Abstract

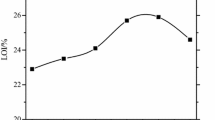

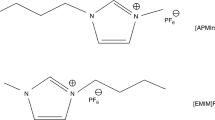

The halogen-free flame retardant (HFFR) thermoplastic elastomers (TPEs) composites filled with aluminum hypophosphite had been prepared by twin-screw extruder. The flame retardancy, thermal stability, charring-effect, mechanical and rheological properties of TPE composites had been investigated by cone calorimeter, limiting oxygen index (LOI), UL-94 (vertical flame) test, thermogravimetric analysis (TGA), scanning electron microscopy (SEM), ultimate tensile and rheometer. The research results indicated that the flame retardancy and thermal stability of flame retardant (FR) TPEs had been dramatically improved. Obvious char-forming effect can be found for the samples with the addition of polyphenylene oxide (PPO) during high heat flow conditions, which presented more content and more compact of residue compared to the samples without PPO after combustion of cone calorimeter. Mechanical and rheological characteristics showed that the tensile strength and processability can be well maintained for FR TPEs composites, which was very important for industrial applications.

Similar content being viewed by others

References

M. M. Hirschler and T. Piansay, Fire. Mater., 31, 373 (2007).

A. R. Horrocks, S. Nazare, and B. Kandola, Fire. Safety. J., 39, 259 (2004).

M. A. Cardenas, D. Garcia-Lopez, I. Gobernado-Mitre, J. C. Merino, J. M. Pastor, J. D. Martinez, J. Barbeta, and D. Calveras, Polym. Degrad. Stab., 93, 2032 (2008).

G. Beyer, J. Fire. Sci., 23, 75 (2005).

R. Shanks and I. Kong, Thermoplastic Elastomers [M], 8, 137 (2012).

M. B. Alanalp and A. Durmus, Polymer, 142, 267 (2018).

R. R. Babu and K. Naskar, Adv. Rubber Compos., 239, 219 (2011).

K. Pal and J. N. Rastogi, J. Appli. Polym. Sci., 94, 407 (2004).

Y. Q. Shi, L. B. Fu, X. L. Chen, J. Guo, F. Q. Yang, J. G. Wang, Y. Y. Zheng, and Y. Hu, Nanomaterials, 7, 259 (2017).

C. Y. Hsieh, W. C. Su, C. S. Wu, L. K. Lin, K. Y. Hsu, and Y. L. Liu, Polymer, 54, 2945 (2013).

M. J. Chen, Z. B. Shao, X. Li. Wang, L. Chen, and Y. Z. Wang, Ind. Eng. Chem. Res., 51, 9769 (2012).

L. C. Wang, J. Q. Jiang, P. K. Jiang, and J. H. Yu, J. Polym. Res., 17, 891 (2010).

L. C. Wang, J. H. Yu, Z. L. Tang, and P. K. Jiang, J. Mater. Sci., 45, 6668 (2010).

L. C. Wang, G. L. Wang, and P. K. Jiang, J. Appl. Polym. Sci., 120, 368 (2011).

L. C. Wang, X. F. Wu, C. Wu, J. H. Yu, G. L. Wang, and P. K. Jiang, J. Appl. Polym. Sci., 121, 68 (2011).

D. W. Xu, H. C. Lu, Q. Huang, B. F. Deng, and L. Li, RSC Adv., 8, 5034 (2018).

B. Xu, X. Wu, W. Ma, L. J. Qian, F. Xin, and Y. Qiu, J. Anal. Appl. Pyrol., 134, 231 (2018).

Y. Zhong, W. Wu, X. Lin, and M. Li, J. Appl. Polym. Sci., 131, 41094 (2014).

J. S. Yi, Y. Liu, and X. F. Cai, J. Therm. Anal. Calorim., 113, 753 (2013).

X. Q. Su, Y. W. Yi, J. Tao, H. Q. Qi, and D. Y. Li, Polym. Degrad. Stab., 105, 12 (2014).

H. D. Chen, J. H. Wang, A. Q. Ni, A. X. Ding, X. Han, and Z. H. Sun, Materisls, 11, 111 (2018).

C. M. Feng, M. Y. Liang, J. L. Jiang, J. G. Huang, and H. B. Liu, Thermo. Acta., 627, 83 (2016).

C. H. Chen, C. H. Lin, T. I. Wong, M. W. Wang, and T. Y. Juang, Polymer, 149, 286 (2018).

G. Tang, X. J. Huang, H. C. Ding, X. Wang, S. D. Jiang, K. Q. Zhou, B. B. Wang, W. Yang, and Y. Hu, RSC. Adv., 4, 8985 (2014).

X. J. Lai, S. Tang, H. Q. Li, and X. R. Zeng, Polym. Degrad. Stab., 113, 22 (2015).

G. J. Jiang, H. Wu, and S. Y. Guo, J. Macro. Sci. Part B: Phys., 46, 533 (2007).

H. M. Tiggemann, D. Tomacheski, F. Celso, V. F. Ribeiro, and S. M. B. Nachtigall, Polym. Testing, 32, 1373 (2013).

C. F. Antunes, M. V. Duin, and A. V. Machado, Mater. Chem. Phys., 133, 410 (2012).

V. F. Ribeiro, D. N. Simões, M. Pittol, D. Tomacheski, R. M. C. Santana, Polym. Testing, 63, 204 (2017).

H. M. Tiggemann, V. F. Ribeiro, F. Celso, and S. M. B. Nachtigall, Appl. Clay Sci., 109, 151 (2015).

R. R. Tiwari and D. R. Paul, Polymer, 52, 5595 (2011).

P. A. Enright and C. M. Fleischmann, Fire Technol., 35, 153 (1999).

D. C. O. Marney, L. J. Russell, and R. Mann, Fire Mater., 32, 357 (2008).

K. Carpenter and M. Janssens, Fire Technol., 41, 79 (2005).

X. Y. Huang, P. K. Jiang, C. Kim, F. Liu, and Y. Yin, Euro. Polym. J., 45, 377 (2009).

Acknowledgement

The High-level Scientific Research Start-up Foundation for the introduction of talent from Nantong University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, LC., Sun, Q. & Zhang, CC. The Charring Effect and Flame Retardant Properties of Thermoplastic Elastomers Composites Applied for Cable. Fibers Polym 21, 2599–2606 (2020). https://doi.org/10.1007/s12221-020-9778-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-020-9778-y