Abstract

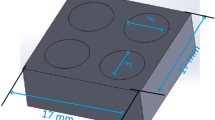

while choosing 3D printing in preference to traditional manufacturing methods (injection molding, CNC machining or casting), it is worth considering optimizing spatial models for mass reduction. One method of mass reduction is to implement cellular structures into the designed component. CAD software, such as NX, Catia, Creo, SolidWorks are not suitable for this type of operation, due to the fact that they use boundary representations (b-reps) to express the shapes of solid objects. The nTopology software takes a new design approach using implicit modeling techniques. Focusing on the design aspect, the paper proposes workflows to model objects consisting of cellular structures. The emphasis is on the strength test specimens, printing them in both DMLS/SLM and SLS technologies. A volumetric scanning technique was applied to validate the produced objects, thus obtaining a real solid model of the specimens. The aim of the study was to develop configured workflows for the design of the strength test specimens.

Similar content being viewed by others

Abbreviations

- SLM :

-

Selective laser melting

- SLS :

-

Selective laser sintering

- TPMS :

-

Triple periodic minimal surface

- \({\overline \rho_{rel}}\) :

-

Relative density [%]

References

A. Nazir, K. M. Abate, A. Kumar and I. J. Y. Jeng, A state-of-the-art review on types, design, optimization, and additive manufacturing of cellular structures, Int. J. Adv. Manuf. Technol., 104 (2019) 3489–3510.

O. Rehme, Cellular Design for Laser Freeform Fabrication, Cuvillier Verlag, Gottingen (2010).

L. J. Gibson, Cellular Solids, Structure and Properties, Cambridge Solid State Science Series (1997).

M. Benedetti, A. du Plessis, R. O. Ritchie, M. Dallago, S. M. J. Razavi and I. F. Berto, Architected cellular materials: a review on their mechanical properties towards fatigue-tolerant design and fabrication, Mater. Sci. Eng. R Rep., 144 (2021) 100606.

T. Maconachie et al., SLM lattice structures: properties, performance, applications and challenges, Mater. Des., 183 (2019) 108137.

C. Yan et al., Chapter 2 — design of TPMS structures, Triply Periodic Minimal Surface Lattices Additively Manufactured by Selective Laser Melting, Red. Academic Press (2021) 27–38.

R. Hedayati, M. Sadighi, M. Mohammadi-Aghdam and I. A. A. Zadpoor, Mechanical properties of regular porous biomaterials made from truncated cube repeating unit cells: Analytical solutions and computational models, Mater. Sci. Eng. C, 60 (2016) 163–183.

D. Herzog, V. Seyda, E. Wycisk and I. C. Emmelmann, Additive manufacturing of metals, Acta Mater., 117 (2016) 371–392.

M. Askari et al., Additive manufacturing of metamaterials: a review, Addit. Manuf., 36 (2020) 101562.

G. Allen, Field-driven design, nTopology (2022).

G. Allen, nTopology modeling technology, nTopology (2022).

A. Safdar, H. Z. He, L. Wei, A. Snis and I. L. E. Chavez de Paz, Effect of process parameters settings and thickness on surface roughness of EBM produced Ti-6Al-4V, Rapid Prototyp. J., 18 (5) (2012) 401–408.

S. Liu and Y. C. Shin, Additive manufacturing of Ti6Al4V alloy: A review, Materials and Design, 164 (2019) 107552.

Author information

Authors and Affiliations

Corresponding author

Additional information

Kevin Moj is currently a Ph.D. student at Opole University of Technology. He received his master’s degree in mechanical engineering in 2020. His research interests include metal 3D printing, with a particular focus on cellular structures.

Rights and permissions

About this article

Cite this article

Moj, K., Robak, G., Owsiński, R. et al. A new approach for designing cellular structures: design process, manufacturing and structure analysis using a volumetric scanner. J Mech Sci Technol 37, 1113–1118 (2023). https://doi.org/10.1007/s12206-022-2107-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-022-2107-1