Abstract

In this present study, the particle behavior and heat transfer coefficients for particle-gas and particle-particle re found by using a computational model in a fluidization process. A conical shape is selected as a reactor due to its wide ange of applications. The equations describing gas and particle motions and heat transfer are solved by using the Eulerian two-fluid approach. Glass bead particles of two different sizes (2 mm and 4 mm) are used as bed materials, and the air is used as a fluidized gas. The velocity of the gas inlet is varied from 1.3 m/s to 2.6 m/s. The results demonstrate that the particle-gas eat transfer coefficient according to the velocity of the air inlet reaches its maximum value around 2.1 m/s, then decreases thereafter. Besides, at the same velocity, the particle-particle heat transfer coefficient reaches its maximum value, then decrease thereafter with increasing the velocity of the inlet air.

Similar content being viewed by others

Abbreviations

- Ar:

-

Reactor cross sectional area, m2

- d:

-

Diameter, m

- ess :

-

Restitution coefficient for particle collisions

- g̅:

-

Acceleration due to gravity, m/s2

- go :

-

Radial distribution function

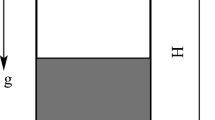

- H:

-

Enthalpy, kJ/kg

- hgs :

-

Heat transfer coefficient between gas and solid phases, W/ (m2-K)

- hss :

-

Particle-particle heat exchange coefficient, W/ (m3-K)

- Is :

-

Particle head, (m)

- k:

-

Thermal conductivity, W/ (m-K)

- m:

-

Mass, kg

- N:

-

Number of phase

- Nu:

-

Nusselt number

- Pr:

-

Prandtl number

- P:

-

Pressure, (Pa)

- Res :

-

Particle Reynolds number

- T:

-

Temperature, K

- t:

-

Time, s

- v̅:

-

Velocity vector, m/s

- α :

-

Inter-phase momentum exchange coefficient, kg/ (m3s)

- ε :

-

Volume fraction

- γ :

-

Collision dissipation of energy fluctuation, kg/ (ms3)

- λs :

-

Solid bulk viscosity, Pas

- ώ:

-

Viscosity, Pas

- ρ :

-

Density, kg/m3

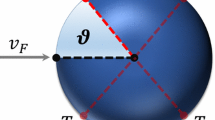

- Θ :

-

Granular temperature, m2/s2

- T :

-

Stress tensor, Pa

- φ :

-

Internal friction angle (°)

- ψjsi :

-

Transfer of kinetic energy (J)

- g:

-

Gas phase

- s:

-

Solid phase

- i:

-

Index, i

- j:

-

Index, j

References

D. Kunii and O. Levenspiel, Fluidization Engineering, Esevier (2013).

E. Natarajan, A. Nordin and A. Rao, Overview of combustion and gasification of rice husk in fluidized bed reactors, Biomass and Bioenergy, 14 (1998) 533–546.

K. Tomishige, M. Asadullah and K. Kunimori, Syngas production by biomass gasification using Rh/CeO2/SiO2 catalysts and fluidized bed reactor, Catalysis Today, 89 (2004) 389–403.

Z. Zhou, A. Yu and P. Zulli, Particle scale study of heat transfer in packed and bubbling fluidized beds, AIChE Journal, 55 (2009) 868–884.

C. Wen and T. Chang, Particle to particle heat transfer in air fluidized beds, Proceedings of International Symposium on Fluidization (1967)

N. Decker and L. Glicksman, Heat transfer in large particle fluidized beds, International Journal of Heat and Mass Transfer, 26 (1983) 1307–1320.

C. Delvosalle and J. Vanderschuren, Gas-to-particle and particle-to-particle heat transfer in fluidized beds of large particles, Chemical Engineering Science, 40 (1985) 769–779.

T. F. McKenna, R. Spitz and D. Cokljat, Heat transfer from catalysts with computational fluid dynamics, AIChE Journal, 45 (1999) 2392–2410.

Z. Mansoori, M. Saffar-Avval, H. Basirat-Tabrizi, G. Ahmadi and S. Lain, Thermo-mechanical modeling of turbulent heat transfer in gas-solid flows including particle collisions, International Journal of Heat and Fluid Flow, 23 (2002) 792–806.

J. Chang, G. Wang, J. Gao, K. Zhang, H. Chen and Y. Yang, CFD modeling of particle-particle heat transfer in dense gassolid fluidized beds of binary mixture, Powder Technology, 217 (2012) 50–60.

J. Ngoh and E. W. C. Lim, Effects of particle size and bubbling behavior on heat transfer in gas fluidized beds, Applied Thermal Engineering, 105 (2016) 225–242.

L. Zhou et al., Experimental study and transient CFD/DEM simulation in a fluidized bed based on different drag models, RSC Advances, 7 (2017) 12764–12774.

Z. Qinghong, W. Shuyan, L. Huilin, L. Guodong, W. Shuai and Z. Guangbo, A coupled Eulerian fluid phase-Eulerian solids phase-Lagrangian discrete particles hybrid model applied to gas-solids bubbling fluidized beds, Powder Technology, 315 (2017) 385–397.

M. Bernard, E. Climent and A. Wachs, Controlling the quality of two-way Euler/Lagrange numerical modeling of bubbling and spouted fluidized beds dynamics, Industrial & Engineering Chemistry Research, 56 (2016) 368–386.

S. Tebianian et al., Comparison of particle velocity measurement techniques in a fluidized bed operating in the square-nosed slugging flow regime, Powder Technology, 296 (2016) 45–52.

V. Kouprianov and W. Permchart, Emissions from a conical FBC fired with a biomass fuel, Applied Energy, 74 (2003) 383–392.

V. I. Kuprianov and P. Arromdee, Combustion of peanut and tamarind shells in a conical fluidized-bed combustor: A comparative study, Bioresource Technology, 140 (2013) 199–210.

P. Ninduangdee and V. I. Kuprianov, Study on burning oil palm kernel shell in a conical fluidized-bed combustor using alumina as the bed material, Journal of the Taiwan Institute of Chemical Engineers, 44 (2013) 1045–1053.

R. Yusuf, B. Halvorsen and M. C. Melaaen, An experimental and computational study of wall to bed heat transfer in a bubbling gas-solid fluidized bed, International Journal of Multiphase Flow, 42 (2012) 9–23.

Q. Hou, Z. Zhou and A. Yu, Computational study of heat transfer in bubbling fluidized beds with geldart a powder, Seventh International Conference on CFD in the Minerals and Process Industries, Melbourne, Australia (2009).

D. Patil, J. Smit, M. van Sint Annaland and J. Kuipers, Wall-to-bed heat transfer in gas-solid bubbling fluidized beds, AIChE Journal, 52 (2006) 58–74.

M. Hamzehei, H. Rahimzadeh and G. Ahmadi, Computational and experimental study of heat transfer and hydrodynamics in a 2D gas-solid fluidized bed reactor, Industrial & Engineering Chemistry Research, 49 (2010) 5110–5121.

Z. Shu, J. Wang, Q. Zhou, C. Fan and S. Li, Evaluation of multifluid model for heat transfer behavior of binary gas-solid flow in a downer reactor, Powder Technology, 281 (2015) 34–48.

H. M. Abdelmotalib, M. A. Youssef, A. A. Hassan, S. B. Youn and I.-T. Im, Numerical study on the wall to bed heat transfer in a conical fluidized bed combustor, International Journal of Precision Engineering and Manufacturing, 16 (2015) 1551–1559.

R. G. Szafran and A. Kmiec, CFD modeling of heat and mass transfer in a spouted bed dryer, Industrial & Engineering Chemistry Research, 43 (2004) 1113–1124.

P. C. Johnson and R. Jackson, Frictional-collisional constitutive relations for granular materials, with application to plane shearing, Journal of Fluid Mechanics, 176 (1987) 67–93.

Fluent, Inc., FLUENT 6.3 User’S Guide, Fluent documentation (2006).

H. K. Versteeg and W. Malalasekera, An Introduction to Computational Fluid Dynamics: The Finite Volume Method, Pearson Education (2007).

V. Mathiesen, T. Solberg and B. H. Hjertager, An experimental and computational study of multiphase flow behavior in a circulating fluidized bed, International Journal of Multiphase Flow, 26 (2000) 387–419.

S. Qiaoqun, L. Huilin, L. Wentie, H. Yurong, Y. Lidan and D. Gidaspow, Simulation and experiment of segregating/mixing of rice husk-sand mixture in a bubbling fluidized bed, Fuel, 84 (2005) 1739–1748.

D. Gidaspow, R. Bezburuah and J. Ding, Hydrodynamics of Circulating Fluidized Beds: Kinetic Theory Approach, Dept. of Chemical Engineering, Illinois Inst. of Tech., Chicago, IL, United States (1991).

M. Syamlal, The Particle-particle Drag Term in a Multiparticle Model of Fluidization, EG and G Washington Analytical Services Center, Inc., Morgantown, WV (1987).

C. Lun, S. B. Savage, D. Jeffrey and N. Chepurniy, Kinetic theories for granular flow: Inelastic particles in Couette flow and slightly inelastic particles in a general flowfield, Journal of Fluid Mechanics, 140 (1984) (1984) 223–256.

D. Gunn, Transfer of heat or mass to particles in fixed and fluidised beds, International Journal of Heat and Mass Transfer, 21 (1978) 467–476.

J. Sun and M. Chen, A theoretical analysis of heat transfer due to particle impact, International Journal of Heat and Mass Transfer, 31 (1988) 969–975.

S. Patankar, Numerical Heat Transfer and Fluid Flow, CRC Press (1980).

O. Levenspiel, Fluidization Engineering, Butterworth-Heinemann (1991).

S. Yang, K. Luo, M. Fang, J. Fan and K. Cen, Discrete element study of solid mixing behavior with temperature difference in three-dimensional bubbling fluidized bed, Industrial & Engineering Chemistry Research, 53 (2014) 7043–7055.

Acknowledgments

This research is supported by the Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education (NRF-20170R1D1 A3B03036041).

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Editor Yang Na

Mohamed Yahya Hashim received his Master degree at Heat Transfer and Reactive Flow Lab. of Jeonbuk National University. He is currently a Ph.D. candidate at Fluid Engineering Lab. of Jeon-buk National University. His research focuses on swirling flow and ther-moacoustic instabilities in gas turbine combustors.

Hamada M. Abdelmotalib received the B.S. and M.S. in Mechanical Engineering from Minia university, Minia, Egypt in 2006 and 2011, respectively, and the Ph.D. from Jeonbuk National University, Korea in 2016. In 2016, he joined the Department of Mechanical Power and Energy, Faculty of Engineering, Minia University as a lecturer. His main research fields are, numerical modeling, fluidization, heat transfer, combustion, and pyrolysis.

Jong Seok Kim received the B.S., |M. S. ^degrees and Ph.D. in Chemical Engineering from Jeonbuk National University, Jeonju, Korea in 1987, 1991 and 1995, respectively. In 1998, he joined the Department of Chemical Engineering, Jeonbuk National University. His main research interests is transport phenomena in energy materials.

Dong-Guk Ko is a Research Professor in the Department of Mechanical Engineering, Jeonbuk National University. He received his Ph.D. degree in Mechanical Engineering in 2015 from Jeonbuk National University, Korea. His research interests include renewable energy, heat transfer and flow dynamics in various mechanical systems.

Ik-Tae Im received the |M. S. ^degree and Ph.D. in Mechanical Engineering from Hanyang University, Seoul, Korea in 1995 and 1999, respectively. In 2008, he joined the Department of Mechanical Design Engineering, Jeonbuk National University, where he has researched on a wide range of heat transfer applications, from heat exchanger to optimization of process parameters for reactors design. His research interests include various heat transfer problems with chemical reactions.

Rights and permissions

About this article

Cite this article

Hashim, M.Y., Abdelmotalib, H.M., Kim, J.S. et al. A numerical study on gas-to-particle and particle-to-particle heat transfer in a conical fluidized bed reactor. J Mech Sci Technol 34, 2391–2402 (2020). https://doi.org/10.1007/s12206-020-0516-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-020-0516-6