Abstract

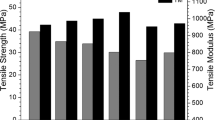

Bio-based CaCO3 powder was synthesized via size reduction method from waste eggshells. The XRD analysis revealed that eggshell powder consists of CaCO3 in calcite form. The inclusion level of CaCO3 contents were varied of 5, 10, 15, 20 and 25 wt.% of prepared CaCO3-polyester film. Effects of different proportions of prepared chicken eggshell and commercial CaCO3 filler on the polyester resin composites films were compared by means of mechanical and physical test. It was found that the addition of CaCO3 filler to the polyester films leads to improve the mechanical properties. The findings revealed that the best and optimum CaCO3 filler content was 10 wt.% and among the prepared polyester films, eggshell CaCO3-polyester films showed the best performance. The mechanical properties of CaCO3-polyester films were measured in terms of tensile strength, elongation-at-break, tensile modulus, flexural strength and impact strength. For eggshell CaCO3- polyester films, the maximum values of the aforementioned mechanical properties were 52.70 MPa, 4.63 %, 1868.70 MPa, 101.20 MPa and 8.40 kJ/m2, respectively, whereas for commercial CaCO3-polyester films those values were 48.12 MPa, 4.50 %, 1790.30 MPa, 97.50 MPa and 8.21 kJ/m2, respectively. Further, water absorption of the composite films as a function of time had also been investigated at 10 wt.% filler content.

Similar content being viewed by others

References

H. Duan, L. Zhang, L. Wang, and X. Yang, J. Wuhan Univ. Technol.-Mater. Sci. Ed., 23, 460 (2008).

N. G. McCrum, C. P. Buckley, and C. B. Bucknall, “Principles of Polymer Engineering”, 2nd ed., pp.242–245, Oxford University Press, New York, 1997.

A. K. Kulshreshtha and C. Vasile, “Handbook of Polymer Blends and Composites”, Vol. 1, p.10, Rapra Technology Limited, Shawbury, UK, 2002.

G. C. Onuegbu and I. O. Igwe, Mater. Sci. Appl., 2, 811 (2011).

N. A. Bhatt, H. S. Mehta, and Dr. D. Jyoti Sen, World J. Pharm. Pharm. Sci. (WJPPS), 4, 405 (2015).

P. Toro, R. Quijada, M. Yazdani-Pedram, and J. L. Arias, Mater. Lett., 61, 4347 (2007).

P. Glatz and Z. Miao, “High Value Products from Hatchery Waste”, pp.9–13, Rural Industries Research and Development Corporation, Kingston, 2009.

A. M. King’ori, Indian J. Poult. Sci., 10, 908 (2011).

M. S. Islam, Y. Kusumoto, and M. Abdulla-Al-Mamun, Mater. Lett., 66, 165 (2011).

M. Arbatti, X. Shan, and Z. Cheng, Adv. Mater., 19, 1369 (2007).

T. Amirhossein, T. Bo, and V. Krishnan, J. Nanobiotechnol., 9, 1 (2011).

S. B. Hassan, V. S. Aigbodion, and S. N. Patrick, Tribol. Ind., 34, 217 (2012).

J. Tao, H. Pan, J. Wang, J. Wu, B. Wang, X. Xu, and R. Tang, J. Phys. Chem. C, 112, 1492 (2008).

S. Ojha, G. Raghavendra, and S. K. Acharya, Polym. Compos., 35, 180 (2014).

O. A. Samson, A. U. Mohammed, A. A. Wasiu, and A. B. Muyideen, J. Miner. Mat. Charact. Eng., 1, 145 (2013).

R. R. H. Michele, S. B. Palova, and B. Daniela, Mat. Res., 15, 204 (2012).

M. N. Prabhakar, A. U. R. Shah, K. Chowdoji Rao, and J.-I. Song, Fiber. Polym., 16, 1119 (2015).

V. P. Kommula, K. Obi Reddy, M. Shukla, T. Marwala, and A. Varada Rajulu, Int. J. Polym. Anal. Charact., 19, 693 (2014).

S. I. Abdel-Salam, M. S. Metwally, A. A. Abdel-Hakim, S. El Begway, and E. S. Elshafie, Nat. Sci., 9, 116 (2011).

H. Ismail, H. D. Rozman, R. M. Jaffri, and I. Z. A. Mohd, Eur. Polym. J., 33, 1627 (1997).

A. H. Abdullah, D. S. Rusel, and A. S. Abdulwahab, J. Basrah Res., 37, 36 (2011).

C. W. Shyang, Malaysian Polym. J., 3, 1 (2008).

C. T. Ratnam, S. F. Radin, and S. Shuhaily, Malaysian Polym. J., 5, 17 (2010).

R. Sana, K. Foued, B. M. Yosser, J. Mounir, M. Slah, and D. Bernard, Fiber. Polym., 16, 2451 (2015).

K. Oksman and C. Craig, J. Appl. Polym. Sci., 67, 503 (1998).

J. Z. Lu, Q. Wu, and H. S. McNabb, Wood Fiber Sci., 32, 88 (2000).

F. Mengeloglu, R. Kurt, D. J. Gardner, and S. O’Neill, Iran Polym. J., 16, 477 (2007).

Y. Xu and M. Hanna, Packag. Technol. Sci., 20, 165 (2007).

G. Ji, H. Zhu, C. Qi, and M. Zeng, Polym. Eng. Sci., 49, 1383 (2009).

T. A. Hassan, V. K. Rangari, and S. Jeelani, ACS Sustain. Chem. Eng., 2, 706 (2014).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shafiur Rahman, G.M., Aftab, H., Shariful Islam, M. et al. Enhanced physico-mechanical properties of polyester resin film using CaCO3 filler. Fibers Polym 17, 59–65 (2016). https://doi.org/10.1007/s12221-016-5612-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-016-5612-y