Abstract

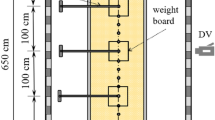

A series of ISO 5658-2 flame spread experiments on Douglas-fir specimens were carried out to investigate the relationship between flame spread characteristics and thermal thickness of solid combustibles, which is greatly influenced by char formation during combustion. Computations using the fire dynamics simulator (FDS) were performed to recreate these experiments. The measured and calculated flame spread characteristics were then compared and analyzed based on thermal thickness and char residue ratio. The results clearly show that the effects of char formation on the surface of wood during combustion are more noticeable in thermally thick regimes than in thermally thin regimes. The findings provide an important foundational understanding of the influence of char formation on solid combustibles on flame retardant properties, which has not previously been studied.

Similar content being viewed by others

Abbreviations

- M s :

-

Smoke yield

- SEA :

-

Specific extinction area

- V duct :

-

Volumetric flow rate measured in the duct exhaust

- MLR :

-

Mass loss rate

- C s :

-

Light attention by soot particles

- K m :

-

Mass specific extinction coefficient

- δ p :

-

Effective work

- k :

-

Thermal conductivity

- ρ :

-

Density

- c p :

-

Heat capacity

- t ig :

-

Ignition time

- c p :

-

Heat capacity

- E :

-

Activation energy

- A :

-

Pre-exponential factor

- h c :

-

Heat of combustion

- T s :

-

Temperature of surface

- t :

-

Time

- \(\dot q_s^{\prime \prime \prime}\) :

-

Heat loss

- \(\dot q_{conv}^{\prime \prime}\) :

-

Convective flux

- \(\dot q_{rad}^{\prime \prime}\) :

-

Radiative flux

- β :

-

Coverts solid material, α

- \({{\dot q}^{\prime \prime}}\) :

-

Heat release rate per unit area

- \({{\dot m}^{\prime \prime}}\) :

-

Mass loss rate per unit area of solid material

- p s,α :

-

Bulk density of solid material

- R :

-

Universal gas constant

- v s,α :

-

Mass fraction of the residue of the component is represented

- D* :

-

Characteristic fire diameter

- \({\dot Q}\) :

-

Heat release rate

References

UNFCCC, Measurements for Estimation of Carbon Stocks in Afforestation and Reforestation Project Activities under the Clean Development Mechanism, Guidance Document, UC CC:Learn, https://www.uncclearn.org/resources/library/measurements-for-estimation-of-carbon-stocks-in-afforestation-and-reforestation-project-activities-under-the-clean-development-mechanism/ (accessed on 23 November 2022).

O. Matvienko, D. Kasymov, E. Loboda, A. Lutsenko and O. Daneyko, Modeling of wood surface ignition by wildland firebrands, Fire, 5 (2) (2022) 38.

H. Salehizadeh, R. S. P. Hakes and M. J. Gollner, Critical ignition conditions of wood by cylindrical firebrands, Frontiers in Mechanical Engineering, 7 (2021) 17.

S. Suzuki and S. L. Manzello, Garnering understanding into complex firebrand generation processes from large outdoor fires using simplistic laboratory-scale experimental methodologies, Fuel, 267 (2020) 117–154.

D. Kasymov, M. Agafontsev, V. Perminov, P. Martynov, V. Reyno and E. Loboda, Experimental investigation of the effect of heat flux on the fire behavior of engineered wood samples, Fire, 3 (4) (2020) 61.

H. C. Kung, A mathematical model of wood pyrolysis, Combustion and Flame, 18 (1972) 185–195.

K. M. Bryden, K. W. Ragland and C. J. Rutland, Modeling thermally thick pyrolysis of wood, Biomass and Bioenergy, 22 (2002) 41–53.

B. Schartel and T. R. Hull, Development of fire-retarded materials—interpretation of cone calorimeter data, Fire and Materials, 31 (2007) 327–354.

C. D. Blasi, Modeling and simulation of combustion processes of charring and non-charring solid fuels, Progress in Energy and Combustion Science, 19 (1993) 71–104.

W. H. Twilley and V. Babrauskas, User’s Guide for the Cone Calorimeter, NBS Special Publication 745, Government Printing Office, Washington, DC, USA (1998).

B. Östman, J. Stensaas and P. Hovde, Smoke Production in the Cone Calorimeter and the Room Fire Test for Surface Products-Correlation Studies, Rapport 1 8903013, Institutet för Träteknisk Forskning (Trätek), Stockholm, Sweden (1992).

W. G. Mulholland and M. Y. Choi, Measurement of the mass specific extinction coefficient for acetylene and ethene smoke using the large agglomerate optics facility, Symposium (International) on Combustion, 27 (1) (1998) 1515–1522.

T. K. Hong, B. S. Roh and S. H. Park, Measurements of optical properties of smoke particulates produced from burning polymers and their implications, Energies, 13 (9) (2020) 2299.

W. G. Mulholland and C. Croarkin, Specific extinction coefficient of flame generated smoke, Fire and Materials, 24 (5) (2000) 209–252.

K. McGrattan, S. Hostikka, J. Floyd, R. McDermott and M. Vanella, Fire Dynamics Simulator Technical Reference Guide Volume 1: Mathematical Model, NIST Special Publication 1018-1, 6th ed., NIST, Gaithersburg, MD, USA (2021).

W. Mell, A. Maranghides, R. McDermott and S. Manzello, Numerical simulation and experiments of burning douglas fir trees, Combustion and Flame, 156 (10) (2009) 2023–2041.

X. Wang, P. Zhu, H. Xu and M. Fan, Experimental study on the autoignition characteristics of pure and oil-impregnated transformer insulating paper board, Journal of Thermal Analysis and Calorimetry, 127 (3) (2017) 2489–2497.

V. Babrauskas, Ignition Handbook: Principles and Applications to Fire Safety Engineering, Fire Investigation, Risk Management and Forensic Science, Fire Science Publishers, Issaquah WA, USA (2003).

International Organization for Standardization, ISO 5658-2:2006 Reaction to fire tests Spread of flame, Part 2: Lateral Spread on Building and Transport Products in Vertical Configuration, ISO, Geneva, Switzerland (2006).

X. Wnag, Fire dynamics simulator (FDS) pyrolysis model analysis of heavy goods vehicle fires in road tunnels, Ph.D. Thesis, University of Canterbury, Christchurch, New Zealand (2017).

X. Wnag, C. M. Fleischmann and M. J. Spearpoint, Parameterising study of tunnel experiment materials for application to the fire dynamics simulator pyrolysis model, Journal of Fire Sciences, 34 (6) (2016) 490–514.

N. Wei and A. Chen, A study on the evacuation spacing of undersea tunnels in different ventilation velocity conditions, Fire, 5 (2) (2022) 48.

K. McGrattan, J. Floyd, G. Forney and H. Baum, Improved radiation and combustion routines for a large eddy simulation fire model, Fire Safety Science Proceedings of Seventh (7th) International Symposium, International Association for Fire Safety Science (IAFSS), Boston, MA, USA (2003) 16–21.

K. Hill, J. Dreisbach, F. Joglar, B. Najafi, K. McGrattan, R. Peacock and A. Hamins, Verification and Validation of Selected Fire Models for Nuclear Power Plant Applications, NUREG 1824, U. S. Nuclear Regulatory Commission, Washington, DC, USA (2007).

Z. M. Nikolaou and N. Swaminathan, Heat release rate markers for premixed combustion, Combustion and Flame, 161 (12) (2014) 3073–3084.

Acknowledgments

This study was supported by research fund from Chosun University, 2019.

Author information

Authors and Affiliations

Corresponding author

Additional information

Ter Ki Hong received his master of mechanical engineeering from Chosun University in 2018. Currently, he is pursuing a Ph.D. at Chosun University. His research interest covers thermal engineering including combustion & fire science.

Seul Hyun Park received his Ph.D. from Drexel University in 2007. Upon completion of his Ph.D., he worked as a postdoctoral associate for 3 years at National Institute of Standards and Technology (NIST). After serving as a senior research engineer at Korea Aerospace Research Institute (KARI) from 2010 through 2013, he comes to Chosun University as an Assistant Professor. His research interest covers a wide range of areas in thermal engineering including combustion & fire science and heat transfer.

Rights and permissions

About this article

Cite this article

Hong, TK., Park, SH. Influences of the presence of char layer on flame spreads over wood with different thermal thickness. J Mech Sci Technol 37, 3841–3848 (2023). https://doi.org/10.1007/s12206-023-0646-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-023-0646-8