Abstract

Lead toxicity in perovskite materials, which have hazardous effects on the environment and the human body, has drawn considerable attention to emerging photovoltaic technology perovskite solar cells. Despite the capability of other strategies to prevent lead leakage, chemisorption is another efficient approach to block Pb leaching by employing Pb absorbents in/out of device structures. This review discusses lead toxicity and summarizes the recent research about chemisorption strategies by their functions: additives, the hole-transporting layers, interfacial modifiers, and encapsulation layers. Finally, the basic guidelines and challenges for designing novel Pb-adsorbing materials and encapsulation structures are presented.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Perovskite solar cells (PSCs), as a promising new-generation solar cell technology, have been the focus of massive academic research because of their excellent photoelectric properties, including long charge carrier diffusion length, high charge carrier mobility, high absorption coefficients, and low trap densities [1,2,3,4]. The power conversion efficiency (PCE) of PSCs has dramatically climbed from 3.8% to 25.7% over the past decade [5,6,7,8,9,10,11]. An increasing number of scientific research teams and high-tech enterprises have entered the field of perovskite photovoltaics (PV), which prompted its entry into the stage of industrialization [12, 13].

Although numerous efforts, such as compositional engineering [14,15,16], interface engineering [17, 18], and the development of all-inorganic perovskites [7, 19,20,21,22], have been exerted for scaling of manufacture and long-term stability issues with encouraging results, lead (Pb) is likely to be a crucial challenge to PSCs’ path toward practical applications in sustainable communities, thus attracting an increasing amount of attention (Fig. 1a). Given its unique properties, including high density, low melting point, malleability, ductility, and high corrosion resistance, Pb has been widely applied, such as in Pb-acid batteries, alloys, and ammunition (Fig. 1b) [23, 24]. Intrinsically, the high superior photovoltaic feathers of Pb may be ascribed to its combination of high crystal symmetry, high electronic dimensionality, unique atomic electronic configuration, and strong spin–orbit coupling [25]. Given that PSCs are subject to a polytropic environment, which consists of acidic rains, heavy snow, and hail, they have a hazardous effect on the ecosystem to leak Pb from broken and end-to-life devices due to the solubility in water. Pb is severely toxic to humans and wildlife, breaking green and sustainable goals. Thus, the solar cell community is highly concerned about the toxicity of Pb in PSCs and has come up with strategies, such as lead-free PSCs, to deal with the issues of Pb leakage.

a Number of research articles and reviews on Pb leakage; b usage of Pb in different worldwide applications until 2012. Data from Ref. [44]

Pb-free PSCs

The use of Pb-free perovskite material is a promising strategy to reduce Pb leakage. For example, Sn is the most appropriate candidate for replacing lead because it belongs to the same periodic table group and has the same electron configuration [26]. Although the highest certified PCE of 14.6% had been obtained, Sn-based devices have shown critical stability issues because Sn ions are more stable in the Sn4+ oxidation state than those in the Sn2+ state [27, 28]. As for other eco-friendly elements, such as Cu, Bi, and Ge, the performance of their devices is extremely poor to replace Pb-based PSCs due to massive trap states and severe ion migration [29,30,31]. Countless endeavors, such as additive engineering, interface engineering, and two-dimensional (2D)/3D heterojunction, have been directed toward the development of low-toxicity perovskite materials with high efficiency and long-term stability [32,33,34].

Recycling of PSCs

Compared with the traditional disposal methods for end-to-life PSCs, such as landfills and incineration, recycling lead-based PSCs has enormous economic and ecological benefits for their final disposal. From the technological and economic point of view, recycling PSCs promotes the reuse of glass and semiconductor materials, which account for approximately 70% of the total cost [35, 36]. Thus, this method has the potential to reduce production costs with regard to implementation on a mass scale. Many research teams have verified that the recycled PbI2 is pure enough to make devices with comparable performance with commercial PbI2 [37, 38]. Additionally, the high recycling recovery rate is beneficial to reducing the potential risk of lead contamination, making PSC-based photovoltaic technology more environmentally friendly. However, the reused devices face some problems, such as the drop in PCE and stability, which may be ascribed to the introduction of charge traps on the interface after recycling. Therefore, subsequent research is still required to improve the efficiency and stability of regenerated PSCs.

Physical Encapsulation

Researchers proposed physical encapsulations to prevent Pb from leaching out of broken PSCs. Physical encapsulation utilizes self-healing polymeric materials and a glass cover sheet as barriers to inhibit devices from moisture ingress and eliminate the outflow of Pb components from decomposition [39,40,41,42]. Given the present understanding, a limited amount of research has been conducted on physical encapsulation to solve the safety issue of potential lead leaching. Bert et al. [40] reported glass–glass encapsulation as a barrier to lead leakage. The encapsulation was employed in Si/perovskite tandem modules to estimate the performance in fire accidents. Jiang et al. [39] reported an epoxy resin with self-healing properties and mechanical strength as the physical encapsulation. The star-shaped microcracks caused by the simulated hail impact can be recovered after heating because its glass transition temperature (over 42 ℃) was close to the actual operating temperature. However, the current material is limited to epoxy resin, and physical packaging can slow down lead leakage. As a result, toxic lead compounds (such as lead iodide (PbI2)) will still leak into the environment after long-term operations [43].

In addition to physical encapsulation, chemisorption is an efficient approach to blocking Pb leaching by employing Pb absorbents in/out of device structures. In chemisorption, some functional materials with multiple functional groups, including thiols, phosphate groups, etc., are placed inside or outside the device to trap the mobile Pb2+ by bonding. This method can have a better capacity to protect from Pb leakage because of its superior Pb leakage reduction (> 99%) compared with physical encapsulation. In addition, these Pb-adsorbing materials can be additives in precursors, interfacial agents, or encapsulants in PSCs to modulate the morphology of perovskite film, reduce the trap density at the interface, and improve the morphology for moisture resistance. Thus, the chemisorption approach can maintain the excellent performance of Pb-based PSCs and has a simple, efficient, and practical operation in contrast to Pb-free PSCs and recycling. Nonetheless, the materials used in chemisorption may result in secondary pollution. When Pb-adsorbing materials become gradually inactive during a long-time operation, they must be removed by toxic organic solvents, such as toluene, and will indirectly contaminate soil and groundwater. On the other hand, some reported chemisorption methods are combined with additional modification or encapsulation, which increases the production cost to a certain extent. No review has provided a comprehensive summary and discussion about this issue.

This review first discusses the toxicity of lead. It then summarizes the recent research about chemisorption strategies by their functions, such as additives, the hole-transporting layers (HTLs), modifier in the intrinsic device, and an extra encapsulation layer on an external device. Finally, the basic guidelines and challenges for designing novel encapsulation structures and Pb-adsorbing materials to reduce Pb leakage are presented.

Pb Toxicity

Pb Usage in PSCs

Although Pb-based PSCs have achieved significant progress in efficiency and stability, the Pb component leaking out of broken and degraded devices has a severe harmful influence on the environment and human health. Therefore, more governments and researchers appealed to the limitations of the use of lead photovoltaic materials. In the European Union, the utilization of lead-containing materials is controlled by the RoHS directives [44] and REACH compliance [45]. In 2013, the regulation further restrained any electronic devices from containing the maximal concentration of Pb of 0.1 wt.% in each homogeneous material. Similarly, the US Environmental Protection Agency announced that the maximum allowable lead contents in air and water are 0.15 µg/m3 and 15 µg/L, respectively [46, 47]. In China, lead amounts in drinking water and air (year average) must be less than 0.01 mg/L and 0.5 µg/m3, respectively [48, 49].

Although the removal of Pb content in PSCs is impractical, the reduction of Pb usage will lessen its content in the related waste. Zhu et al. [50] theoretically revealed that although the perovskite layer had one-third of the original thickness, at least 96% of the original PCE can be maintained by introducing an optical spacer layer. Using this method, the Pb content can be reduced by 70% in PSCs or modules. The partial replacement of Pb by other metal cations was also proposed with an improved PCE compared with an entire Pb replacement (see Pb-free PSCs in Introduction). If accidental Pb is released into the environment, physical and biological remedies, such as soil replacement, isolation, thermal treatment, and Pb-capturing bio-organisms, are readily available.

However, most perovskite materials in Pb-based PSCs contain over 10% lead [51]. On the other hand, some commercial solar cells in the PV market use abundant lead; for instance, the Pb concentration of C-Si modules is up to 6.1 g/m2, which violates the RoHS [52]. However, these toxic PV modules are exempted from Pb content limits. The heavy metal compounds (CdS, PbS, and CdTe) used in the PV industry have poor water solubility. By contrast, the water solubility of PbI2 is relatively higher at 340 mg/L, which is 11 orders higher compared with those of PbS and PbSe [53]. Although the current PV technologies, including silicon solar cells, can mitigate the risk of Pb leakage to a certain degree, some essential steps should be implemented to handle and dispose of Pb-based perovskite materials efficiently.

Impact on Ecology

Many issues impact the potential danger of toxicity of Pb, and high water solubility is one of the most nonnegligible causes. When lead halide perovskite encounters water or humid air, it will slowly degrade into water-soluble compounds of lead and accumulate in the human body through the food chain [51]. In addition, water solubility is closely bound up with bioavailability; increasing the lead contamination of soil with lead from perovskite by 10% will increase the lead contamination in plants by over 100% [54].

Li et al. [53] studied the biological impact of lead from PSCs on mint plants (Mentha spicata). When mint plants were grown on soil with Pb contamination, the plant organs, such as roots, stems, and leaves, exhibited an evident distinction in contrast to plants grown in natural soil due to the bioavailability of lead from perovskite, which displayed a bioaccumulation potential of lead in food chains. Surprisingly, the roots of mint grown on perovskite-contaminated soil showed a similar bioavailable effect compared with the control samples (Fig. 2a). The hygroscopicity of organic cations was the main reason that influenced the bioavailability of metals through the changeable pH of the soil during perovskite degradation.

Copyright © 2020 Nature Publishing Group. b Schematic of mobility of Pb compounds in the human body. Reprinted with permission from Ref. [58]. Copyright © 2016 Nature Publishing Group

a Mint plants grown on control soil (left) and 250 mg/kg Pb2+ perovskite-polluted soil (right). Reprinted with permission from Ref. [53].

Copious research has addressed the catastrophic effect of up to a few micrograms of heavy metals that accumulate in the human body, particularly in children [55,56,57]. Pb can flow in the human body via the blood circulation system and reach bones in the form of lead phosphate, which requires 40–50 years of decomposition and probably induces cancer (Fig. 2b). Furthermore, lead poisoning can cause severe nerve disease and organ failure. Lead poisoning will occur when the Pb content reaches 5 µg/dL in the blood [58].

Chemisorption Strategies

Chemisorption is an efficient and practical strategy to reduce Pb leaching from damaged PSCs by introducing Pb-adsorbing materials, which capture free Pb2+ ions via coordination bond in Pb-containing solutions [59]. Based on their functions, we divided lead adsorbents into additives, HTLs, interfacial modifiers, and encapsulation layers. Table 1 outlines the state-of-the-art chemisorption strategies for preventing lead leakage.

Additives

Additives are widely adopted for efficient, stable, and hysteresis-free PSCs, which can modulate the morphology of halide perovskite, stabilize perovskite phases, and suppress nonradiative recombination in perovskites [55,56,57]. Some additives with Pb-capturing capability can effectively reduce the lead outflow due to the chelating Pb released from degraded or broken PSCs.

Some additives treated as Lewis base molecules have the good coordination capability with lead cations. As a result, these additives improve perovskite grain size and crystallinity and prevent the lead leakage. To date, several additives have been reported to have the lead chelating capability. Horváth et al. [60] employed phosphate salts (e.g., (NH4)2HPO4) with different dispersed structures in MAPbI3. Once exposed to the water, phosphate salts reacted with lead ions, forming highly stable and insoluble lead phosphate complexes (e.g., insoluble Pb2PO4I). Therefore, the phosphate salt additive can be employed as a safety additive to block the potential danger of Pb leakage into the environment.

Niu et al. [61] utilized dormant acrylamide as an additive in perovskite precursor to reduce Pb leakage into water from devices. The acrylamide additive can form an in situ perovskite-polymer hybrid structure within light adsorption layers during the annealing process. Additionally, when water permeates the perovskite layers, polymer networks can capture the Pb ions in which the carbonyl groups chelated, thus preventing the dissolution of Pb2+ from devices into the water. Consequently, the resultant inverted device showed an excellent PCE of 22.1% and good stability (T80 > 1000 h). Compared with the control device (2.9 ppm), the optimized PSC reduced the Pb leakage concentration to 0.74 ppm.

Liang et al. [62] developed a fullerene-porphyrin dyad fullerene (FPD) in a precursor, and it was composed of multiple functional groups, such as a C60 cage, a porphyrin ring, ester, and pentafluorophenyl groups (Fig. 3a). The electron-deficient C60 and pentafluorophenyl groups can alleviate ion migration and suppress deep defects in the perovskite film. In addition, the porphyrin ring and ester can fix the Pb ions due to the formation of a metalloporphyrin complex and a coordination bond with Pb, respectively. The FPD-based device with an optimal PCE of 23% was achieved. Notably, when the perovskite film with FPD was immersed in water for different times, it released a lower Pb amount than the bare device, and this finding was attributed to the firm chemical bondings, such as Pb…O = C, thus mitigating the risk of lead leakage (Fig. 3d).

Copyright © 2021 Wiley–VCH. e PBSA powder in 10 mL PbI2 aqueous solution (top); soaking test for unsealed PSCs. Reprinted with permission from Ref. [63]. Copyright © 2021 Wiley–VCH. f Soaking test for unsealed with a pH of ~ 5.7. Reprinted with permission from Ref. [64]. Copyright © 2021 Springer

Schematic view of the chemical structure of a FPD, b PBSA, and c 4TA. d Soaking test with water for different durations. Reprinted with permission from Ref. [62].

Hu et al. [63] added an amphoteric phenylbenzimidazole sulfonic acid (PBSA) in the perovskite precursor. The sulfonic group and imidazole ring in PBSA chemically interacted with Pb2+ to passivate ionic defects of perovskite, leading to the retardation of hysteresis. In addition, the functional groups can restrain the Pb leakage, which was attributed to the reaction between S = O from the sulfonic group and N in the imidazole ring with Pb (Fig. 3b). Finally, the device with 0.3% mol PBSA yielded the best PCE of 23.27%. Significantly, when the unpackaged device was soaked in deionized (DI) water, the Pb leakage content decreased from ≈3.5 ppm to < 1 ppm, meeting the Chinese sewage water standard (Fig. 3e). Similarly, Li et al. [64] employed 4-[(trifluoromethyl) sulphanyl]-aniline (4TA) in the perovskite precursor, which included trifluoromethyl (‒CF3) and aniline (‒NH2) moieties (Fig. 3c). The multifunctional groups passivated the surface trap states and improved perovskite crystallization, which led to a PCE enhancement from 18% to 20.24%. Furthermore, 4TA can reach the quintile Pb leakage concentration of perovskite without 4TA because the aniline of 4TA can form coordination bonds with free Pb2+, which inhibits the leakage of lead ions.

Although the Pb-adsorbing additive can boost the PCE of the device and block Pb outflow, the excessive additive can hamper the performance of PSCs. In addition, in situ polymerization must be induced at a suitable temperature that does not damage perovskite crystal structures.

The carbon electrode efficiently prevents moisture from permeating perovskite films, thus improving the stability of PSCs [65,66,67]. Despite the advantage, the cost of carbon is significantly lower than that of commonly used Au or Ag electrodes. Chen et al. [43] mixed cation-exchange resins (CERs) and carbon paste in specific mass ratios of 1:10, 1:5, and 1:2 to form the carbon electrode with Pb-capturing capability (Fig. 4a). The electron dispersive spectroscopy showed that sulfur was well dispersed in the carbon clusters, indicating that the porous structure of the carbon electrode can load small-sized CER nanoparticles (NPs) without a detrimental effect on the conductivity (Fig. 4c, d). Meanwhile, the CERs can immobilize the free Pb2+ ions in the device due to the sulfonate groups’ strong ionic bonding capacity. As a result, carbon electrodes mixed with CERs had no adverse effect on the device performance but further reduced the lead leakage to 14.3 ppb, which was below the drinking water level of the US 40 Code of Federal Regulations. In addition, when CERs were blade coated on the surface of the metal electrode, the PSCs with the structure of ITO/PTAA/perovskite/C60/BCP/Cu also decreased the Pb leakage concentration to 1.92 ppm, which was less than that of the controlled device (Fig. 4b). However, when exposed to ultraviolet (UV) radiation and rainwater in the long term, CERs may release some acidic molecules to corrode the metal electrode due to the chemical instability of sulfonate groups.

a Device’s representative structure with CER. b Damaged PSCs with mesoporous sulfonic acid-based resin (left) and lead concentration mapped on the damaged solar panel under heavy acidic rainfall (right). c Cross-sectional scanning electron microscopy (SEM) images of PSCs prepared with neat carbon paste (left) and a carbon/CER (5:1) mixture (right). d Distribution of sulfur (red dots) in cross-sectional SEM. Reprinted with permission from Ref. [43].

Hole-Transport Layers (HTLs)

The frail long-term stability is one of the bottlenecks for the commercialization of PSCs due to the degradation of perovskite and hygroscopicity of dopants in the commonly used HTMs, such as Li-TFSI and tBP. Polymers are one of the promising candidates for dopant-free HTMs, which have suitable optoelectronic properties and high hole mobility [68,69,70]. Moreover, polymeric HTMs can possess Pb cleating groups to mitigate the Pb leakage. Lee et al. [71] designed conjugated polymeric HTMs with green-processing and lead capturing capability, namely alkoxy-PTEG (Fig. 5a). The HTM had tetraethylene glycol and alkoxy-based groups, improving the solubility in nonaromatic green solvents, such as 3-methylcyclohexanone and 2-methyl anisole, and interacting with Pb ions via chelation, respectively. The thickness of the alkoxy-PTEG layer was ≈27 nm, which was considerably smaller than that of the spiro-OMeTAD layer; an optimized device with an alkoxy-PTEG layer yielded a PCE of 21.2% (Fig. 5b). The binding constant (Kbinding) was 2.76 M−1, calculated via proton nuclear magnetic resonance spectroscopy (Fig. 5c). In addition, UV–visible (UV–vis) spectroscopy confirmed that the alkoxy-PTEG-based devices can capture over 80% of the under-coordinated Pb ions, proving the strong lead capturing capability. However, polymeric HTMs also have some inevitable problems, such as batch-to-batch variation in molecular weights and the necessity of tedious purification, which may negatively influence the device’s performance. On the other hand, the scaling of polymeric HTLs is a critical challenge from the laboratory to commercial size for PSCs, which will raise the cost substantially. Lastly, the thickness of polymer HTLs is always below 100 nm for efficient hole transportation, which is insufficient to block the Pb leakage.

a Chemical structures of alkoxy-PC8, thiophenyl-PTEG, and alkoxy-PTEG. b Current density–voltage (J–V) curves of alkoxy-PTEG devices processed by CB, 2-MA, and 3-MC. c Plots of chemical shifts versus [Pb2+]. Reprinted with permission from Ref. [71].

Interfacial Modifiers

Interfaces play a critical role in charge extraction and transportation in PSCs. However, they are susceptible to nonradiative recombination, mainly due to the possible interfacial traps and specific charge distributions. Furthermore, interfaces between grain boundaries are the major pathway for moisture invasion and Pb leakage sites, thus causing the poor performance of devices and hazardous Pb contamination. Modifiers have a passivation effect on interfaces, which lowers the deficit density, forms energy-level alignment, and suppresses ion migration. Meanwhile, some functionalized modifiers with hydrophilic groups, such as thiols and phosphates, have a strong capacity in Pb adsorption to protect the environment from Pb pollution.

Perovskite/HTM Interface

The interface between perovskite and HTM is related to the hole-extraction process, barrier on electron injection, and device stability [72,73,74,75]. Metal–organic frameworks (MOFs) have been investigated as a modifier to passivate the interface to reduce interfacial deficits and lead leakage [76]. Huckaba et al. [77] designed porous MOFs named FeBTC/PDA, which stands for FeBTC¼ Iron(III) benzene tricarboxylic acid, PDA¼ poly(dopamine), containing numerous Pb binding groups, such as catechol and amine functional groups. Consequently, the MOF can remove about 88% of Pb in Pb-containing solution to meet the drinking water standards.

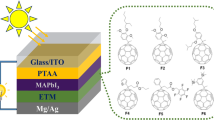

Chen et al. [78] blade coated a mesoporous sulfonic acid on PTAA at room temperature at about 120 to 150 nm as a Pb absorbent (Fig. 6a). The mesoporous resin as an insulating scaffold in device structure can have a negligible influence on either the crystallinity or morphology of the perovskite film, leading to the champion PCE of 20.6% (Fig. 6b). In addition, mesoporous resins can passivate the perovskite film, resulting in improved VOC and fill factor (FF). The hydrophilicity of sulfonic acid contained many sulfonate groups for the capture of Pb2+ ions dissolved in rainwater. Acidic water (pH = 4.2, HNO3/DI water mixture) was dripped onto the damaged module for 1 h. As a result, the device with mesoporous resin reduced the leaked Pb amount to 11.9 ppb (Fig. 6c). In addition, it was placed on top of the metal electrode. The Pb content in water from broken PSCs gradually decreased to ~ 1.5 ppb, approaching the detection limit of the inductively coupled plasma (ICP) mass spectrometry instrument. In this work, in addition to the Pb absorbent layer, the perovskite film and PTAA layer were prepared by blade coating, which aided the scalable device process and achieved about a 100% high material usage rate compared with spin coating. Nevertheless, the polymeric scaffold in the device was extremely thick to extract the charge due to its insulating property. In addition, some polar solvents used in perovskite precursors, such as dimethylformamide, may dissolve the polymeric Pb adsorbent to lower the Pb trapping effect.

Copyright © 2021 Nature Publishing Group. d, e, and f were reprinted with permission from Ref. [84]. Copyright © 2022 Elsevier

Chemical structure of a mesoporous sulfonic acid and d ZnP. J–V curves of the device b with mesoporous sulfonic acid and with e ZnP. Pb leakage with c mesoporous sulfonic acid and d ZnP. a, b, and c were reprinted with permission from Ref. [78].

Porphyrins have been investigated in PSCs as cathode buffers, interfacial agents, and HTMs due to their excellent chemical stability and photoelectric features [79, 80]. Cao et al. [81,82,83] reported an array of thiol copper(II) porphyrins (Cu-por). The thiols in the peripheral substituent efficaciously adsorbed Pb2+ through the Pb–S bond, blocking the Pb emission from the degraded PSCs [83]. Moreover, the central Cu atom in Cu-por offered more electrons to the porphyrin ring to tune the electron distribution for iodide and iodine restriction, thus having a passivation effect on the perovskite film. The resultant PSCs modified with Cu-por gained a champion PCE of over 21% and exhibited good moisture, heating, and light stability. When immersed in water for 10 min, the perovskite film modified with Cu-por showed no noticeable decomposition. In the UV–vis spectra, the PbI2 absorbance intensity of the perovskite film modified with Cu-por was notably weaker than that of bare film, demonstrating the strong Pb-adsorbing effect of Cu-por. To further improve the effect of eliminating Pb, researchers designed a polymerizable zinc porphyrin (Zn-por) with carbonyl groups to reduce the defects in perovskite and prevent the Pb leakage from damaged devices [84] (Fig. 6d). Compared with Cu-por, the in situ polymerization of Zn-por was induced through annealing treatment to sufficiently coat the perovskite film for nonradiative recombination suppression. Meanwhile, the Zn atom contributed more electrons to the porphyrin ring, thus notably improving the intramolecular dipole. Therefore, the PSCs with Zn-por exhibited a PCE of 20.53% and a good resistance against heating and light (Fig. 6f). The UV–vis spectra showed the weaker intensity of PbI2 in Zn-por-treated perovskite film than that in the pristine film (Fig. 6e). The results showed that the carbonyl groups of polymeric Zn-por sufficiently chelated with lead to confine Pb ions within the perovskite crystal.

Hu et al. [85] used PBSA to modify the perovskite/HTL interface. Sulfate groups in PBSA can firmly bind with Pb ions in water, forming water-insoluble solids. When immersed in water, the unpackaged device with PBSA modification released a lower Pb concentration (< 5 ppm) than the bare device. In addition to PBSA treatment, benzophenone-3 was used to passivate the ETL/perovskite interface, improving the light stability. Based on its tautomeric structure, the perovskite film was protected from the degradation caused by UV light, and the related PSC extended the T80 lifetime to over 2000 h.

ETM/Perovskite Interface

Unlike the perovskite/HTL interface, the ETM/perovskite interface is significant in enhancing the electron transfer, suppressing the carrier recombination, and modulating the perovskite crystal growth [3, 13, 86, 87].

Meng et al. [88] employed the amphipathic diphosphatidyl glycerol (Di-g) as an interfacial agent to treat the surface of perovskite films in flexible PSCs (Fig. 7a). Given the dramatic water resistance of hydrocarbon chains, Di-g molecules can prohibit the perovskite film from eroding after being soaked into water for 6 h and have a negligible effect on the perovskite film morphology. Combined with the polydimethylsiloxane (PDMS) encapsulation, the device released no evident lead ion after 48 h soaking in water (Fig. 7b). Although the flexible device with Di-g modification had striking uniformity and low lead leakage level, the lead leakage in the control sample was generally severe and most noticeable at the edge of FPSCs (Fig. 7c). This result was due to the capability of the phosphonic acid groups in Di-g molecules to firmly coordinate with Pb ions to mitigate the hazardous effect of Pb leakage. The device with Di-g modification displayed a PCE of over 20% and suppressed 96% lead leakage.

Copyright © 2021 Wiley–VCH. d, e, and f were reprinted with permission from Ref. [90]. Copyright © 2021 Wiley–VCH

Molecular structures of a Di-g and d ATMP. b Lead ion concentration in soaking test with the encapsulated PSCs for 48 h. c Lead leakage distribution at different positions in the flexible PSC. e Schematic of Pb2+ adsorption by different ETLs. An ICP-OES was used to quantify the Pb2+ concentrations in water. a, b, and c were reprinted with permission from Ref. [88].

The mesoporous scaffold is the indispensable component in n-i-p mesoporous device configurations, such as TiO2, Al2O3, ZrO2, and SiO2, and it can improve the quality of the interface to enhance charge extraction and reduce charge recombination. Mokhtar et al. [89] dispersed hydroxyapatite (Ca10(PO4)6(OH)2, HAP) in TiO2 NPs as mixed mesoporous scaffolds. Perovskite films were spin coated onto different scaffolds (0%, 30%, 70%, and 100%) based on the HAP/TiO2 scaffold composition. As a result, the mixed scaffold can coarsen the grains of perovskite films up to 745 nm, and this result was ascribed to the HAP coordination with halide perovskite. Furthermore, owing to the PO43− coordination with Pb ions, HPA can minimize the toxic effect of Pb leakage from the broken device. As a result, the PCE of 20.98% was achieved, and the Pb content for the encapsulated with HPA decreased to 0.55 ppm, which was lower than that of the Chinese sewage water standard (< 1 ppm). However, the annealing process of HAP/TiO2 scaffolds must be formed at 450 ℃ for 30 min, likely reducing Pb-capturing capability. On the other hand, the annealing process limited the Pb-adsorbing layer to extensive scale applications.

Zhang et al. [90] treated the SnO2/perovskite interface with amino trimethylene phosphonic acid (ATMP) mixed with KOH (ATMP-K) (Fig. 7d). ATMP can interact with hydroxyls on the surfaces of SnO2 by forming P = O–Sn bonds. In addition to the hydroxyl removal from the SnO2 surface, ATMP gave rise to a favorable work function shift, which increased to about 0.6 eV higher than that of the bare SnO2. Furthermore, SnO2 with ATMP-K and bare SnO2 were soaked in the lead wastewater for 5 days, and the Pb2+ concentrations were quantified by ICP–optical emission spectrometer (ICP-OES). The SnO2 with ATMP-K modification can decrease the Pb amount of contained Pb water by 11.3-fold due to the strong Pb–O═P bonding (Fig. 7e). Furthermore, the passivation effect of ATMP-K reduced the traps on the surface of SnO2 and improved the perovskite crystal morphology, leading to an increase in PCE to 23.52%.

ETM/Metal Electrode Interface

MOFs have been investigated as modifiers to passivate the interface to reduce interfacial deficits and lead leakage. Huckaba et al. [77] designed porous MOFs, called FeBTC/PDA, which contained numerous Pb binding groups (such as catechol) and amine functional groups. These MOFs can achieve about 88% Pb removal to meet the drinkable water standard, indicating the Pb adsorption effect of MOFs. Later, Wu et al. [91] reported 2D MOF (denoted as ZrL3) with free-standing thiol-array disulfide groups to passivate the interface between perovskite and cathode and mitigate the Pb leakage (Fig. 8a). As a result, the ZrL3 combined with bis-C60 increased the FF to 81.28% and achieved the best PCE of 22.02% because of its hole-blocking capability. More importantly, the thiols in ZrL3 can effectively capture Pb ions to inhibit the leakage of Pb2+ into the environment. Thus, for the device with ZrL3, 5 ppm Pb was detected in water with pH ~ 5.6, and over 80% of Pb leaking out of damaged devices was removed by forming a water-insoluble complex (Fig. 8b, c, respectively).

Copyright © 2020 Nature Publishing Group. d, e, and f were reprinted with permission from Ref. [92]. Copyright © 2021 Wiley–VCH

Chemical structures of a thiol-decked carboxyl linker H3L3 (left); structural model of the corresponding 2D MOF ZrL3 (right) and d PFDT (left) and schematic of vapor-assisted self-assembly process (right). Degraded PSCs with reference sample and with b ZrL3 and e PFDT in DI water with a pH of ~ 5.5. Pb concentration in the contaminated water c with 2D MOF ZrL3 and f PFDT. a, b, and c were reprinted with permission from Ref. [91].

Similar results were also obtained by Zhang et al. [92] when they modified the thiol-functionalized perfluoroalkyl molecules (H, H, H, H-perfluorodecanethiol, PFDT) on the interface between perovskite films and Ag electrodes via vapor-assisted self-assembly deposition (Fig. 8e). The F atoms can improve the moisture tolerance of perovskite film based on its superhydrophobicity. In addition, the thiol groups can eliminate the traps on the surface of perovskite thin film and suppress the Pb leakage based on the metal–thiol bond. Finally, the device showed a PCE as high as 21.79%; in the water soaking test, the Pb concentration leaking from the degraded PSCs was reduced to 2.05 mg/L. Given that the thickness of modifiers usually ranges from ~ 20 nm to 50 nm, they cannot completely trap the lead ions leaking from a typical 500–1000 nm-thick perovskite layer (Fig. 8e). Additionally, some Pb-adsorbing modifiers are sensitive to pH, heat, and oxygen, leading to the degradation of Pb capture performance (Fig. 8f).

Encapsulation Layers

Encapsulation is one of the effective ways to deal with the poor stability of devices for commercial use of PSCs, which can protect the perovskite layer from environmental factors, such as oxygen and moisture [93, 94]. Additionally, several types of polymers, such as PDMS [95], polytetrafluoroethylene [96], and UV-cured resin (UVR) [97], can be applied for encapsulation due to their excellent chemical stability, mechanical strength, and low cost.

Li et al. [98] reported a successful polymer encapsulation method using PDMS mixed with sulfonated graphene aerogels (S-GA) as a lead-absorbing encapsulant, which covered both sides of the flexible perovskite solar modules (PVSMs) (Fig. 9a). The SEM of S-GA exhibited a smooth morphology with plenty of wrinkle structures for Pb trapping. The functionalized graphene aerogels with large specific surface area and copious sulfonate groups can effectively capture Pb2+ in an aqueous solution. As a result, the PVSMs with S-GA achieved over 99% of the Pb adsorption rate in the water dripping test (Fig. 9b). The encapsulant with S-GA can efficiently absorb lead ions through different bending conditions, such as directions, radiuses, and circles, verifying the excellent mechanical property of the Pb-absorbing encapsulant (Fig. 9c). Later, they also employed the mixture of a CER and UVR as an encapsulation material for coating the metal side of devices to reduce lead leakage [99]. The CER showed a strong Pb adsorption capability owing to the abundant sulfonic acid groups (Fig. 9d). The lead leaking from the degraded devices can be bonded with sulfonic acid groups to form Pb-based precipitates for Pb trapping. Consequently, perovskite solar modules reduced the Pb leaking concentration below 5 ppm with a rigid or flexible dual-functional encapsulation strategy (Fig. 9e, f). In addition to its strong Pb adsorption capability, the encapsulant did not negatively influence the PCE of devices and showed long-term stability in ambient air. Compared with the robust glass encapsulation, the cost of resin is also ultra-low (~ 0.03 $/m2). The functionalized additives with hydrophilic groups, including carboxyl groups and sulfonic acid groups, will reduce the compatibility with the polymeric encapsulant, leading to impairment of the physical strength of the encapsulation layers.

Copyright © 2021 Wiley–VCH. d, e, and f were reprinted with permission from Ref. [99]. Copyright © 2022 Elsevier

Chemical structures of a S-GA and d CER. b PSCs with/without S-GA in contaminated water. c Pb concentration in different tests. e Photograph of damaged PVSMs placed in the high-humidity condition (RH = 85%) for 7 days. f Pb leaching comparison of rigid and flexible modules with UVR and UVR-C as an encapsulant. a, b, and c were reprinted with permission from Ref. [98].

Li et al. [100] coated a phosphonic acid DMDP on the front and back sides of the device stack to suppress the leakage of Pb entirely (Fig. 10a, b, respectively). Despite its insolubility in water, functional phosphonic acid groups in DMDP can capture Pb in rainwater. In addition, an EDTMP–PEO film was prepared on the device’s backside to protect the perovskite film from DMDP and further fix the Pb ions by forming a Pb-chelating complex (Fig. 10b). All PSCs were sealed with EVA coating to enhance the moisture tolerance. Consequently, the device with Pb-sequestrating encapsulation obtained 97.7% sequestration efficiency (SQE) according to the calculation in the water soaking test (Fig. 10c). Moreover, the stability of devices in ambient air was improved. Subsequently, to simplify the fabrication of the Pb sequestration layer and provide guidelines about its scalable production, Li et al. [101] applied a scotch-tape-like structure, including the standard EVA layer and pre-coated DMDP film on both sides (Fig. 10d). The encapsulated device with whether n-i-p or p-i-n structure displayed a magnificent SQE of over 99% (Fig. 10e). Importantly, this Pb sequestration film amalgamates with the encapsulation materials and is independent of the device stack preparation, which has a negligible effect on the performance of PSCs.

Copyright © 2020 Nature Publishing Group. d and e were reprinted with permission from Ref. [101]. Copyright © 2021 Nature Publishing Group

a Encapsulated device structure. b Chemical structure of Pb absorbent DMDP and ETDMP. c Pb leakage with Pb absorbent in water soaking test at different temperatures. d Pb-absorbing tape fabrication and device integration. e Pb leakage with Pb-absorbing tape in different device structures. a, b, and c were reprinted with permission from Refs. [100, 101].

Aiming at the problem that the standard tempered glass used for PSC substrate or encapsulation can shatter when damaged, Xiao et al. [102] developed a self-healable lead-adsorbing ion gel on both sides of modules. The ion gel encapsulation can prevent lead outflow below the minimum detection limit (< 1 ppb) in the simulated hail-and-water soaking experiment. The modules were rolled with a car (> 1500 kg) to evaluate the mechanical strength and then soaked in water. The ion gel encapsulation modules had fewer cracks and negligible lead leakage, indicating a solid mechanical property.

Pb-adsorbing materials usually have specific functional groups, including phosphate, thiol, sulfonate, and acylamino. According to the equilibrium constant of precipitation and dissolution (Ksp) of Pb compounds, the Pb–S bond has the highest binding energy between Pb2+ and thiol. Although the binding energy of the Pb–O bond is slightly weaker than that of Pb–S bond, phosphate and sulfonate can firmly interact with free Pb2+ in Pb-containing solutions to inhibit the leakage of Pb2+. Furthermore, polymeric Pb-adsorbing encapsulation materials are usually polymers with abundant and diverse Pb-adsorbing groups that can capture most of the Pb ions from the degraded perovskite layer.

Conclusions and Outlook

In summary, the introduction of Pb-absorbing materials is required for the safe use of PSCs. In addition to phosphonic acid and thiol groups, other functionalized groups, such as sulfonic, carboxyl, and amine groups, with chelating effects can coordinate with lead to form a water-insoluble complex. The development of new materials with one or more Pb-adsorbing groups is a practical approach to mitigate the dispersion of lead into the environment. However, the research on Pb leakage is still in the early stage, and challenges in the development of Pb-absorbing materials should be overcome as follows:

-

(1)

No damage to the performance and stability of PSCs

When Pb-absorbing materials are applied to the internal device as additives, HTLs, or modifiers, they are closely associated with charge transfer and perovskite crystallization or nonradiative recombination at either the bulk perovskite or interface. Excess concentration of Pb absorbents as “impurity” will result in low efficiency and poor stability. On the other hand, if the Pb-absorbing materials are introduced as encapsulation, the high transmittance of Pb absorbents ensures that sufficient light transmits into the perovskite active layer.

-

(2)

Environmental friendliness

Pb-absorbing materials have a strong hydrophobicity if washed off by rainfalls and thus contaminate the soil and groundwater. When these materials are end to life, they must be removed safely or decomposed into non-toxic compounds. For clean disposal, electrokinetic remediation technologies, including electromigration, electrophoresis, and electrolysis, may be introduced to decontaminate Pb-absorbing materials.

-

(3)

Low-cost

Although some organic materials can effectively capture Pb ions, they have tedious synthesis and relatively low yield, potentially limiting the device performance and scale-up. Pb-absorbing materials are often combined with glass encapsulation, which increases the total production cost. More efforts need to be exerted into finding effective and low-cost Pb-absorbing materials.

The extra encapsulation layer with a Pb-adsorbing material is the most promising method, reducing Pb leakage to water by over 97% and restricting significant Pb sequestration layers. The low-cost and chemically stable polymers with Pb-chelating capability reduce the fabrication cost and provide a firm shield against moisture, light, and oxygen. Although Pb-adsorbing materials as additives or modifiers necessitate additional modifications to critical components of PSCs, such as spin coating and vapor-assisted process, thus increasing the cost, the encapsulants with Pb-adsorbing materials can simplify device fabrication and configuration, potentially facilitating device performance and scale-up. In addition, functional Pb-adsorbing encapsulants can be peeled off from the end-to-life and damage devices by solvent and hot-melt methods and recycled further. Conversely, Pb-adsorbing materials as additives or modifiers can form Pb complexes, which are not reused for PSCs and possibly result in the secondary pollution of the environment.

We propose that the chemisorption strategy integrating additives, modifiers, and encapsulations can completely adsorb Pb2+ to eliminate Pb contamination. First, the Pb-adsorbing additive can bond with uncoordinated Pb2+ in the bulk perovskite film. Then, the Pb-adsorbing interfacial modifiers inhabit Pb ions from diffusing into other functional layers when the degradation of the perovskite layer occurs. The Pb-adsorbing encapsulation layer is the last but significant barrier to Pb leakage. Although the devices and modules are broken or end-to-life, many Pb compounds will be blocked, which are released from the cracks of the degraded perovskite layer. Finally, the multi-level chemisorption strategy can achieve Pb leakage-free goal.

In addition, lead-free perovskite material and cyclic utilization are indispensable steps for achieving sustainable and clean PSCs. Lead-free PSCs are subject to severe oxidation and defect density. Thus, a deeper and fundamental understanding of how additive engineering and surface modification affect the overall crystal structure, thin film morphology, and photoelectronic features of lead-free PSCs is needed as well. The cyclic utilization is based on life cycle assessment (LCA), a widely practical practice method used to quantify environmental impacts and energy consumption [103, 104]. Moreover, more detailed economic models and more accurate input parameters, such as price elasticity, marginal production, and consumption, are required for LCA to promote the development of Pb cyclic utilization in PSCs.

Lastly, simplification of lead leakage test procedures for PSCs is still one of the most effective strategies to design a mathematical model of lead leakage under various weather conditions in computers. Therefore, integrating efficient Pb absorbents, non-toxic perovskite formation, accurate test methods, and low-cost recycling should be further explored.

References

Kojima A, Teshima K, Shirai Y et al (2009) Organometal halide perovskites as visible-light sensitizers for photovoltaic cells. J Am Chem Soc 131(17):6050–6051

Zhang F, Zhu K (2021) Breakthrough: phase-pure 2D perovskite films. Joule 5(1):14–15

Yoo JJ, Seo G, Chua MR et al (2021) Efficient perovskite solar cells via improved carrier management. Nature 590(7847):587–593

Xiao CX, Zhang F, Chen XH et al (2021) SMART perovskite growth: enabling a larger range of process conditions. ACS Energy Lett 6(2):650–658

Min H, Lee DY, Kim J et al (2021) Perovskite solar cells with atomically coherent interlayers on SnO2 electrodes. Nature 598(7881):444–450

Jeong J, Kim M, Seo J et al (2021) Pseudo-halide anion engineering for α-FAPbI3 perovskite solar cells. Nature 592(7854):381–385

Heo JH, Zhang F, Xiao CX et al (2021) Efficient and stable graded CsPbI3−xBrx perovskite solar cells and submodules by orthogonal processable spray coating. Joule 5(2):481–494

Kim D, Jung HJ, Park IJ et al (2020) Efficient, stable silicon tandem cells enabled by anion-engineered wide-bandgap perovskites. Science 368(6487):155–160

Azmi R, Ugur E, Seitkhan A et al (2022) Damp heat–stable perovskite solar cells with tailored-dimensionality 2D/3D heterojunctions. Science 376(6588):73–77

Kim M, Jeong J, Lu HZ et al (2022) Conformal quantum dot–SnO2 layers as electron transporters for efficient perovskite solar cells. Science 375(6578):302–306

Zhang F, Park SY, Yao CL et al (2022) Metastable Dion-Jacobson 2D structure enables efficient and stable perovskite solar cells. Science 375(6576):71–76

Wu TH, Qin ZZ, Wang YB et al (2021) The main progress of perovskite solar cells in 2020–2021. Nano-Micro Lett 13:152

Wu PF, Wang SR, Li XG et al (2021) Advances in SnO2-based perovskite solar cells: from preparation to photovoltaic applications. J Mater Chem A 9(35):19554–19588

Kim G, Min H, Lee KS et al (2020) Impact of strain relaxation on performance of α-formamidinium lead iodide perovskite solar cells. Science 370(6512):108–112

Lee JW, Tan S, Seok SI et al (2022) Rethinking the A cation in halide perovskites. Science 375(6583):eabj1186

Zhu HW, Pan LF, Eickemeyer FT et al (2022) Efficient and stable large bandgap MAPbBr3 perovskite solar cell attaining an open circuit voltage of 1.65 V. ACS Energy Lett 7(3):1112–1119

Dai ZH, Yadavalli SK, Chen M et al (2021) Interfacial toughening with self-assembled monolayers enhances perovskite solar cell reliability. Science 372(6542):618–622

Fu Q, Liu H, Tang XC et al (2022) Multifunctional two-dimensional polymers for perovskite solar cells with efficiency exceeding 24%. ACS Energy Lett 7(3):1128–1136

Gu XJ, Xiang WC, Tian QW et al (2021) Rational surface-defect control via designed passivation for high-efficiency inorganic perovskite solar cells. Angew Chemie Int Ed 60(43):23164–23170

Yoon SM, Min H, Kim JB et al (2021) Surface engineering of ambient-air-processed cesium lead triiodide layers for efficient solar cells. Joule 5(1):183–196

Chen YT, Wei N, Miao YF et al (2022) Inorganic CsPbBr3 perovskite nanocrystals as interfacial ion reservoirs to stabilize FAPbI3 perovskite for efficient photovoltaics. Adv Energy Mater 22:203

Mi JY, Chen YT, Liu XM et al (2022) Synergistic stabilization of CsPbI3 inorganic perovskite via 1D capping and secondary growth. J Energy Chem 68:387–392

UNEP’s activities on lead and cadmium. https://www.unep.org/es/node/1192

Mallick A, Visoly-Fisher I (2021) Pb in halide perovskites for photovoltaics: reasons for optimism. Mater Adv 2(19):6125–6135

Xiao ZW, Song ZN, Yan YF (2019) From lead halide perovskites to lead-free metal halide perovskites and perovskite derivatives. Adv Mater 31(47):e1803792

Pitaro M, Tekelenburg EK, Shao SY et al (2022) Tin halide perovskites: from fundamental properties to solar cells. Adv Mater 34(1):2105844

Jiang XY, Li HS, Zhou QL et al (2021) One-step synthesis of SnI2·(DMSO)x adducts for high-performance tin perovskite solar cells. J Am Chem Soc 143(29):10970–10976

Ye T, Wang K, Hou YC et al (2021) Ambient-air-stable lead-free CsSnI3 solar cells with greater than 7.5% efficiency. J Am Chem Soc 143(11):4319–4328

Cortecchia D, Dewi HA, Yin J et al (2016) Lead-free MA2CuClxBr4–x hybrid perovskites. Inorg Chem 55(3):1044–1052

Krishnamoorthy T, Ding H, Yan C et al (2015) Lead-free germanium iodide perovskite materials for photovoltaic applications. J Mater Chem A 3(47):23829–23832

Wang M, Zeng P, Bai S et al (2018) High-quality sequential-vapor-deposited Cs2AgBiBr6 thin films for lead-free perovskite solar cells. Sol RRL 2(12):1870238

Yu BB, Chen ZH, Zhu YD et al (2021) Heterogeneous 2D/3D tin-halides perovskite solar cells with certified conversion efficiency breaking 14%. Adv Mater 33(36):2102055

Cao JP, Yan F (2021) Recent progress in tin-based perovskite solar cells. Energy Environ Sci 14(3):1286–1325

Wang CB, Zhang YT, Gu FD et al (2021) Illumination durability and high-efficiency Sn-based perovskite solar cell under coordinated control of phenylhydrazine and halogen ions. Matter 4(2):709–721

Kadro JM, Hagfeldt A (2017) The end-of-life of perovskite PV. Joule 1(1):29–46

Kim BJ, Kim DH, Kwon SL et al (2016) Selective dissolution of halide perovskites as a step towards recycling solar cells. Nat Commun 7:11735

Chen B, Fei CB, Chen SS et al (2021) Recycling lead and transparent conductors from perovskite solar modules. Nat Commun 12:5859

Park SY, Park JS, Kim BJ et al (2020) Sustainable lead management in halide perovskite solar cells. Nat Sustain 3(12):1044–1051

Jiang Y, Qiu LB, Juarez-Perez EJ et al (2019) Reduction of lead leakage from damaged lead halide perovskite solar modules using self-healing polymer-based encapsulation. Nat Energy 4(7):585–593

Conings B, Babayigit A, Boyen HG (2019) Fire safety of lead halide perovskite photovoltaics. ACS Energy Lett 4(4):873–878

Wan JW, Yu XX, Zou JJ et al (2021) Lead contamination analysis of perovskite modules under simulated working conditions. Sol Energy 226:85–91

Huang ZQ, Long J, Dai RY et al (2021) Ultra-flexible and waterproof perovskite photovoltaics for washable power source applications. Chem Commun (Camb) 57(51):6320–6323

Chen SS, Deng YH, Gu HY et al (2020) Trapping lead in perovskite solar modules with abundant and low-cost cation-exchange resins. Nat Energy 5(12):1003–1011

Sanka Ganesan, Pecht Michael G (2006) Lead-free electronics. In: Ganesan Sanka (ed) Michael pecht. Wiley, Hoboken

Understanding REACH-ECHA. https://echa.europa.eu/regulations/reach/ understanding-reach

USA Environmental Protection Agency. USA Environmental Protection Agency Criteria Air Pollutants. https://www.epa.gov/criteria-air-pollutants/naaqs-table

USA Environmental Protection Agency. USA Environmental Protection Agency water quality criteria. https://www.epa.gov/ground-water-and-drinking-water/national-primary-drinking-water-regulations#one

Ministry of Ecology and Environment of the People’s Republic of China (2006). Standards for drinking water quality. GB 5749-2006. https://www.mee.gov.cn

Ministry of Ecology and Environment of the People’s Republic of China, 2012. Ambient air quality standards. GB 3095–2012. https://www.mee.gov.cn

Zheng YF, Su R, Xu ZJ et al (2019) Perovskite solar cell towards lower toxicity: a theoretical study of physical lead reduction strategy. Sci Bull 64(17):1255–1261

Abate A (2017) Perovskite solar cells go lead free. Joule 1(4):659–664

Ren M, Qian XF, Chen YT et al (2022) Potential lead toxicity and leakage issues on lead halide perovskite photovoltaics. J Hazard Mater 426:127848

Li JM, Cao HL, Jiao WB et al (2020) Biological impact of lead from halide perovskites reveals the risk of introducing a safe threshold. Nat Commun 11:310

Ponti C, Nasti G, di Girolamo D et al (2022) Environmental lead exposure from halide perovskites in solar cells. Trends Ecol Evol 37(4):281–283

Benmessaoud IR, Mahul-Mellier AL, Horváth E et al (2015) Health hazards of methylammonium lead iodide based perovskites: cytotoxicity studies. Toxicol Res (Camb) 5(2):407–419

Kumar A, Kumar A, Cabral-Pinto MMS et al (2020) Lead toxicity: health hazards, influence on food chain, and sustainable remediation approaches. Int J Environ Res Public Health 17(7):2179

Wang GY, Zhai YJ, Zhang SR et al (2020) An across-species comparison of the sensitivity of different organisms to Pb-based perovskites used in solar cells. Sci Total Environ 708:135134

Babayigit A, Ethirajan A, Muller M et al (2016) Toxicity of organometal halide perovskite solar cells. Nat Mater 15(3):247–251

Wu PF, Wang SR, Li XG et al (2022) Beyond efficiency fever: preventing lead leakage for perovskite solar cells. Matter 5(4):1137–1161

Horváth E, Kollár M, Andričević P et al (2021) Fighting health hazards in lead halide perovskite optoelectronic devices with transparent phosphate salts. ACS Appl Mater Interfaces 13(29):33995–34002

Niu BF, Wu HT, Yin JL et al (2021) Mitigating the lead leakage of high-performance perovskite solar cells via in situ polymerized networks. ACS Energy Lett 6(10):3443–3449

Liang YM, Song PQ, Tian HR et al (2022) Lead leakage preventable fullerene-porphyrin dyad for efficient and stable perovskite solar cells. Adv Funct Mater 32(14):2110139

Hu YQ, He ZY, Jia XR et al (2022) Dual functions of performance improvement and lead leakage mitigation of perovskite solar cells enabled by phenylbenzimidazole sulfonic acid. Small Methods 6(2):2101257

Li X, Du JY, Duan H et al (2022) Moisture-preventing MAPbI3 solar cells with high photovoltaic performance via multiple ligand engineering. Nano Res 15(2):1375–1382

Chu QQ, Sun ZJ, Ding B et al (2020) Greatly enhanced power conversion efficiency of hole-transport-layer-free perovskite solar cell via coherent interfaces of perovskite and carbon layers. Nano Energy 77:105110

Wang HL, Liu HC, Li WP et al (2020) Inorganic perovskite solar cells based on carbon electrodes. Nano Energy 77:105160

Zhang CY, Chen M, Fu F et al (2022) CNT-based bifacial perovskite solar cells toward highly efficient 4-terminal tandem photovoltaics. Energy Environ Sci 15(4):1536–1544

Jiang XQ, Zhang JF, Liu Y et al (2021) Dopant-free polymer/2D/3D perovskite solar cells with high stability. Nano Energy 90:106521

Sun XL, Li Z, Yu XY et al (2021) Efficient inverted perovskite solar cells with low voltage loss achieved by a pyridine-based dopant-free polymer semiconductor. Angew Chem Int Ed Engl 60(13):7227–7233

Guo ZL, Jena AK, Takei I et al (2021) Dopant-free polymer HTM-based CsPbI2Br solar cells with efficiency over 17% in sunlight and 34% in indoor light. Adv Funct Mater 31(42):2103614

Lee J, Kim GW, Kim M et al (2020) Nonaromatic green-solvent-processable, dopant-free, and lead-capturable hole transport polymers in perovskite solar cells with high efficiency. Adv Energy Mater 10(8):1902662

Shalan AE, Akman E, Sadegh F et al (2021) Efficient and stable perovskite solar cells enabled by dicarboxylic acid-supported perovskite crystallization. J Phys Chem Lett 12(3):997–1004

Zhu H, Ren Y, Pan L et al (2021) Synergistic effect of fluorinated passivator and hole transport dopant enables stable perovskite solar cells with an efficiency near 24. J Am Chem Soc 143(8):3231–3237

Zhu HW, Liu YH, Eickemeyer FT et al (2020) Tailored amphiphilic molecular mitigators for stable perovskite solar cells with 23.5% efficiency. Adv Mater 32(12):1907757

Wang QR, Lin ZH, Su J et al (2022) Dithiol surface treatment towards improved charge transfer dynamic and reduced lead leakage in lead halide perovskite solar cells. EcoMat 2:e12185

Dou J, Zhu C, Wang H et al (2021) Synergistic effects of Eu-MOF on perovskite solar cells with improved stability. Adv Mater 33(39):2102947

Huckaba AJ, Sun DT, Sutanto AA et al (2020) Lead sequestration from perovskite solar cells using a metal-organic framework polymer composite. Energy Technol 8(7):2000239

Chen SS, Deng YH, Xiao X et al (2021) Preventing lead leakage with built-in resin layers for sustainable perovskite solar cells. Nat Sustain 4(7):636–643

Mai CL, Zhou Q, Xiong Q et al (2021) Donor-π-acceptor type porphyrin derivatives assisted defect passivation for efficient hybrid perovskite solar cells. Adv Funct Mater 31(7):2007762

Li CP, Yin J, Chen RH et al (2019) Monoammonium porphyrin for blade-coating stable large-area perovskite solar cells with >18% efficiency. J Am Chem Soc 141(15):6345–6351

Yan PJ, Cao J, Pang J et al (2021) Chemical encapsulation of perovskite film by Tetra-thiol copper(II) porphyrin for stable and clean photovoltaics. Org Electron 93:106158

Xiao GB, Wang LY, Mu XJ et al (2021) Lead and iodide fixation by thiol copper(II) porphyrin for stable and environmental-friendly perovskite solar cells. CCS Chem 3(10):25–36

Li CL, Wang LY, Yan PJ et al (2021) Perovskite surface management by thiol and amine copper porphyrin for stable and clean solar cells. Chem Eng J 409:128167

Liang HX, Wang WD, Mai SB et al (2022) Lead fixation by spider web-like porphyrin polymer for stable and clean perovskite solar cells. Chem Eng J 429:132405

Hu YQ, Song WW, Wang XY et al (2022) A holistic sunscreen interface strategy to effectively improve the performance of perovskite solar cells and prevent lead leakage. Chem Eng J 433:134566

Hang PJ, Xie JS, Kan CX et al (2021) Stabilizing fullerene for burn-in-free and stable perovskite solar cells under ultraviolet preconditioning and light soaking. Adv Mater 33(10):2006910

Wang FY, Li X, Duan H et al (2022) Toward efficient, moisture-resistant and lead-leakproofness perovskite solar cells: coordination-driven reconstructing homogeneous amorphous perovskitoid/crystalline perovskite photoabsorber. Chem Eng J 428:132528

Meng XC, Hu XT, Zhang YY et al (2021) A biomimetic self-shield interface for flexible perovskite solar cells with negligible lead leakage. Adv Funct Mater 31(52):2106460

Mokhtar MZ, He JY, Li MH et al (2021) Bioinspired scaffolds that sequester lead ions in physically damaged high efficiency perovskite solar cells. Chem Commun (Camb) 57(8):994–997

Zhang JL, Li RJ, Apergi S et al (2021) Multifunctional molecule engineered SnO2 for perovskite solar cells with high efficiency and reduced lead leakage. Sol RRL 5(10):2100464

Wu SF, Li Z, Li MQ et al (2020) 2D metal–organic framework for stable perovskite solar cells with minimized lead leakage. Nat Nanotechnol 15(11):934–940

Zhang H, Li K, Sun M et al (2021) Design of superhydrophobic surfaces for stable perovskite solar cells with reducing lead leakage. Adv Energy Mater 11(41):2102281

Aranda CA, Caliò L, Salado M (2021) Toward commercialization of stable devices: an overview on encapsulation of hybrid organic-inorganic perovskite solar cells. Curr Comput-Aided Drug Des 11(5):519

Li JL, Xia R, Qi WJ et al (2021) Encapsulation of perovskite solar cells for enhanced stability: structures, materials and characterization. J Power Sources 485:229313

Liu ZY, Sun B, Shi TL et al (2016) Enhanced photovoltaic performance and stability of carbon counter electrode based perovskite solar cells encapsulated by PDMS. J Mater Chem A 4(27):10700–10709

Kim M, Kang TW, Kim SH et al (2019) Antireflective, self-cleaning and protective film by continuous sputtering of a plasma polymer on inorganic multilayer for perovskite solar cells application. Sol Energy Mater Sol Cells 191:55–61

Ma S, Bai Y, Wang H et al (2020) 1000 h operational lifetime perovskite solar cells by ambient melting encapsulation. Adv Energy Mater 10(9):1902472

Li Z, Wu X, Li B et al (2022) Sulfonated graphene aerogels enable safe-to-use flexible perovskite solar modules. Adv Energy Mater 12(5):2103236

Li Z, Wu X, Wu SF et al (2022) An effective and economical encapsulation method for trapping lead leakage in rigid and flexible perovskite photovoltaics. Nano Energy 93:106853

Li X, Zhang F, He HY et al (2020) On-device lead sequestration for perovskite solar cells. Nature 578(7796):555–558

Li X, Zhang F, Wang JX et al (2021) On-device lead-absorbing Tapes for sustainable perovskite solar cells. Nat Sustain 4(12):1038–1041

Xiao X, Wang MX, Chen SS et al (2021) Lead-adsorbing ionogel-based encapsulation for impact-resistant, stable, and lead-safe perovskite modules. Sci Adv 7(44):eabi8249

Leccisi E, Fthenakis V (2021) Life cycle energy demand and carbon emissions of scalable single-junction and tandem perovskite PV. Prog Photovolt Res Appl 29(10):1078–1092

Tian XY, Stranks SD, You FQ (2021) Life cycle assessment of recycling strategies for perovskite photovoltaic modules. Nat Sustain 4(9):821–829

Acknowledgements

This work was financially supported by research start-up funding of Talent Professor at Tianjin University (No. 216127).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that there is no conflict of interest.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wu, P., Zhang, F. Recent Advances in Lead Chemisorption for Perovskite Solar Cells. Trans. Tianjin Univ. 28, 341–357 (2022). https://doi.org/10.1007/s12209-022-00316-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12209-022-00316-z