Abstract

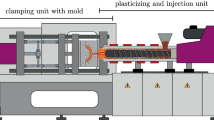

In the present study, a numerical model of the injection molding filling stage was developed by combining non-Newtonian behavior, heat transfer, and thermo-elastic behavior in order to precisely predict mold deformation. In general, local deformation of an injection mold can be caused by two critical factors – elastic compression induced by the plastic melt and thermal expansion due to rapid heat transfer from the plastic melt. As severe mold deformation lowers the dimensional accuracy of the molded product or results in failure of the injection mold, the accurate prediction of mold deformation is critical to the design and manufacture of precision injection mold. In this regard, a numerical model considering the relevant physical behavior was developed and applied to a center-gated disc model. Both the melt flow behavior and effect of heat transfer inside the mold cavity were investigated, which subsequently revealed that the dominant influence is that of thermal expansion due to heat transfer.

Similar content being viewed by others

References

J. Greener and R. Wimberger-Friedl, Precision injection molding: Process, materials, and applications, Carl Hanser Verlag, München, Germany (2006).

J. Zhao, R. H. Mayes, G. Chen, H. Xie and P. S. Chan, Effects of process parameters on the micro molding process, Polymer Engineering and Science, 43 (9) (2003) 1542–1554.

K.-M. Tsai, C.-Y. Hsieh and W.-C. Lo, A study of the effects of process parameters for injection molding on surface quality of optical lenses, Journal of Materials Processing Technology, 290 (7) (2009) 3469–3477.

R. J. Bensingh, S. R. Boopathy and C. Jebaraj, Minimization of variation in volumetric shrinkage and deflection on injection molding of Bi-aspheric lens using numerical simulation, Journal of Mechanical Science and Technology, 30 (11) (2016) 5143–5152.

B.-K. Lee, C. J. Hwang, D. S. Kim and T. H. Kwon, Replication quality of flow-through microfilters in microfluidic lab-on-a-chip for blood typing by microinjection molding, Transactions of ASME: Journal of Manufacturing Science and Engineering, 130 (2) (2008) 021010.

S. H. Tang, Y. M. Kong, S. M. Sapuan, R. Samin and S. Sulaiman, Design and thermal analysis of plastic injection mould, Journal of Materials Processing Technology, 171 (2) (2006) 259–267.

J. G. Lee, B.-K. Lee, T. G. Kang and T. H. Kwon, Experimental and numerical investigation of injection molding with micro rib patterns, Polymer Engineering and Science, 50 (6) (2010) 1186–1198.

G. Zheng, W. Guo, Q. Wang and X. Guo, Influence of processing parameters on warpage according to the Taguchi experiment, Journal of Mechanical Science and Technology, 29 (10) (2015) 4153–4158.

C.-H. Wu and Y.-J. Huang, The influence of cavity deformation on the shrinkage and warpage of an injection-molded parts, International Journal of Advanced Manufacturing Technology, 32 (11–12) (2007) 1144–1154.

A. J. Giacomin, A. J. Hade, L. M. Johnson, A. W. Mix, Y.-C. Chen, H.-C. Liao and S.-C. Tseng, Core deflection in injection molding, Journal of Non-Newtonian Fluid Mechanics, 166 (16) (2011) 908–914.

B. Carpenter, S. Patil, R. Hoffman, B. Lilly and J. Castro, Effect of machine compliance on mold deflection during injection and packing of thermoplastic parts, Polymer Engineering and Science, 46 (7) (2006) 844–852.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Editor Hyung Wook Park

Bong-Kee Lee is an Associate Professor in School of Mechanical Engineering at Chonnam National University. He earned his Ph.D. degree in 2009 from Pohang University of Science and Technology. His research interests lie in micro/nano manufacturing and molding technologies.

Rights and permissions

About this article

Cite this article

Jung, J.T., Lee, BK. Fluid-structure interaction model to predict deformation of mold cores in injection molding filling stage. J Mech Sci Technol 32, 817–822 (2018). https://doi.org/10.1007/s12206-018-0132-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-018-0132-2