscopy (SEM). The results show the WPU-2 emulsion demonstrated excellent stability, and the WPU-2 film showed superior thermal stability. The K/S value of the dark cotton knitted fabric finished with WPU-2 emulsion (40 g/l) increased by 18.58 %, and the wet rubbing color fastness of the resulting fabric was enhanced. The SEM results show a layer of film covered the surface of the finished fabric. In summary, the WPU can provide a new technique for enhancing the color depth of fabrics.

Similar content being viewed by others

References

H. Y. Jiang, Y. Wang, H. Quan, and W. Li, Fiber. Polym., 19, 703 (2018).

I. Bramhecha and J. Sheikh, Ind. Eng. Chem. Res., 58, 21252 (2019).

S. Fu, D. Hinks, P. Hauser, and M. Ankeny, Cellulose, 20, 3101 (2013).

E. Mouxiou, I. Eleftheriadis, N. Nikolaidis, and E. Tsatsaroni, J. Appl. Polym. Sci., 108, 1209 (2008).

A. Q. Hou and Y. Q. Shi, Mat. Sci. Eng. B-Adv., 163, 99 (2009).

K. L. Xie, A. Q. Hou, and Y. H. Zhang, J. Appl. Polym. Sci., 100, 720 (2006).

C. Yu, Y. Lu, and F. Wu, J. Appl. Polym. Sci., 136, 48208 (2019).

H. H. Wang and Y. T. Lin, J. Appl. Polym. Sci., 90, 2045 (2003).

M. Soyama, Y. Kiuchi, M. Iji, S. Tanaka, and K. Toyama, J. Appl. Polym. Sci., 131, 40366 (2014).

E. Sharmin, F. Zafar, D. Akram, M. Alam, and S. Ahmad, Ind. Crop. Prod., 76, 215 (2015).

Z. Wu, L. Y. Shen, and L. Zhou, Key Eng. Mater., 492, 525 (2012).

E. L. Brantley and G. K. Jennings, Macromolecules, 37, 1476 (2004).

H. Kim and S. Lee, Fiber. Polym., 19, 965 (2018).

D. S. Cheng, Y. H. Liu, C. W. Yan, Y. Zhou, Z. M. Deng, J. H. Ran, S. G. Bi, S. Y. Li, G. M. Cai, and X. Wang, Cellulose, 28, 6727 (2021).

H. Zhou, H. X. Wang, H. T. Niu, Y. Zhao, Z. G. Xu, and T. Lin, Adv. Funct. Mater., 27, 1604261 (2017).

W. H. Song, B. Wang, L. H. Fan, F. Q. Ge, and C. X. Wang, Appl. Surf. Sci., 463, 403 (2019).

S. Y. Kang, Z. X. Ji, L. F. Tseng, S. A. Turner, D. A. Villanueva, R. Johnson, A. Albano, and R. Langer, Adv. Mater., 30, 1706237 (2018).

L. H. Chan-Chan, R. Solis-Correa, R. F. Vargas-Coronado, J. M. Cervantes-Uc, J. V. Cauich-Rodríguez, P. Quintana, and P. Bartolo-Pérez, Acta Biomater., 6, 2035 (2010).

T. Wang, W. Sun, X. Y. Zhang, H. Y. Xu, and F. Xu, Materials, 10, 1247 (2017).

Y. Wang, R. Chen, T. Li, P. M. Ma, H. J. Zhang, M. L. Du, M. Q. Chen, and W. F. Dong, Ind. Eng. Chem. Res., 59, 458 (2020).

S. McCreath, P. Boinard, E. Boinard, P. Gritter, and J. J. Liggat, Int. J. Adhes. Adhes., 86, 84 (2018).

L. Q. Meng, X. Z. Shi, R. L. Zhang, L. Yan, Z. P. Liang, Y. J. Nie, Z. P. Zhou, and T. F. Hao, J. Appl. Polym. Sci., 137, 49314 (2020).

S. Rattanapan, P. Pasetto, J. F. Pilard, and V. Tanrattanakul, J. Polym. Res., 23, 182 (2016).

S. Zo, S. Choi, H. Kim, E. Shin, and S. Han, J. Nanosci. Nanotechnol., 20, 5014 (2020).

C. H. Dong, X. Wei, and Y. J. Luo, RSC Adv., 8, 42041 (2018).

Z. L. Fan, Q. Li, X. B. Cai, and Z. B. Li, J. Text. Inst., 108, 1227 (2016).

C. S. Xu, Z. S. Cai, J. W. Xing, Y. Ren, W. Z. Xu, and W. Z. Shi, Fiber. Polym., 15, 665 (2014).

C. Alkan, E. Günther, S. Hiebler, Ö. F. Ensari, and D. Kahraman, Sol. Energy, 86, 1761 (2012).

K. Chen, R. W. Liu, C. Zou, Q. Y. Shao, Y. J. Lan, X. Q. Cai, and L. L. Zhai, Sol. Energy Mater. Sol. Cells, 130, 466 (2014).

S. A. Oleyaei, Y. Zahedi, B. Ghanbarzadeh, and A. A. Moayedi, Int. J. Biol. Macromol., 89, 256 (2016).

P. Schön, K. Bagdi, K. Molnár, P. Markus, B. Pukánszky, and G. J. Vancso, Eur. Polym. J., 47, 692 (2011).

Y. Han, J. Hu, and Z. Xin, Prog. Org. Coat., 130, 8 (2019).

Y. T. Han, Z. Chen, W. Dong, and Z. Y. Xin, High Perform. Polym., 27, 824 (2014).

L. Q. Hu, Z. J. Pu, Y. Q. Zhong, L. Z. Liu, J. Cheng, and J. C. Zhong, J. Polym. Res., 27, 129 (2020).

B. Ghanbarzadeh, M. Musavi, A. Oromiehie, K. Rezayi, E. R. Rad, and J. Milani, LWT-Food Sci. Tech., 40, 1191 (2007).

Acknowledgments

This study was supported by the Postgraduate Innovation Fund Project of Xi’an Polytechnic University (No. chx2021005) and the Scientific Research Program Funded by Shaanxi Provincial Education Department (No. 21JY014). This study was also supported by the ShaoxingKeqiao West-Tex Textile Industry Innovation Institute (No. 19KQZD11) and the Key Laboratory Project of Shaanxi Provincial Department of Education (No. 20JS050).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

There are no conflicts to declare.

Rights and permissions

About this article

Cite this article

Xie, Y., Lu, S., Shi, W. et al. Color Depth Enhancement and Improved Rubbing Color Fastness of Cotton Knitted Fabrics via Polyurethane with PCL/PCDL Polyester Soft Segment. Fibers Polym 23, 2638–2647 (2022). https://doi.org/10.1007/s12221-022-4388-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-022-4388-5