Abstract

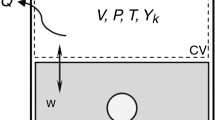

This research investigates the combustion characteristics of gasoline compression ignition engines fueled with gasoline-biodiesel blends. A single-cylinder diesel engine, modified from a commercial four-cylinder engine, was investigated in Gasoline compression ignition (GCI) mode. Also studied were the effects of the different gasoline blends on the variation of the fuel flow rate (on a mass basis). Gasoline blended with a range of 5-20 % biodiesel and pure diesel was injected into the measuring vessel with various injection pressures and durations by a seven-hole Bosch injector and a common-rail system. The injection pressures were varied from 200 to 1350 bar, and the injection duration was from 800 to 1050 ms while repeating the injection 1000 times for each run. To characterize the combustion, the test engine was mounted with an AC dynamometer and the pressure traces were measured using a piezo-electric pressure transducer. Only pure gasoline mixed with five percent biodiesel as a lubricity enhancer was injected into the cylinder while varying the injection pressure. The injection pressures were set at 600 and 1000 bar while the injection duration was altered to control the same equivalent ratio (λ = 1). Operated in the low-speed condition, the engine speed was fixed at 1200 rpm. Other engine parameters including engine oil, coolant water, and intake air temperature were controlled at the same operating condition for each experiment. To understand the combustion characteristics such as Heat release rate (HRR) and burning duration, the data was analyzed with the one-zone thermodynamic model. Exhaust emissions (CO, NOX and THC) were measured using an exhaust gas analyzer for each case, as well. The results showed that fuel properties had an effect on the injection flow rate. Higher viscosity fuel resulted in a lower injection rate. The injection pressure showed the greatest effect on the fuel flow rate. The higher the injection pressure, the higher the injection flow rate. At the same injection pressure and duration, the injection flow rate was reduced with an increase in the amount of biodiesel in the blend. In terms of combustion phenomena, a 5 % gasoline-biodiesel blend (GB05) showed the most significant differences in combustion when injected at high versus low injection pressures. At the higher injection pressure, the benefits of using diesel fuel were clear, but GB05 combustion at high pressures resulted in increased concentrations of undesirable emissions. On the other hand, GB05 fuel presented clear advantages when injected at a lower pressure. Depending on the injection pressure, the merits of gasoline on the exhaust emission were evaluated, especially with respect to CO, NOX and THC emissions reductions.

Similar content being viewed by others

References

S. Onishi, S. H. Jo, K. Shoda, P. Do Jo and S. Kato, Active thermo-atmosphere combustion (ATAC)-A new combustion process for internal combustion engines, SAE International (1979).

M. Noguchi, Y. Tanaka, T. Tanaka and Y. Takeuchi, A study on gasoline engine combustion by observation of intermediate reactive products during combustion, SAE International (1979).

S. Kimura, O. Aoki, H. Ogawa, S. Muranaka and Y. Enomoto, New combustion concept for ultra-clean and highefficiency small di diesel engines, SAE International (1999).

C. Noehre, M. Andersson, B. Johansson and A. Hultqvist, Characterization of partially premixed combustion, SAE International (2006).

S. Sasaki, T. Ito and S. Iguchi, Smoke-less rich combustion by low temperature oxidation in diesel engines, Aachen Colloq. Automob. Engine Technol. (2000) 767.

K. Akihama, Y. Takatori, K. Inagaki, S. Sasaki and A. M. Dean, Mechanism of the smokeless rich diesel combustion by reducing temperature, SAE International (2001).

S. L. Kokjohn, R. M. Hanson, D. A. Splitter and R. D. Reitz, Fuel Reactivity controlled compression ignition (RCCI): A pathway to controlled high-efficiency clean combustion, Int. J. Engine Res., 12 (2011) 209–226.

L. Tong, H. Wang, Z. Zheng, R. Reitz and M. Yao, Experimental study of RCCI combustion and load extension in a compression ignition engine fueled with gasoline and PODE, Fuel, 181 (2016) 878–886.

P. M. Najt and D. E. Foster, Compression-ignited homogeneous charge combustion, SAE International (1983).

M. Christensen, A. Hultqvist and B. Johansson, Demonstrating the multi fuel capability of a homogeneous charge compression ignition engine with variable compression ratio, SAE International (1999).

J. Willand, R.-G. Nieberding, G. Vent and C. Enderle, The knocking syndrome-Its cure and its potential, SAE International (1998).

J. Lavy et al., Innovative ultra-low nox controlled autoignition combustion process for gasoline engines: The 4-SPACE project, SAE International (2000).

D. Splitter, M. Wissink, D. DelVescovo and R. D. Reitz, Improving the understanding of intake and charge effects for increasing RCCI engine efficiency, SAE Int. J. Engines, 7 (2014) 913–927.

G. T. Kalghatgi, Auto-ignition quality of practical fuels and implications for fuel requirements of future SI and HCCI engines, SAE International (2005).

G. T. Kalghatgi, P. Risberg and H.-E. Ångström, Advantages of fuels with high resistance to auto-ignition in late-injection, low-temperature, compression ignition combustion, SAE International (2006).

R. Hanson, D. Splitter and R. D. Reitz, Operating a heavyduty direct-injection compression-ignition engine with gasoline for low emissions, SAE International (2009).

S. L. Kokjohn, R. M. Hanson, D. A. Splitter and R. D. Reitz, Experiments and modeling of dual-fuel HCCI and PCCI combustion using in-cylinder fuel blending, SAE Int. J. Engines, 2 (2009) 24–39.

V. Manente, B. Johansson and P. Tunestal, Partially premixed combustion at high load using gasoline and ethanol, a comparison with diesel, SAE International (2009).

V. Manente, P. Tunestal, B. Johansson and W. J. Cannella, Effects of ethanol and different type of gasoline fuels on partially premixed combustion from low to high load, SAE International (2010).

C. Woo, H. Goyal, S. Kook, E. R. Hawkes and Q. N. Chan, Double injection strategies for ethanol-fuelled Gasoline compression ignition (GCI) combustion in a single-cylinder light-duty diesel engine, SAE Int. (2016).

C. P. Kolodziej, M. Sellnau, K. Cho and D. Cleary, Operation of a gasoline direct injection compression ignition engine on naphtha and e10 gasoline fuels, SAE Int. J. Engines, 9 (2016) 979–1001.

Y. Putrasari and O. Lim, A study on combustion and emission of GCI engines fueled with gasoline-biodiesel blends, Fuel, 189 (2017) 141–154.

M. Sellnau, J. Sinnamon, K. Hoyer and H. Husted, Gasoline direct injection compression ignition (GDCI)-Diesel-like efficiency with low co2 emissions, SAE Int. J. Engines, 4 (2011) 2010–2022.

M. Sellnau, M. Foster, K. Hoyer, W. Moore, J. Sinnamon and H. Husted, Development of a Gasoline direct injection compression ignition (GDCI) engine, SAE Int. J. Engines, 7 (2014) 835–851.

M. C. Sellnau, J. Sinnamon, K. Hoyer, J. Kim, M. Cavotta and H. Husted, Part-load operation of Gasoline directinjection compression ignition (GDCI) engine, SAE International (2013).

H. G. Kim and S. H. Choi, The characteristics of biodiesel and oxygenated additives in a compression ignition engine, J. Mech. Sci. Technol., 27 (2013) 1539–1543.

I. Cesur, Investigation of the effects of steam injection on the emissions and performance of a diesel engine using waste chicken oil methyl ester, J. Mech. Sci. Technol., 30 (2016) 4773–4779.

B. S. Chauhan, N. Kumar and H. M. Cho, Performance and emission studies on an agriculture engine on neat Jatropha oil, J. Mech. Sci. Technol., 24 (2010) 529–535.

B. P. Singh, Performance and emission characteristics of conventional engine running on jatropha oil, J. Mech. Sci. Technol., 27 (2013) 2569–2574.

H. Caliskan and K. Mori, Environmental, enviroeconomic and enhanced thermodynamic analyses of a diesel engine with Diesel oxidation catalyst (DOC) and Diesel particulate filter (DPF) after treatment systems, Energy, 128 (2017) 128–144.

P. Jiao, Z. Li, B. Shen, W. Zhang, X. Kong and R. Jiang, Research of DPF regeneration with NOx-PM coupled chemical reaction, Appl. Therm. Eng., 110 (2017) 737–745.

Y. Bao, Q. N. Chan, S. Kook and E. Hawkes, Spray penetrations of ethanol gasoline and iso-octane in an optically accessible spark-ignition direct-injection engine, SAE Int. J. Fuels Lubr., 7 (2014) 1010–1026.

M. M. Khonsari and E. R. Booser, Applied tribology: Bearing design and lubrication, 2nd Ed., Wiley (2008).

G. Knothe, The lubricity of biodiesel, SAE Int. (2005).

I. M. Atadashi, M. K. Aroua and A. A. Aziz, High quality biodiesel and its diesel engine application: A review, Renew. Sustain. Energy Rev., 14 (2010) 1999–2008.

J.-K. Kim, C.-H. Jeon, E.-S. Yim and C.-S. Chung, Lubricity characterization of hydrogenated biodiesel as an alternative diesel fuel, J. KSTLE, 28 (2012) 321–327.

R. Payri, A. García, V. Domenech, R. Durrett and A. H. Plazas, An experimental study of gasoline effects on injection rate, momentum flux and spray characteristics using a common rail diesel injection system, Fuel, 97 (2012) 390–399.

R. Payri, A. Garcia, V. Domenech, R. Durrett and A. Plazas Torres, Hydraulic behavior and spray characteristics of a common rail diesel injection system using gasoline fuel, SAE Tech. Pap. (2012).

P. Tinprabath, C. Hespel, S. Chanchaona and F. Foucher, Influence of biodiesel and diesel fuel blends on the injection rate under cold conditions, Fuel, 144 (2015) 80–89.

C. Woo, S. Kook and E. R. Hawkes, Effect of intake air temperature and common-rail pressure on ethanol combustion in a single-cylinder light-duty diesel engine, Fuel, 180 (2016) 9–19.

R. Opat et al., Investigation of mixing and temperature effects on HC/CO emissions for highly dilute low temperature combustion in a light duty diesel engine, SAE International (2007).

C. P. Koci et al., Detailed unburned hydrocarbon investigations in a highly-dilute diesel low temperature combustion regime, SAE Int. J. Engines, 2 (2009) 858–879.

S. Mendez, J. T. Kashdan, G. Bruneaux, B. Thirouard and F. Vangraefschepe, Formation of unburned hydrocarbons in low temperature diesel combustion, SAE Int. J. Engines, 2 (2009) 205–225.

J. B. Heywood, Internal combustion engine fundamentals, McGraw-Hill (1988).

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Jeong Park

Ock-Taeck Lim received his B.S. and M.S. in Mechanical Engineering from Chonnam National University, Korea, in 1998 and 2002, respectively. He received his Ph.D. from Keio University in 2006. Dr. Lim is currently a Professor at the School of Automotive and Mechanical Engineering at Ulsan University in Ulsan, Korea. Dr. Lim’s research interests include internal combustion engines, alternative fuels, and thermodynamics.

Sakda Thongchai has received his B. Eng., M.B.A., and M.Eng. from King Mongkut's Institute of Technology Ladkrabang. Presently, he is working on his Ph.D. in Mechanical and Automotive Engineering under the supervision of Professor Ock-Taeck Lim at the School of Mechanical Engineering at the University of Ulsan, Rep. of Korea.

Rights and permissions

About this article

Cite this article

Thongchai, S., Lim, O. Investigation of the combustion characteristics of gasoline compression ignition engine fueled with gasoline-biodiesel blends. J Mech Sci Technol 32, 959–967 (2018). https://doi.org/10.1007/s12206-018-0146-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-018-0146-9