Abstract

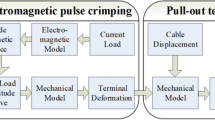

Design of a field shaper plays an essential role in the electromagnetic crimping process. It needs to be designed in such a manner that maximum magnetic field is concentrated at the active working zone. Simultaneously it is essential to take care of the mechanical strength of the field shaper so that the von Mises stress acting over the field shaper should always be lower than the strength of the material used for making field shaper. In this manuscript, numerical and experimental work is carried out in the variation of the effective height of the field shaper, to get the most suitable effective working zone height for maximum magnetic pressure acting over the workpiece. Research is carried out over the electrical interconnectors as an application, to achieve maximum crimping of the terminal over the wire strands. Results like the current density Von-Mises stress, magnetic field, Lorentz force, terminal deformation, and contact length are discussed in detail. These results will help to design a field shaper for different industrial applications.

Similar content being viewed by others

References

S. F. Golovashchenko, Material formability and coil design in electromagnetic forming, Journal of Materials Engineering and Performance, 16(3) (2007) 314–320.

A. K. Rajak, R. Kumar, H. Basumatary and S. D. Kore, Numerical and experimental study on effect of different types of field-shaper on electromagnetic terminal-wire crimping process, International Journal of Precision Engineering and Manufacturing, 19(3) (2018) 453–459.

V. Psyk, D. Risch, B. L. Kinsey, A. E. Tekkaya and M. Kleiner, Electromagnetic forming—A review, Journal of Materials Processing Technology, 211(5) (2011) 787–829.

A. K. Rajak and S. D. Kore, Experimental investigation of aluminium-copper wire crimping with electromagnetic process: Its advantages over conventional process, Journal of Manufacturing Processes, 26 (2017) 57–66.

R. Chaharmiri and A. F. Arezoodar, The effect of various stepped field shaper on magnetic pressure and radial displacement in electromagnetic inside bead forming: Experimental and simulation analysis using maxwell and abaqus software, Journal of Manufacturing Science and Engineering, 139 (2017) 061003–1–6.

H. Yu, C. Li, Z. Zhao and Z. Li, Effect of field shaper on magnetic pressure in electromagnetic forming, Journal of Materials Processing Technology, 168 (2005) 245–249.

H. Yu, Z. Xu, Z. Fan, Z. Zhao and C. Li, Mechanical property and microstructure of aluminum alloy-steel tubes joint by magnetic pulse welding, Materials Science & Engineering A, 561(2013) 259–265.

H. Suzuki, M. Murata and H. Negishi, The effect of a field shaper in electromagnetic tube bulging, Journal of Mechanical Working Technology, 15 (1987) 229–240.

P. L. Eplattenier, G. Cook, C. Ashcraft, M. Burger, J. Imbert and M. Worswick, Introduction of an Electromagnetism Module in Ls-Dyna for Couple Mechanical-Thermal-Electromagnetic Simulations, Steel Research International, 80(5) (2009) 351–358.

A. C. Jeanson, F. Bay, N. Jacques, G. Avrillaud, M. Arrigoni and G. Mazars, A coupled experimental/numerical approach for the characterization of material behaviour at high strain-rate using electromagnetic tube expansion testing, International Journal of Impact Engineering, 98 (2016) 75–87.

J. P. M. Correia, M. A. Siddiqui, S. Ahzi, S. Belouettar and R. Davies, A simple model to simulate electromagnetic sheet free bulging process, International Journal of Mechanical Sciences, 50 (2008) 1466–1475.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Seok-min Kim

Ashish Rajak received his Ph.D. in Mechanical Engineering from IIT Guwahati, India. Currently, he is working as a Post Doc at the Impulse Manufacturing Lab (Glenn Daehn Lab), The Ohio State University, USA. His main research interest includes electromagnetic forming, joining and powder compaction using experimental and simulation approaches.

Ramesh Kumar received his Ph.D. in Mechanical Engineering from IIT Guwahati, India. Currently, he is working as an Assistant Professor in Saharsa College of Engineering, Bihar, India. He works in electromagnetic crimping, cladding, and forming.

Sachin D Kore is currently a faculty in the Mechanical Engineering Department, Dean of Academic Affairs and Student Affairs, IIT Goa, India. He specializes in electromagnetic pulse welding and forming, modeling of the electromagnetic pulse welding process and friction stir welding.

Rights and permissions

About this article

Cite this article

Rajak, A.K., Kumar, R. & Kore, S.D. Designing of field shaper for the electro-magnetic crimping process. J Mech Sci Technol 33, 5407–5413 (2019). https://doi.org/10.1007/s12206-019-1035-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-019-1035-1