Abstract

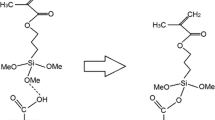

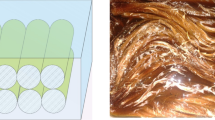

Natural fiber reinforced polymer composite has been widely used in various industry fields. Natural fiber treatment can effectively improve its mechanical and durability properties, and expands its applications. In the present study, isocyanate was proposed to treat flax fibers in order to reduce the hydrophilic properties of the fibers, and to enhance the bonding of flax fiber to epoxy matrix. The isocyanate treated fabric was evaluated with fourier transform infra-red (FTIR), scanning electron microscopy (SEM) and water uptake. The effects of the fiber treatment on the mechanical properties of flax fabric reinforced epoxy (FFRP) plates were investigated. FTIR and SEM analysis indicated that isocyanate reacts with flax fiber, forming a thin polymer layer on the fiber surface. The water absorption test showed that isocyanate treatment decreased the water uptake of the flax fabric by 4`-18 times compared to the control fabric. The flexural and tensile strength of FFRP with isocyanate solution treated fabrics were enhanced more than 20 %, attributed to the improved adhesion of fiber to epoxy. Based on the above results, the treatment method of flax fiber with isocyanate is considered as an effective approach to improve both hydrothermal ageing resistance and mechanical properties of FFRPs.

Similar content being viewed by others

References

C. G. Li, G. J. Xian, and H. Li, Int. J. Fatigue, 120, 141 (2019).

O. Faruk, A. K. Bledzki, H.-P. Fink, and M. Sain, Prog. Polym. Sci., 37, 1552 (2012).

M. George, M. Chae, and D. C. Bressler, Prog. Mater. Sci., 83, 1 (2016).

M. Bar, R. Alagirusamy, and A. Das, Compos. Struct., 197, 63 (2018).

M. Bar, A. Das, and R. Alagirusamy, J. Reinf. Plast. Compos., 36, 818 (2017).

I. O. Bakare, F. E. Okieimen, C. Pavithran, H. P. S. Abdul Khalil, and M. Brahmakumar, Mater. Des., 31, 4274 (2010).

T. Gurunathan, S. Mohanty, and S. K. Nayak, Compos. Part A-Appl. Sci. Manuf., 77, 1 (2015).

M. Bar, R. Alagirusamy, and A. Das, J. Text. Inst., 10, 1369 (2019).

Y. Xie, C. A. S. Hill, Z. Xiao, H. Militz, and C. Mai, Compos. Part A-Appl. Sci. Manuf., 41, 806 (2010).

L. Yan, B. Kasal, and L. Huang, Compos. Part B-Eng., 92, 94 (2016).

T.-T.-L. Doan, H. Brodowsky, and E. Mäder, Compos. Sci. Technol., 72, 1160 (2012).

A. Le Duigou, A. Kervoelen, A. Le Grand, M. Nardin, and C. Baley, Compos. Sci. Technol., 100, 152 (2014).

M. Bar, A. Das, and R. Alagirusamy, Compos. Part A-Appl. Sci. Manuf., 107, 260 (2018).

J. Karger-Kocsis, H. Mahmood, and A. Pegoretti, Prog. Mater. Sci., 73, 1 (2015).

M. M. Kabir, H. Wang, K. T. Lau, and F. Cardona, Compos. Part B-Eng., 43, 2883 (2012).

W. Wang, G. Xian, and H. Li, Cellulose, 26, 8165 (2019).

O. Arnould, D. Siniscalco, A. Bourmaud, A. Le Duigou, and C. Baley, Ind. Crops Prod., 97, 224 (2017).

N. M. Girouard, S. Xu, G. T. Schueneman, M. L. Shofner, and J. C. Meredith, ACS Appl. Mater. Interfaces, 8, 1458 (2016).

Z. Xu, X. Lin, and H. Liu, Iranian Polym. J., 28, 417 (2019).

G. Siqueira, J. Bras, and A. Dufresne, Langmuir, 26, 402 (2010).

N. Sgriccia, M. C. Hawley, and M. Misra, Compos. Part A-Appl. Sci. Manuf., 39, 1632 (2008).

J. Gironès, M. T. B. Pimenta, F. Vilaseca, A. J. F. de Carvalho, P. Mutjé, and A. A. S. Curvelo, Carbohydr. Polym., 68, 537 (2007).

A. Karmarkar, S. S. Chauhan, J. M. Modak, and M. Chanda, Compos. Part A-Appl. Sci. Manuf., 38, 227 (2007).

H. Ishikawa, H. Takagi, A. N. Nakagaito, M. Yasuzawa, H. Genta, and H. Saito, Composite Interfaces, 21, 329 (2014).

ASTM D790-03, Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials, ASTM International, West Conshohocken, PA, 2003.

U. Tayfun, M. Dogan, and E. Bayramli, Polym. Compos., 38, 2874 (2017).

T. Hänninen, A. Thygesen, S. Mehmood, B. Madsen, and M. Hughes, Ind. Crops Prod., 39, 7 (2012).

T. Yu, C.-M. Wu, C.-J. Wang, and S.-P. Rwei, Compos. Interfaces, 20, 483 (2013).

Acknowledgements

This work is financially supported by Chinese MIIT Special Research Plan on Civil Aircraft with grant No. MJ-2015-H-G-103 and the National Natural Science Foundation of China with Grant No. 51878223.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, W., Fu, R., Deng, Q. et al. Surface Modification of Flax Fibers with Isocyanate and Its Effects on Fiber/Epoxy Interfacial Properties. Fibers Polym 21, 2888–2895 (2020). https://doi.org/10.1007/s12221-020-9722-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-020-9722-1