Abstract

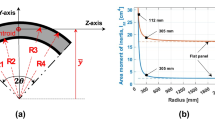

This paper presents the progressive failure analysis of carbon nano tubes/polymer/fiber reinforced laminated curved composite panels under transverse pressure load distributed over the panel surface for various taper configurations. The ply-by-ply stresses were computed using the finite element method with displacement fields derived based on higher order shear deformation theory (HSDT). The first ply failure was predicted based on Tsai-Wu failure criterion, and the stiffness degradation method were employed to track post-failure behavior and failure progression. The verification of the current method is performed by comparing the results of the FE analysis with the numerical results available in literature and experimental tests. Finally, various parametric analysis were performed to investigate the influence of MWCNTs concentration, taper configurations and curved geometries on the failure characteristics. It was noticed that the failure resistance of the panel significantly enhanced with the addition of CNT filler, regardless of the considered taper configurations. It was also noticed that the hyperbolic and cylindrical geometries have the highest and lowest overall stiffness and strength. It was observed that the taper configuration TC-3 results a higher LPF load among the other taper configurations for all the considered curved geometries. Finally, the present work could be used as a guide to study the failure characteristics of CNT reinforced laminated tapered curved composite panels, which finds many application in finds many applications in windmill, turbine and helicopter blades.

Similar content being viewed by others

References

G. Akhras and W. C. Li, Compos. Struct., 79, 34 (2007).

R. Ganesan, Compos. Struct., 82, 159 (2008).

M. Teotia and R. K. Soni, Eng. Fail. Anal., 94, 412 (2018).

J. N. Reddy and A. K. Pandey, Comput. Struct., 25, 371 (1987).

S. Tolson and N. Zabaras, Comput. Struct., 38, 361 (1991).

Y. S. N. Reddy, C. M. D. Moorthy, and J. N. Reddy, Int. J. Non. Linear. Mech., 30, 629 (1995).

A. J. Vizzini and S. W. Lee, J. Am. Helicopter Soc., 40, 43 (1995).

T.-Y. Kam, H. F. Sher, T. N. Chao, and R. R. Chang, Int. J. Solids Struct., 33, 375 (1996).

B. G. Prusty, S. K. Satsangi, and C. Ray, J. Reinf. Plast. Compos., 20, 671 (2001).

R. Ganesan and D. Zhang, Sci. Eng. Compos. Mater., 11, 79 (2004).

P. F. Liu and J. Y. Zheng, Mater. Des., 31, 3825 (2010).

M. Romanowicz, Int. J. Solids Struct., 51, 2549 (2014).

K. Bakshi and D. Chakravorty, Thin-Walled Struct., 76, 1 (2014).

C.-S. Lee, J.-H. Kim, S. Kim, D.-M. Ryu, and J.-M. Lee, Compos. Struct., 121, 406 (2015).

A. M. Gadade, A. Lal, and B. N. Singh, Mech. Adv. Mater. Struct., 23, 739 (2016).

Y. Yang, X. Liu, Y.-Q. Wang, H. Gao, R. Li, and Y. Bao, Compos. Sci. Technol., 151, 85 (2017).

A. Kumar, Structures, 14, 95 (2018).

M. Fakoor and S. M. N. Ghoreishi, Polym. Test., 70, 533 (2018).

D. Biswas and C. Ray, Int. J. Mech. Sci., 161, 105057 (2019).

R. Joshi, P. Pal, and S. K. Duggal, Eur. J. Mech., 81, 103964 (2020).

S. A. M. Ghannadpour and N. Abdollahzadeh, Int. J. Non. Linear. Mech., 121, 103292 (2020).

P. Rozylo, M. Ferdynus, H. Debski, and S. Samborski, Materials (Basel), 13, 1138 (2020).

K. Choi, Y. Hwang, H. Kim, and H. Kim, Compos. Struct., 224, 110990 (2019).

K. Jin, H. Wang, J. Tao, and D. Du, Compos. Part A, 124, 105490 (2019).

S. Lin, L. Yang, H. Xu, X. Jia, X. Yang, and L. Zu, Compos. Struct., 255, 113046 (2021).

L. Wan, Y. Ismail, Y. Sheng, K. Wu, and D. Yang, J. Compos. Mater., 55, 1091 (2021).

X. S. Sun, V. B. C. Tan, and T. E. Tay, Comput. Struct., 89, 1103 (2011).

J. Gu, K. Li, and L. Su, Mater., 12, 3292 (2019).

J. Galos, Compos. Struct., 236, 111920 (2020).

P. K. Bajpai and I. Singh, “Reinforced Polymer Composites: Processing, Characterization and Post Life Cycle Assessment”, John Wiley & Sons, 2019.

K. Stamoulis, S. K. Georgantzinos, and G. I. Giannopoulos, Int. J. Struct. Integr., 11, 670 (2019).

S. K. Georgantzinos, Nanotechnology, 10, 10 (2019).

J. Wuite and S. Adali, Compos. Struct., 71, 388 (2005).

S. J. Mehrabadi and B. S. Aragh, Thin-Walled Struct., 80, 130 (2014).

P. Kumar and J. Srinivas, Compos. Struct., 177, 158 (2017).

K. Mehar and S. K. Panda, Adv. Polym. Technol., 37, 1643 (2018).

J. N. Reddy and C. F. Liu, Int. J. Eng. Sci., 23, 319 (1985).

M. S. Qatu, Appl. Acoust., 44, 215 (1995).

A. Bhimaraddi, Int. J. Solids Struct., 27, 897 (1991).

A. B. Arumugam and V. Rajamohan, Iran. J. Sci. Technol. Trans. Mech. Eng., 43, 155 (2019).

S. Goswami and W. Becker, J. Compos. Mater., 50, 201 (2015).

M. R. Garnich and V. M. K. Akula, Appl. Mech. Rev., 62, 1 (2009).

Y. S. N. Reddy and J. N. Reddy, Compos. Sci. Technol., 44, 227 (1992).

M. K. Kassa and A. B. Arumugam, Polym. Compos., 41, 3322 (2020).

M. K. Kassa, A. B. Arumugam, and T. Rana, Mater. Today Proc., 26, 944 (2020).

M. Kim, F. A. Mirza, and J. I. Song, WIT Trans. Built Environ., 112, 279 (2010).

V. Lupăşteanu, N. Ţăranu, and S. Popoaei, Bull. Polytech. Inst. Jassy, 63, 83 (2013).

M. Cho and J.-Y. Yoon, Compos. Struct., 40, 115 (1997).

Acknowledgments

The authors are grateful to Science and Engineering Research Board (SERB), India for providing financial support through a funded project under Early Career Research Award, Grant No: ECR/2018/000827 to carry out this computational work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Conflict of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Rights and permissions

About this article

Cite this article

Kassa, M.K., Selvaraj, R. & Arumugam, A.B. A Finite Element Based Progressive Failure Analysis of Carbon Nanotubes/Polymer/Fiber Reinforced Laminated Composite Tapered Panels. Fibers Polym 23, 3552–3568 (2022). https://doi.org/10.1007/s12221-022-4072-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-022-4072-9