Abstract

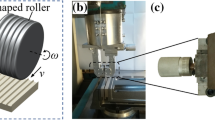

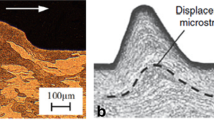

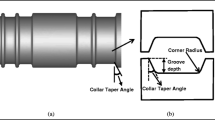

Micro-riblets (grooves) can reduce surface friction in turbulent flow by up to 10 %. Furthermore, roll forming is an effective method for manufacturing large-area groove structures. In this study, the fluidity of metal during the multi-pass rolling of microgrooves was studied, and the reason for the accumulation of materials at the end of rolling was explained. A comparative analysis was conducted between single-pass rolling and multi-pass rolling. Then, according to the distribution of stress field and strain field, the force and flow tendency of the metal during rolling were studied. The gradually changing streamlined roller tooth profile promoted the flow of metal to both sides of the gear hob. Given the same reduction, the forming height of micro-grains during multi-pass rolling was 64.2 % higher than that during single-pass rolling.

Similar content being viewed by others

References

A. Shourangiz-Haghighi and A. R. Tavakolpour-Saleh, A neural network-based scheme for predicting critical unmeasurable parameters of a free piston stirling oscillator, Energy Convers. Manage., 196 (2019) 623–639.

S. Zare, A. Tavakolpour-Saleh, A. Shourangiz-Haghighi and T. Binazadeh, Assessment of damping coefficients ranges in design of a free piston stirling engine: simulation and experiment, Energy, 185 (2019) 633–643.

A. Shourangiz-Haghighi, M. Diazd, Y. Zhang, J. Li, Y. Yuan, R. Faraji, L. Ding and J. M. Guerrero, Developing more efficient wind turbines: a survey of control challenges and opportunities, IEEE Ind. Electron. Mag., 14 (2020) 53–64.

M. J. Walsh, Riblets as viscous drag reduction technique, AIAA Journal, 21(4) (1983) 485–486.

P. D. McClure, B. Smith, W. Baker and P. Yagle, Design and testing of 3-D riblets, AIAA Scitech 2020 Forum, Orlando (2020) 0311.

B. Denkena, J. Köhler and B. Wang, Manufacturing of functional riblet structures by profile grinding, CIRP J. Manuf. Sci. Technol., 3 (2010) 14–26.

B. Denkena, D. Boehnke and B. Wang, Manufacturing of functional microstructured surfaces by grinding with vitrified SiC-and cBN-wheels, International Journal of Abrasive Technology, 2(2) (2009) 207–222.

B. Denkena, T. Grove and T. Krawczyk, Tools and strategies for grinding of riblets on freeformed compressor blades, Procedia CIRP, 55 (2016) 182–187.

B. Denkena, J. Kästner and B. Wang, Advanced microstructures and its production through cutting and grinding, CIRP Annals, 59(1) (2010) 67–72.

R. Hockauf, E. Asadi, B. Denkena, T. Grove and M. Wurz, Grinding of riblets with beaver tooth multi-layer tools, Procedia CIRP, 71 (2018) 155–159.

G. Xiao, Y. He, Y. Huang and Q. Li, Shark-skin-inspired micro-riblets forming mechanism of TC17 titanium alloy with belt grinding, IEEE Access, 7 (2019) 107635–107647.

Y. Huang, Y. Wu, Y. He, Q. Zhao, G. Xiao, S. He and K. Song, Experimental study on laser assisted belt grinding of shark-skin bio-inspired riblets under different surface roughness, Procedia CIRP, 89 (2020) 277–281.

P. Gao, X. Wang, Z. Liang, S. Zhang, T. Zhou, P. Yan and L. Jiao, Effects of machining inclination angles on microgroove quality in micro ball end milling of Ti-6Al-4V, The International Journal of Advanced Manufacturing Technology, 92 (2017) 2725–2734.

J. Yan, T. Kaneko, K. Uchida, N. Yoshihara and T. Kuriya-gawa, Fabricating microgrooves with varied cross-sections by electrodischarge machining, The International Journal of Advanced Manufacturing Technology, 50 (2010) 991–1002.

H. M. Chow, B. H. Yan and F. Y. Huang, Micro slit machining using electro-discharge machining with a modified rotary disk electrode (RDE), Journal of Materials Processing Technology, 91 (1999) 161–166.

J. Lei, X. Wu, Z. Wang, B. Xu, L. Zhu and W. Wu, Electrical discharge machining of micro grooves using laminated disc electrodes made of Cu and Sn foils, Journal of Materials Processing Technology, 271 (2019) 455–462.

J. J. J. Kaakkunen, J. Tiainen, A. Jaatinen-Värri, A. Grönman and M. Lohtander, Nanosecond laser ablation of the trapezoidal structures for turbomachinery applications, Procedia Manufacturing, 25 (2018) 435–442.

J. J. J. Kaakkunen, J. Tiainen, A. Jaatinen-Värri, A. Grönman and M. Lohtander, Fabrication of surfaces with reduced friction using nanosecond laser, Procedia Manufacturing, 17 (2018) 14–21.

F. Siegel, U. Klug and R. Kling, Extensive micro-structuring of metals using picosecond pulses-ablation behavior and industrial relevance, Journal of Laser Micro/Nanoengineering, 4(2) (2009) 104–110.

A. Žemaitis, J. Mikšys, M. Gaidys, P. Gecys and M. Gedvilas, High-efficiency laser fabrication of drag reducing riblet surfaces on pre-heated Teflon, Materials Research Express, 6(6) (2019) 065309.

X. C. Wang and Y. C. Wan, Picosecond laser fabrication of the riblet-array surface texture on Ti64 alloy substrate, Journal of Laser Micro/Nanoengineering, 14(3) (2019) 206–213.

L. Bin and W. J. Meng, Roll molding of microchannel arrays on Al and Cu sheet metals: a method for high-throughput manufacturing, Journal of Micro- and Nano-Manufacturing, 2 (2014) 011007.

Z. Xu, L. Peng and X. Lai, Investigation on the roll-to-plate microforming of riblet features with the consideration of grain size effect, The International Journal of Advanced Manufacturing Technology, 109 (2020) 2055–2064.

T. Romans and G. Hirt, Rolling of drag reducing riblet-surfaces, 51st AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Orlando (2010) 3062.

K. Shimoyama, S. Yokoyama, S. Kaneko and F. Fujita, Effect of grooved roll profiles on microstructure evolutions of AZ31 sheets in periodical straining rolling process, Materials Science and Engineering A, 611 (2014) 58–68.

F. Klocke, B. Feldhaus, H. Wegner and V. Bäcker, Rolling of defined riblet structures on compressor blades of Ti6AI4V, Steel Research International, 81(9) (2010) 178–181.

M. Terhorst, D. Trauth and F. Klocke, Riblet rolling on Ti6AI4V compressor blades, 60 Excellent Inventions in Metal Forming, Springer, Berlin, Heidelberg (2015) 245–250.

F. Klocke, B. Feldhaus and S. Mader, Development of an incremental rolling process for the production of defined riblet surface structures, Prod. Eng. Res. Devel., 1 (2007) 233–237.

Q. Wang, J. Sun, X. Li, Z. Wang, P. Wang and D. Zhang, Analysis of lateral metal flow-induced flatness deviations of rolled steel strip: mathematical modeling and simulation experiments, Applied Mathematical Modelling, 77 (2020) 289–308.

H. Utsunomiya, T. Ito and R. Matsumoto, Flattening of surface grooves in cold flat rolling, Procedia Engineering, 81 (2014) 155–160.

S. Kalpakjian and S. R. Schmid, Manufacturing Processes for Engineering Materials, 5th Ed., Pearson Education, London (2007).

H. C. Kwon and Y. T. Im, Interactive computer-aided-design system for roll pass and profile design in bar rolling, Journal of Materials Processing Technology, 123(3) (2002) 399–405.

S. Tipalin, M. Petrov and N. F. Shpunkin, To the influence of the deformation speed on hardening process during the cold sheet forming, Solid State Phenomena, 284 (2018) 513–518.

X. J. Gao, G. M. Zhu, H. H. Wang, N. N. Guo and Z. S. Wang, Research on micro riblets rolling process based on uncertainty analysis, Materials Today Communications, 27 (2021) 102302.

J. L. Yin, G. M. Zhu, M. K. Ding, X. J. Gao, N. N. Guo and Z. S. Wang, Simulation of incremental rolling process for a new roller profile, Forging and Stamping Technology, 44 (2019) 6–13.

M. H. Besha, D. K. Sinha, C. Venkatesh and S. S. Gautam, Analysis of effective stresses for titanium alloys in continuous forming process, Materials Today: Proceedings, 49(2) (2022) 383–389.

Acknowledgements

This work was supported by the Natural Science Foundation of Shandong Province of China (Grant Nos. ZR2021ME222, ZR2017MEE036, and ZR2017BEM003).

Author information

Authors and Affiliations

Corresponding author

Additional information

Xujie Gao is a Ph.D. candidate at the School of Mechanical Engineering, Shandong University of Technology. He obtained his Master’s degree from the same university in 2012. His research interest includes the plastic forming process of metal materials.

Huihang Wang is taking his Master’s degree at Shandong University of Technology. His research interests include metal plastic forming processes and die technology.

Guangming Zhu obtained his Ph.D. from Yanshan University in 2004. He is currently a Professor and Doctoral Supervisor of Shandong University of Technology, among other important directorships. His team’s research interests include metal plastic forming equip- ment, process, and automation in the fields of strip rolling, seamless steel tube forming, incremental roll forming, and steel final forming.

Rights and permissions

About this article

Cite this article

Gao, X., Wang, H., Zhu, G. et al. Research on metal flow law of micro-riblets based on multi-pass rolling. J Mech Sci Technol 36, 2277–2286 (2022). https://doi.org/10.1007/s12206-022-0410-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-022-0410-5