Abstract

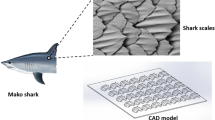

Microscale wrinkles can be utilized to enhance the characteristics of products. For example, a shark skin having riblet surface can move faster underwater, minimizing fluid flow resistance. We introduce a novel approach to fabricate microscale metallic wrinkles using a soft lithography and electroforming process; we also evaluated the effects of wrinkles by computational fluid dynamics (CFD) analyses. For the generation of metallic wrinkles, a UV-curable resin, NOA68T was used to fabricate a master wrinkling pattern by mechanism of compressive forces on a skin of the weakly polymerized resin layer. The master pattern was molded and replicated as metallic wrinkles on a surface via soft lithography and electroforming processes. To understand the advantages of a wavy surface on reduction of flow resistance, we carried out two- and three-dimensional (2D and 3D) CFD analyses. The drag coefficient of a wrinkled 2D square model was decreased about 17.1 %, and a 3D real wrinkle model showed 4.9 to 7.3 % reduction of it compared to without wrinkle models. We believe that it is possible to reduce the fluid flow resistance using wavy surfaces that can easily be generated selectively or wholly on an arbitrary surface.

Similar content being viewed by others

References

D. W. Bechert, M. Bruse and W. Hage, Experiments with three-dimensional riblets as an idealized model of shark skin, Experiments in Fluids, 28 (2000) 403–412.

B. N. J. Persson, Wet adhesion with application to tree frog adhesive toe pads and tires, Journal of Physics: Condensed Matter, 19 (2007) 1–16.

G. M. Whitesides, The origins and the future of microfluidics, Nature, 442 (2006) 368–373.

D. Y. Zhang, Y. H. Luo, L. I. Xiang and H. W. Chen, Numerical simulation and experimental study of drag-reducing surface of a real shark skin, J. of Hydrodynamics, 23 (2011) 204–211.

M. Ibn Eihaj and M. Schadt, Optical polymer thin films with isotropic and anisotropic nano-corrugated surface topologies, Nature, 410 (2001) 796–799.

U. Manna, C. D. C. Matthew and M. L. David, Shrink-to-fit superhydrophobicity: Thermally-induced microscale wrinkling of thin hydrophobic multilayers fabricated on flexible shrink-wrap substrates, Advanced Materials, 25 (2013) 3085–3089.

Y. Li, S. Dai, J. John and K. R. Carter, Superhydrophobic surfaces from hierarchically structured wrinkled polymers, Applied Materials Interfaces, 5 (2013) 11066–11073.

Z. J. Zhao, X. Li and S. H. Park, Generation of various wrinkle shapes on single surface by controlling thickness of weakly polymerized layer, Material Letters, 155 (2015) 125–129.

S. J. Kim, H. J. Park, J. C. Lee, S. Park, P. Ireland and S. H. Park, A simple method to generate hierarchical nanoscale structures on microwrinkles for hydrophobic applications, Material Letters, 105 (2013) 50–53.

F. Greco, A. Bellacicca, M. Gemmi, V. Cappello, V. Mattoli and P. Milani, Conducting shrinkable nanocomposite based on au-nanoparticle implanted plastic sheet: Tunable thermally induced surface wrinkling, ACS Applied Materials & Interfaces, 7 (2015) 7060–7065.

M. Guvendiren, S. Yang and J. A. Burdick, Swellinginduced surface patterns in hydrogels with gradient crosslinking density, Advanced Functional Materials, 19 (2009) 3038–3045.

M. W. Moon, S. H. Lee, J. Y. Sun, K. H. Oh, A. Vaziri and J. W. Hutchinson, Controlled formation of nanoscale wrinkling patterns on polymers using focused ion beam, Scripta Materialia, 57 (2007) 747–750.

Y. Xia and G. M. Whitesides, Soft lithography, Angewandte Chemie International Edition, 37 (1998) 550–575.

T. Chuang, P. J. Hai, Y. Z. Chuan and H. L. Cong, Controlled fabrication of hierarchically microstructured surfaces via surface wrinkling combined with template replication, Chinese Chemical Letters, 26 (2015) 15–20.

T. W. Lim and D. Y. Yang, Direct fabrication of nanowrinkled 3D microstructures using fitfully accumulated twophoton polymerization, Int. J. Prec. Eng. Manuf., 16 (2015) 2427–2431.

S. M. Kang, J. H. Kim and S. M. Kim, Partial wrinkle generation for switchable attachment and high adhesion hysteresis, Int. J. Prec. Eng. Manuf., 18 (2017) 133–137.

X. Li, Z. J. Zhao and S. H. Park, Out-of-plane stretching for simultaneous generation of different morphological wrinkles on a soft matter, Applied Physics A, 122 (2016) 1–8.

D. Y. Zhang, Y. H. Luo, L. I. Xiang and H. W. Chen, Numerical simulation and experimental study of drag-reducing surface of a real shark skin, J. of Hydrodynamics Ser. B, 23 (2011) 204–211.

F. E. Fish, P. W. Weber, M. M. Murray and L. E. Howle, The tubercles on humpback whales' flippers: application of bio-inspired technology, Integrative and Comparative Biology, 51 (2011) 203–213.

J. Choi, W. P. Jeon and H. Choi, Mechanism of drag reduction by dimples on a sphere, Physics of Fluids, 18 (2006) 1–4.

M. Kim, S. M. Lee, S. J. Lee, Y. W. Kim, L. Li and D. W. Lee, Effect on friction reduction of micro/nano hierarchical patterns on sapphire wafers, Int. J. Prec. Manuf. Green Technol., 4 (2017) 27–35.

D. H. Yu and A. Kareem, Numerical simulation of flow around rectangular prism, J. of Wind Engineering & Industrial Aerodynamics, 67 (1997) 195–208.

J. Rodriguez-Hernandez, Wrinkled interfaces: Taking advantage of surface instabilities to pattern polymer surfaces, Progress in Polymer Science, 42 (2015) 1–41.

B. A. Younis and V. P. Przulj, Computation of turbulent vortex shedding, Computational Mechanics, 37 (2006) 408–425.

J. A. McGeough, M. C. Leu, K. P. Rajurkar, A. K. M. De Silva and Q. Liu, Electroforming process and application to micro/macro manufacturing, CIRP Annals - Manufacturing Technology, 50 (2001) 499–514.

F. A. Chudnovskii, L. L. Odynets, A. L. Pergament and G. B. Stefanovich, Electroforming process and application to micro/macro manufacturing, J. of Solid State Chemistry, 122 (1996) 95–99.

Y. Joshua, M. Feng, D. T. Matthew, A. A. O. Douglas, R. S. Duncan, N. L. Chun and W. Stanley, The mechanism of electroforming of metal oxide memristive switches, Nanotechnology, 20 (2009) 215201–215209.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Suk Goo Yoon

Jeong Ho Yang is a M.S. course student at Pusan National University. His research interests are fabrication of microscale wrinkle and its application to fluidic flow characteristics.

Sang Hu Park is a Professor in the School of Mechanical Engineering at Pusan National University. He earned his M.A. and Ph.D. in mechanical engineering at Korea Advanced Institute of Science and Technology (KAIST, Korea) in 1996 and 2006, respectively. His research fields are the development of 3D printing process, mechanical design, and manufacturing technology, especially for multi-scale structures.

Rights and permissions

About this article

Cite this article

Yang, JH., Park, SH. CFD analysis of effects on fluid flow resistance of metallic wavy structures. J Mech Sci Technol 32, 1705–1711 (2018). https://doi.org/10.1007/s12206-018-0327-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-018-0327-1