Abstract

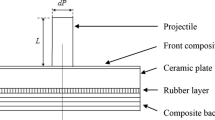

A lightweight multilayer ceramic composite armor with a sandwich structure back plate was proposed by studying the penetration process, damage mechanism, and the function of each layer of the composite armor against the 12.7 mm armor-piercing projectile. The effectiveness of the simulation was verified by comparing the experimental and simulation data. The effects of crack initiation in the ceramics, abrasion of ceramics, and size of ceramic cones on the penetration resistance of targets were discussed. The structural configuration of backplate sequence and thickness ratio was optimized through finite element simulation on ANSYS/LS-DYNA. Results indicate that boundary constraints have a significant effect on the antipenetration performance of ceramics. The antipenetration performance is the best when the structure of restrained composite armor is Al6061/Al2O3/TC4/Kevlar®/TC4 and the thickness ratio of the TC4 transition and back plates is 4:3.

Similar content being viewed by others

Abbreviations

- V o :

-

Initial velocity

- V r :

-

Residual velocity

- A :

-

Thickness ratio

References

C. H. Yang et al., Analysis of the low velocity impact response of functionally graded carbon nanotubes reinforced composite spherical shells, J. Mech. Sci. Technol., 32(6) (2018) 2681–2691.

J. Radin and W. Goldsmith, Normal projectile penetration and perforation of layered targets, Int. J. Impact. Eng., 7(2) (1988) 229–259.

M. W. Ali et al., An experimental and numerical investigation of the ballistic response of multi-level armor against armor piercing projectiles, Int. J. Impact Eng., 110(SI) (2017) 47–56.

P. K. Jena et al., An experimental study on the ballistic impact behavior of some metallic armor materials against 7.62 mm deformable projectile, Mater. & Des., 31(7) (2010) 3308–3316.

M. M. Shokrieh and G. H. Javadpour, Penetration analysis of a projectile in ceramic composite armor, Compos. Struct., 82(2) (2008) 269–276.

I. Marom and S. R. Bodner, Projectile perforation of multilayered beams, Int. J. Mech. Sci., 21(8) (1979) 489–504.

C. W. Ong et al., Advanced layered personnel armor, Int. J. Impact Eng., 38(5) (2011) 369–383.

D. Hu et al., Investigation on the ballistic behavior of mosaic SiC/UHMWPE composite armor systems, Ceram. Int., 43(13) (2017) 10368–10376.

W. L. Goh et al., Effects of hardness of steel on ceramic armor module against long rod impact, Int. J. Impact Eng., 109 (2017) 419–426.

Q. Wang, Z. Chen and Z. Chen, Design and characteristics of hybrid composite armor subjected to projectile impact, Mater. Des., 46 (2013) 634–639.

A. Kolopp, S. Rivallant and C. Bouvet, Experimental study of sandwich structures as armor against medium-velocity impacts, Int. J. Impact Eng., 61(2) (2013) 24–35.

J. G. Hetherington, The optimization of two component composite armors, Int. J. Impact Eng., 12(3) (1992) 409–414.

M. Lee and Y. H. Yoo, Analysis of ceramic/metal armor systems, Int. J. Impact Eng., 25(9) (2001) 819–829.

R. Cortés et al., Numerical modelling of normal impact on ceramic composite armors, Int. J. Impact Eng., 12(4) (1992) 639–650.

J. Z. Li, L. S. Zhang and F. L. Huang, Experiments and simulations of tungsten alloy rods penetrating into alumina ceramic/603 armor steel composite targets, Int. J. Impact Eng., 3 (2017) 101: 1–8.

D. Bürger et al., Ballistic impact simulation of an armor-piercing projectile on hybrid ceramic/fiber reinforced composite armors, Int. J. Impact Eng., 43(5) (2012) 63–77.

J. Shi and D. Grow, Effect of double constraints on the optimization of two-component armor systems, Compos. Struct., 79(3) (2007) 445–453.

C. C. Holland et al., Effect of design on the performance of steel-alumina bilayers and trilayers subject to ballistic impact, Mech. Mater., 91 (2015) 241–251.

J. J. Demange, V. Prakash and J. M. Pereira, Effects of material microstructure on blunt projectile penetration of a nickel-based super alloy, Int. J. Impact Eng., 36(8) (2009) 1027–1043.

G. R. Johnson and W. H. Cook, Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures, Eng. Fract. Mech., 21(1) (1985) 31–48.

D. Fernández-Fdz, R. Zaera and J. Fernández-Sáez, A constitutive equation for ceramic materials used in lightweight armors, Comput. Struct., 89(23–24) (2011) 2316–2324.

X. Wang and J. Shi, Validation of Johnson-Cook plasticity and damage model using impact experiment, Int. J. Impact Eng., 60 (2013) 67–75.

A. Serjouei et al., Empirical ballistic limit velocity model for bilayer ceramic-metal armor, Int. J. Prot. Struct., 6(3) (2015) 509–527.

M. J. Pawar et al., Comparison of ballistic performances of Al2O3 and AlN ceramics, Int. J. Impact Eng., 98 (2016) 42–51.

A. Serjouei et al., Experimental validation of BLV model on bilayer ceramic-metal armor, Int. J. Impact Eng., 77 (2015) 30–41.

T. J. Holmquist, G. R. Johnson and C. M. Lopatin, High strain rate properties and constitutive modeling of glass, 15th International Symposium on Ballistics, Jerusalem, Israel (1995) 237–244.

G. R. Johnson and T. J. Holmquist, Response of boron carbide subjected to large strains, high strain rates, and high pressures, J. Appl. Phys., 85(12) (1999) 8060–8073.

T. J. Holmquist, D. W. Templeton and K. D. Bishnoi, Constitutive modeling of aluminum nitride for large strain, high-strain rate, and high-pressure applications, Int. J. Impact Eng., 25(3) (2001) 211–231.

T. J. Holmquist and G. R. Johnson, Modeling prestressed ceramic and its effect on ballistic performance, Int. J. Impact Eng., 31(2) (2005) 113–127.

T. J. Holmquist and G. R. Johnson, A computational constitutive model for glass subjected to large strains, high strain rates and high pressures, J. Appl. Mech., 78(5) (2011) 051003.

D. C. Drucker and W. Prager, Soil mechanics and plastic analysis or limit design, Q. Appl. Math., 10(2) (1952) 157–165.

A. K. Bandaru et al., Ballistic impact response of Kevlar® reinforced thermoplastic composite armors, Int. J. Impact Eng., 89 (2016) 1–13.

J. Sun et al., The delamination of carbon fiber reinforced composites during cutting by flexible linear shaped charge, J. Mech. Sci. Technol., 34(4) (2020) 1515–1522.

B. Loret and J. H. Prevost, Dynamic strain localization in elasto-(visco-)plastic solids, Part 1. General formulation and one-dimensional examples, Comput. Method Appl. M, 83(3) (1990) 247–273.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Nos. 51678308 and 51278249).

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Editor Chongdu Cho

Jianzhong Lai serves as a Professor at the School of Materials Science and Engineering, Nanjing University of Science and Technology, Nanjing, China. He received his Ph.D. from Southeast University. His research interests include advanced composite and 3D printing materials.

Rights and permissions

About this article

Cite this article

Cao, J., Lai, J., Zhou, J. et al. Experiments and simulations of the ballistic response of ceramic composite armors. J Mech Sci Technol 34, 2783–2793 (2020). https://doi.org/10.1007/s12206-020-0611-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-020-0611-8