Abstract

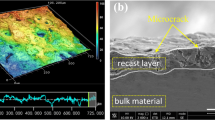

In PM/EDM, it is known that when used electrically conductive powders, highly homogeneous alloyed layers can be formed where the gap extends slightly more than using non-conductive powders and regulates spark discharge and machining voltage more uniform. Boron element is non-conductive but when alloyed with steel, materials with high abrasion and corrosion resistance are obtained. In this study, the effects of boron oxide powders addition into dielectric fluid on microstructure and hardness of steel workpiece in electrical discharge machining (EDM) were investigated. For this purpose, by using a prismatic steel workpiece and a copper electrode in kerosene mixed with boron oxide (B2O3) powders, the morphology of the machined specimens at different powder concentrations and pulse duration settings were observed and investigated. In addition, the micro hardness of the layers occurred as a result of EDM was measured and discussed. The highest surface hardness value of 941 HV is measured over machined specimen with B2O3 powder addition, whereas the lowest surface hardness value of 413 HV is measured.

Similar content being viewed by others

References

M. Jeswani, Effect of the addition of graphite powder to kerosene used as the dielectric fluid in electrical discharge machining, Wear, 70 (2) (1981) 133–139.

N. Mohri, N. Saito, H. Narumiya, H. Kawatsu, Y. Ozaki, K. Kobayashi and Y. Tsunekawa, Finish machining by EDM using powder suspended working fluid, Journal of The Japan Society of Electrical Machining Engineers, 25 (1991) 47–60.

N. Mohri, N. Saito, M. Higashi and N. Kinoshita, A new process of finish machining on free surface by EDM methods, CIRP Annals-Manufacturing Technology, 40 (1) (1991) 207–210.

Q. Y. Ming and L. Y. He, Powder-suspension dielectric fluid for EDM, Journal of Materials Processing Technology, 52 (1) (1995) 44–54.

K. Masui, Surface modification of tool steels by alloying method using EDM process, ISEM-XI (1995).

Y. Uno and A. Okada, Surface generation mechanism in electrical discharge machining with silicon powder mixed fluid, International Journal of Electrical Machining, 2 (1997) 13–18.

T. Yih-Fong and C. Fu-Chen, Investigation into some surface characteristics of electrical discharge machined SKD-11 using powder-suspension dielectric oil, Journal of Materials Processing Technology, 170 (1–2) (2005) 385–391.

H.-M. Chow, B.-H. Yan, F.-Y. Huang and J.-C. Hung, Study of added powder in kerosene for the micro-slit machining of titanium alloy using electro-discharge machining, Journal of Materials Processing Technology, 101 (1–3) (2000) 95–103.

P. Janmanee and A. Muttamara, Surface modification of tungsten carbide by electrical discharge coating (EDC) using a titanium powder suspension, Applied Surface Science, 258 (19) (2012) 7255–7265.

G. Kibria, B. Sarkar, B. Pradhan and B. Bhattacharyya, Comparative study of different dielectrics for micro-EDM performance during microhole machining of Ti-6Al-4V alloy, The International Journal of Advanced Manufacturing Technology, 48 (5–8) (2010) 557–570.

G. Kibria and B. Bhattacharyya, Analysis on Geometrical Accuracy of Microhole during Micro-EDM of Ti-6Al-4V using Different Dielectrics, AIP Conference Proceedings, AIP (2011) 155–160.

A. Molinetti, F. L. Amorim, P. C. Soares and T. Czelusniak, Surface modification of AISI H13 tool steel with silicon or manganese powders mixed to the dielectric in electrical discharge machining process, The International Journal of Advanced Manufacturing Technology, 83 (5–8) (2016) 1057–1068.

A. Bhattacharya, A. Batish and N. Kumar, Surface characterization and material migration during surface modification of die steels with silicon, graphite and tungsten powder in EDM process, Journal of Mechanical Science and Technology, 27 (1) (2013) 133–140.

S. S. Sidhu, A. Batish and S. Kumar, Study of surface properties in particulate-reinforced metal matrix composites (MMCs) using powder-mixed electrical discharge machining (EDM), Materials and Manufacturing Processes, 29 (1) (2014) 46–52.

C. Prakash, H. Kansal, B. Pabla and S. Puri, Multiobjective optimization of powder mixed electric discharge machining parameters for fabrication of biocompatible layer on β-Ti alloy using NSGA-II coupled with Taguchi based response surface methodology, Journal of Mechanical Science and Technology, 30 (9) (2016) 4195–4204.

C. Cogun, B. Özerkan and T. Karacay, An experimental investigation on the effect of powder mixed dielectric on machining performance in electric discharge machining, Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 220 (7) (2006) 1035–1050.

A. G. Matuschka, Boronizing, Carl Hanser Verlag München, Vienne (1980) 11, 16–25, 37, 55–58, 66.

B. Selçuk, Borlanmış AISI 1020 ve 5115 çeliklerinin sürtünme ve aşınma davranışlarının incelenmesi, Ph.D. Thesis, Erciyes University Institute of Science and Technology, Kayseri, Turkey (1994) 45–81.

N. Bozkurt, Boryayınımıyla çeliklerde yüzey sertleştirme, Ph.D. Thesis, İstanbul Technical University Institute of Science and Technology, İstanbul, Turkey (1984) 54–70.

C. Demir, The evaluation of boron minerals as energy sources, M.Sc. Thesis, Selçuk University Institute of Science and Technology, Chemical Engineering, Konya, Turkey (2006).

N. Tawichai, U. Intatha, S. Eitssayeam, K. Pengpat, G. Rujijanagul and T. Tunkasiri, Influence of B2O3 on electrical properties and phase transition of lead-free Ba (Ti0. 9Sn0. 1) O3 ceramics, Phase Transitions, 83 (1) (2010) 55–63.

R. A. Smith, Boric oxide, boric acid and borates, Ullman’s Encyclopedia of Industrial Chemistry, 5th Ed., V.C.H. Verlagsgesellschaft m.b.h, 265269, A4 (1985).

R. A. Smith and R. B. McBroom, Boron oxides, boric acid and borates, Kirk-Othmer Encyclopedia of Chemical Technology, John Wiley and Sons, New York, 4 (1992) 368–377.

N. Acarkan, Boron products and their uses, Proceedings of the 1st International Boron Symposium, Kütahya, Turkey (2002) 1–5.

G. F. Benedict, Nontraditional manufacturing processes, Mercel Decker Inc., New York, USA (1987).

H. A.-G. El-Hofy, Advanced machining processes, Blacklick, McGraw-Hill Companies, OH, USA (2005).

J. Liu and Y. Guo, Modeling of white layer formation in electric discharge machining (EDM) by incorporating massive random discharge characteristics, Procedia CIRP, 42 (2016) 697–702.

J. A. McGeough, Advanced methods of machining, Chapman and Hall Ltd., London, UK (1988).

R. Manivannan and M. P. Kumar, Multi-response optimization of Micro-EDM process parameters on AISI304 steel using TOPSIS, Journal of Mechanical Science and Technology, 30 (1) (2016) 137–144.

D. L. Reger, S. R. Goode and D. W. Ball, Chemistry: Principles and practice, Cengage Learning (2009).

T. Savaşkan, Malzeme Bilgisi ve Muayenesi, Derya Kitabevi, Trabzon, Turkey (1999).

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Yongho Jeon

Hacı Bekir Özerkan received his Ph.D. degree in Mechanical Engineering from Gazi University. Since 2001, he has been working in Gazi University and his current position is the Lecturer at Gazi University Technical Vocational High School. His research interests include non-traditional machining and conventional machining methods.

Rights and permissions

About this article

Cite this article

Özerkan, H.B. Simultaneous machining and surface alloying of AISI 1040 steel by electrical discharge machining with boron oxide powders. J Mech Sci Technol 32, 4357–4364 (2018). https://doi.org/10.1007/s12206-018-0834-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-018-0834-0