Abstract

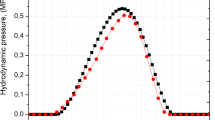

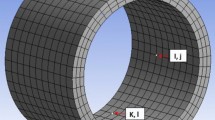

In present study, a fluid-structure interaction (FSI) approach is proposed for predicting the effects of roughness on the performance of hydrodynamically lubricated three-dimensional (3D) journal bearing, taking mechanical deformation effects. The multi-phase cavitation mass flow conservation model is adopted, in which the phase change boundary condition is allowable. The results show that the mechanical deformation effect on bearing performance has been confirmed to be substantial. When the deformation of the structure is considered in calculating the change of film thickness, the bearings carry less load (i.e. 30–70 % smaller depending on the surface roughness value) as compared to the case in which the deformation is neglected. It is also highlighted that the hydrodynamic pressure and load support decrease with surface roughness.

Similar content being viewed by others

References

K. Gururajan and J. Prakash, Roughness effects in narrow porous journal bearing with arbitrary porous wall thickness, International Journal of Mechanical Sciences, 44(5) (2002) 1003–1016.

N. B. Naduvinamani, P. S. Hiremath and G. Gurubasavaraj, Effects of surface roughness on the static characteristics of rotor bearings with couple stress fluids, Computer & Structures, 80 (2002) 1243–1253.

G. K. Kalavathi, P. A. Dinesh and K. Gururajan, Influence of roughness on porous finite journal bearing with heterogeneous slip/no-slip surface, Tribology International, 102 (2016) 174–181.

S. Cui, L. Gu, M. Fillon, L. Wang and C. Zhang, The effects of surface roughness on the transient characteristics of hydrodynamic cylindrical bearings during startup, Tribology International, 128 (2018) 421–428.

H. Liu, H. Xu, P. J. Ellison and Z. Jin, Application of computational fluid dynamics and fluid-structure interaction method to the lubrication study of a rotor-bearing system, Tribology Letters, 38(3) (2010) 325–336.

A. Charitopoulos, D. Fouflias, C. I. Papadopoulos, L. Kaiktsis and M. Fillon, Thermohydrodynamic analysis of a textured sector-pad thrust bearing: Effects on mechanical deformations, Mechanics & Industry, 15(5) (2014) 403–411.

M. Wodtke, A. Schubert, M. Fillon, M. Wasilczuk and P. Pajaczkowski, Large hydrodynamic thrust bearing: Comparison of the calculations and measurements, Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, 228(9) (2014) 974–983.

A. Linjamaa, A. Lehtovaara, R. Larsson, M. Kallio and S. Söchting, Modelling and analysis of elastic and thermal deformations of a hybrid journal bearing, Tribology International, 118 (2018) 451–457.

T. Adams, C. Grant and H. Watson, A Simple algorithm to relate measured surface roughness to equivalent sand-grain roughness, International Journal of Mechanical Engineering and Mechatronics, 1(2) (2012) 66–71.

H. K. Versteeg and W. Malalashekra, An Introduction to Computational Fluid Dynamics, The Finite Volume Method, Second Ed., Pearson Education Limited, England (2007).

ANSYS, ANSYS Fluent, Version 16.0: User Manual, ANSYS, Inc., Canonsburg, USA (2017).

S. Cupillard, S. Glavatskih and M. J. Cervantes, Computational fluid dynamics analysis of a journal bearing with surface texturing, Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, 222(2) (2008) 97–107.

G. Gao, Z. Yin, D. Jiang and X. Zhang, Numerical analysis of plain journal bearing under hydrodynamic lubrication by water, Tribology International, 75 (2014) 31–38.

Q. Lin, Z. Wei, N. Wang and Y. Zhang, Effect of recess configuration on the performances of high-speed hybrid journal bearing, Industrial Lubrication and Tribology, 68(3) (2016) 301–307.

D. Y. Dhande and D. W. Pande, Multiphase flow analysis of hydrodynamic journal bearing using CFD coupled fluid structure interaction considering cavitation, Journal of King Saud University — Engineering Sciences, 30(4) (2018) 345–354.

D. Sun, S. Li, C. Fei, Y. Ai and R. P Liem, Investigation of the effect of cavitation and journal whirl on static and dynamic characteristics of journal bearing, Journal of Mechanical Science and Technology, 33(1) (2019) 77–86.

P. Zwart, A. G. Gerber and T. Belamri, A two-phase flow model for predicting cavitation dynamics, Proceedings of the Fifth International Conference on Multiphase Flow, Yokohama, Japan, May (2004).

B. Jakobsson and L. Floberg, The Finite Journal Bearing, Considering Vaporization, Göteborg Gumperts Förlag, Sweden (1957).

Acknowledgments

This research is fully supported by RPI-BT (Research Publication International-High Reputation) Grant, No. 387-05/UN7.P4.3/PP/2018. The authors fully acknowledged Institute for Research and Community Services (LPPM) Diponegoro University for the approved fund which makes this important research viable and effective.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Tatacipta Dirgantara

Mohammad Tauviqirrahman is Head of Laboratory for Engineering Design and Tribology at the Engineering Faculty, Diponegoro University, Indonesia. He received his doctoral degree from Twente University, The Netherlands (2013). His research interests include tribology in lubricant and surface modification.

Jamari is a Senior Researcher at Laboratory for Engineering Design and Tribology at the Engineering Faculty, Diponegoro University, Indonesia. He received his doctoral degree from Twente University, The Netherlands (2006). His research area is contact mechanic and biomechanic.

Rights and permissions

About this article

Cite this article

Tauviqirrahman, M., Ichsan, B.C., Jamari et al. Influence of roughness on the behavior of three-dimensional journal bearing based on fluid-structure interaction approach. J Mech Sci Technol 33, 4783–4790 (2019). https://doi.org/10.1007/s12206-019-0919-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-019-0919-4