Abstract

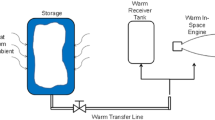

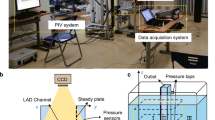

The purpose of a liquid acquisition device (LAD) is to separate liquid and vapor phases inside a spacecraft propellant storage tank in the reduced gravity and microgravity conditions of space so that vapor-free liquid can be extracted to the transfer line. A popular type of LAD called a screen channel LAD or gallery arm, uses a fine porous screen and surface tension forces of the liquid to allow pure liquid to flow through the screen while blocking vapor penetration. To analyze, size, and optimize the design of LADs for future in-space propellant transfer systems, models and data are required for the four fundamental influential factors for LAD systems, including bubble point, flow-through-screen pressure drop, wicking rate, and screen compliance for a wide variety of screen meshes. While there is sporadic data available for three of these parameters, there is no published quantitative data for screen compliance. During the transient startup of propellant transfer, the liquid must be accelerated from rest to the steady flow demand velocity, which causes the screen to deform or comply, so compliance data is required for accurate transient LAD analyses; most design codes only consider steady state analysis. This paper presents screen compliance experiments on 14 different screens, examining the effects of fineness of mesh, open area, and screen metal type on compliance. A basic equation of state is also developed and validated against the data which can be easily integrated into any transient LAD flow code to model propellant transfer.

Similar content being viewed by others

Abbreviations

- A CH :

-

Cross sectional area of the control volume channel

- A SC :

-

Screen open area

- a SC :

-

Gravitational acceleration relative to the fluid flow

- B :

-

Screen thickness

- g :

-

Acceleration due to gravity

- h SC :

-

Height of liquid column on top of screen

- K SC :

-

Linear slope for ΔPSC/TSC curve in screen compliance

- n s :

-

Number of shute wires per inch

- n w :

-

Number of warp wires per inch

- s SC :

-

Wetted circumference of the screen\

- t :

-

Time

- T SC :

-

Effective thickness of the screen deflection

- T SCmax :

-

Maximum effective thickness of the screen deflection

- T SC0 :

-

Initial effective thickness of the screen deflection

- u :

-

Velocity of the Fluid

- V SC :

-

Volume Extracted from Liquid Reservoir under Screen

- w SC :

-

Width of the Screen

- x :

-

Dimension along the Channel

- z :

-

Height relative to the acceleration vector

- ΔP BP :

-

Bubble point pressure

- ΔP SC :

-

Screen compliance pressure difference across screen

- ν :

-

Fluid kinematic viscosity

- ρ :

-

Fluid density

References

Camarotti, C.F.: Screen database development for the influential factors of liquid acquisition device screens. M.S. Thesis, University of Florida (2017). http://ufdc.ufl.edu/UFE0051077/00001

Conrath, M., Dreyer, M.: Gas breakthrough at a porous screen. Int J Multiphase Flow. 42, 29–41 (2012)

Darr, S.: Hydrodynamic model of screen channel liquid acquisition devices for in-space cryogenic propellant management. PhD Dissertation, University of Florida (2016).

Darr, S., Camarotti, C., Hartwig, J., Chung, J.: Hydrodynamic model of screen channel liquid acquisition devices for in-space cryogenic propellant management. Phys. Fluids. 29, (2016)

Dhir, V.J., Warrier, G.R., Aktinol, E., Eggers, J., Sheredy, W., Booth, W.: Nucleate pool boiling experiments on the international space station. Microgravity Sci. Technol. 5, 307–325 (2012)

Fu, J., Chen, X., Huang, Y.: Compression frequency choice for compression mass gauge method and effect on measurement accuracy. Microgravity Sci. Technol. 25, 213–223 (2013)

Hartwig, J.: Liquid acquisition devices for advanced in-space cryogenic propulsion systems. Elsevier, Boston (2015)

Hartwig, J.W.: Screen channel liquid acquisition device bubble point tests in liquid nitrogen. Cryogenics. 74, 95–105 (2016)

Hartwig, J.W., Darr, S.: Influential factors for liquid acquisition device screen selection. Appl. Therm. Eng. 66, 548–562 (2014)

Hartwig, J.W., Kamotani, Y.: The static bubble point pressure model for cryogenic screen channel liquid acquisition devices. Int. J. Heat Mass Transf. (2016)

Hartwig, J., Mann Jr., J.: A predictive bubble point pressure model for porous liquid acquisition device screens. Journal of Porous Media. 17(7), 587–600 (2014)

Hartwig, J.W., McQuillen, J.: Screen channel liquid acquisition device bubble point tests in liquid methane. J. Thermophys. Heat Transf. 29(2), 364–379 (2015)

Hartwig, J.W., Chato, D.J., McQuillen, J.B., Vera, J., Kudlac, M.T., Quinn, F.D.: Screen channel liquid acquisition device outflow tests in liquid hydrogen. Cryogenics. 295–306 (2014a)

Hartwig, J.W., Darr, S.R., McQuillen, J.B., Rame, E., Chato, D.J.: A steady state pressure drop model for screen channel liquid acquisition devices. Cryogenics. 64, 260–271 (2014b)

Hartwig, J.W., McQuillen, J.B., Chato, D.J.: Screen channel LAD bubble point tests in liquid hydrogen. Int. J. Hydrog. Energy. 39(2), 853–861 (2014c)

Hartwig, J., Mann, J.A., Darr, S.R.: Parametric analysis of the liquid hydrogen and nitrogen bubble point. Cryogenics. 25–36 (2014d)

Hartwig, J.W., McQuillen, J., Jurns, J.M.: Screen channel liquid acquisition device bubble point tests in liquid oxygen. J. Thermophys. Heat Transf. 29(2), 353–363 (2015)

Hastings, L.J., Bolshinskiy, L.G., Schunk, R.G., Martin, A.K., Eskridge, R.H., Hamill, B.D.,. .. Pendleton, M.L.: NASA/TP—2011–216,474 thermal integration of a liquid acquisition device into a cryogenic feed system. Marshall Space Flight Center, Huntsville, Alabama: National Aeronautics and Space Administration (2011).

Jaekle, Jr.: AIAA-91-2172 Propellant management device conceptual design and analysis: vanes. AIAA/SAE/ASME/ASEE 27th Joint Propulsion Conference, (pp. 1–13). Sacramento, CA (1991).

Jaekle, Jr.: AIAA-93-1970 propellant management device conceptual design and analysis: sponges. AIAA/SAE/ASME/ASEE 29th Joint Propulsion Conference and Exhibit, (pp. 1–14). Monterey, CA (1993).

Jaekle, Jr.: AIAA-97-2811 propellant management device conceptual design and analysis: galleries. 33rd AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit. Seattle, WA (1997)

Johnson, W., Sutherlin, S., & Tucket, S.: Cryogenic propellant insulation system design tools for mass optimization of space vehicles. SPACE 2008 Conference. (2008, September 9–11)

Kulev, N., Dreyer, M.: Drop tower experiments on non-isothermal reorientation of cryogenic liquids. Microgravity Sci. Technol. 22, 463–474 (2010)

Marchetta, J.G.: Simulation of LOX reorientation using magnetic positive positioning. Microgravity Sci. Technol. 18, 31 (2006)

Meserole, J.S., Jones, O.S.: Pressurant effects on cryogenic liquid acquisition devices. J. Spacecr. Rocket. 236–243 (1993)

Nishizu, T., Torikata, Y., Yamashita, T., Sakamoto, T., Futaya, Y., Tateno, A., Nakano, A.: Liquid volume measurement for cryogen under microgravity condition. Microgravity Sci. Technol. 18, 190–195 (2006)

Paynter, H.: Acquisition expulsion system for earth obital propulsion system. Martin Matietta Corp, 3. In: MCR-1973-97 (1973)

Roadmaps, N. T.: TA 2.4.2.3: In-space tank-to-tank propellant transfer (2015).

Zimmerli, G., Asipauskas, M., Wagner, J., & Follo, J.: Propellant quantity gauging using the radio frequency mass gauge. 49th Aerospace Sciences Meeting (2011, Jaunuary 4–7).

Acknowledgements

This work was funded by the Evolvable Cryogenics Project under the Space Technology Mission Directorate at the National Aeronautics and Space Administration (NASA) as well as the Florida Space Grant Consortium (FSGC) Masters Fellowship Program.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Camarotti, C., Deng, O., Darr, S. et al. Screen Compliance Experiments for Application of Liquid Acquisition Device in Space. Microgravity Sci. Technol. 31, 109–122 (2019). https://doi.org/10.1007/s12217-018-9671-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12217-018-9671-0